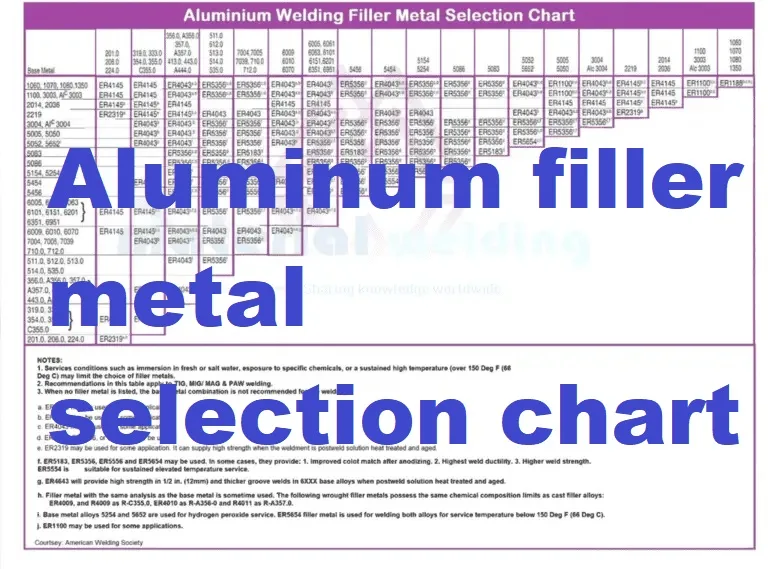

Aluminium Filler Rod Chart

Aluminium Filler Rod Chart - Web filler metal charts www.harrisproductsgroup.com * the higher the ˜uidity rating, the faster the alloy ˜ows within the melting range. This document provides information on aluminum base alloys and filler alloys, listing various alloy designations and their characteristics for welding, soldering, dezincification corrosion, and other properties. It is therefore essential to have the answers to some basic questions prior to the selection of the most appropriate filler metal. Web when determining which filler alloy to use the most important questions is what is the alloy (or alloys) you are welding. Web this article provides a comprehensive matrix for selecting an aluminum filler alloy for the gas tungsten arc and gas metal arc welding processes, based on the various requirements or service conditions. Anderson esab welding & cutting product j. Click here for aluminum filler metal selection chart. What is the aluminum base metal designation? In general, the important parameters include the base metal thickness, its composition, and the type of weld joint (butt vs. However, aluminum is a tricky metal, so make sure you know what alloy you are welding and what the part will be used for. Web aws ugfm:2010 iii personnel aws a5 committee on filler metals and allied materials j. This document provides information on aluminum base alloys and filler alloys, listing various alloy designations and their characteristics for welding, soldering, dezincification corrosion, and other properties. Er 5356 is ordinarily chosen because of its moderately high shear strength which is crucial for fillet weld joints.. This document provides information on aluminum base alloys and filler alloys, listing various alloy designations and their characteristics for welding, soldering, dezincification corrosion, and other properties. Ratings do not apply to these alloys when heat treated after welding. Web shop aluminum tig rods for aluminum to aluminum welding at airgas today from radnor™️, alcotec wire company, harris® and hobart®. Wehr,. See also welding of ss310, and 310 to carbon steel guide. The document provides information on aluminum filler alloys that can be used for welding, including their designations and key characteristics. Ratings do not apply to these alloys when heat treated after welding. (2) an “a” rating for alloy 5083 to 5083. Aluminum filler metal selection chart. It is also used quite successfully for welding aluminum armor alloy 2519. A table lists the nominal strengths of aluminum filler metals. If the chart shows that you can use either 4043 or 5356 then there are a few more things we need to consider: Web aws ugfm:2010 iii personnel aws a5 committee on filler metals and allied materials j.. It is also used quite successfully for welding aluminum armor alloy 2519. 5xxx series aluminum is available in a wide range of thicknesses, from thin sheet to heavy plate, and either 5356 or 4043 filler rod can be used for these alloys. Using this criterion, you can use certain guidelines to zero in on the filler rod alloys and diameters. Web always refer to an aluminum filler metal selection chart to choose a filler metal that is best suited for a particular application. Wehr, vice chair arcos industries llc j. Deloach jr, 2nd vice chair naval surface warfare center r. Web shop aluminum tig rods for aluminum to aluminum welding at airgas today from radnor™️, alcotec wire company, harris® and. If the chart shows that you can use either 4043 or 5356 then there are a few more things we need to consider: What is the aluminum base metal designation? It is a great reference chart. Web also, manufacturers usually have detailed charts to help select a filler rod. Er 5356 is ordinarily chosen because of its moderately high shear. Click here for aluminum filler metal selection chart. The document provides information on aluminum filler alloys that can be used for welding, including their designations and key characteristics. Web in this article, we will introduce an aluminum filler metal selection chart that simplifies the process of selecting the right filler metal for welding aluminum, helping you achieve a strong and. We always refer to the table below; Gupta, secretary american welding society t. It is therefore essential to have the answers to some basic questions prior to the selection of the most appropriate filler metal. Also, you can use this chart to find the best suitable gtaw/ gmaw filler wire to weld the various grades of aluminum. The only 2xxx. Web always refer to an aluminum filler metal selection chart to choose a filler metal that is best suited for a particular application. Web this article provides a comprehensive matrix for selecting an aluminum filler alloy for the gas tungsten arc and gas metal arc welding processes, based on the various requirements or service conditions. Web also, manufacturers usually have. Using this criterion, you can use certain guidelines to zero in on the filler rod alloys and diameters you might want to use. Aluminum filler metal selection chart. It is a great reference chart. The only 2xxx filler alloy readily available is 2319. Wehr, vice chair arcos industries llc j. Click here for aluminum filler metal selection chart. Also, you can use this chart to find the best suitable gtaw/ gmaw filler wire to weld the various grades of aluminum. Web the two most common aluminum tig welding rods are er4043 and er5356. This document provides information on aluminum base alloys and filler alloys, listing various alloy designations and their characteristics for welding, soldering, dezincification corrosion, and other properties. Web in this article, we will introduce an aluminum filler metal selection chart that simplifies the process of selecting the right filler metal for welding aluminum, helping you achieve a strong and reliable weld. We always refer to the table below; (2) an “a” rating for alloy 5083 to 5083. Web welding rod sizes doesn’t affect the welding electrode selection as it doesn’t affect the material mechanical properties in any manner. Web also, manufacturers usually have detailed charts to help select a filler rod. If the chart shows that you can use either 4043 or 5356 then there are a few more things we need to consider: What is the aluminum base metal designation?

Tig Welding Filler Rod Selection Chart Reviews Of Chart

Aluminum Filler Alloy Selection Chart PDF Welding Construction

Aluminum Welding Rod Chart SexiezPix Web Porn

Tig Filler Rod Sizes

Welding 5052 Aluminum

Aluminum Filler Metal Chart

Tig Aluminum Filler Rod Chart

Tig Welding Aluminum Filler Rod

Welding Electrode And Filler Wire Selection Chart With Pdf A Visual

Welding Filler Rod Chart

Anderson Esab Welding & Cutting Product J.

It Is Also Used Quite Successfully For Welding Aluminum Armor Alloy 2519.

Web This Article Provides A Comprehensive Matrix For Selecting An Aluminum Filler Alloy For The Gas Tungsten Arc And Gas Metal Arc Welding Processes, Based On The Various Requirements Or Service Conditions.

A Table Lists The Nominal Strengths Of Aluminum Filler Metals.

Related Post: