Blasting Nozzle Size Chart

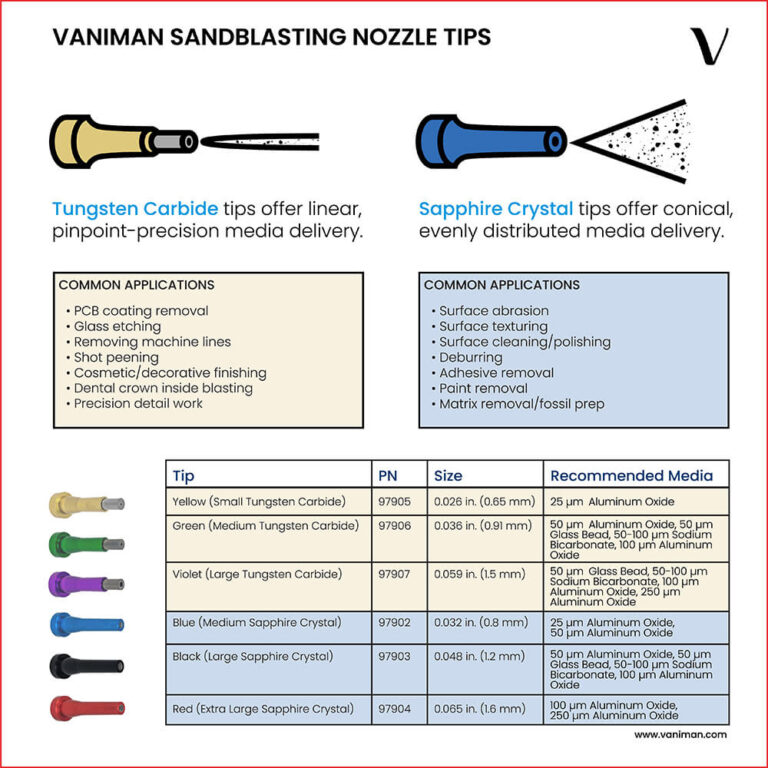

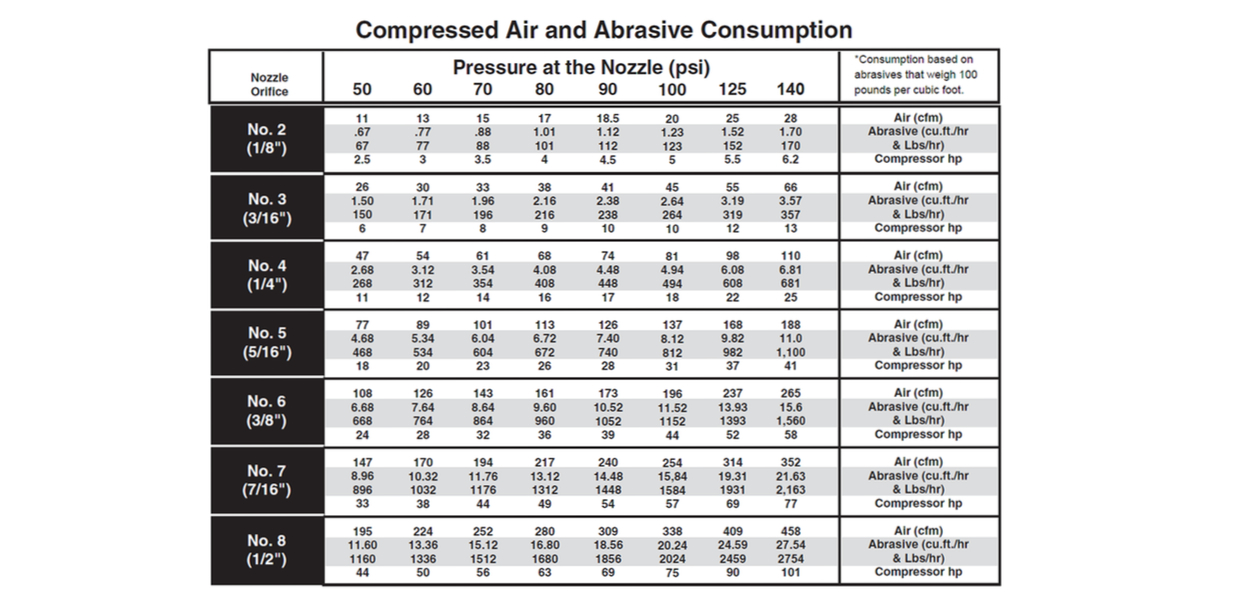

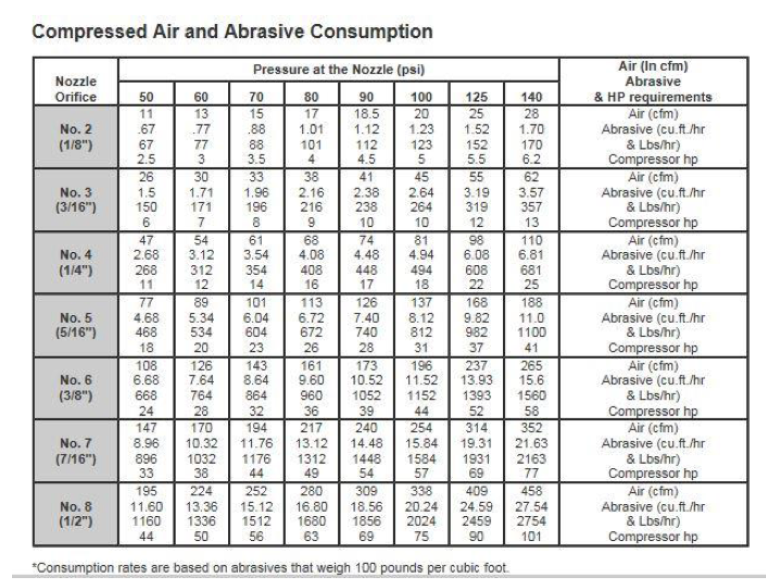

Blasting Nozzle Size Chart - Rugged but lightweight for maximum sandblasting performance, each type of nozzle is designed for a specific type of media application. Click link below for cfm chart. Web nozzle size & your air supply. This will help you in determining compressor size. This page will introduce you to our line of standard, high performance, and specialty blast nozzles. So if you have a #5 nozzle, it has a 5/16 inner diameter, and a #6 nozzle has a 3/8 inner diameter. Use the chart below to find your nozzle bore size: The smaller the nozzle opening, the higher the pressure and velocity of the abrasive blast. Nozzles are measured by their inner diameter, which is expressed as a number. Use this chart to find your nozzle bore size: Based on the factors mentioned earlier, we can create an optimized sandblasting nozzle air consumption cfm chart: Web cfm chart for sandblasting nozzles. If you don’t choose the right nozzle size, your production will suffer. The smaller the nozzle opening, the higher the pressure and velocity of the abrasive blast. Web chart compares relationship between nozzle size, nozzle pressure, and. Another factor you need to consider is your breathing air respirator. Web blast nozzle buying guide | blast nozzle comparison chart. The number size represents 1/16 increments. #2 nozzle has a 1/8″ orifice (3.2mm) #3 nozzle has a 3/16″ orifice (4.8mm) #4 nozzle has a 1/4″ orifice (6.35mm) #5 nozzle has a 5/16″ orifice (8mm) #6 nozzle has a 3/8″. Nozzle bore size (inch) pressure at nozzle (psi) 50 60 70 80 90 100 125 1/8 air (cfm) 12 13 15 18 19 21 26 abrasives. Based on the factors mentioned earlier, we can create an optimized sandblasting nozzle air consumption cfm chart: Web our chart below illustrates the cfm requirements for different nozzle sizes at different pressures. Click link. Another factor you need to consider is your breathing air respirator. Web actual efficiency increase/ decrease will vary depending on abrasive type and size, blast nozzle type, size and wear, hose sizes and wear, temperature, moisture content of compressed air, etc. Web finding the correct nozzle size depends on which black diamond abrasive product you are blasting. Web a full. Web blasting is the process where small angular or spherical particles are propelled at a part by compressed air, or mechanical high speed rotating wheels or water pumps. The number size represents 1/16 increments. This page will introduce you to our line of standard, high performance, and specialty blast nozzles. Web ensure consistent and adequate nozzle pressure to optimize your. Web ensure consistent and adequate nozzle pressure to optimize your blasting operations. The blast machine capacity, the piping, the hoses, and—most importantly—air volume. Use a abrasive wet or dry blast nozzle pressure gauge to measure air pressure at the nozzle. The blast media type, shape, size, density, and hardness, along with media acceleration and volume of media, combined with blasting. #2 nozzle has a 1/8″ orifice (3.2mm) #3 nozzle has a 3/16″ orifice (4.8mm) #4 nozzle has a 1/4″ orifice (6.35mm) #5 nozzle has a 5/16″ orifice (8mm) #6 nozzle has a 3/8″ orifice (9.5mm) #7 nozzle has a 7/16″ orifice (11.1mm) Web our chart below illustrates the cfm requirements for different nozzle sizes at different pressures. Laminar flow design. This will help you in determining compressor size. Nozzle bore size (inch) pressure at nozzle (psi) 50 60 70 80 90 100 125 1/8 air (cfm) 12 13 15 18 19 21 26 abrasives. The smaller the nozzle opening, the higher the pressure and velocity of the abrasive blast. Web finding the correct nozzle size depends on which black diamond. Nozzle bore size (inch) pressure at nozzle (psi) 50 60 70 80 90 100 125 1/8 air (cfm) 12 13 15 18 19 21 26 abrasives. Rugged but lightweight for maximum sandblasting performance, each type of nozzle is designed for a specific type of media application. When choosing a nozzle size, its size is dependent on a variety of factors:. Laminar flow design long venturi. View our abrasive nozzle sizing chart for more details. #2 nozzle has a 1/8″ orifice (3.2mm) #3 nozzle has a 3/16″ orifice (4.8mm) #4 nozzle has a 1/4″ orifice (6.35mm) #5 nozzle has a 5/16″ orifice (8mm) #6 nozzle has a 3/8″ orifice (9.5mm) #7 nozzle has a 7/16″ orifice (11.1mm) Web chart compares relationship. Web ensure consistent and adequate nozzle pressure to optimize your blasting operations. #2 nozzle has a 1/8″ orifice (3.2mm) #3 nozzle has a 3/16″ orifice (4.8mm) #4 nozzle has a 1/4″ orifice (6.35mm) #5 nozzle has a 5/16″ orifice (8mm) #6 nozzle has a 3/8″ orifice (9.5mm) #7 nozzle has a 7/16″ orifice (11.1mm) View our abrasive nozzle sizing chart for more details. Explore the chart to find the perfect nozzle size, considering factors like diameter and material compatibility. Web our chart below illustrates the cfm requirements for different nozzle sizes at different pressures. Web the nozzle size is determined by the diameter of the nozzle opening. Web chart compares relationship between nozzle size, nozzle pressure, and efficiency. Web nozzle size & your air supply. Use a abrasive wet or dry blast nozzle pressure gauge to measure air pressure at the nozzle. Web cfm chart for sandblasting nozzles. If you don’t choose the right nozzle size, your production will suffer. When choosing a nozzle size, its size is dependent on a variety of factors: The number size represents 1/16 increments. Click link below for cfm chart. Web blasting is the process where small angular or spherical particles are propelled at a part by compressed air, or mechanical high speed rotating wheels or water pumps. Use this chart to find your nozzle bore size:

Sand Blasting Nozzle 3/4" Thread. Sandblaster Parts

Sandblaster Nozzle Size Chart (INFOGRAPHIC) Sandblasting Applications

Blast Nozzle Chart A Visual Reference of Charts Chart Master

Blast Nozzle Selection Guide (VIDEO)

Blasting Nozzle Size Chart

Understanding Sandblasting Compressor Size Requirements Sandblasting

Sandblasting Nozzle Size Chart

Sand Blasting Nozzle Size Chart

Sandblast Nozzle Size Chart A Visual Reference of Charts Chart Master

Blast Nozzle Cfm Chart

Another Factor You Need To Consider Is Your Breathing Air Respirator.

Nozzle Bore Size (Inch) Pressure At Nozzle (Psi) 50 60 70 80 90 100 125 1/8 Air (Cfm) 12 13 15 18 19 21 26 Abrasives.

Web Actual Efficiency Increase/ Decrease Will Vary Depending On Abrasive Type And Size, Blast Nozzle Type, Size And Wear, Hose Sizes And Wear, Temperature, Moisture Content Of Compressed Air, Etc.

Rugged But Lightweight For Maximum Sandblasting Performance, Each Type Of Nozzle Is Designed For A Specific Type Of Media Application.

Related Post: