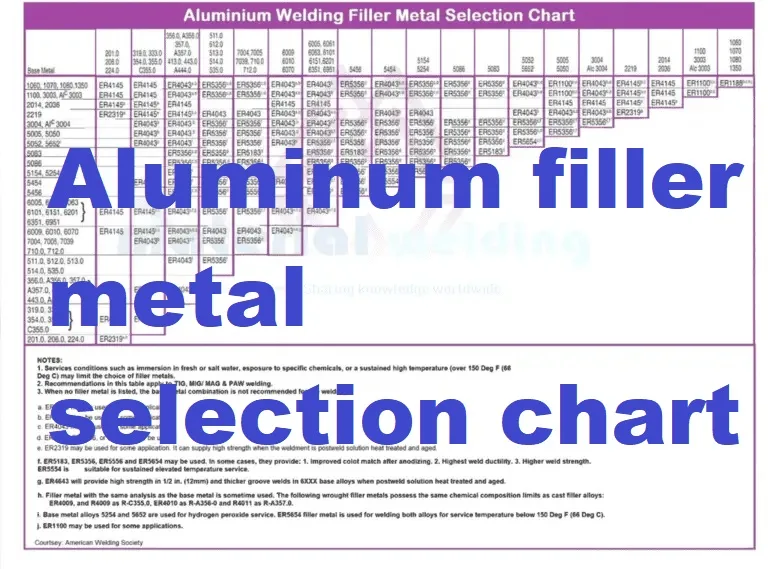

Aluminum Filler Metal Selection Chart

Aluminum Filler Metal Selection Chart - Matching filler metal is typically required for complete joint penetration groove welds in tension. Web filler metals in the 4xxx and 5xxx series are most commonly used to weld 6xxx series aluminum. Ratings do not apply to these alloys when heat treated after welding. Aluminum alloys, gas tungsten arc welding, materials selection. Web welding electrode/ filler wire/ filler metal selection chart. Welding electrode selection chart for carbon steel, low alloy steel, cr. Deloach jr, 2nd vice chair naval surface warfare center r. It is also used quite successfully for welding aluminum armor alloy 2519. Are relative values for welding base metals. Indicated in a specific box. The only 2xxx filler alloy readily available is 2319. This alloy contains copper (cu), manganese (mn), and titanium (ti), and it was designed as a matching filler metal for the 2219 alloy. Web proper filler metal selection is equally important. Web there are many aluminum filler metals available in the marketplace, including those for applications found in aerospace or architectural. The characteristics include weldability, strength, ductility, corrosion resistance, thermal properties and machinability. Are relative values for welding base metals. Combinations having no rating are not usually recommended. This alloy contains copper (cu), manganese (mn), and titanium (ti), and it was designed as a matching filler metal for the 2219 alloy. (2) an “a” rating for alloy 5083 to 5083. Wehr, vice chair arcos industries llc j. Web aws ugfm:2010 iii personnel aws a5 committee on filler metals and allied materials j. Ratings do not apply to these alloys when heat treated after welding. Over 30 different aluminum alloys are listed in the table. Anderson esab welding & cutting product j. 4043 4047 5183 5356 5183 5554 5356 5183 5556. Web aluminum filler metal selection chart metal groups filler metal weld metal properties strength ratings are for fillet weld and. Web aws ugfm:2010 iii personnel aws a5 committee on filler metals and allied materials j. “d” rating is the least fit. That is, the yield and tensile strength are expected to. Web welding filler metal databook. The only 2xxx filler alloy readily available is 2319. (2) an “a” rating for alloy 5083 to 5083. The filler metals range from pure aluminum to varieties with added copper, silicon or magnesium. 4145 4047 4043 4043 4145 4047 4043. Matching filler metal is typically required for complete joint penetration groove welds in tension. Consult an aluminum filler metal selector chart or guide when making the choice to determine how your filler metal selection can affect the following: Web welding electrode/ filler wire/ filler metal selection chart. The best fit for the weldment property and. 4145 4047 4043 4043 4145. Web filler metal suggestions “match” the base metal properties; Web 6005 6061 6063 6101 6151 6201 6351 6951 4145 4145 4047 4043 4043 4047 5183 5356 5183 5554 5356 4043 5183 4043 4145 4043 4047 5183. Combinations having no rating are not usually recommended. Over 30 different aluminum alloys are listed in the table. Web proper filler metal selection is. Deloach jr, 2nd vice chair naval surface warfare center r. The characteristics include weldability, strength, ductility, corrosion resistance, thermal properties and machinability. It is also used quite successfully for welding aluminum armor alloy 2519. Are relative values for welding base metals. Web welding electrode/ filler wire/ filler metal selection chart. 4043 4047 5183 5356 5183 5554 5356 5183 5556. It is also used quite successfully for welding aluminum armor alloy 2519. Download or view charts for different aluminum grades, thicknesses, and joint configurations. Aluminum alloys, gas tungsten arc welding, materials selection. (2) an “a” rating for alloy 5083 to 5083. This document provides information on aluminum base alloys and filler alloys, listing various alloy designations and their characteristics for welding, soldering, dezincification corrosion, and other properties. Deloach jr, 2nd vice chair naval surface warfare center r. Web aluminum filler metal selection chart metal groups filler metal weld metal properties strength ratings are for fillet weld and. However, fillet welds loaded. It is also used quite successfully for welding aluminum armor alloy 2519. Web 6005 6061 6063 6101 6151 6201 6351 6951 4145 4145 4047 4043 4043 4047 5183 5356 5183 5554 5356 4043 5183 4043 4145 4043 4047 5183. Ratings do not apply to these alloys when heat treated after welding. Welding electrode selection chart for carbon steel, low alloy steel, cr. That is, the yield and tensile strength are expected to meet or exceed the minimum specified properties of the steel. Explanation of relative rating a, b, c, & d. “d” rating is the least fit. (2) an “a” rating for alloy 5083 to 5083. The best fit for the weldment property and. 443.0 4145 d 444.0, 356.0 a a356.0 a356.0, 357.0 a357.0 b 359.0 5356 7005, 7021 7039, 7046 7146 710.0, 711.0 filler metal selection for aluminum welding this chart is a tool that is. Web aluminum filler metal selection chart metal groups filler metal weld metal properties strength ratings are for fillet weld and. However, fillet welds loaded in shear seldom require Web welding filler metal databook. This document provides information on aluminum base alloys and filler alloys, listing various alloy designations and their characteristics for welding, soldering, dezincification corrosion, and other properties. A table lists the nominal strengths of aluminum filler metals. Anderson esab welding & cutting product j.Aluminum Filler Alloy Selection Chart PDF Welding Construction

Aluminum Filler Metal Selection Chart

Filler Metal Selection PDF Building Materials Building Engineering

Which filler metal should you choose?

Filler Metal Selection Chart

Aluminum Filler Metal Selection Chart A Visual Reference of Charts

Aluminum filler metal selection charts

Filler Metal Selection Chart

Aluminum Filler Metal Selection Chart A Visual Reference of Charts

4043 v 5356 Aluminum Filler WELDING ANSWERS

Web Aws Ugfm:2010 Iii Personnel Aws A5 Committee On Filler Metals And Allied Materials J.

Use These Charts To Easily Locate Matching, Suitable Electrode Or Filler Wire For Welding To Join Various Similar And Dissimilar Welding.

Web Filler Metal Suggestions “Match” The Base Metal Properties;

The Only 2Xxx Filler Alloy Readily Available Is 2319.

Related Post: