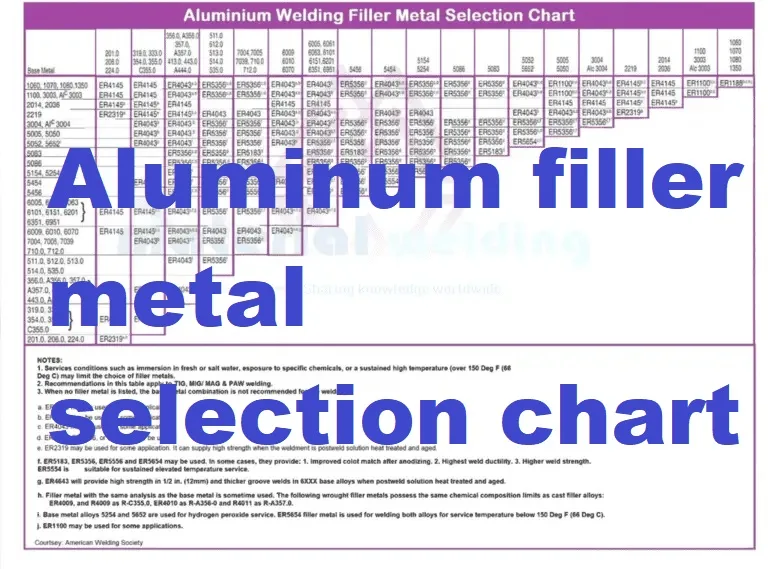

Aluminum Filler Metal Chart

Aluminum Filler Metal Chart - Web welding electrode/ filler wire/ filler metal selection chart. Web 6005 6061 6063 6101 6151 6201 6351 6951 4145 4145 4047 4043 4043 4047 5183 5356 5183 5554 5356 4043 5183 4043 4145 4043 4047 5183. Are relative values for welding base metals. Web welding filler metal databook. Ratings do not apply to these alloys when heat treated after welding. Web alcotec’s team of expert engineers and quality technicians offer an educational welding program combining their years of aluminum manufacturing experience with expertise in. This document provides information on aluminum base alloys and. Web filler metals in the 4xxx and 5xxx series are most commonly used to weld aluminum. If there is more than one filler metal that meets the design criteria. Combinations having no rating are not usually recommended. Filler metal property ratings a, b, c and d. Web aluminum filler metal selection chart. This document provides information on aluminum base alloys and. Web 7005, 70 21 7039, 7 046 7146 710.0, 711.0 413.0, 443.0 444.0, 356.0 a356.0, 3 57.0 359.0 319.0, 333.0 35 4.0, 355.0 c355.0, 380.0 319.0, 333.0 35 4.0, 355.0 Web 6005 6061 6063 6101 6151. Web this article provides a comprehensive matrix for selecting an aluminum filler alloy for the gas tungsten arc and gas metal arc welding processes, based on the various. If there is more than one filler metal that meets the design criteria. Web the filler metal located in that row in the gray box is the most suitable match. Explanation of. This document provides information on aluminum base alloys and. Web this article provides a comprehensive matrix for selecting an aluminum filler alloy for the gas tungsten arc and gas metal arc welding processes, based on the various. Web aluminum filler metal alloys available and proper use guidelines. Web filler metals in the 4xxx and 5xxx series are most commonly used. Web aluminum filler metal selection chart. Filler metal property ratings a, b, c and d. If there is more than one filler metal that meets the design criteria. Web this article provides a comprehensive matrix for selecting an aluminum filler alloy for the gas tungsten arc and gas metal arc welding processes, based on the various. Web 6005 6061 6063. Combinations having no rating are not usually recommended. Web welding filler metal databook. Explanation of relative rating a, b, c, & d. Aluminum filler alloys come from the 1xxx, 2xxx, 4xxx, and 5xxx alloy families. Filler metal property ratings a, b, c and d. Web aws fmc:2000, filler metal comparison charts, is the tenth revision of this popular comparison of trade names of welding electrodes and rods. Web this article provides a comprehensive matrix for selecting an aluminum filler alloy for the gas tungsten arc and gas metal arc welding processes, based on the various. If there is more than one filler metal that. Web 7005, 70 21 7039, 7 046 7146 710.0, 711.0 413.0, 443.0 444.0, 356.0 a356.0, 3 57.0 359.0 319.0, 333.0 35 4.0, 355.0 c355.0, 380.0 319.0, 333.0 35 4.0, 355.0 Web welding filler metal databook. Combinations having no rating are not usually recommended. This document provides information on aluminum base alloys and. Web aws fmc:2000, filler metal comparison charts, is. Use these charts to easily locate matching, suitable electrode or filler wire for welding to join various. Web aws ugfm:2010 iii personnel aws a5 committee on filler metals and allied materials j. The document appears to be a table listing various. If there is more than one filler metal that meets the design criteria. Wehr, vice chair arcos industries llc. Web filler metals in the 4xxx and 5xxx series are most commonly used to weld aluminum. Web 7005, 70 21 7039, 7 046 7146 710.0, 711.0 413.0, 443.0 444.0, 356.0 a356.0, 3 57.0 359.0 319.0, 333.0 35 4.0, 355.0 c355.0, 380.0 319.0, 333.0 35 4.0, 355.0 Web 6005 6061 6063 6101 6151 6201 6351 6951 4145 4145 4047 4043 4043. Web 7005, 70 21 7039, 7 046 7146 710.0, 711.0 413.0, 443.0 444.0, 356.0 a356.0, 3 57.0 359.0 319.0, 333.0 35 4.0, 355.0 c355.0, 380.0 319.0, 333.0 35 4.0, 355.0 Wehr, vice chair arcos industries llc j. Aluminum filler alloys come from the 1xxx, 2xxx, 4xxx, and 5xxx alloy families. This document provides information on aluminum base alloys and. Web. Aluminum filler alloys come from the 1xxx, 2xxx, 4xxx, and 5xxx alloy families. Explanation of relative rating a, b, c, & d. Web this article provides a comprehensive matrix for selecting an aluminum filler alloy for the gas tungsten arc and gas metal arc welding processes, based on the various. If there is more than one filler metal that meets the design criteria. Filler metal property ratings a, b, c and d. Web aws ugfm:2010 iii personnel aws a5 committee on filler metals and allied materials j. Web filler metals in the 4xxx and 5xxx series are most commonly used to weld aluminum. Web 7005, 70 21 7039, 7 046 7146 710.0, 711.0 413.0, 443.0 444.0, 356.0 a356.0, 3 57.0 359.0 319.0, 333.0 35 4.0, 355.0 c355.0, 380.0 319.0, 333.0 35 4.0, 355.0 Web welding filler metal databook. Web aluminum filler metal selection chart. Web welding electrode/ filler wire/ filler metal selection chart. Web the filler metal located in that row in the gray box is the most suitable match. This document provides information on aluminum base alloys and. Web aws fmc:2000, filler metal comparison charts, is the tenth revision of this popular comparison of trade names of welding electrodes and rods. Ratings do not apply to these alloys when heat treated after welding. Use these charts to easily locate matching, suitable electrode or filler wire for welding to join various.Filler Metal Selection PDF Building Materials Building Engineering

Aluminum Filler Metal Selection Chart

Aluminum filler metal selection charts

Filler Metal Selection Chart

Which filler metal should you choose?

Weld Filler Metal Selection Chart

Aluminum Filler Metal Selection Chart A Visual Reference of Charts

Aluminum Filler Alloy Selection Chart PDF Welding Construction

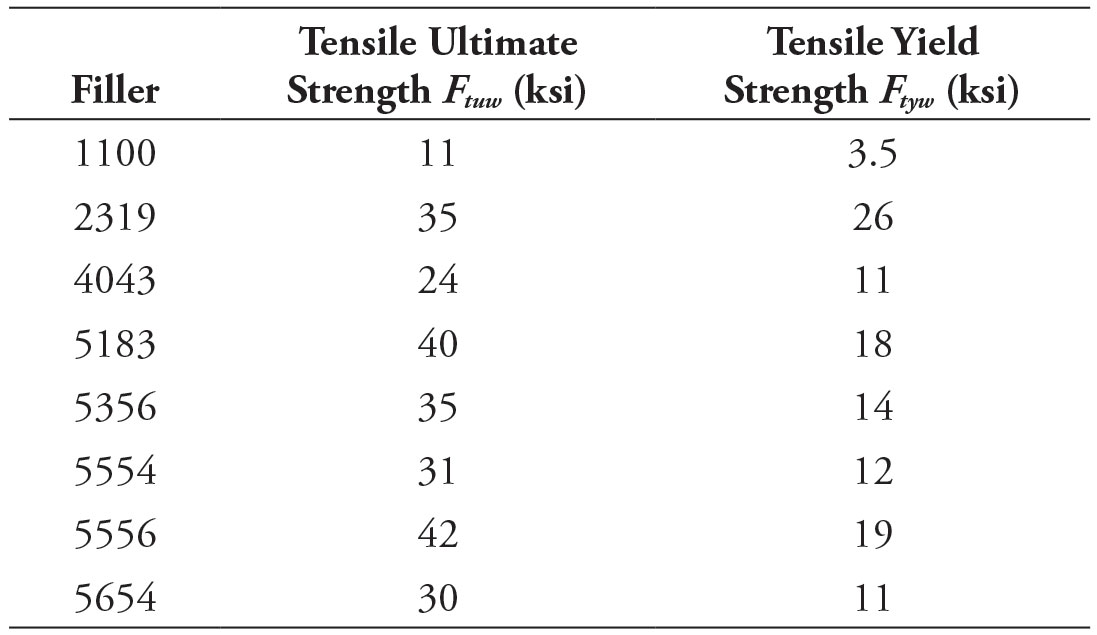

STRUCTURE magazine The 2020 Aluminum Design Manual

4043 v 5356 Aluminum Filler WELDING ANSWERS

Web Alcotec’s Team Of Expert Engineers And Quality Technicians Offer An Educational Welding Program Combining Their Years Of Aluminum Manufacturing Experience With Expertise In.

Combinations Having No Rating Are Not Usually Recommended.

Web 6005 6061 6063 6101 6151 6201 6351 6951 4145 4145 4047 4043 4043 4047 5183 5356 5183 5554 5356 4043 5183 4043 4145 4043 4047 5183.

Wehr, Vice Chair Arcos Industries Llc J.

Related Post: