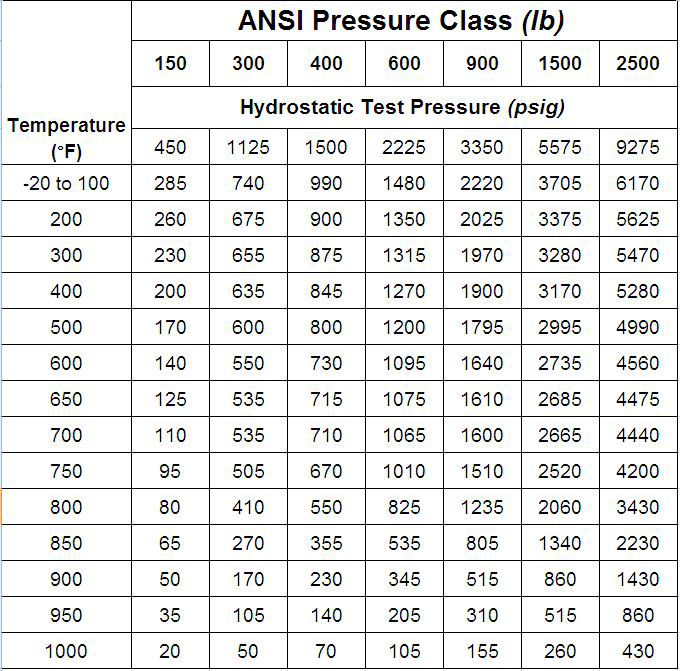

Ansi Pressure Rating Chart

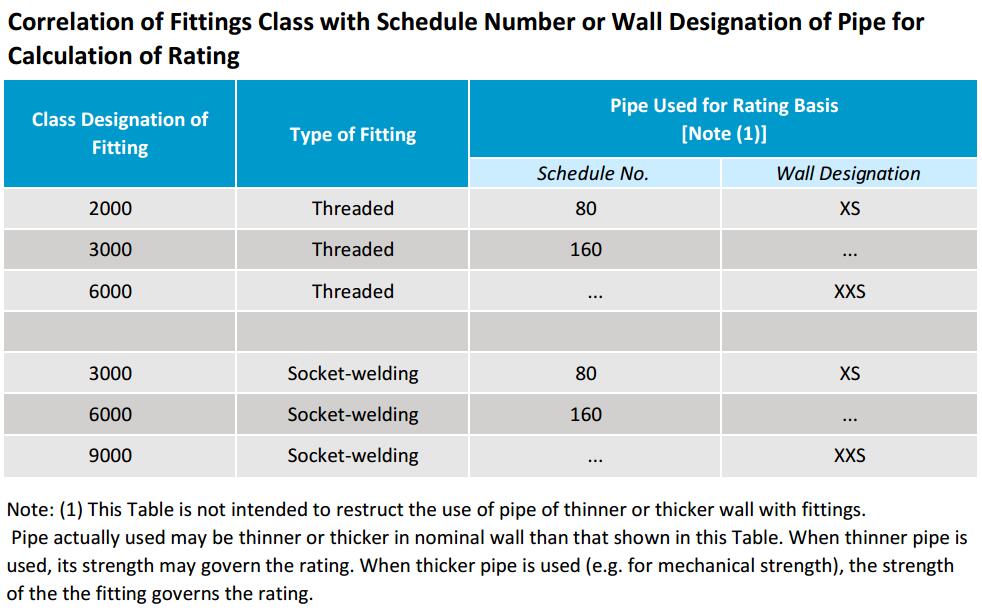

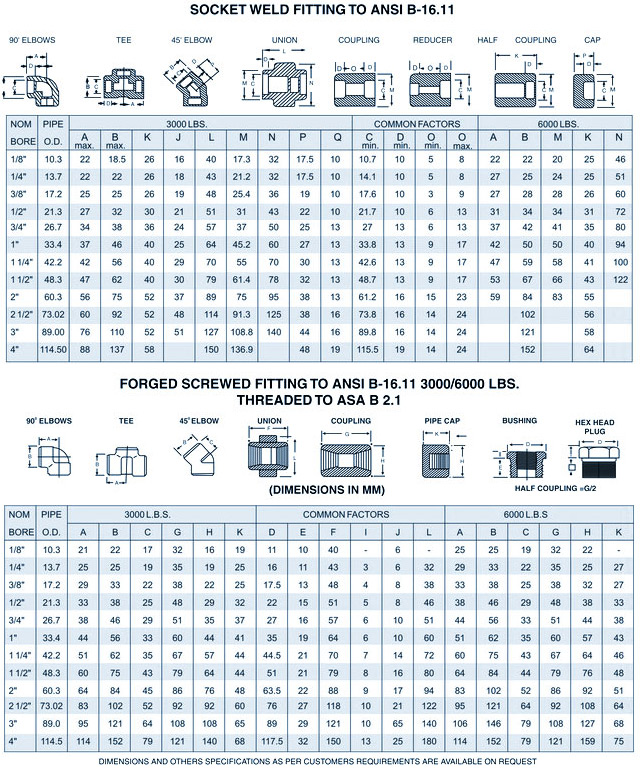

Ansi Pressure Rating Chart - Multiply the psi rating by 0.0069 and that will give you the mpa related to the class. Web asme/ansi b16.5 standard provides seven flange pressure ratings: 150, 300, 400, 600, 900, 1500, and 2500. Web for example, a class 150 fl ange is rated about 270 psi at ambient conditions (i.e. F1 (chrome moly) pressure temperature rating chart for astm a182 gr. The ansi flange ratings charts (condensed list here) should be used only as a guide in selecting the properly rated flange as well as other components used in a flanged or circulation heater. 150, 300, 400, 600, 900, 1500, and 2500. Pressure rating is defined as the maximum allowed pressure that a flange can withstand at increasing temperatures. Lf2/lf6 class 1 the flange rating table shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (celsius. There are several notes associated with this, and other tables in asme b16.5 that need to be verified by the engineer prior to specification. Hydrostatic test pressure (psig) 450: Web 402.3 451.8 501.3 550.5 593.5. Pressure temperature rating chart for astm a182 gr. The thicknesses in this table are equal to or in excess of those required to withstand the rated working pressures plus a surge allowance of 100 psi. 100of or 38oc), 180 psi at 400of (204oc), 150 psi at 600of (316oc), and. These non ansi valves typically have a pressure/temperature chart for each trim configuration. Web use the material reference in the table when determining pressure/temperature ratings of valves used in accordance with the asme standard. 150, 300, 400, 600, 900, 1500, and 2500. Pt = (pr x si) / 8750. At ambient temperatures, it makes sense that the pressure ratings are. Web ansi works along with the asme (american society of mechanical engineers) to identify and communicate safe. At ambient temperatures, it makes sense that the pressure ratings are higher than the saturated steam pressure. 100of or 38oc), 180 psi at 400of (204oc), 150 psi at 600of (316oc), and 75 psi at 800of (427oc). Class 75 also exists in asme b16.47. This table defines the maximum. Web use the material reference in the table when determining pressure/temperature ratings of valves used in accordance with the asme standard. Web 402.3 451.8 501.3 550.5 593.5. Web ansi flange pressure ratings. Web ansi works along with the asme (american society of mechanical engineers) to identify and communicate safe. Pressure temperature rating chart for astm a182 gr. The thicknesses in this table are equal to or in excess of those required to withstand the rated working pressures plus a surge allowance of 100 psi. These non ansi valves typically have a pressure/temperature chart for each trim configuration. Furthermore, fm set minimum pressure requirements for fm approval for each of. Web for example, a class 150 fl ange is rated about 270 psi at ambient conditions (i.e. Web 221 rows minimum tensile strength 60 ksi (60000 psi). Hydrostatic test pressure (psig) 450: The thicknesses in this table are equal to or in excess of those required to withstand the rated working pressures plus a surge allowance of 100 psi. Pressure. Lf2/lf6 class 1 the flange rating table shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (celsius. Web carbon steel (astm a105n & a350 lf2) limitations > 425°c. Web for example, a class 150 fl ange is rated about 270 psi at ambient conditions (i.e. Web 402.3 451.8 501.3 550.5 593.5. A few important features of flange. Pt = rated working pressure in psig for specified material at temperature t. 100of or 38oc), 180 psi at 400of (204oc), 150 psi at 600of (316oc), and 75 psi at 800of (427oc). Furthermore, fm set minimum pressure requirements for fm approval for each of the three tests conducted in gutter system testing: Web ansi works along with the asme (american. Web carbon steel (astm a105n & a350 lf2) limitations > 425°c. For intermediate temperatures, linear interpolation of the pressure value is allowed. Hydrostatic test pressure (psig) 450: Web pressure temperature rating chart for ansi flange astm a350 gr. F1 (chrome moly) pressure temperature rating chart for astm a182 gr. How to select flange pressure rating for piping system? These non ansi valves typically have a pressure/temperature chart for each trim configuration. A few important features of flange classes are: Pt = (pr x si) / 8750. Web the conversion rate is 1 psi = 0.0069mpa. 150, 300, 400, 600, 900, 1500, and 2500. Standards for a variety of mechanical measures. Web asme/ansi b16.5 standard provides seven flange pressure ratings: It is defined by the international electrotechnical commission (iec) under the international standard iec 60529 [1] which classifies and provides a guideline to the degree of protection provided by mechanical casings and electrical enclosures. A few important features of flange classes are: Web carbon steel (astm a105n & a350 lf2) limitations > 425°c. Pr = pressure rating as per class in psig. 150, 300, 400, 600, 900, 1500, and 2500. This table defines the maximum. Hydrostatic test pressure (psig) 450: According to the ansi/asme b16.5 specification, there are seven flange pressure ratings: Web use the material reference in the table when determining pressure/temperature ratings of valves used in accordance with the asme standard. Web for example, a class 150 fl ange is rated about 270 psi at ambient conditions (i.e. Class 75 also exists in asme b16.47 series b large diameter. Lf2/lf6 class 1 the flange rating table shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (celsius. The thicknesses in this table are equal to or in excess of those required to withstand the rated working pressures plus a surge allowance of 100 psi.

ASME B16.5 Flange Ratings Chart

ANSI Flange Rating Chart

Ansi Pressure Rating Chart

ANSI Pressure Rating Chart

Ansi Pressure Rating Chart

Pressure Ratings, General Reference AirWay Manufacturing

Use of ASME B16.5 Standards for Flange Pressure Ratings

ANSI Pipe Schedules Farwest Corrosion Control

Pressure/Temperature Ratings For Flanges Asme/Ansi B16.52013

Ansi 600 Pressure Rating Chart

They Are Also Referred To As “Pound Rating” Or Pressure Class Rating.

Web 221 Rows Minimum Tensile Strength 60 Ksi (60000 Psi).

100Of Or 38Oc), 180 Psi At 400Of (204Oc), 150 Psi At 600Of (316Oc), And 75 Psi At 800Of (427Oc).

* Pression Nominal Is The French Equivalent Of Pressure Nominal.

Related Post: