Bolt Chart For 300 Flanges

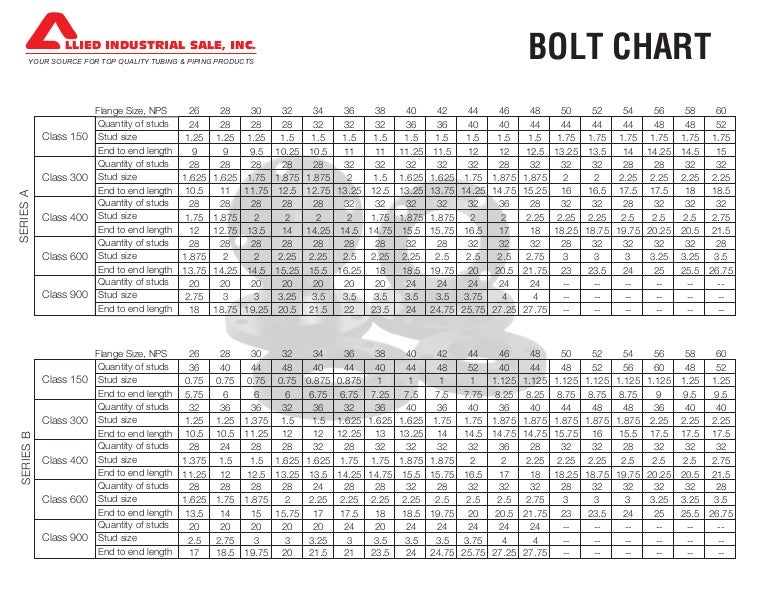

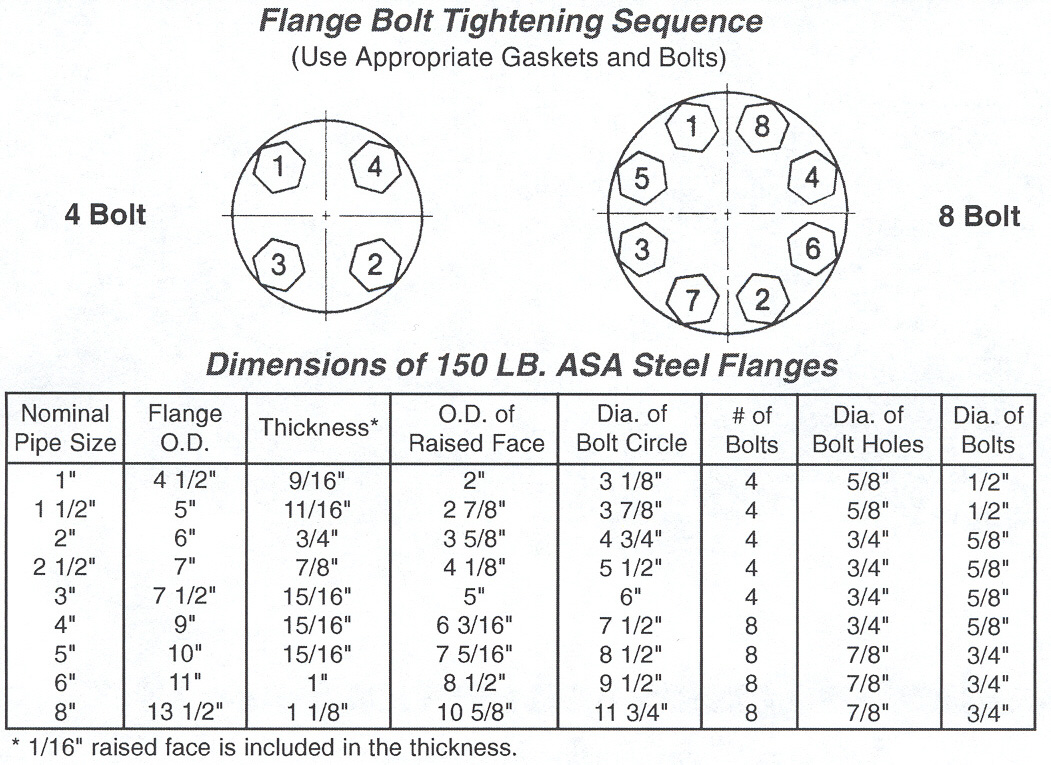

Bolt Chart For 300 Flanges - The asme b16.5 stud lengths are specified from thread to thread. Web the following chart shows the quantity and size of bolts or studs require for a particular flange size and class. Web 300# flange bolt chart with length & diameter of studs, pipe size, and wrench size. Dimension of table 7 are in millimeters, except for diameters of bolts and bolts holes, which are in inch units. 20 25 1 1⁄8 20 6 5 1⁄4 27 1 1⁄4 24 8 7 22 27 1⁄4 1 1⁄4 20 6 1⁄2 5 1⁄2 29 1⁄4 1 1⁄2 24 8 3⁄4 7 1⁄2 Web below is asme b16.5 150#, 300#, 600# stud bolt flange chart information that can assist engineers and pipe fitters with calculating the number of fasteners associated according to flange size. Asme flange bolting (number, diameter, length of stud bolts by asme flange sizes); Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app. Flange dimensions are determined by the pipe size and the pressure class required for the application. Web the size and number of bolts and the bolt circle diameter of 250 lb. Length of stud bolts does not include the height of the points. Nominal quantity bolt nominal quantity bolt nominal quantity bolt pipe size of bolts diameter min max pipe size of bolts diameter min max pipe. Asme flange bolting (number, diameter, length of stud bolts by asme flange sizes); Dimension of table 7 are in millimeters, except for diameters of. Web instant flange bolt sizes and torque patterns: Web the following chart shows the quantity and size of bolts or studs require for a particular flange size and class. Cast iron flanges are the same as shown for 300 lb. Diameter and lengths of the stud and bolt are covered in flange standard asme b16.5 & b16.47. Web 300# flange. The asme b16.5 stud lengths are specified from thread to thread. Bolt reference charts for asme b16.47 series a flanges. 20 25 1 1⁄8 20 6 5 1⁄4 27 1 1⁄4 24 8 7 22 27 1⁄4 1 1⁄4 20 6 1⁄2 5 1⁄2 29 1⁄4 1 1⁄2 24 8 3⁄4 7 1⁄2 As you are going to use bolt. Flange bolt size chart and torque patterns. Lookup bolt lengths, wrench sizes, and torque patters using the flange bolt app. Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. Cast iron flanges are the same as shown. Web 1500 # bolt chart. Web ansi 150# flanges ansi 300# flanges ansi 600# flanges. Web the lengths of the machine bolts are measured from under the head to the top of the bolt. Web below is asme b16.5 150#, 300#, 600# stud bolt flange chart information that can assist engineers and pipe fitters with calculating the number of fasteners. Bolt reference charts for asme b16.47 series a flanges. The asme b16.5 stud lengths are specified from thread to thread. This is for informational purposes only. Length of stud bolts does not include the height of the points. Web the size and number of bolts and the bolt circle diameter of 250 lb. Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. Web the lengths of the machine bolts are measured from under the head to the top of the bolt. Flange bolting chart (inches) stud bolts and nuts for. Web bolting dimensions for 150 to 300 lb. Just enter the flange size, class, and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart, along with wrench size. Flange dimensions are determined by the pipe size and the pressure class required for the application. Web explore the comprehensive. Cast iron flanges are the same as shown for 300 lb. 20 25 1 1⁄8 20 6 5 1⁄4 27 1 1⁄4 24 8 7 22 27 1⁄4 1 1⁄4 20 6 1⁄2 5 1⁄2 29 1⁄4 1 1⁄2 24 8 3⁄4 7 1⁄2 Web ansi 150# flanges ansi 300# flanges ansi 600# flanges. Length of stud bolts does not. Web the following chart shows the quantity and size of bolts or studs require for a particular flange size and class. Dimension of table 7 are in millimeters, except for diameters of bolts and bolts holes, which are in inch units. Pipe circle bolt of *stud bolt circle bolt of *stud bolt size dia. Stud bolt torque chart (tightening sequence. Web explore the comprehensive flange bolting chart at texas flange. Dimension of table 7 are in millimeters, except for diameters of bolts and bolts holes, which are in inch units. Bolt reference charts for asme b16.47 series a flanges. Recommended torque values lubricated stud bolts w/0.15 friction value. Web key charts for stud bolts: Pipe circle bolt of *stud bolt circle bolt of *stud bolt size dia. Stud bolt torque chart (tightening sequence and load to ensure proper flanged joints) stud bolts charts. Web instant flange bolt sizes and torque patterns: 20 25 1 1⁄8 20 6 5 1⁄4 27 1 1⁄4 24 8 7 22 27 1⁄4 1 1⁄4 20 6 1⁄2 5 1⁄2 29 1⁄4 1 1⁄2 24 8 3⁄4 7 1⁄2 Diameter and lengths of the stud and bolt are covered in flange standard asme b16.5 & b16.47. 1 inch = 25.4 mm Bolt reference charts for asme b16.5 flanges cont. Web 1500 # bolt chart. In this article, i have covered flange bolt chart and flange stud size. Web below are flange bolting charts containing specifications for class 150 flanges, class 300 flanges, and class 600 flanges. Nominal quantity bolt nominal quantity bolt nominal quantity bolt pipe size of bolts diameter min max pipe size of bolts diameter min max pipe.

Class 300 Flanges Dimensions In Mm and Weight Chart/ Pressure Rating

Thermometrics Corporation Flanges

Texas Ico Inc. Cleveland, TX Flanges

Technical Info Flange BoltUp Charts

Class 300 Flanges Manufacturers, ASME B16.5 300 Flange Dimensions

300 Flange Bolt Chart

Bolt Chart For Flanges

Flange Dimensions ANSI 300

30 300 Flange Bolt Chart

Asme Flange Bolt Torque Chart

Web 300# Flange Bolt Chart With Length & Diameter Of Studs, Pipe Size, And Wrench Size.

Web Class 300 Class 900 Dimensions In Inches Dimensions In Inches Dimensions In Inches Dimensions In Inches.

Please Contact Us If You Have Any Further Questions.

(2) Length Of Point On Studs And Stud Bolts Shall Be Not Less Than One Nor More Than Two Complete Threads As Measured From The Extreme End Parallel To The Axis.

Related Post: