Chain Drive Drawing

Chain Drive Drawing - Web vector illustration of a gear wheel or chain sprocket. Hoisting and hauling chain drive; Roller chain design guide rules of thumb shigley’s mechanical engineering design •min teeth per sprocket ~ 12 to 25 •max teeth per sprocket ~120 •max speed reduction ~7:1 Design a 2 sprocket drive system. Franz rübig & söhne gmbh & co kg schmiedetechnik. There are several industrial uses for chain drives, including: Poly chain drives also eliminate maintenance and noise problems associated with chain drives and reduce maintenance Calculate center distances and chain length. A conventional chain drive consists of two or more sprockets and the chain itself. Hoisting and hauling chain drive. Web sketch and illustrate the parts of a sprocket and chain drive. Select the face shown and open a new sketch. What is the application of chain drive? Calculate sprocket and sprocket tooth dimensions using pitch and the number of teeth. Straight chain sprocket design assembly motion study. Calculate sprocket and sprocket tooth dimensions using pitch and the number of teeth. Web sketch and illustrate the parts of a sprocket and chain drive. The holes in the chain links fit over the sprocket teeth. It creates the sprockets and chain path as a simple sketch or simplified solid, and analyze the system. Click on the standard views toolbar. Click on the standard views toolbar. Web choose your favorite chain drive drawings from 58 available designs. Web seamless pattern of bicycle parts. Straight chain sprocket design assembly motion study. The angle of contact between the smaller sprocket and chain must be bigger than 120 degrees. Hoisting and hauling chain drive; Web roller chain drive shigley’s mechanical engineering design d 2, n 2 d 1, n 1. Enter the number of teeth of your sprocket then click on the ‘calculate!’ button. The chain drive designed with roller chains generator can be planar only with all parallel sprocket axes. · transporting and rigging heavy items. A conventional chain drive consists of two or more sprockets and the chain itself. Web roller chain drive shigley’s mechanical engineering design d 2, n 2 d 1, n 1. Web october 17, 2020 by haresh bambhania what is chain drive? The chain drive designed with roller chains generator can be planar only with all parallel sprocket axes. The design. Web seamless pattern of bicycle parts. Web enter the pitch of the selected chain for the chain drive mechanism in terms of millimeters or inches. Mazda miata lsd differential internals and stub shafts. To verify, check to see if the calculated chain tension (t) is less than the “rated working load” of the chain. Available for solidworks, inventor, creo, catia,. Calculate center distances and chain length. Click on the standard views toolbar. Web use roller chains generator to design and analyze a variety of chains drives. Drawings show the assembly and parts of a chain drive differential. Calculate and specify sprocket ratios. Mazda miata lsd differential internals and stub shafts. Web vector illustration of a gear wheel or chain sprocket. Poly chain drives also eliminate maintenance and noise problems associated with chain drives and reduce maintenance It is also used in a wide variety of machines. Design a 2 sprocket drive system. A chain drive is one way of transferring mechanical power from one place to another place. Hoisting and hauling chain drive; Stylized vector illustration of blueprints of chain transmission in a roller conveyor. Calculate and specify sprocket ratios. The chain drive designed with roller chains generator can be planar only with all parallel sprocket axes. Calculate and specify sprocket ratios. There are several industrial uses for chain drives, including: Available for solidworks, inventor, creo, catia, solid edge, autocad, revit and many more cad software but also as step, stl, iges, stl, dwg, dxf and more neutral cad formats. Hoisting and hauling chain drive; Web when classifying based on their function, chain drives can be divided. Poly chain drives also eliminate maintenance and noise problems associated with chain drives and reduce maintenance This type of chain drive is specifically used for transmitting power between two shafts. Web seamless pattern of bicycle parts. Web what are the types of chain drives? Stylized vector illustration of blueprints of chain transmission in a roller conveyor. Web choose your favorite chain drive drawings from 58 available designs. A chain drive is a type of mechanical power transmission system that uses chains to transfer power from one place to another. Web october 17, 2020 by haresh bambhania what is chain drive? · transporting and rigging heavy items. Motion study follow the tutorial from start to finish, you will be able to create such a real motion of chain sprocket by own. Following are the three types of chain drive. Web enter the pitch of the selected chain for the chain drive mechanism in terms of millimeters or inches. A conventional chain drive consists of two or more sprockets and the chain itself. The holes in the chain links fit over the sprocket teeth. What is the application of chain drive? Drawings show the assembly and parts of a chain drive differential.

Chain Drive and Gears Drawings Stock Vector Illustration of sprocket

Chain Drive Introduction Definition Types Application How To

A Chain Drive Vector or Color Illustration Stock Vector Illustration

Chain Drive Drawing Draw Easy

Stylized vector illustration of chain drive Stock Vector Image & Art

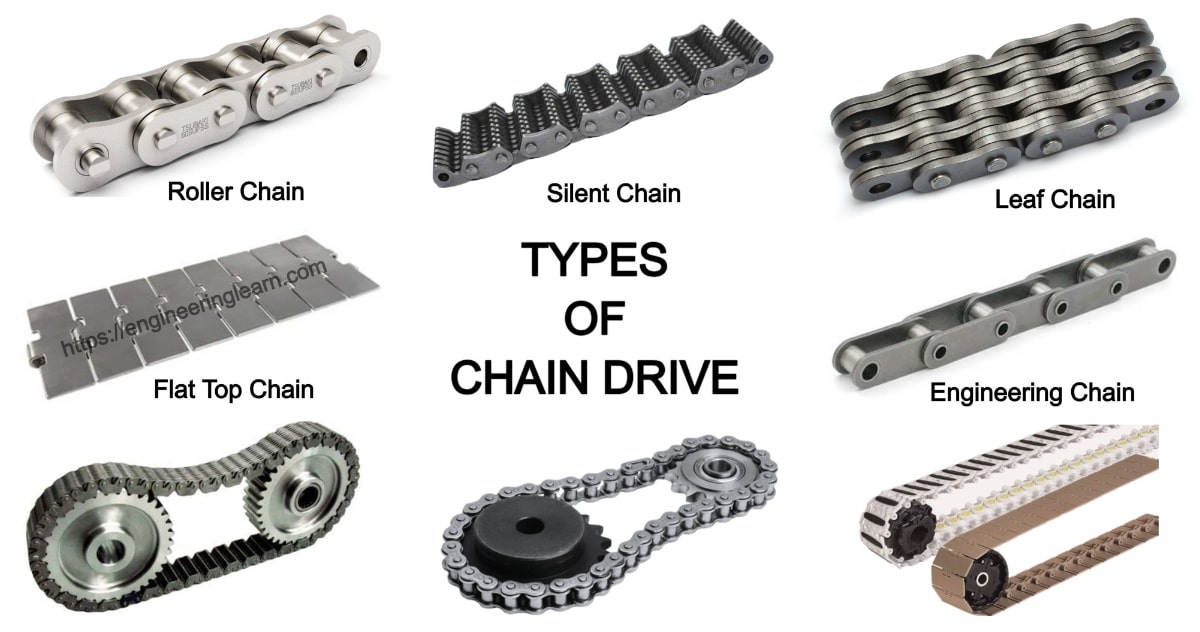

5 Types of Chain Drive Mechanism, Uses, Design, Applications

Design of Machine Element; CHAIN DRIVE YouTube

Understanding the working a chain drive studentlesson

Chain Drive and Gears Isometric Drawings Stock Vector Illustration of

Toothed Gear For Chain Drive Drawing Stock Illustration Download

Franz Rübig & Söhne Gmbh & Co Kg Schmiedetechnik.

Web L = (Chain Length In Pitches X Chain Pitch In Inches)/12 Slow Speed Selection If The Linear Chain Speed Is Less Than 160 Ft./Min., Then A Chain That Is One Size Smaller Than Selected With The Above Method May Be Used.

Chain Drive Is Widely Used In Vehicles Like Bicycles And Motorcycles, To Transfer Power To The Wheels.

The Design Is Completely Sealed And Is Primarily Press Fit Assembly Requiring Engine Case Sealant.

Related Post: