Aluminum Types Chart

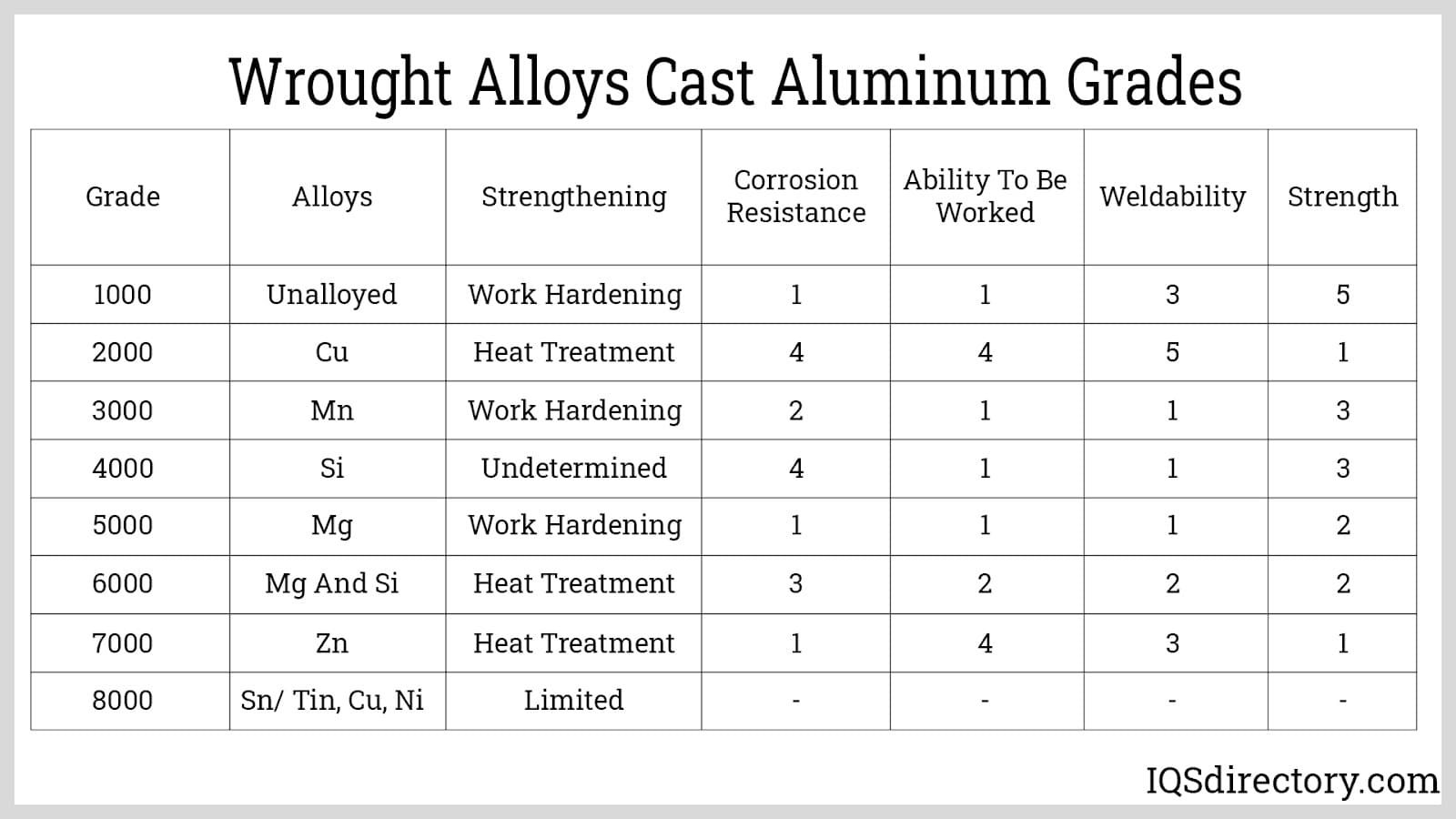

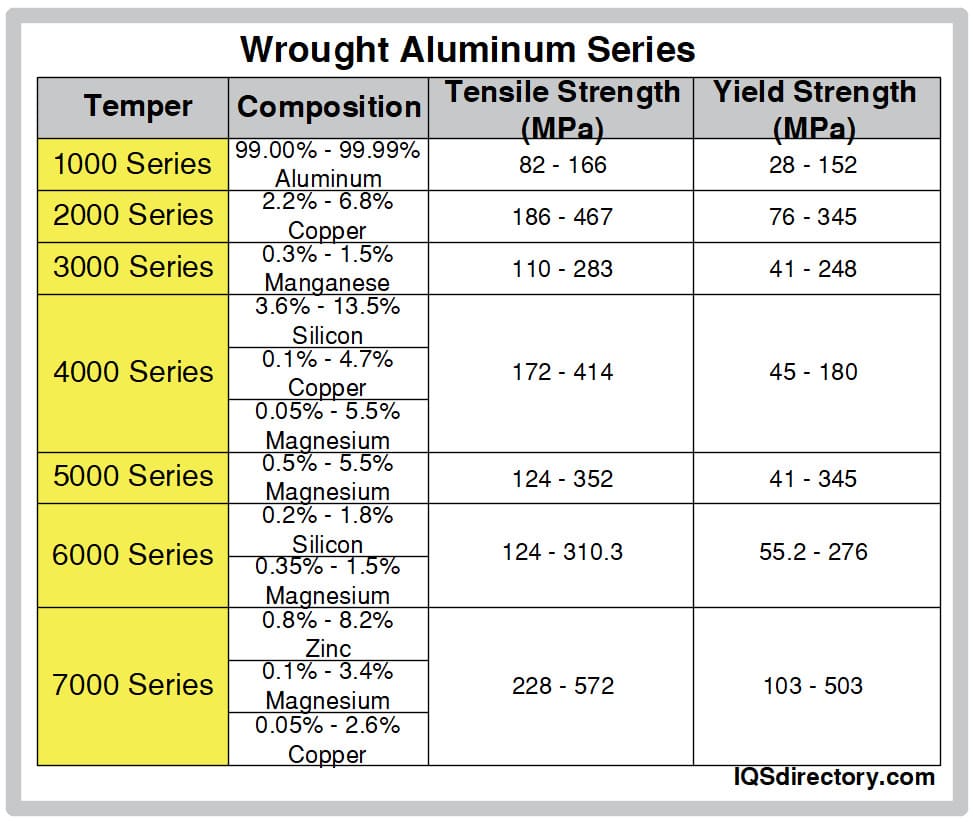

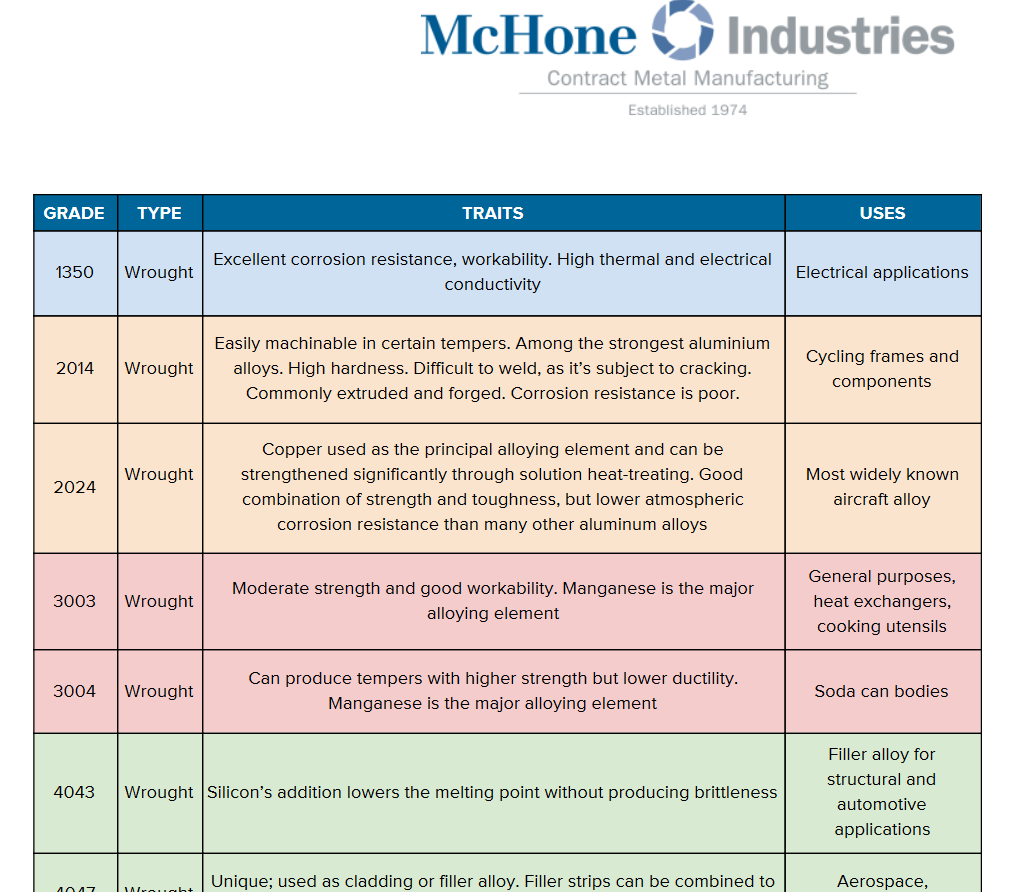

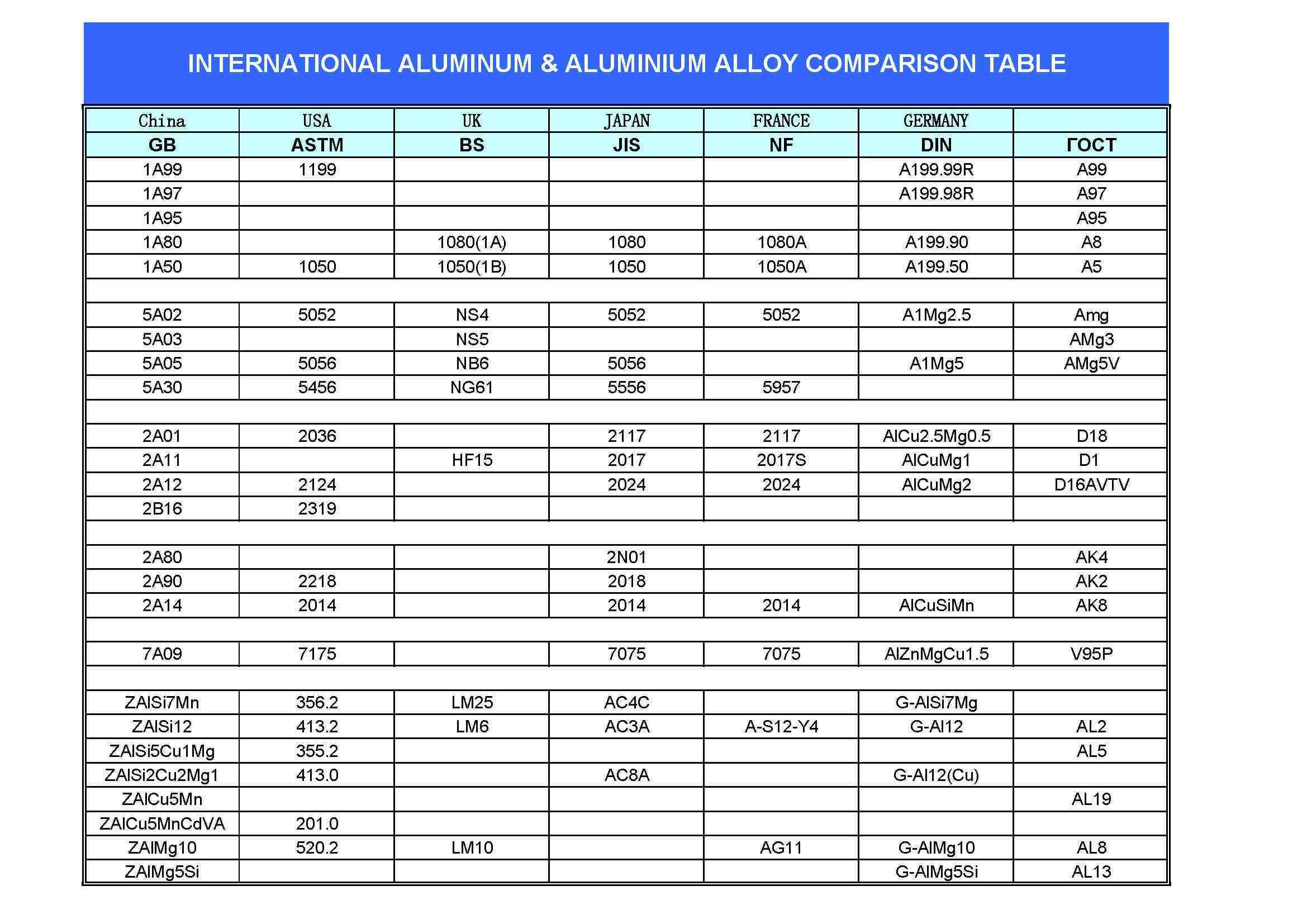

Aluminum Types Chart - Due to their pureness, 1xxx series aluminum alloys are highly resistant to corrosion but susceptible to high temperatures. ( types of aluminum ) Web the standard alloys for industrial use are: These alloys all have varying properties. Web all kinds of products — including: For example, the alloys used for aerospace and automotive parts are lightened with the addition of lithium, while alloys in building and construction are strengthened to manage heavy building loads. This sort of hardness is normal in planes and riveting ventures, yet you can’t weld it. Web all told, there are around 300 types of aluminum alloy, 50 of which are widespread. The different types of aluminum grades in rapid prototyping. Web there are two types of aluminum alloys — wrought and cast. Additionally, the series of aluminum and aluminum alloys are mainly divided into eight series. You will also learn the optimal alloys for specific applications. When choosing an aluminum grade, consider if the following are important factors: Deformed aluminum alloy and cast aluminum alloy. ( types of aluminum ) Iv how to identify aluminum alloy grades? 4.0.1 what are sheet metal aluminum grades? Series six is primarily alloyed with magnesium and silicon. 3 recommended default sheet metal tolerances. 2 5052, 6061, 7075 grade aluminum sheet metal for fabrication. What is an aluminium grade? These alloys all have varying properties. Web there are several types of aluminium grades available in the market, each with its unique set of characteristics. 4.0.1 what are sheet metal aluminum grades? Web from the reflective charm of 1100 aluminum to the robust versatility of 6061 aluminum, the world of aluminum is a captivating blend. What is an aluminium grade? Iv how to identify aluminum alloy grades? Web this article provides an overview of the available aluminum types, their major differences, and various benefits. Web the ways of classification. Consumer electronics, packaging, and parts for automobiles and airplanes — employ these alloys. Its diverse grades cater to a wide range of needs, whether you’re building an aircraft or creating intricate art pieces. Vii common types of aluminum alloy used in machining. Iii applications of aluminum alloys. 2 5052, 6061, 7075 grade aluminum sheet metal for fabrication. Web aluminium is the world¡¯s most abundant metal. Vii common types of aluminum alloy used in machining. Web this article provides an overview of the available aluminum types, their major differences, and various benefits. Aluminum that is most flexible: What is an aluminium grade? Iv how to identify aluminum alloy grades? 4.0.1 what are sheet metal aluminum grades? Web there are two types of aluminum alloys — wrought and cast. These alloys all have varying properties. When choosing an aluminum grade, consider if the following are important factors: There are eight grade series of aluminium. Web aluminum alloy can be divided into two types based on processing method: 2 5052, 6061, 7075 grade aluminum sheet metal for fabrication. Vii common types of aluminum alloy used in machining. In most cases, it can be difficult to choose the correct aluminum grade for your intended application. What's more, 1xxx series alloys with the highest purity are typical. These alloys all have varying properties. Web all told, there are around 300 types of aluminum alloy, 50 of which are widespread. Different grades are associated with different strengths and applications, so you’ll need to choose. 1xxx series alloy contains a minimum of 99% pure aluminum. Web the standard alloys for industrial use are: Deformed aluminum alloy and cast aluminum alloy. Web all kinds of products — including: 2 5052, 6061, 7075 grade aluminum sheet metal for fabrication. What's more, 1xxx series alloys with the highest purity are typical for food packaging and electrical use. V different grades of aluminum alloys. Web this article provides an overview of the available aluminum types, their major differences, and various benefits. Iii applications of aluminum alloys. Web all kinds of products — including: 3 recommended default sheet metal tolerances. Each grade is associated with a particular alloy. Web there are two types of aluminum alloys — wrought and cast. Aluminum grades vary based on the primary alloying materials, which affect their properties. Classifications of aluminum alloys may be in several ways: This group includes high purity aluminum and the wrought alloys in the 1xxx, 3xxx, and 5xxx series. The specifications, properties, classifications and class details are provided for aluminium and aluminium alloys. Web the ways of classification. Due to their pureness, 1xxx series aluminum alloys are highly resistant to corrosion but susceptible to high temperatures. Various combinations of the main alloying elements with other alloying elements. When choosing an aluminum grade, consider if the following are important factors: Web there are several types of aluminium grades available in the market, each with its unique set of characteristics. The different types of aluminum grades in rapid prototyping.

Aluminum Casting What Is It? How Is it Made? Advantages

Comparison Chart Aluminium_ USA Popular Grades V Aluminium Chemistry

Standard Aluminum Extrusions Shapes Chart

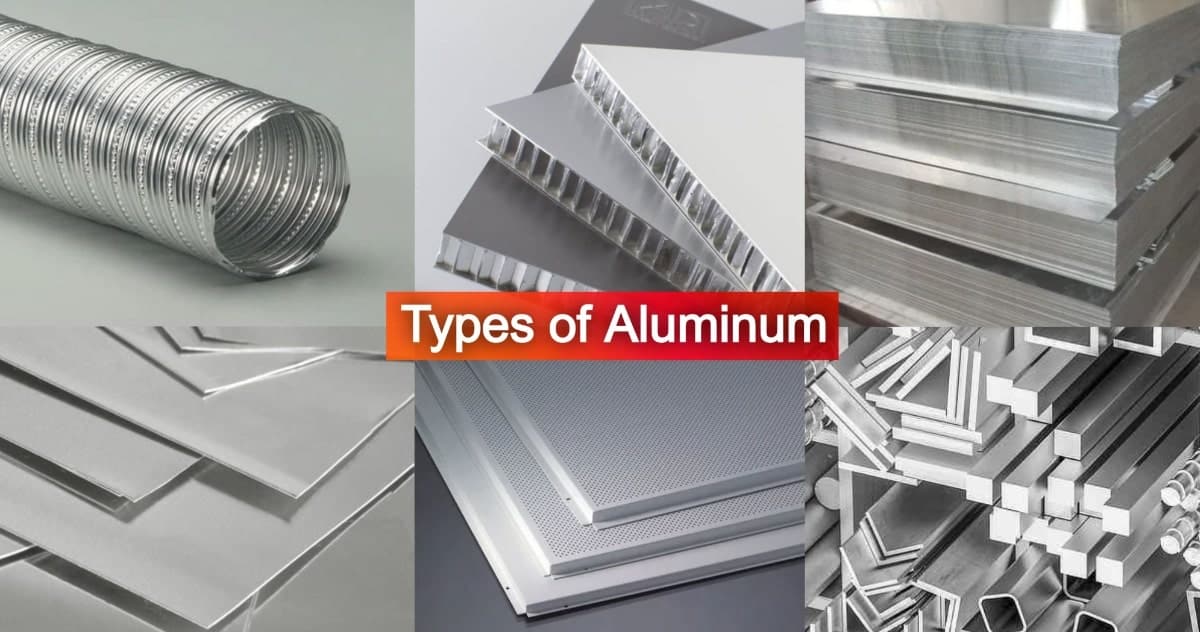

Types of Aluminum Types, Uses, Features and Benefits

Hardness Conversion Chart For Aluminium Alloys Aluminum Grades Chart

INTERNATIONAL ALUMINUM & ALUMINIUM ALLOY COMPARISON TABLE Technology

3003 or 5052 aluminium All MetalShaping

AlAlloysTable I Alloy Elements Light Metal Age Magazine

6 Types of Aluminum Uses and Grades [Explained with Complete Details

Aluminum Aluminum Grades

Consumer Electronics, Packaging, And Parts For Automobiles And Airplanes — Employ These Alloys.

1Xxx Series Alloy Contains A Minimum Of 99% Pure Aluminum.

Vii Common Types Of Aluminum Alloy Used In Machining.

Aluminum That Is Most Flexible:

Related Post: