102 Gear Chart

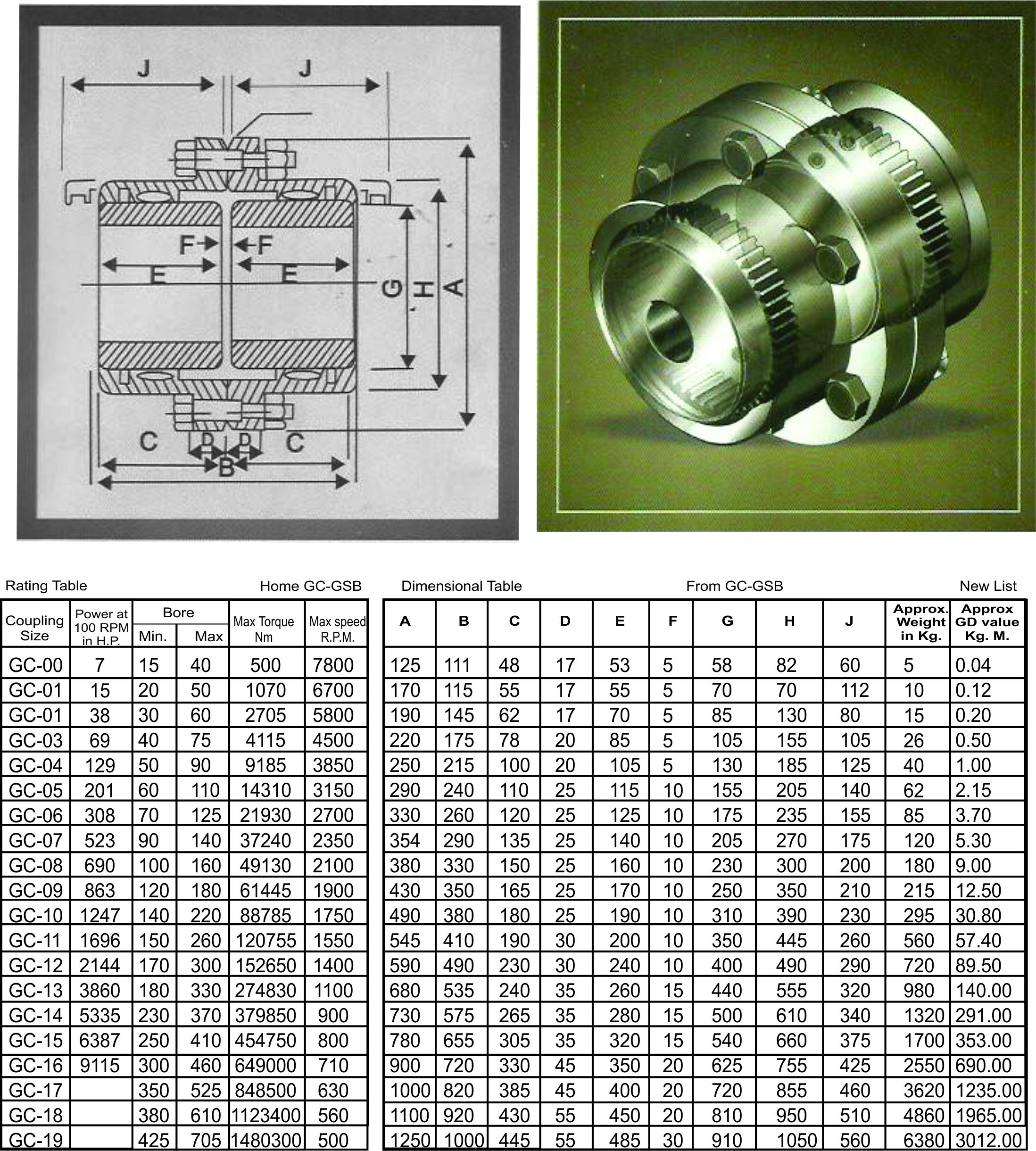

102 Gear Chart - Web the spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel shafts. Module 1.5 metric spur gear sizes. First, you must know about the number of teeth present in your gear system. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct towards other options. Series connected gear ratios are multiplied to find the overall gear ratio, like this: Web most selected gears will have two (or three) speed changes in series between the input shaft and the output shaft. A) check your application against the service factor chart. ♦ accommodates angular, parallel & axial misalignments. 30/21 x 17/11 x 28/13 = 4.755. Simplified ilvl row to make it clearer where the tracks begin and end. Module 1 metric spur gear sizes. Web winters performance offers an extremely durable gear chart for 10 spline quick change, 6 spline quick change, 7” quick change and xtremeliner quick change gears to help you determine the correct final drive ratio for your car at the track or in the shop. For custom metric spur gears, quotes, or additional information,. Web most selected gears will have two (or three) speed changes in series between the input shaft and the output shaft. Web the spur gear is is simplest type of gear manufactured and is generally used for transmission of rotary motion between parallel shafts. Accomidates angular, parallel axial misalignment. 32 upvotes · 8 comments. Web cub cadet gear ratio chart. So kelani introduces a guide on his youtube channel where we can learn various ways to quickly and. Select the nuflex coupling that will accommodate the diameter of the largest shaft. Web cub cadet gear ratio chart 46/10 transmission 86/10 85/11 84/12 84/13 83/13 82/14 81/15 4.60/1 gear 8.6/1 7.73/1 7.0/1 6.46/1 6.38/1 5.86/1 5.4/1 ring ratios 20% 10% stock. Simplified ilvl row to make it clearer where the tracks begin and end. Web cub cadet gear ratio chart 46/10 transmission 86/10 85/11 84/12 84/13 83/13 82/14 81/15 4.60/1 gear 8.6/1 7.73/1 7.0/1 6.46/1 6.38/1 5.86/1 5.4/1 ring ratios 20% 10% stock 13 tooth 10% 16% 23% gear input output underdrive underdrive cub cadet front pinion overdrive overdrive overdrive and. Select the nuflex coupling that will accommodate the diameter of the largest shaft. For custom metric spur gears, quotes, or additional information, please contact us. Web winters performance offers an extremely durable gear chart for 10 spline quick change, 6 spline quick change, 7” quick change and xtremeliner quick change gears to help you determine the correct final drive ratio. Web how to select the right nuflex gear coupling 1. ♦ accommodates angular, parallel & axial misalignments. Usually this will determine the proper size coupling for your application. Series connected gear ratios are multiplied to find the overall gear ratio, like this: Dimension h = 15mm, dimension h = 25mm. Web cub cadet gear ratio chart 46/10 transmission 86/10 85/11 84/12 84/13 83/13 82/14 81/15 4.60/1 gear 8.6/1 7.73/1 7.0/1 6.46/1 6.38/1 5.86/1 5.4/1 ring ratios 20% 10% stock 13 tooth 10% 16% 23% gear input output underdrive underdrive cub cadet front pinion overdrive overdrive overdrive and top bottom. Crown gear teeth for longer. Module 1 metric spur gear sizes.. Crown gear teeth for longer. ♦ generally used up to 120°c. Count the number of teeth on the front cog of your bicycle, and select this value in the picker labeled chainring. Select the nuflex coupling that will accommodate the diameter of the largest shaft. Web gear coupling 2013 f. Count the number of teeth on the front cog of your bicycle, and select this value in the picker labeled chainring. Web were looking at the item level of loot and upgrade tracks in dragonflight season 3! Input gear is the gear that drives the output gear. Generally used upto 120 c. Web these gear couplings are distinguished by their. This means that your hardest gear is 53/11 (gear ratio of 4.8), and your easiest is 39/28 (gear ratio of 1.4). Web gear chart generator shaft c‐c 30.14mm max 26.81mm min p = 64gear pitch fdr = 1.9 mugen seiki mtc2 gear chart spur pinion 84 86 88 90 92 94 96 98 100 102 104 106 108 110 112. 30/21 x 17/11 x 28/13 = 4.755. Usually this will determine the proper size coupling for your application. So kelani introduces a guide on his youtube channel where we can learn various ways to quickly and. Web to use our calculator, use the following guidelines: Web the charts below show our standard metric spur gear sizes and dimensions; Web most selected gears will have two (or three) speed changes in series between the input shaft and the output shaft. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct towards other options. Web bike gear ratio charts. Generally used upto 120 c. Web cub cadet gear ratio chart 46/10 transmission 86/10 85/11 84/12 84/13 83/13 82/14 81/15 4.60/1 gear 8.6/1 7.73/1 7.0/1 6.46/1 6.38/1 5.86/1 5.4/1 ring ratios 20% 10% stock 13 tooth 10% 16% 23% gear input output underdrive underdrive cub cadet front pinion overdrive overdrive overdrive and top bottom. Web combining precise calculations and an intuitive design, bikecalc provides you everything you need to analyze and optimize the gearing on your bicycle, saving you time, guesswork and potentially a costly mistake. ♦ generally used up to 120°c. Simplified ilvl row to make it clearer where the tracks begin and end. Crown gear teeth for longer. Web graphs like this are useful when they are a quick reference. Web combining precise calculations and an intuitive design, bikecalc provides you everything you need to analyze and optimize the gearing on your bicycle, saving you time, guesswork and potentially a costly mistake.

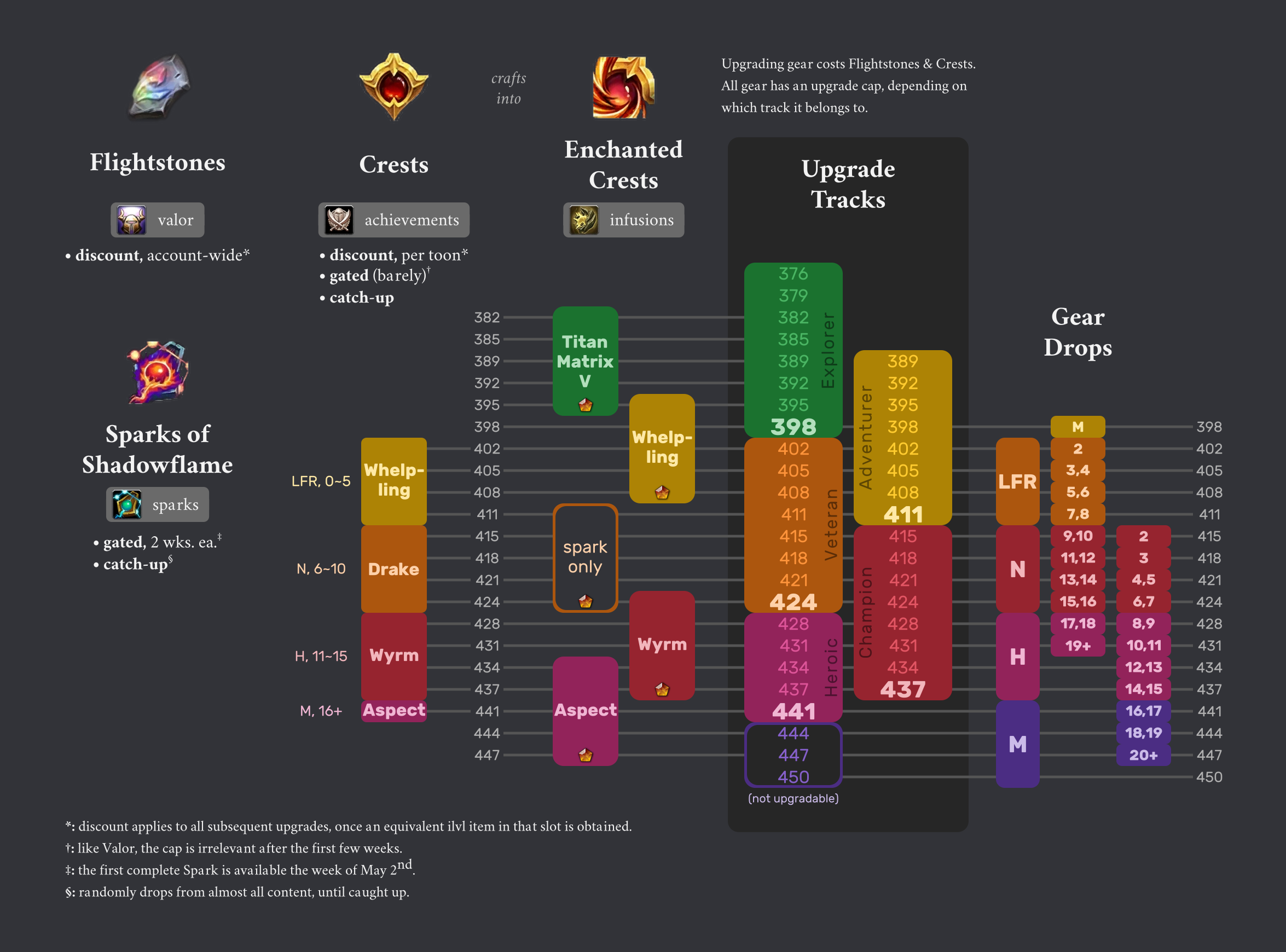

Dragonflight Season 2 Gear Upgrading Charts News Icy Veins

Mikron Type 102 & 102.05 Gear Hobbers

Geared Couplings, Mechanical Gear Couplings, Half Gear Couplings, Nylon

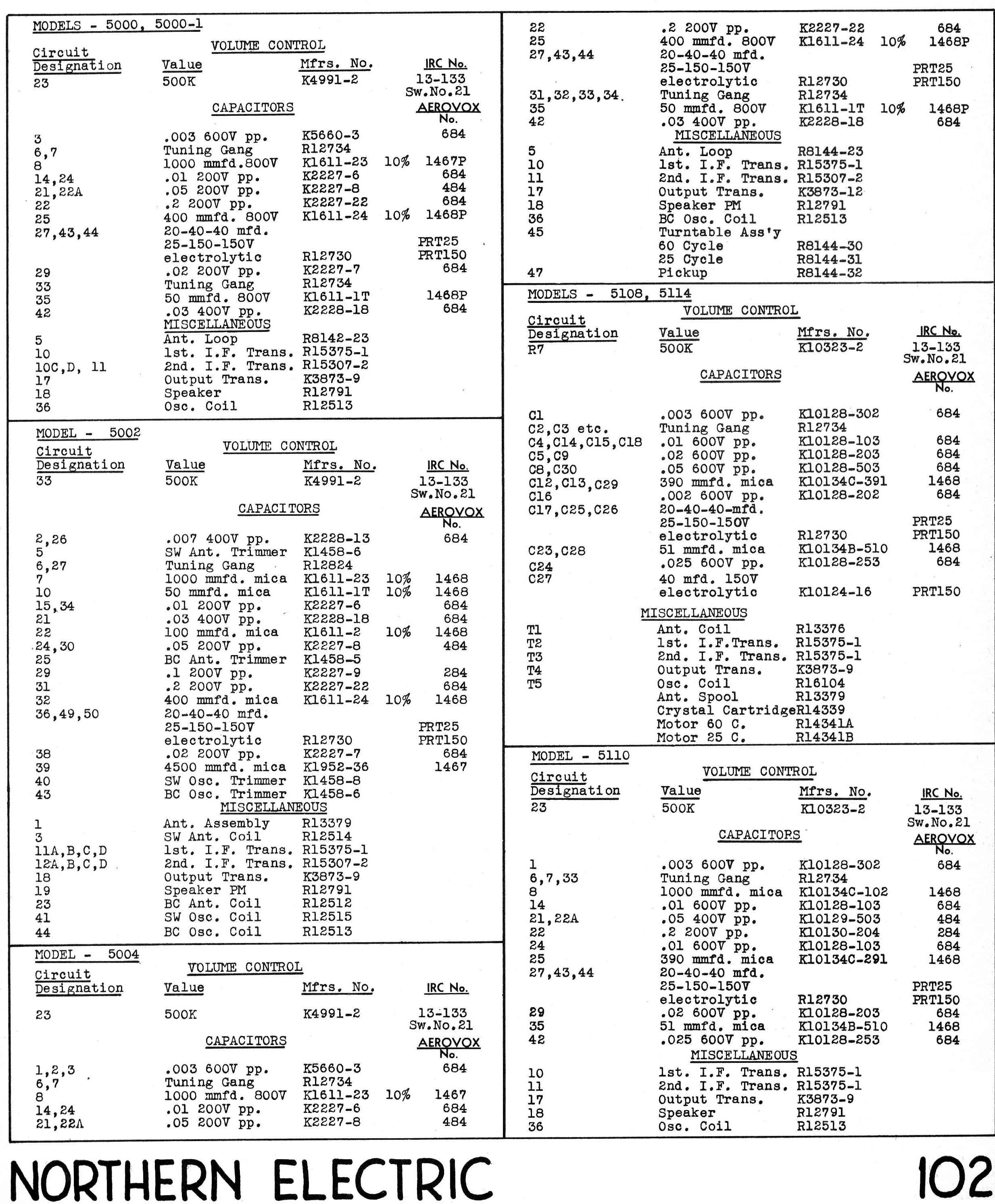

Diagrams and Service Data for Northern Electric 5004 RCC

8MM PULLEY DRIVE RATIO CHART The Blower Shop ?? 99 100 101 102

Mikron Type 102 & 102.05 Gear Hobbers

Mikron Type 102 & 102.05 Gear Hobbers

Ansul R102 Nozzle Chart

KI102 Frequency Charts Klipsch

Mobil Gear Oil Cross Reference Chart Reviews Of Chart

Input Gear Is The Gear That Drives The Output Gear.

The Gear System Includes The Input (Driver) And Output (Driven) Gear.

Select Numbers Of Teeth In Gears And Module (Pitch).

Web The Spur Gear Is Is Simplest Type Of Gear Manufactured And Is Generally Used For Transmission Of Rotary Motion Between Parallel Shafts.

Related Post: