C Chart Six Sigma

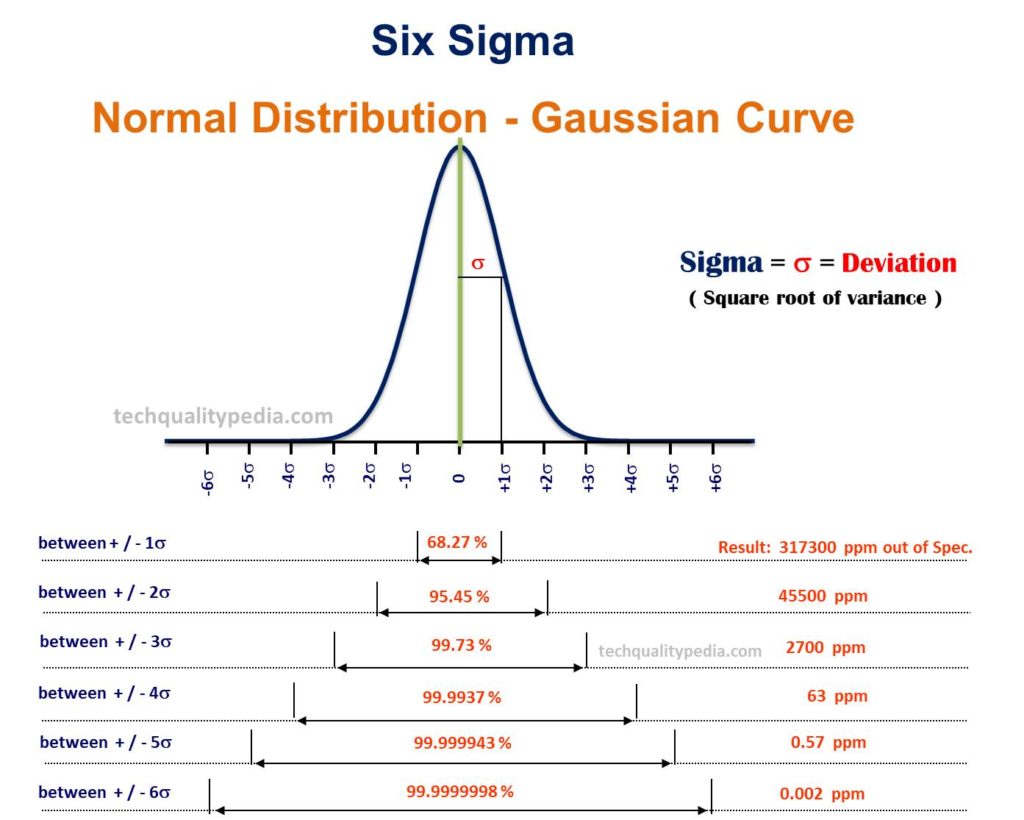

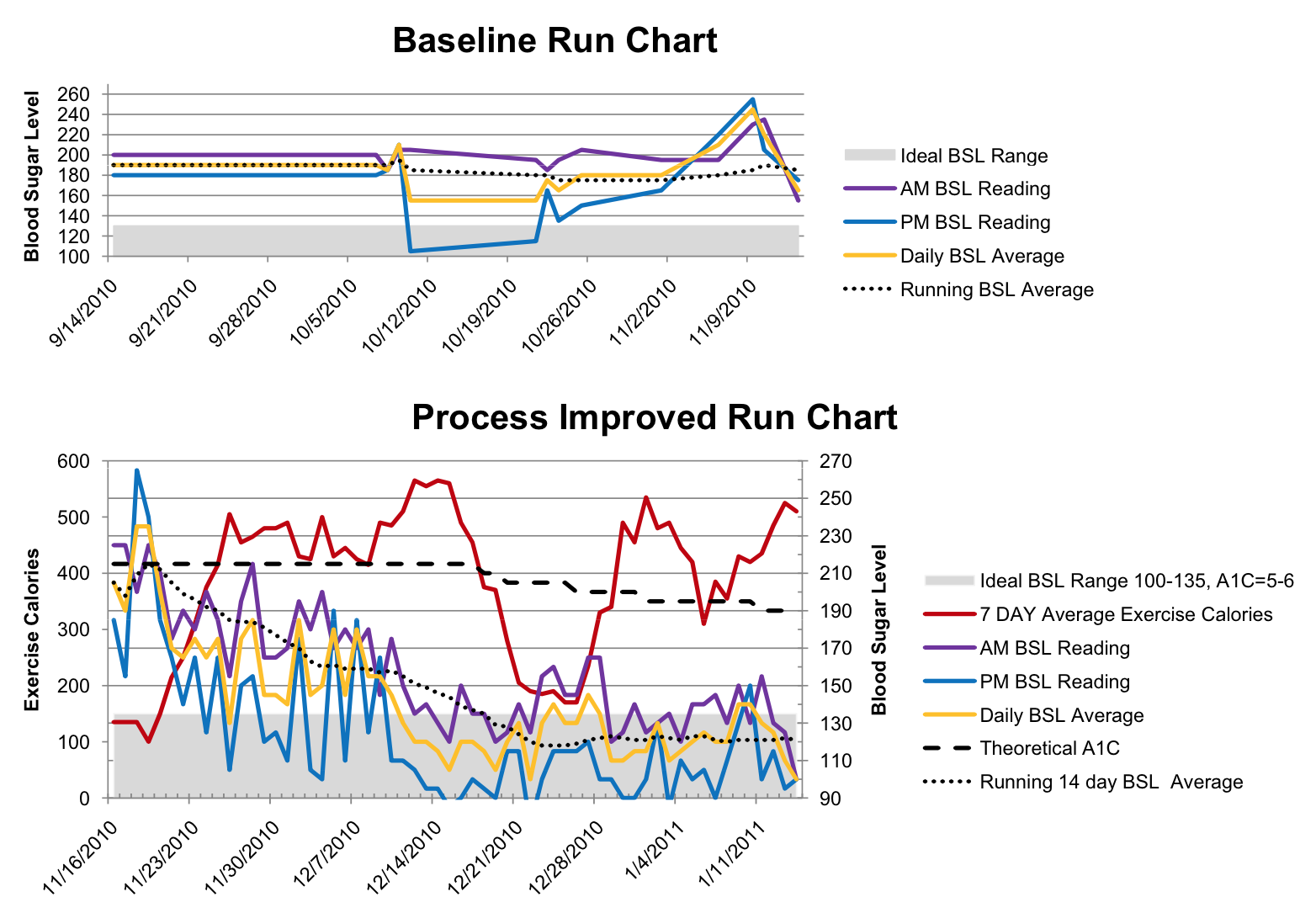

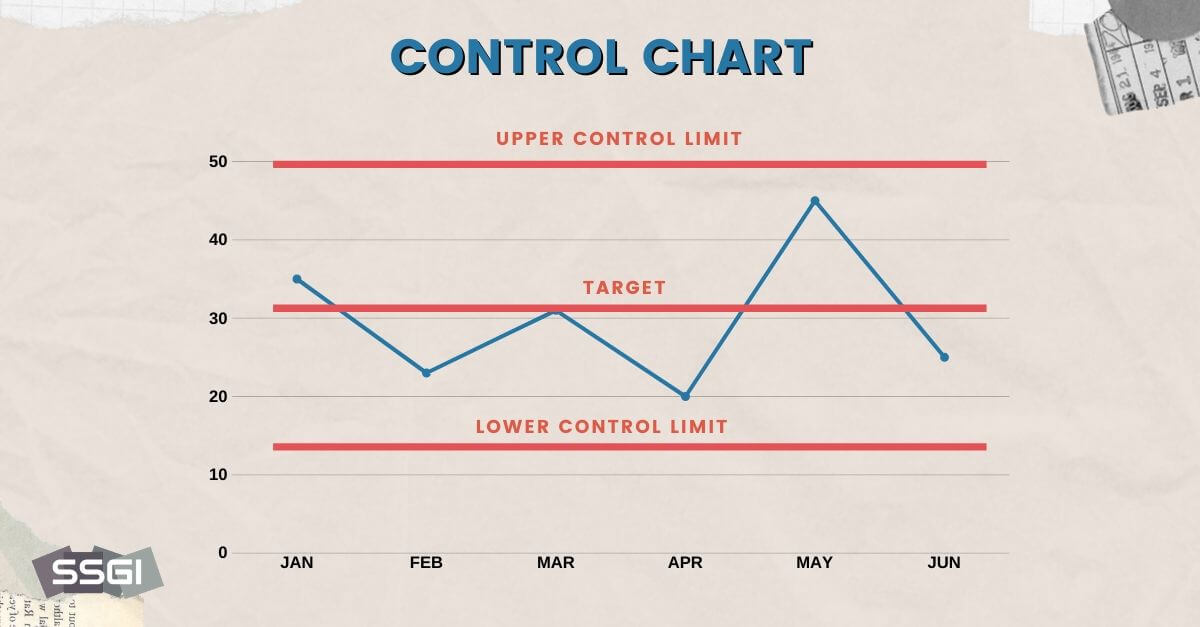

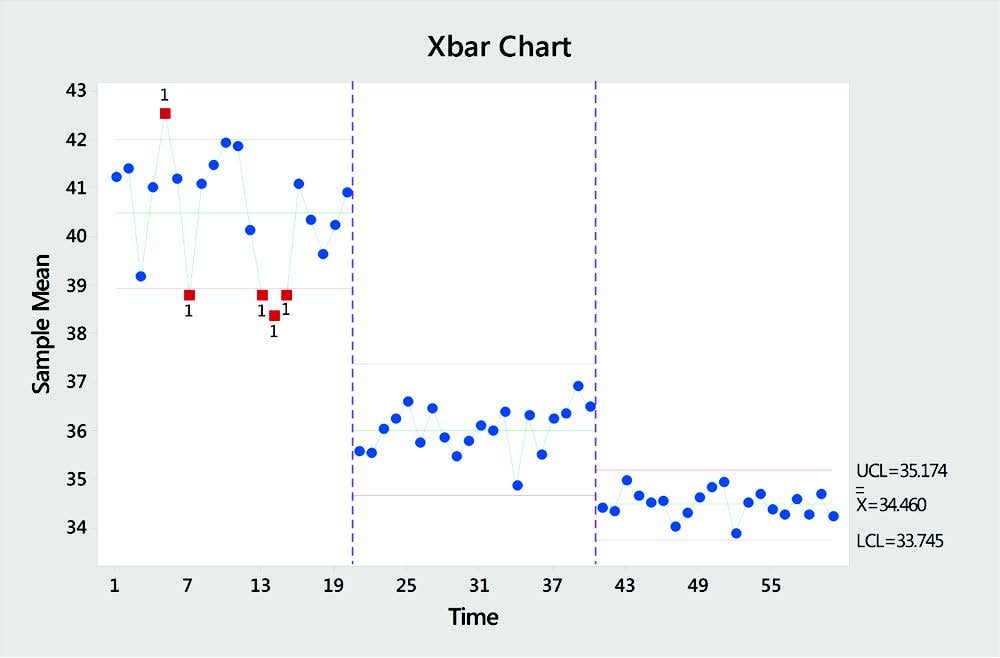

C Chart Six Sigma - In order to see the special cause variation, we need a control chart. Special cause variation does not always indicate the negative part of the process, sometimes it reflects a good indication for the process too. By understanding how control charts work, you can more effectively use them to improve your process and product quality. Web the c chart is a control chart for the number of nonconformities (defects or concerns) per inspection unit. There is a difference between a defect and defective, as there is between a nonconformity and nonconforming unit. Web what are control charts in six sigma? Web a c control chart is a statistical tool used to monitor the number of defects in a process over time. This allows us to see how the process behaves over time. Optical performance comparable to that of a prime lens. The c chart is used when the data can only be whole numbers, as in counting, it is known as attribute, or discrete data. This control chart should be used when the following conditions exist: How do control charts work? Every item in the sample is evaluated for only the number of defects, flaws, or occurrences, etc. Deciding between a green belt or a black belt to lead a six sigma project depends on the project's size and complexity. A c chart is a. Web developed in the 1920s by walter a. Web control charts are an essential tool used in six sigma to monitor process stability and improve quality. The c chart is especially easy to make because the number of defects is plotted directly on the control chart. Control charts dealing with the number of defects or nonconformities are called c charts. Each chart has its specific use and is suitable for analyzing different data types. Web the interviewer wants to understand if you know the roles of different six sigma belt levels. The c chart is especially easy to make because the number of defects is plotted directly on the control chart. By understanding how control charts work, you can more. Each chart has its specific use and is suitable for analyzing different data types. It is generally used to monitor the number of defects in constant size units. How do control charts work? Special cause variation does not always indicate the negative part of the process, sometimes it reflects a good indication for the process too. Web the control chart. This chart is used when the number of samples of each sampling period is essentially the same. Optical performance comparable to that of a prime lens. By understanding how control charts work, you can more effectively use them to improve your process and product quality. There are four types of attribute charts: Constant (fixed) sample size (subgroup size) develop upper. Each chart has its specific use and is suitable for analyzing different data types. This control chart should be used when the following conditions exist: Special cause variation does not always indicate the negative part of the process, sometimes it reflects a good indication for the process too. Web the control chart is a graph used to study how a. Green belts handle smaller projects or are part of teams in larger projects. Optical performance comparable to that of a prime lens. Web six sigma control charts are known as process behavior charts. Web a c control chart is a statistical tool used to monitor the number of defects in a process over time. Sample averages, a centerline, and control. Where m is the number of groups included in the analysis. Green belts handle smaller projects or are part of teams in larger projects. Web developed in the 1920s by walter a. Web control charts for discrete data. It is generally used to monitor the number of defects in constant size units. There is a difference between a defect and defective, as there is between a nonconformity and nonconforming unit. Web a c control chart is a statistical tool used to monitor the number of defects in a process over time. In order to see the special cause variation, we need a control chart. Web the five phases of the six sigma. Web the c chart is a control chart for the number of nonconformities (defects or concerns) per inspection unit. This chart is used when the number of samples of each sampling period is essentially the same. There is a difference between a defect and defective, as there is between a nonconformity and nonconforming unit. On occasion, it also serves as. Web the c chart measures the number of nonconformities per “unit” and is denoted by c. Web what are control charts? This chart is used when the number of samples of each sampling period is essentially the same. Special cause variation does not always indicate the negative part of the process, sometimes it reflects a good indication for the process too. Web what are control charts in six sigma? In six sigma studies, we read control charts in the control phase, like the statistical process cont control chart (spc chart). A c chart is a control chart for monitoring the number of defects per sample. The sample averages and the centerline represent the present behavior of the process. How to make and use a c chart. The count of occurrences of a criteria of interest in a sample of items. Web developed in the 1920s by walter a. C chart is also known as the control chart for defects (counting of the number of defects). It is generally used to monitor the number of defects in constant size units. This control chart should be used when the following conditions exist: Web the control chart is a graph used to study how a process changes over time. There are four types of attribute charts:

6 Sigma Control Chart Introduction Toolkit from Leanscape

What is Control Charts in Six Sigma and How to Create them?

Article Everything You Wanted to Know About Six Sigma

What is Six Sigma? Six Sigma Levels Methodology Tools

10 C CHART IN SIX SIGMA, SIX CHART SIGMA IN C Chart & Formation

Lean Six Sigma The Definitive Guide (2020) SSGI

Six Sigma Road Map Lean six sigma, Six sigma tools, Business process

5 More Critical Six Sigma Tools A Quick Guide

What is Six Sigma? Six Sigma Levels Methodology Tools

22 C CHART IN SIX SIGMA, IN C CHART SIX SIGMA Chart & Formation

Where M Is The Number Of Groups Included In The Analysis.

On Occasion, It Also Serves As A Positive Indicator.

Web An Attribute Chart Is A Type Of Control Chart For Measuring Attribute Data (Vs.

Web What Is A C Chart?

Related Post: