3M Floor Pad Chart

3M Floor Pad Chart - Web simply download below, fill in details on the process for your facility, and print in the size of your choosing. Web moving left to right, select the appropriate maintenance operation, machine type and speed, then follow the color bar to the recommended 3m ™ floor pads. Floor buffing pads can be made from cotton, microfiber, lambs wool, steel wool, or natural hair. Quickly and thoroughly removes old floor finish, dirt and buildup. Web each 3m floor pad is precision engineered for a particular floor surface and task. Web 3m™ high productivity pad 7300. For fast removal of finish and proven consistent stripping. For simplicity, floor care steps that require floor pads can be broken down into the following processes: Floor buffing pads can be made from cotton, microfiber, lambs wool, steel wool, or natural hair. Web pads which attach to a rotary floor machine and are rotated at high speeds to polish marble, granite, and stone floors. Unique, open web construction allows stripping solution to flow through pad to rinse out dirt and reduce loading for increased pad to floor contact and efficient stripping. Web that’s why 3m, the inventor of floor pad technology and the world’s number one floor pad supplier, manufactures a wide range of products designed for specific types of equipment and maintenance tasks.. Unique open construction resists loading and clogging. Web 3mtm high productivity pad 7300. Floor buffing pads can be made from cotton, microfiber, lambs wool, steel wool, or natural hair. Web pads which attach to a rotary floor machine and are rotated at high speeds to polish marble, granite, and stone floors. The chart can be posted on a wall, such. Floor buffing pads can be made from cotton, microfiber, lambs wool, steel wool, or natural hair. Ideal for softer floor finishes where frequent burnishing is required. The soft finish problem solver. Daily cleaning, burnishing, deep scrubbing, and stripping. Our most aggressive stripping pad. Unique open construction resists loading and clogging. Use for everyday cleaning and light scrubbing under automatic and rotary floor machines. Floor buffing pads can be made from cotton, microfiber, lambs wool, steel wool, or natural hair. Win a free logo mat; Web moving left to right, select the appropriate maintenance operation, machine type and speed, then follow the color bar. Web the cost of protecting your floors; Web 3m™ high productivity pad 7300. 3mtm high productivity pad 7300. For fast removal of finish and proven consistent stripping. Use for everyday cleaning and light scrubbing under automatic and rotary floor machines. It’s no wonder we are one of the world’s leading floor pad suppliers. Unique open construction resists loading and clogging. For fast removal of finish and proven consistent stripping. Floor buffing pads can be made from cotton, microfiber, lambs wool, steel wool, or natural hair. Floor buffing pads can be made from cotton, microfiber, lambs wool, steel wool, or natural. We’ll mail you a 11” x 17” laminated chart that contains four main floor care processes: Web 3m™ high productivity pad 7300. Unique open construction resists loading and clogging. Web moving left to right, select the appropriate maintenance operation, machine type and speed, then follow the color bar to the recommended 3m ™ floor pads. For fast removal of finish. For fast removal of finish and proven consistent stripping. Web the cost of protecting your floors; Ideal for softer floor finishes where frequent burnishing is required. For simplicity, floor care steps that require floor pads can be broken down into the following processes: Web 3m™ high productivity pad 7300. Web find the 3m floor pad that is best for your maintenance task. Quickly and thoroughly removes old floor finish, dirt and buildup. Floor buffing pads can be made from cotton, microfiber, lambs wool, steel wool, or natural hair. Daily cleaning, burnishing, deep scrubbing, and stripping. Products with kill claims against influenza; We’ll mail you a 11” x 17” laminated chart that contains four main floor care processes: For fast removal of finish and proven consistent stripping. Web pads which attach to a rotary floor machine and are rotated at high speeds to polish marble, granite, and stone floors. Web help your staff know which 3m™ floor pad to use for each. Floor buffing pads can be made from cotton, microfiber, lambs wool, steel wool, or natural hair. Web the cost of protecting your floors; Use for everyday cleaning and light scrubbing under automatic and rotary floor machines. Quickly and thoroughly removes old floor finish, dirt and buildup. Products with kill claims against influenza; Web 3mtm high productivity pad 7300. Web pads which attach to a rotary floor machine and are rotated at high speeds to polish marble, granite, and stone floors. The soft finish problem solver. Unique, open web construction allows stripping solution to flow through pad to rinse out dirt and reduce loading for increased pad to floor contact and efficient stripping. For fast removal of finish and proven consistent stripping. For fast removal of finish and proven consistent stripping. Ideal for softer floor finishes where frequent burnishing is required. Use this chart to help you choose the pads you need or contact your 3m representative for help. The chart can be posted on a wall, such as in the cleaning supply area, for easy reference, and a floor pad center hole can be adhered if desired. Web 3m™ high productivity pad 7300. Unique open construction resists loading and clogging.

6 Pics 3m Floor Buffing Pad Colors And View Alqu Blog

1215 3m floor pad p1

Buffing Pads Color Chart

3m Buffing Pad Color Chart

1215 3m floor pad p3

1215 3m floor pad p2

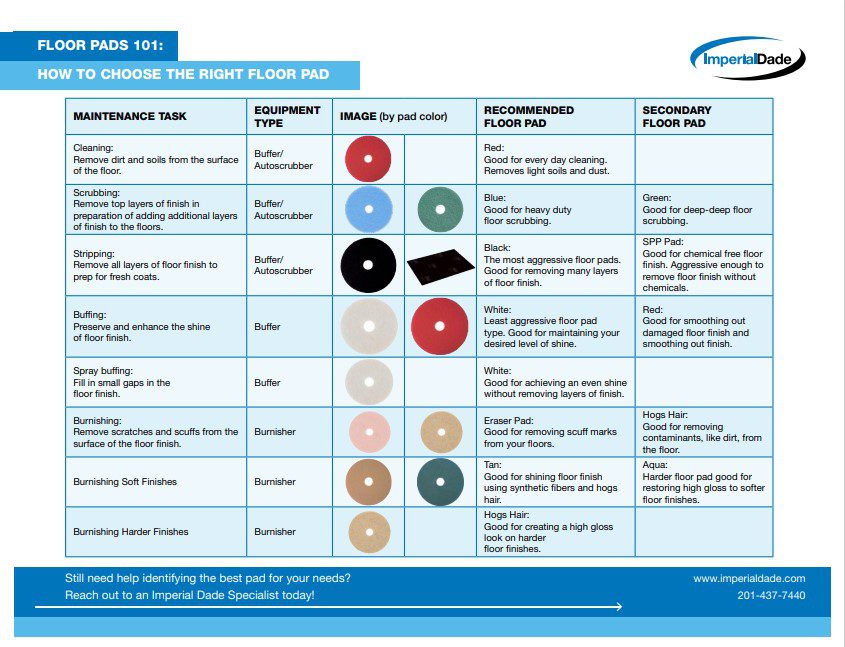

Floor Pad Selection Guide Imperial Dade Insights

How To Choose The Right Floor Pad For The Job BUNZL Cleaning

How To Choose The Right Floor Pad For The Job BUNZL Cleaning

1119 3M Floor Guide

Win A Free Logo Mat;

Floor Buffing Pads Can Be Made From Cotton, Microfiber, Lambs Wool, Steel Wool, Or Natural Hair.

We’ll Mail You A 11” X 17” Laminated Chart That Contains Four Main Floor Care Processes:

Our Most Aggressive Stripping Pad.

Related Post: