Carbon Steel Grade Chart

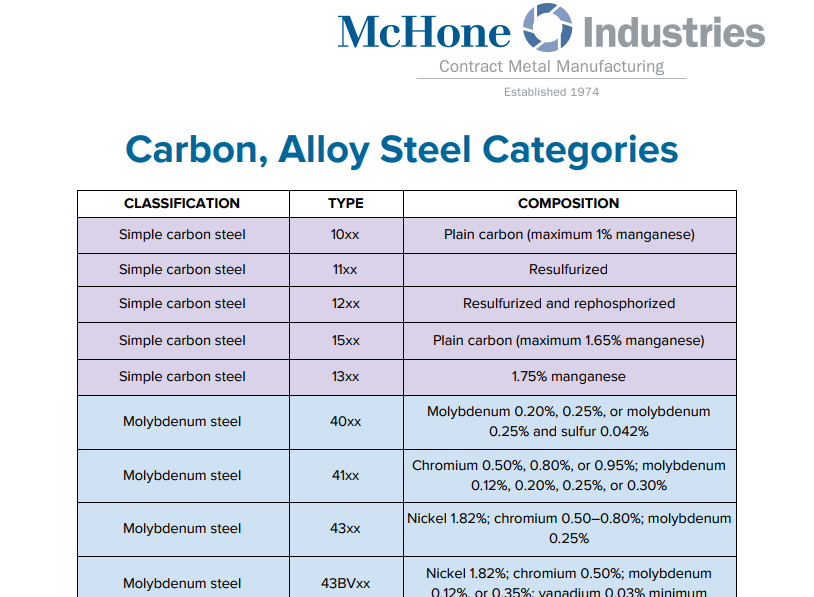

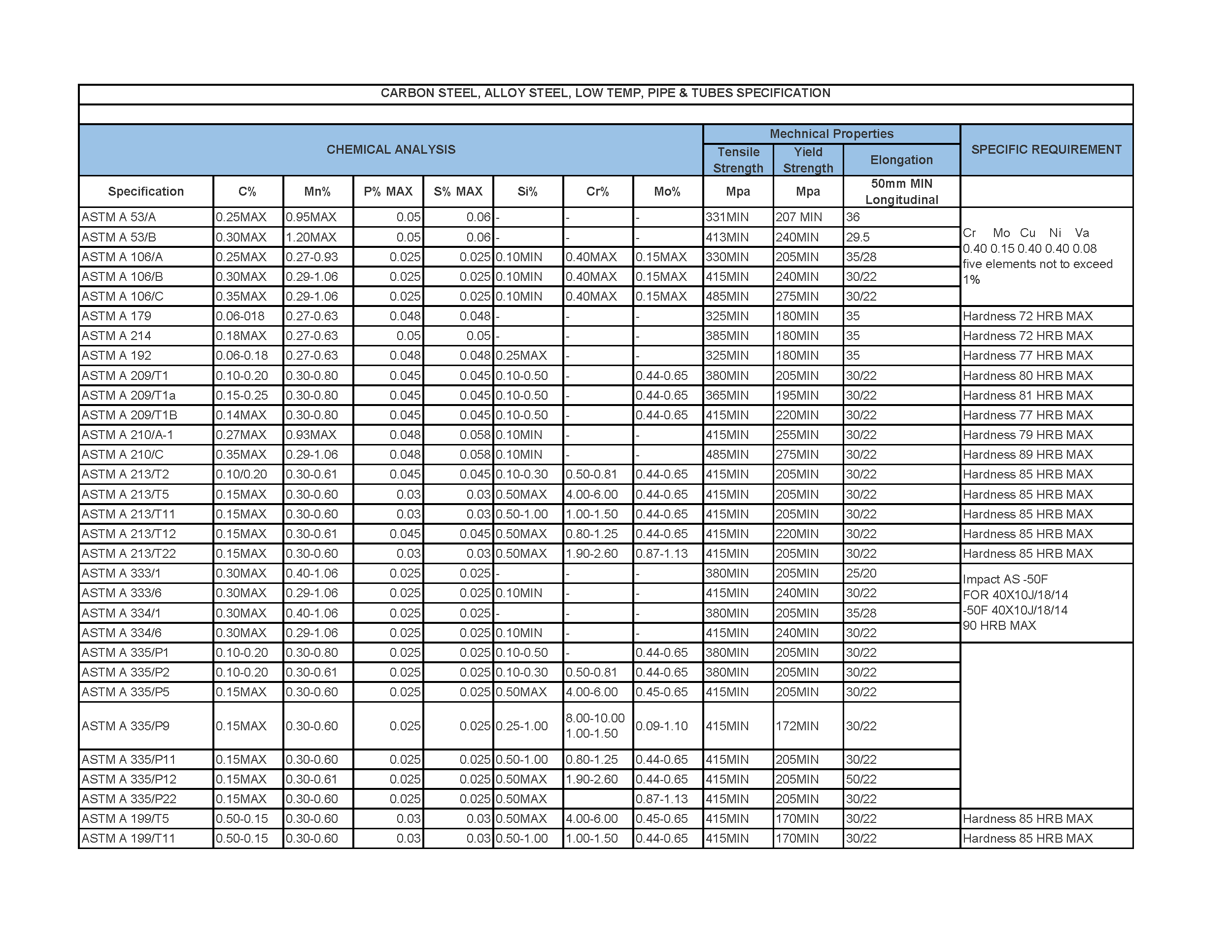

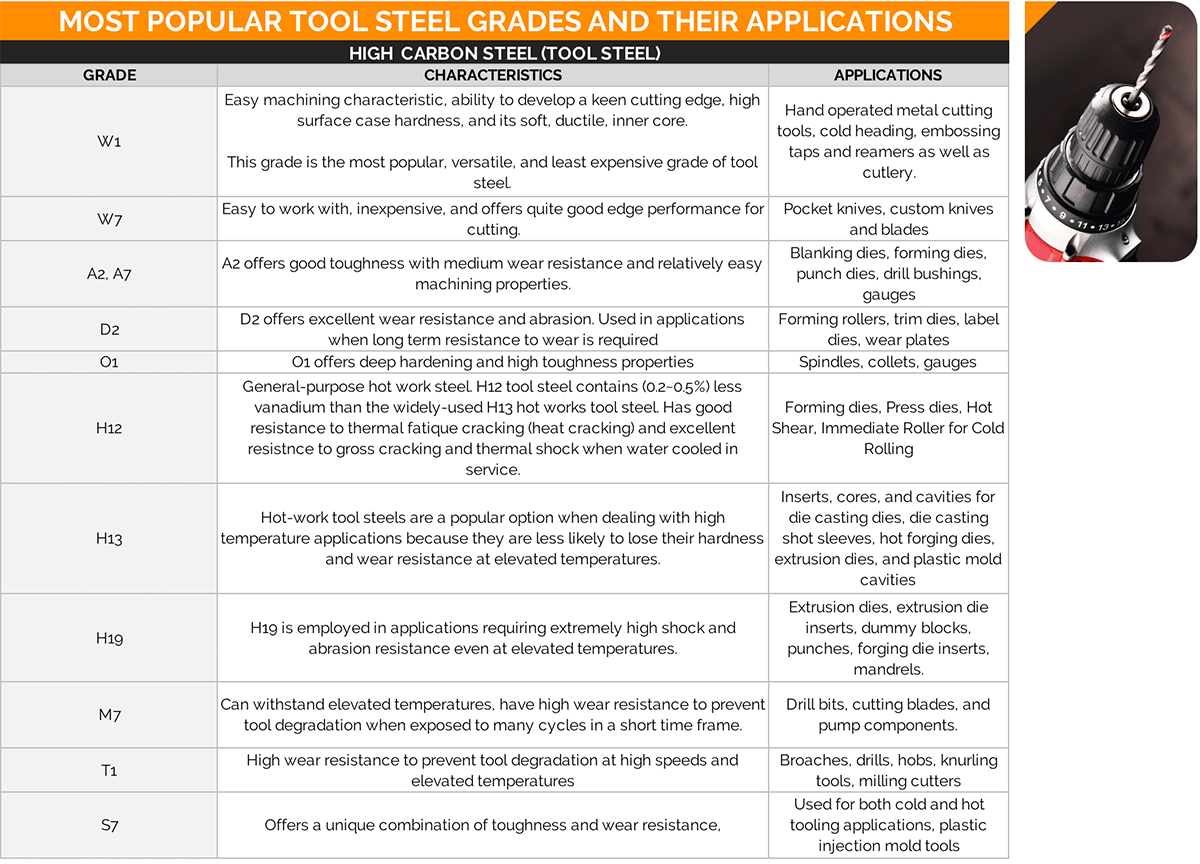

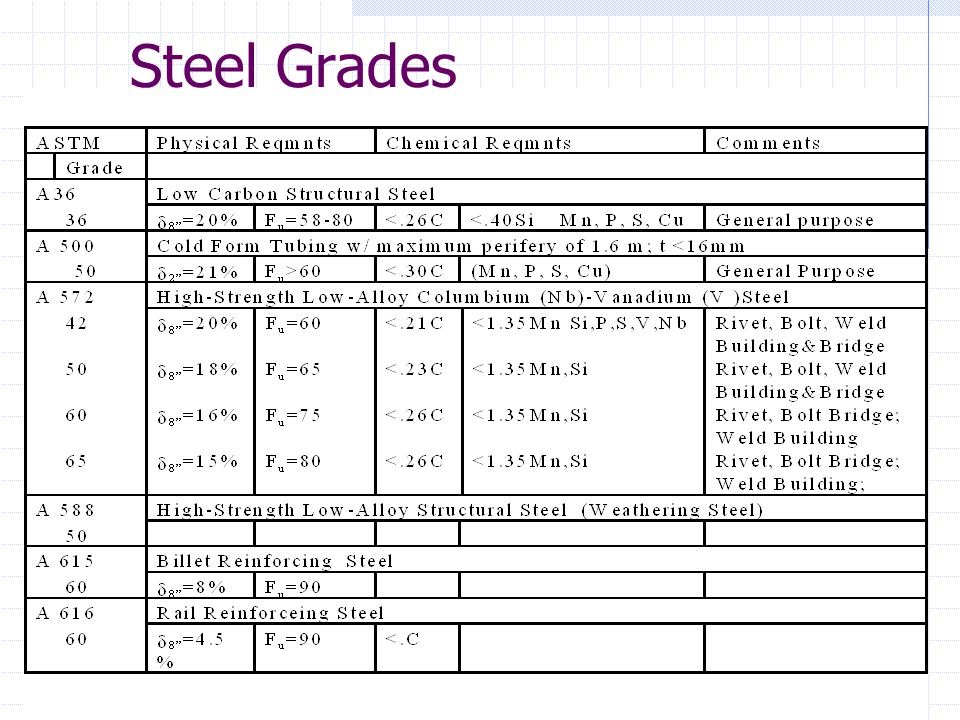

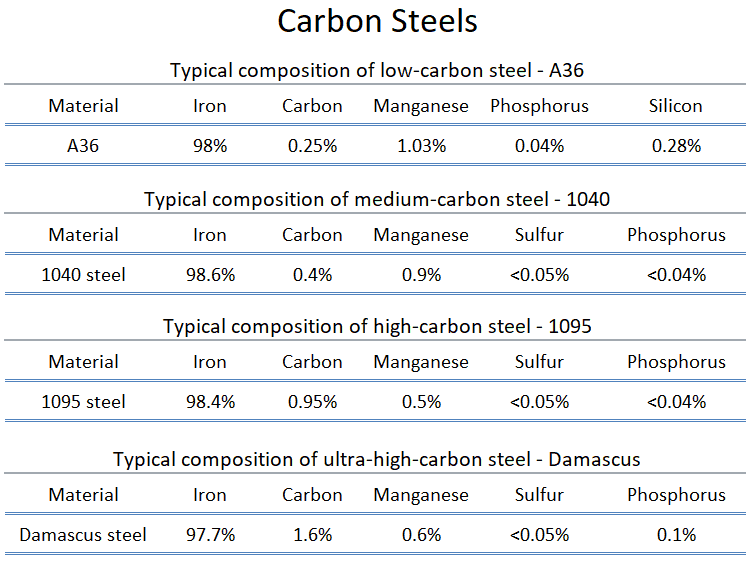

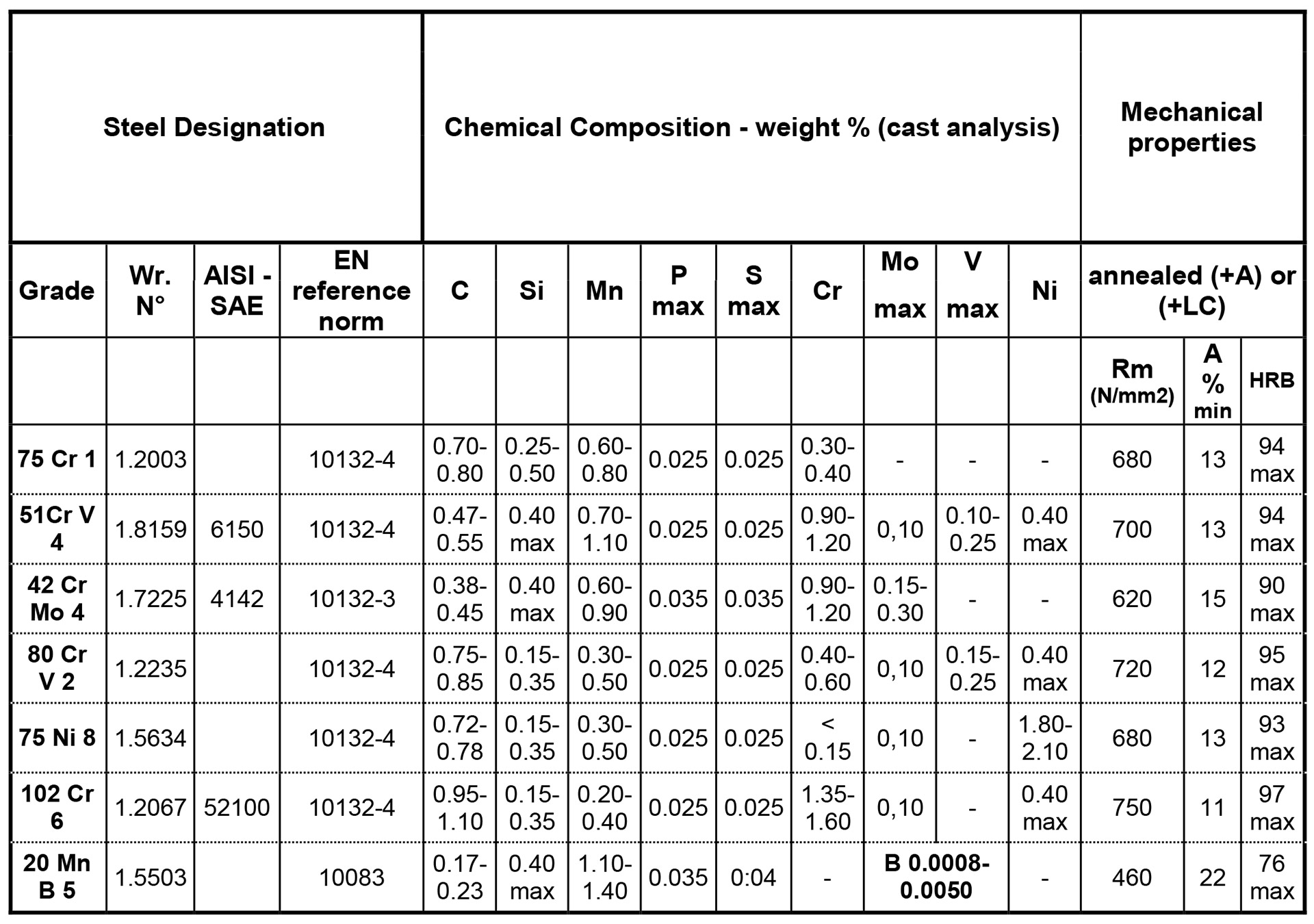

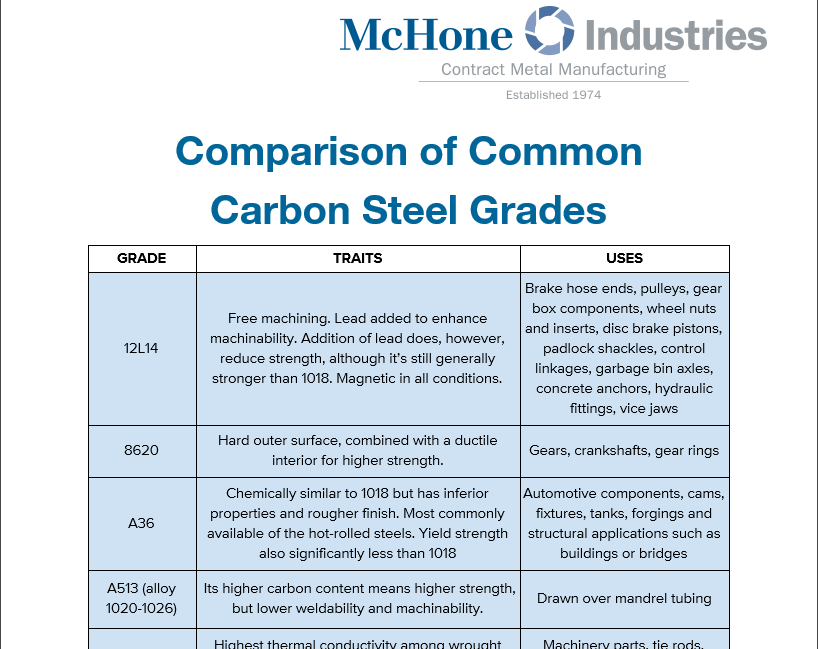

Carbon Steel Grade Chart - Widely recognized grades include a36, known for its good weldability and machinability; It is very strong and holds shape memory well, making easy to shape. Low (or mild), medium and high carbon steel. Medium carbon steel has a carbon range of 0.31% to 0.60%, and a manganese content ranging from.060% to 1.65%. Normally available to or will be furnished to astm standard. Low carbon steel (or mild steel) is one of the most common types of carbon steel, with a carbon content between 0.04% and 0.30%. Web carbon steel plate is manufactured for a variety of applications based on its carbon content. The system is based on the chemical compositions of the steels and alloys. The first digit indicates that this is plain carbon steel. Strength is a critical factor in metal uses, for example, some applications require stronger aluminum parts, while some products need high steel hardness or yield strength of steel, this may determine the selection of cnc machining material or product design. Web below are the properties of the grades of carbon steel: Steel is considered to be carbon steel when: Each of these categories contain different levels of carbon, show in the chart below. Understand properties, applications, and differences to make informed decisions. A529 and a572, noted for their strength and toughness; Learn more about carbon steel and the differences between high, medium and low carbon steel. Steel grades are categorized into four main types based on their chemical composition and properties: Low carbon steel plate, depending on its thickness offers characteristics such as maximum cold forming capability, weldability and improved machining. For all critical applications, verify to the applicable industry or. Carbon steel, alloy steel, stainless steel, and tool steel. Medium carbon steel has a carbon range of 0.31% to 0.60%, and a manganese content ranging from.060% to 1.65%. Web api 5b and 5ct provide various steel grades and color codes of each grade, offering detailed and overall information of casing and tubing, which help you clearly pick out the most. Steel is considered to be carbon steel when: A529 and a572, noted for their strength and toughness; Web explore our detailed comparison chart of carbon structural steel grades. And 1020, 1045, and 4130, valued for their versatility and balance of properties. Learn more about carbon steel and the differences between high, medium and low carbon steel. A529 and a572, noted for their strength and toughness; Widely recognized grades include a36, known for its good weldability and machinability; Steel is divided into categories based on its carbon content: Low carbon steel (or mild steel) is one of the most common types of carbon steel, with a carbon content between 0.04% and 0.30%. Explanatory notes(ferrouis) specify impact tests. Explanatory notes(ferrouis) specify impact tests per astm standard. Steel is divided into categories based on its carbon content: Learn more about carbon steel and the differences between high, medium and low carbon steel. Web to make things easier for your evaluation, we’ve compiled a carbon steel grades chart highlighting the most commonly used carbon steel grades and their applications. Understand. Web the carbon present in steel is typically reduced so that it fits into three main categories of carbon steel: Steel is divided into categories based on its carbon content: Explanatory notes(ferrouis) specify impact tests per astm standard. Strength is a critical factor in metal uses, for example, some applications require stronger aluminum parts, while some products need high steel. Strength is a critical factor in metal uses, for example, some applications require stronger aluminum parts, while some products need high steel hardness or yield strength of steel, this may determine the selection of cnc machining material or product design. A529 and a572, noted for their strength and toughness; Learn more about carbon steel and the differences between high, medium. Web explore our detailed comparison chart of carbon structural steel grades. Steel grades are categorized into four main types based on their chemical composition and properties: Carbon steel, alloy steel, stainless steel, and tool steel. And 1020, 1045, and 4130, valued for their versatility and balance of properties. Each of these categories contain different levels of carbon, show in the. Low carbon steel plate, depending on its thickness offers characteristics such as maximum cold forming capability, weldability and improved machining. Metals and materials table of contents. Carbon steel, alloy steel, stainless steel, and tool steel. Steel is considered to be carbon steel when: The first digit indicates that this is plain carbon steel. Low (or mild), medium and high carbon steel. The system is based on the chemical compositions of the steels and alloys. The second digit indicates there are no alloying elements. Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. Carbon steel, alloy steel, stainless steel, and tool steel. Web carbon steel plate is manufactured for a variety of applications based on its carbon content. The table chart below gives typical mechanical characteristics for selected carbon steel properties. Web the carbon present in steel is typically reduced so that it fits into three main categories of carbon steel: Web carbon steel is organized into three main categories: Strength is a critical factor in metal uses, for example, some applications require stronger aluminum parts, while some products need high steel hardness or yield strength of steel, this may determine the selection of cnc machining material or product design. No minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying. Each of these categories contain different levels of carbon, show in the chart below. A529 and a572, noted for their strength and toughness; Web explore our detailed comparison chart of carbon structural steel grades. Explanatory notes(ferrouis) specify impact tests per astm standard. Pipes, tubes, plates, castings, forgings, and wrought fittings.

Asme Steel Grades Chart A Visual Reference of Charts Chart Master

Learn about different types of Carbon Steel Piping Material

Carbon Steel Grades Comparison Chart

Metal Grade Carbon Steel Grades Chart slideshare

Carbon Steel vs Alloy Steel Comparison Pros and Cons Material

Carbon Steel Grades Chart

Carbon metal content, Classification of Steel and Alloy Steels

:max_bytes(150000):strip_icc()/export-jJHGn-5be075fbc9e77c00516c9b1d.png)

Different Steel Types and Properties

Structural Steel Grade Comparison Chart A Visual Reference of Charts

Metal Grades Designations for grading sheet metals

Low Carbon Steel Plate, Depending On Its Thickness Offers Characteristics Such As Maximum Cold Forming Capability, Weldability And Improved Machining.

Understand Properties, Applications, And Differences To Make Informed Decisions.

Web Below Are The Properties Of The Grades Of Carbon Steel:

For All Critical Applications, Verify To The Applicable Industry Or Requisite Material / Steel Standard.

Related Post: