Center Drill Size Chart

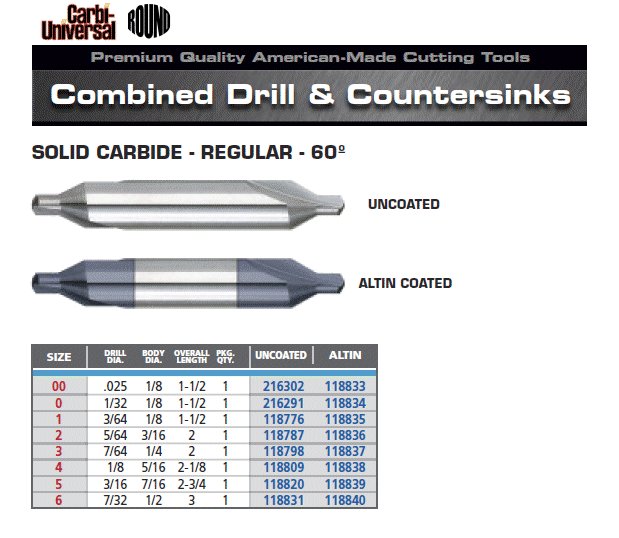

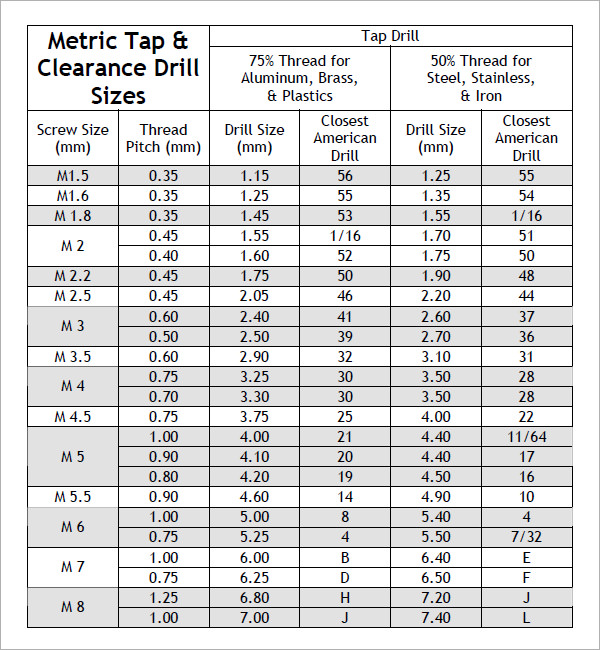

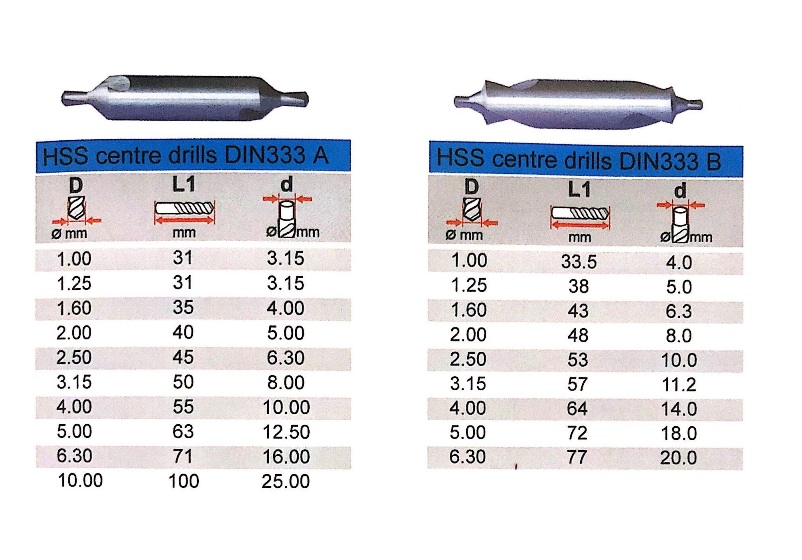

Center Drill Size Chart - Read hundreds of great mechanical engineering articles at engineeringclicks.com: Web learn how to choose the best center drill for your machining projects. Sheet metal gauges & weights: Web choose from our selection of center drills, including over 10,400 products in a wide range of styles and sizes. Which may cause imbalance in the work piece, incorrect dimensions or poor finishes. Not double ended universal material suitability. See the chart for different sizes from 00 to 18. A.k.a “titan2” this tutorial was downloaded from. For typical mechanical tolerances that are achievable see: Web which may cause imbalance in the work piece, incorrect dimensions or poor finishes. Web the drill size chart contains twist drill data for up to 1.0 inches in diameter. Web learn how to choose the best center drill for your machining projects. Web which may cause imbalance in the work piece, incorrect dimensions or poor finishes. These resources typically list recommended center drill sizes for different hole sizes and materials. Use the table. Web 9 rows find the size, body dia, drill dia, bell dia, drill length and oal of centerdrills for standard and bell types. Sheet metal gauges & weights: Ansi size drill bit chart. One such tool is the center drill, which is used to create a starting point for a drill or lathe. Drill size chart for number and letter. This helps prevent subsequent drill tools from wobbling and thus ensures they will be positioned precisely. Web learn how to choose the best center drill for your machining projects. Web 9 rows find the size, body dia, drill dia, bell dia, drill length and oal of centerdrills for standard and bell types. Have you ever wondered about the tools that. The decimal equivalents of the diameters are shown in both english and metric units. Psteel web thinning ≥ ø 2.000 • relieved cone • without protective countersink • for center holes to din 332, part 1, form a • d1 ≤ 0.8 mm: Have you ever wondered about the tools that are used in metalworking and their various sizes? Use. Web learn how to choose the right center drill size for different materials, hole sizes, and drilling methods. Web center drills create a conical cut on the face of the part. The size of the center drill needed is determined by the size of the part being supported, along with the size of center needed. Sheet metal gauges & weights:. Drill size & decimal equivalents: Web center drills come in a range of sizes. Incorrect drill depths being too shallow or too deep will lead to improper work holding. Drill charts and formulas can provide valuable guidance in selecting the correct size of a center drill. Web learn how to choose the right center drill size for different materials, hole. Web use drill charts and formulas: These resources typically list recommended center drill sizes for different hole sizes and materials. Web drill size chart 0.2087 to 1.0000 inch range size in size designation inches size designation 7.2 mm 0.2835 9.40 mm 7.25 mm 0.2854 9.5 mm 7.3 mm 0.2874 3/8 inch letter l 0.2900 letter v 7.40 mm 0.2913. In. Web choose from our selection of center drills, including over 10,400 products in a wide range of styles and sizes. Use the table below to find the recommended depth range of. Web (top) metric drill bit sizes. The decimal equivalents of the diameters are shown in both english and metric units. Ansi size drill bit chart. Not double ended universal material suitability. This helps prevent subsequent drill tools from wobbling and thus ensures they will be positioned precisely. Fractional sizes are measured in inches, while metric sizes are measured in millimeters. Web use drill charts and formulas: Psteel web thinning ≥ ø 2.000 • relieved cone • without protective countersink • for center holes to din. Read hundreds of great mechanical engineering articles at engineeringclicks.com: Drill charts and formulas can provide valuable guidance in selecting the correct size of a center drill. Use the table below to find the recommended depth range of. See the table of dimensions for different sizes of centerdrills. Which may cause imbalance in the work piece, incorrect dimensions or poor finishes. Web use drill charts and formulas: Iso (metric size drills) & conversion to. One such tool is the center drill, which is used to create a starting point for a drill or lathe. Psteel web thinning ≥ ø 2.000 • relieved cone • without protective countersink • for center holes to din 332, part 1, form a • d1 ≤ 0.8 mm: This helps prevent subsequent drill tools from wobbling and thus ensures they will be positioned precisely. Ansi size drill bit chart. Consult these references to identify the appropriate center drill size for your specific drilling. Web the drill size chart contains twist drill data for up to 1.0 inches in diameter. Web 9 rows find the size, body dia, drill dia, bell dia, drill length and oal of centerdrills for standard and bell types. Web the drill size chart below contains all commonly used centre drill bit sizes. Have you ever wondered about the tools that are used in metalworking and their various sizes? These center drills come in different sizes, each serving a specific purpose. Web center drills create a conical cut on the face of the part. The size of the center drill needed is determined by the size of the part being supported, along with the size of center needed. Web learn how to choose the right center drill size for different materials, hole sizes, and drilling methods. Drill size chart for number and letter gauges.

Drill Size Chart Black and White Download Printable PDF Templateroller

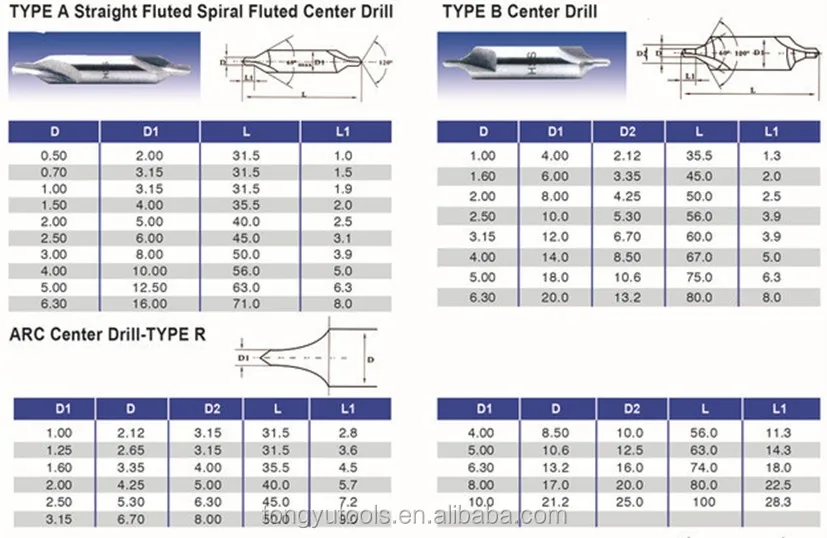

Center Drill Dimension Chart Drill Guide Sheet for CNC Shop

Standard Drill Size Chart

Center Drill Sizes ubicaciondepersonas.cdmx.gob.mx

Plastic drill bits lowes, drill size chart metric inch

DIN333A HSS Centre Drill Bits MUYE TOOLS DANYANG

Center Drill Chart Store

Center Drill Dimensions Chart

Centre Drill

Center Drill Sizes Chart

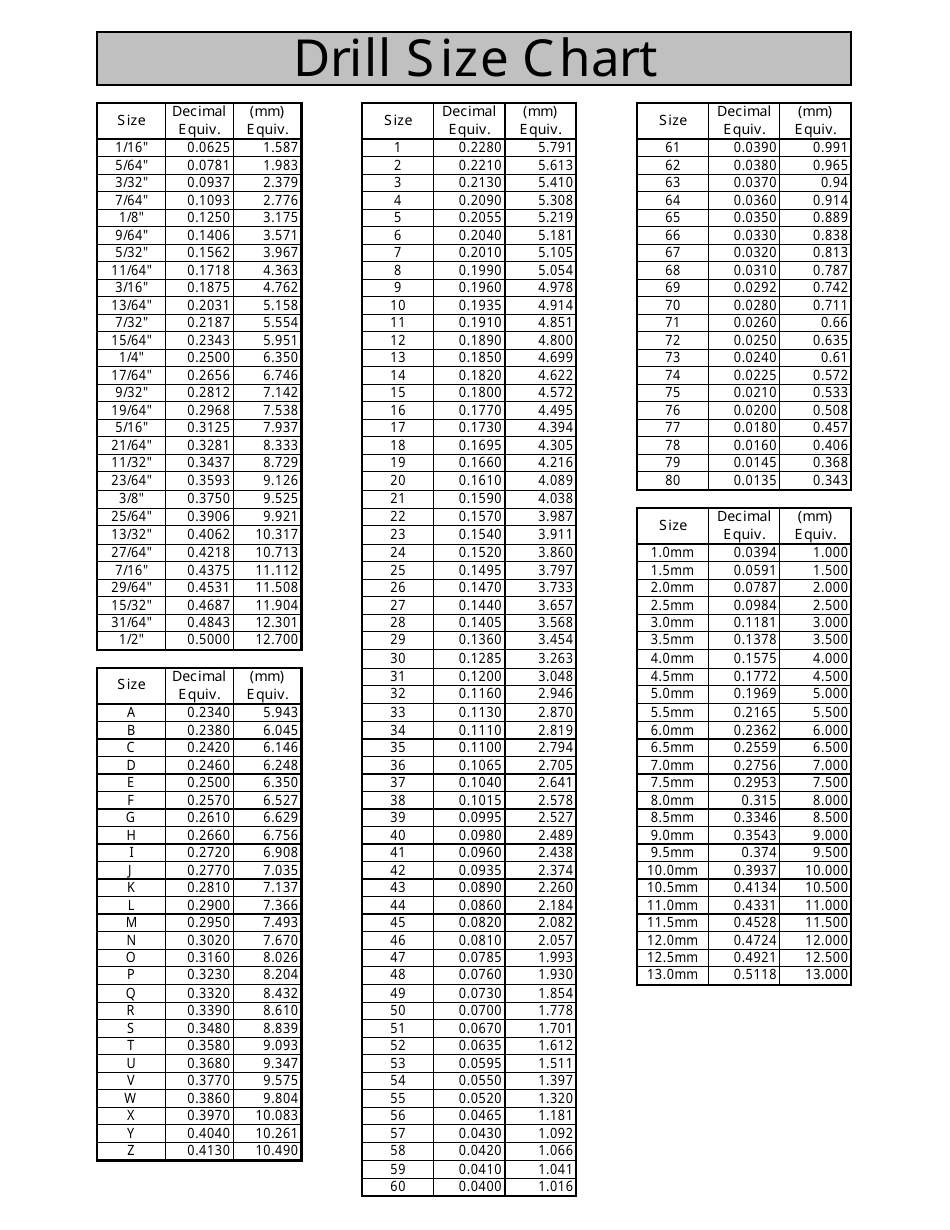

Drill Size & Decimal Equivalents:

Web The Drill Size Chart Provides A List Of Standard Size Drill Bits In Several Measurement Systems, Including Fractional, Metric, Wire Gauge Number, And Letter.

Web Which May Cause Imbalance In The Work Piece, Incorrect Dimensions Or Poor Finishes.

For Typical Mechanical Tolerances That Are Achievable See:

Related Post: