Aluminum Spool Gun Welding Settings Chart

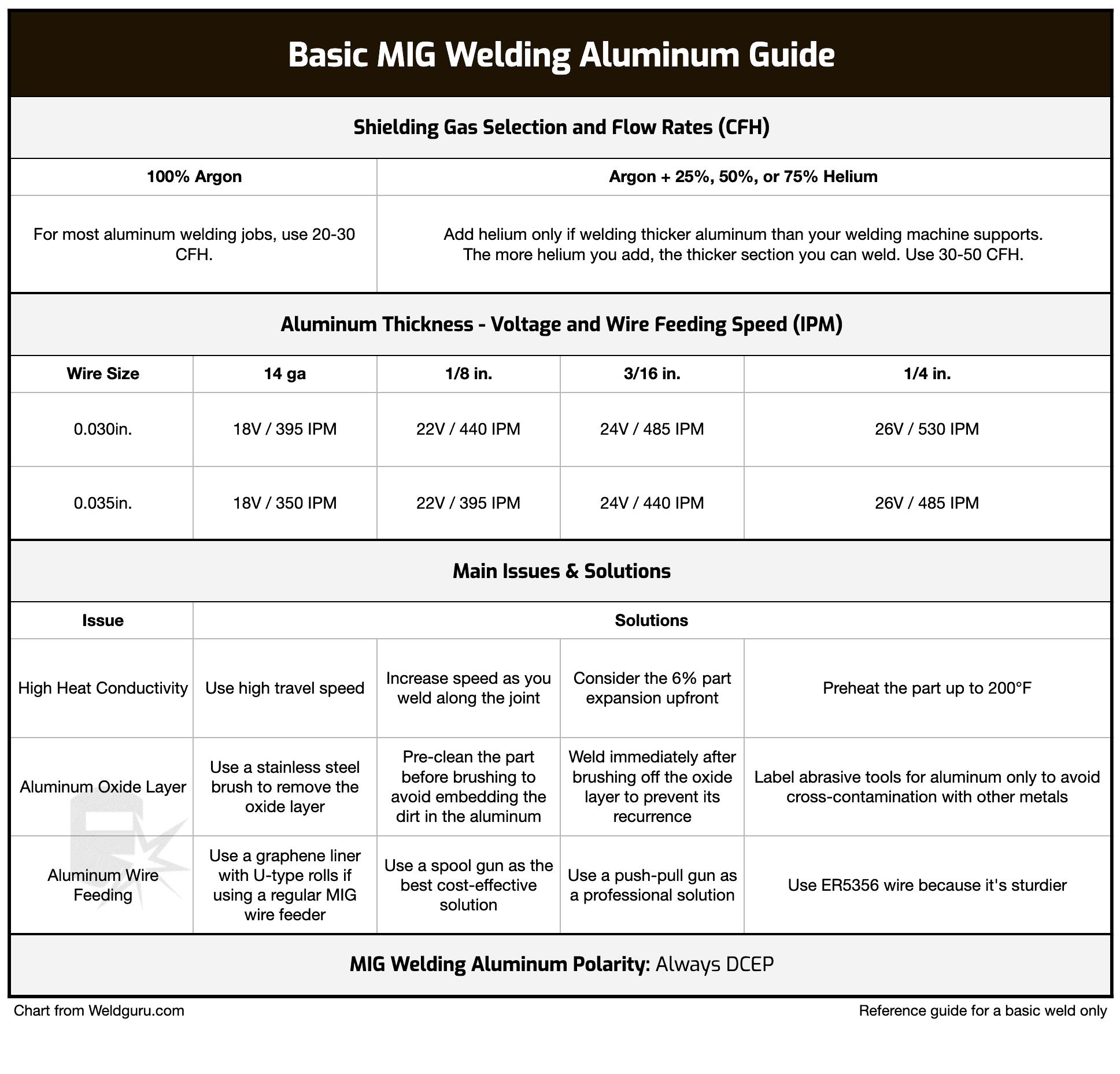

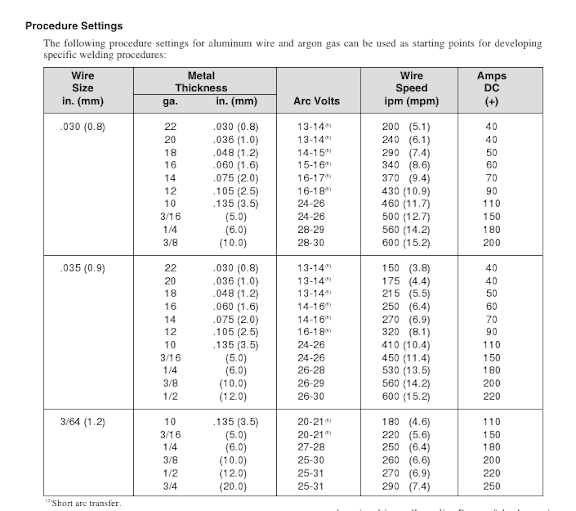

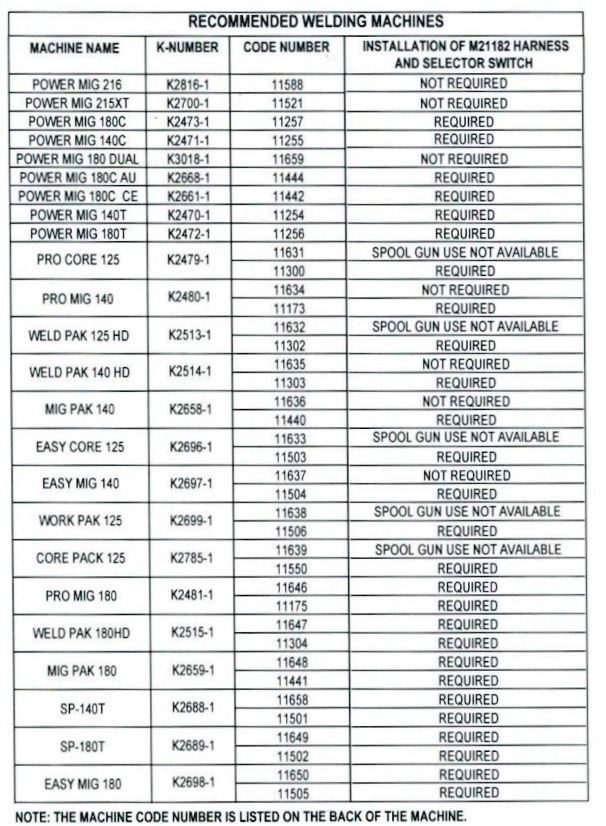

Aluminum Spool Gun Welding Settings Chart - Web the melting point for aluminum is 1,221 degrees fahrenheit, while some steel starts melting at 2,500 degrees. Determine which spool gun works with each welder, and if an adapter is needed. For many, gtaw is the preferred process, but gmaw offers some obvious benefits: Plate was at about 85f before i started. Using a spool gun eliminates the possibility of birdnesting because the wire only feeds a few inches. Aluminum is a soft metal that conducts heat very well, so it takes a lot of heat to get it to melt. Web swapping your traditional mig gun for a spool gun when welding aluminum can help prevent issues like binding. Problem with mig on aluminum with spoolgun. Web here are charts showing the wire speed and voltage speed settings required for mig aluminum welding. Unlike the oxide on steel, this is a significant difference from the temperature of the core metal. Using a spool gun eliminates the possibility of birdnesting because the wire only feeds a few inches. Web how to mig weld aluminum: Web in reading some other threads here someone posted the correct setting for this type/thickness of material was 5/75 (current/wire feed), however my manual says 10/75 for 14 guage (which is a bit thinner, but in the. Make sure your bottle of shielding gas is full, and the hookups are clean and tight. Web how to mig weld aluminum: Welding thin 16 ga and 18 ga aluminum with a spool gun. In general thicker wires feed better, while smaller diameter wires work better on thinner material. As it seems to vary a lot with some machines. Web here are charts showing the wire speed and voltage speed settings required for mig aluminum welding. Optimized spool gun procedures for aluminum. Web welder settings with 5356. Just bought a spoolmatic 30h to use on my trailblazer 302, i've welded with all the other processes several years but this is a first for me with aluminum and need some. Using a spool gun eliminates the possibility of birdnesting because the wire only feeds a few inches. In general thicker wires feed better, while smaller diameter wires work better on thinner material. Web the picture below is of a weld that was done using a step and pause welding technique with the spool gun. Here are some settings that will. Determine which spool gun works with each welder, and if an adapter is needed. Web first, consult the welding parameter chart on your machine to see what wires the machine and spool gun are designed to work with. But before using these values, we suggest that you have a decent understanding of your preferred metal. These two settings are with.035. The few times i've seen mig on aluminum i don't remember ever seeing as much soot. In general thicker wires feed better, while smaller diameter wires work better on thinner material. In general, miller recommends using either a.030 or.035 in. However, aluminum has an oxide layer on top that doesn’t melt until 3,700 degrees. Showing how to setup machine and. I am new to welding aluminum and i have a ironman 230 with a optional hobart spool gun. For many, gtaw is the preferred process, but gmaw offers some obvious benefits: I tried the settings on this chart. In general thicker wires feed better, while smaller diameter wires work better on thinner material. Web the melting point for aluminum is. Here are some settings that will get you in the ball park. Showing how to setup machine and spool gun, installing the aluminium wire reel and checking wire feed tension. How to mig weld aluminium with spool gun part 2. Diameter aluminum wire for most projects. As it seems to vary a lot with some machines. Welding thin 16 ga and 18 ga aluminum with a spool gun. Web find spool gun hookup information for miller welders. Recommended settings for voltage and wire speed. Using a spool gun eliminates the possibility of birdnesting because the wire only feeds a few inches. You can view parts 2,3 & 4 of this video via this links below. Recommended settings for voltage and wire speed. 621k views 3 years ago mig welding (gas metal arc welding. Determine which spool gun works with each welder, and if an adapter is needed. I've already had the tube on the spoolmate rebored to fit standard tips like those for the regular gun. Web welder settings with 5356. Determine which spool gun works with each welder, and if an adapter is needed. The few times i've seen mig on aluminum i don't remember ever seeing as much soot. I tried the settings on this chart. Can you short circuit thicker material. Welding aluminum is difficult because of the metal’s physical properties. However, aluminum has an oxide layer on top that doesn’t melt until 3,700 degrees. Higher deposition rates, less operator training and higher productivity. Web swapping your traditional mig gun for a spool gun when welding aluminum can help prevent issues like binding. Does anyone know where to find them? Spool gun welding on aluminum mig is the most common welding processes for hobbyists, and it’s a mainstay for commercial fabrication and repair facilities. Web have a few questions about welding aluminum with a spool gun. Does anyone have tips/tricks for achieving maximum aluminum weld quality with spool guns? Web how to mig weld aluminum: Web welder settings with 5356. But before using these values, we suggest that you have a decent understanding of your preferred metal. How to mig weld aluminium with spool gun part 2.

How To Use Aluminum Spool Gun

How To MIG Weld Aluminum Beginners Guide (with Chart)

Aluminum Spool Gun Welding Settings Chart

How to Use a Spool Gun to Weld Aluminum Kevin Caron YouTube

Aluminum Spool Gun Welding Settings Chart

Spoolgun welding of Aluminum

How To MIG Weld Aluminum Beginners Guide (with Chart)

First time with spool gun and aluminum how'd I do? r/Welding

M21182 Spool Gun Switch Lincoln Norstar N890002

Aluminum Spool Gun Welding Settings Chart

Web Find Spool Gun Hookup Information For Miller Welders.

Make Sure Your Bottle Of Shielding Gas Is Full, And The Hookups Are Clean And Tight.

Here Are Some Settings That Will Get You In The Ball Park.

Aluminum Is A Soft Metal That Conducts Heat Very Well, So It Takes A Lot Of Heat To Get It To Melt.

Related Post: