Copper Hardness Chart

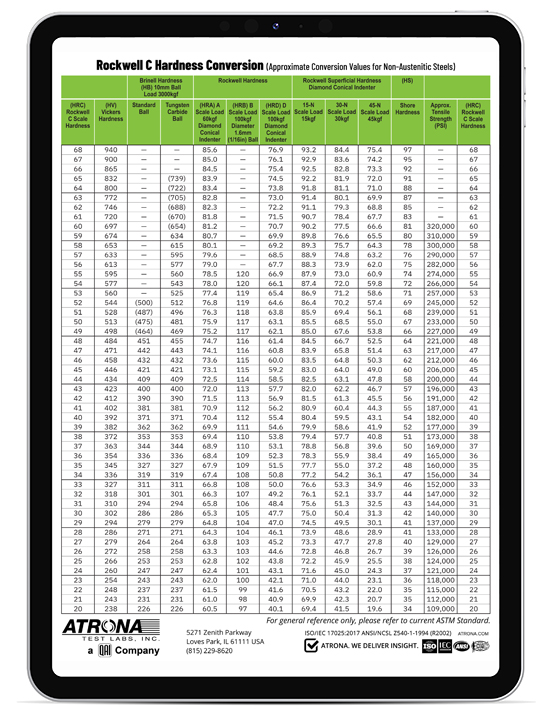

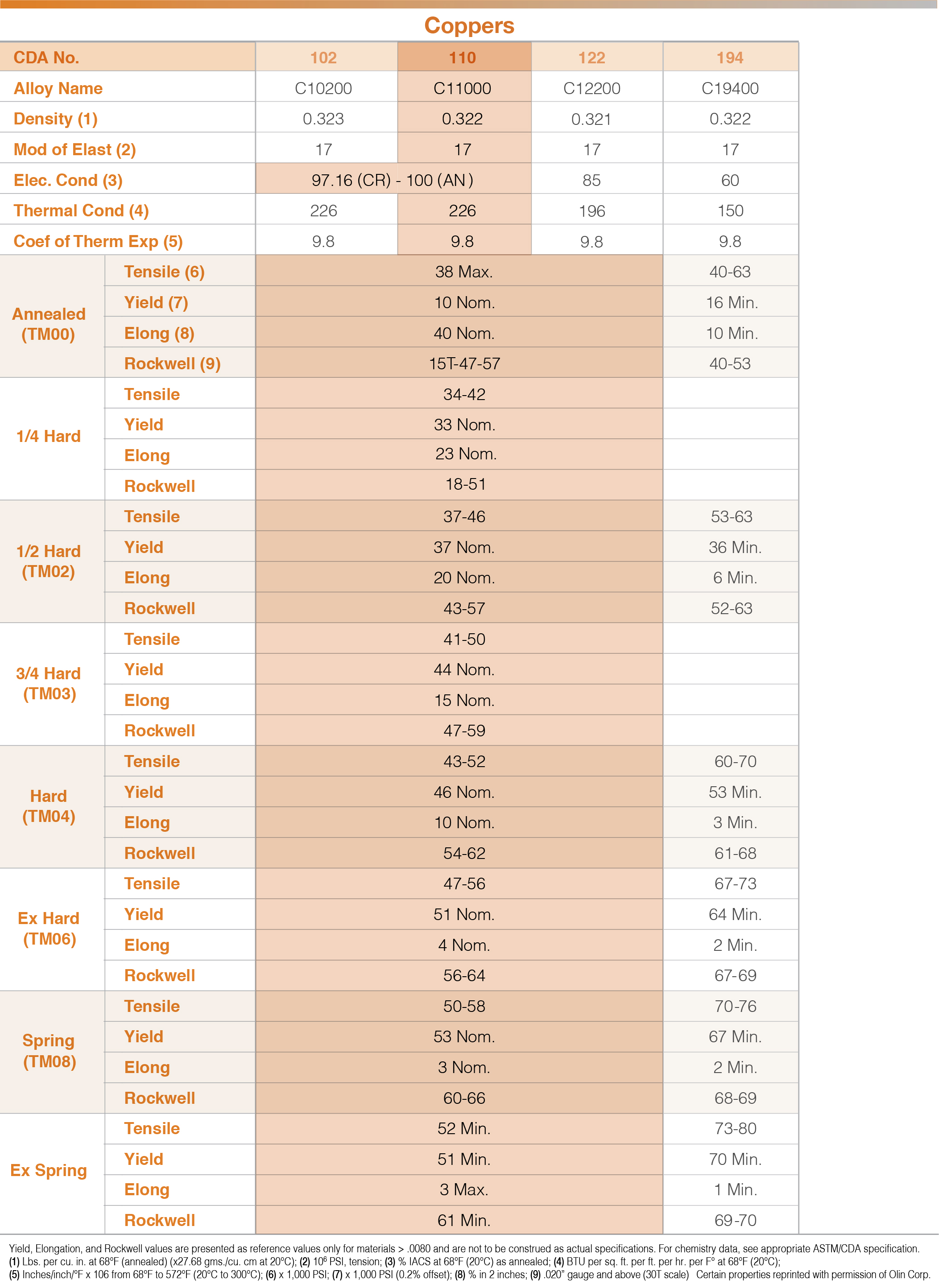

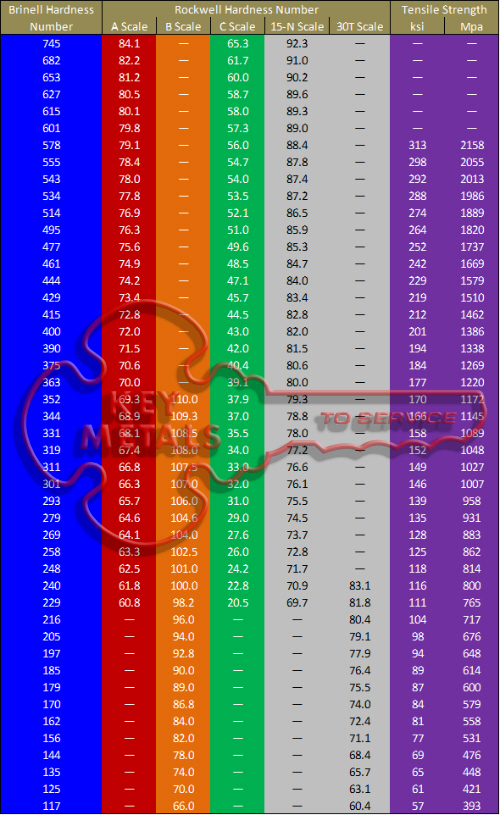

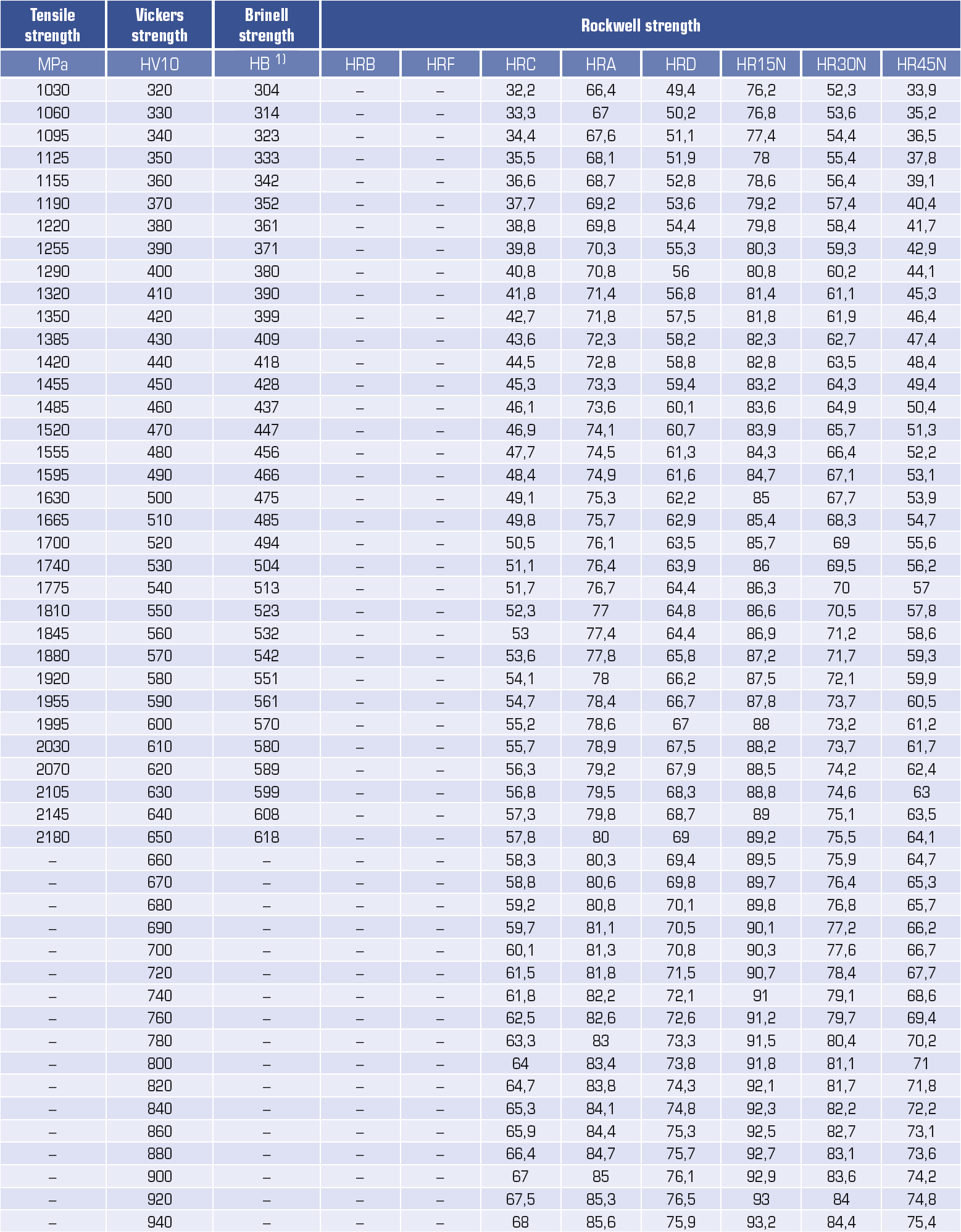

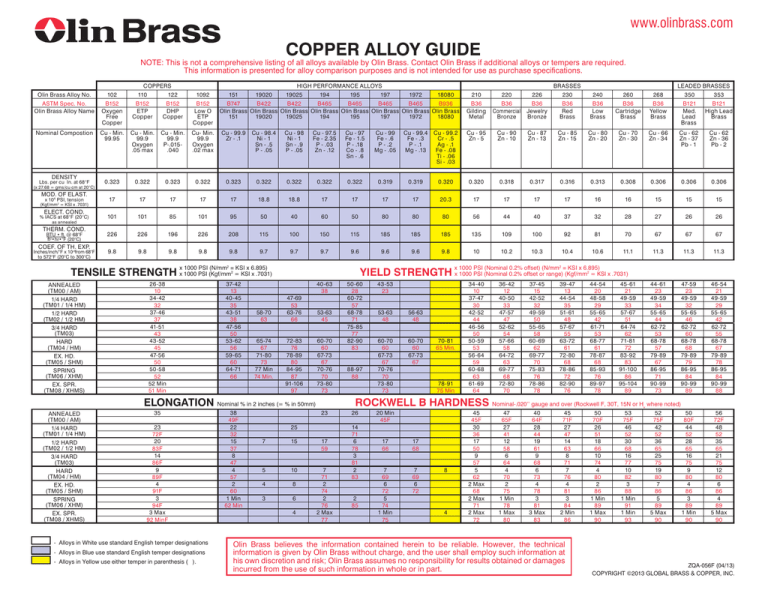

Copper Hardness Chart - Or fill out the form below : Web 73 rows properties of chemical elements. Web explore a collection of tables and charts that provide hardness data for different materials including metals, polymers, rocks, ceramics, and more. It consists of 99.9 percent copper, and is available in six tempers designated by astm b370 as: Discover how to select the right alloy for your needs and achieve optimal performance. Web 007 approximate hardness conversion numbers for copper no. This is not a comprehensive listing of all alloys available by olin brass. 060 (soft), h00 (cold rolled), h01 (cold rolled, high yield), h02 (half hard), h03 (three quarter hard), and h04 (hard). Web materion's aerospace data sheet reviews inorganic chemicals typically used for thermal protection systems & specialty coatings for aerospace applications including mesh size, purity, and compound types. 4 ways to get a quote! Web 007 approximate hardness conversion numbers for copper no. It consists of 99.9 percent copper, and is available in six tempers designated by astm b370 as: Contact olin brass if additional alloys or tempers are required. Web this comprehensive hardness conversion table serves as an invaluable reference, facilitating the seamless transition between brinell hardness and rockwell hardness scales, and vice. (2) this is a high conductivity copper which has, in the annealed condition a minimum conductivity of 100% iacs. Hardness of copper alloys depends strongly on certain alloy. The graph bars on the material properties cards below compare h02 c11000 copper to: Contact olin brass if additional alloys or tempers are required. 060 (soft), h00 (cold rolled), h01 (cold rolled,. Discover how to select the right alloy for your needs and achieve optimal performance. Web 007 approximate hardness conversion numbers for copper no. Web explore a collection of tables and charts that provide hardness data for different materials including metals, polymers, rocks, ceramics, and more. Wrought coppers (top), all copper alloys (middle), and the entire database (bottom). Copper alloys are. Web the copper most commonly used for sheet and strip applications complies with astm b370. The graph bars on the material properties cards below compare h00 c11000 copper to: All values are taken at room temperature (approximately 20°c or 68°f). Forever on the lookout for new approaches, pm works closely with some of the best innovators in the industry. Web. Additions of other elements to copper strengthen it and form copper alloys, including brasses, phosphor bronzes and copper nickels. This is not a comprehensive listing of all alloys available by olin brass. 060 (soft), h00 (cold rolled), h01 (cold rolled, high yield), h02 (half hard), h03 (three quarter hard), and h04 (hard). Here we collect the metal strength chart (tensile,. It is not a specification of copper and copper alloy products. Web 1.1 this is a classification of temper designations for copper and copper alloys—wrought and cast. This is not a comprehensive listing of all alloys available by olin brass. Copper alloys are alloys based on copper, in which the main alloying elements are zn, sn, si, al, ni. Contact. Web 007 approximate hardness conversion numbers for copper no. Contact olin brass if additional alloys or tempers are required. Additions of other elements to copper strengthen it and form copper alloys, including brasses, phosphor bronzes and copper nickels. It is not a specification of copper and copper alloy products. Web the copper most commonly used for sheet and strip applications. It is not a specification of copper and copper alloy products. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and mechanical properties chart of common metals of different grades for your reference. Wrought coppers (top), all copper alloys (middle), and the entire database (bottom). Forever on the lookout for new approaches, pm works closely. Additions of other elements to copper strengthen it and form copper alloys, including brasses, phosphor bronzes and copper nickels. Wrought coppers (top), all copper alloys (middle), and the entire database (bottom). (1) oxygen and trace elements may vary depending on the process. It consists of 99.9 percent copper, and is available in six tempers designated by astm b370 as: Web. All values are taken at room temperature (approximately 20°c or 68°f). 4 ways to get a quote! Forever on the lookout for new approaches, pm works closely with some of the best innovators in the industry. Web explore a collection of tables and charts that provide hardness data for different materials including metals, polymers, rocks, ceramics, and more. Web the. Web mechanical properties of copper grades and alloys. The graph bars on the material properties cards below compare h02 c11000 copper to: Web this comprehensive hardness conversion table serves as an invaluable reference, facilitating the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Discover how to select the right alloy for your needs and achieve optimal performance. Web explore a collection of tables and charts that provide hardness data for different materials including metals, polymers, rocks, ceramics, and more. Web 007 approximate hardness conversion numbers for copper no. All values are taken at room temperature (approximately 20°c or 68°f). Web the following tables provide a curated list of brinell hardness (hb) values for different copper alloys. It is not a specification of copper and copper alloy products. This is not a comprehensive listing of all alloys available by olin brass. Copper alloys are alloys based on copper, in which the main alloying elements are zn, sn, si, al, ni. H02 c11000 copper is c11000 copper in the h02 (half hard) temper. This is not a comprehensive listing of all alloys available by olin brass. H00 c11000 copper is c11000 copper in the h00 (1/8 hard) temper. Web get the most out of your copper alloys with our conversion chart for hardness and strength. Web the copper most commonly used for sheet and strip applications complies with astm b370.

Rockwell C Hardness Conversion Chart PDF ATRONA Test Labs Loves

Copper Alloys Wieland Heyco

Copper Hardness Chart

Hardness Chart Key Metals

Metal Hardness Scale Chart

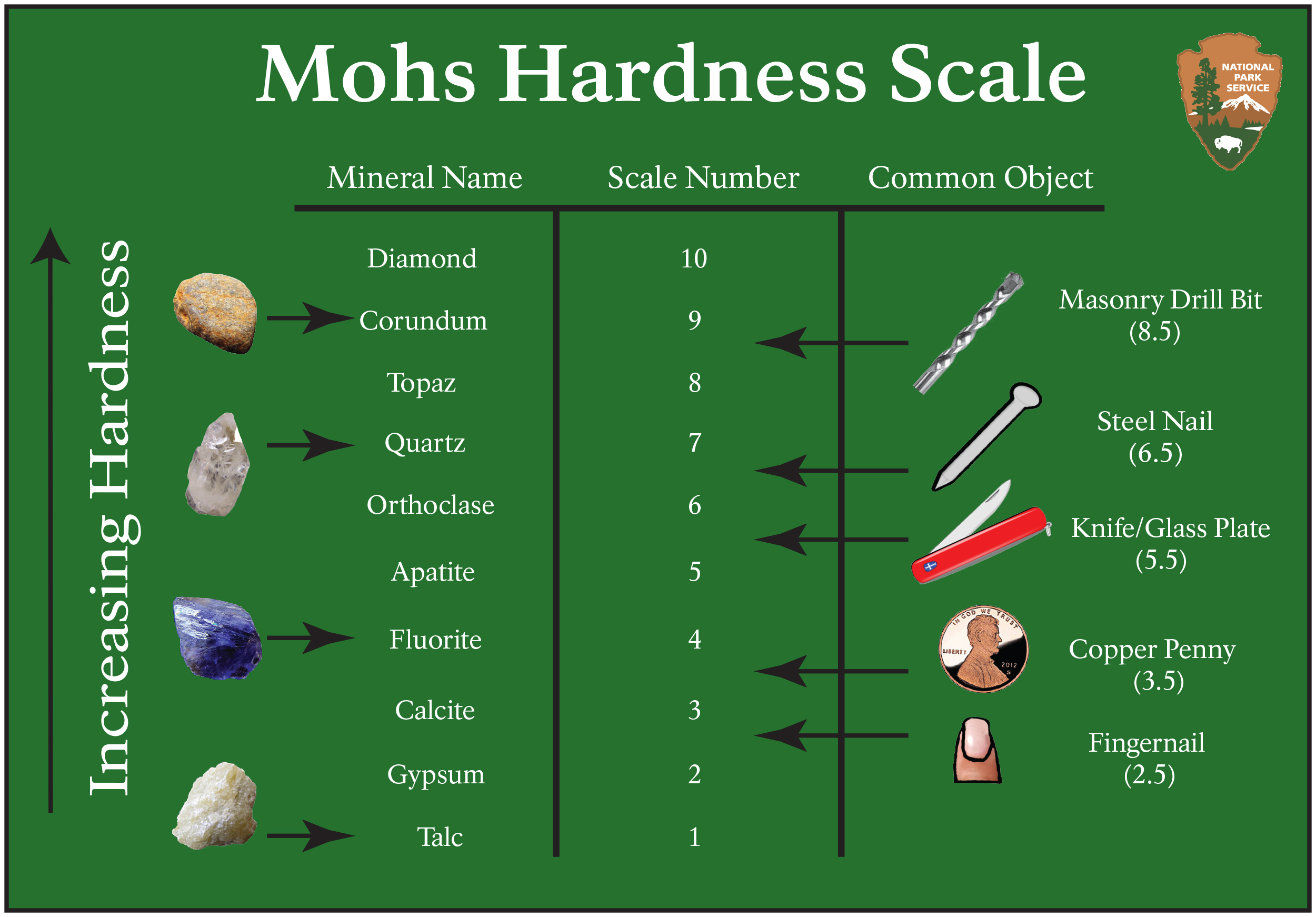

Mohs Hardness Scale (U.S. National Park Service)

copper alloy guide

Approximate Hardness Conversion Chart For Copper No 102 To 142

PM Hardness Chart 6 Moly Super Duplex Copper Nickel Alloys6 Moly

Mohs Scale Field

Or Fill Out The Form Below :

Witthoff, Which Was Published In 1956, Represented A Thorough Revision And Rewriting Of The Earlier Work.

Wrought Coppers (Top), All Copper Alloys (Middle), And The Entire Database (Bottom).

060 (Soft), H00 (Cold Rolled), H01 (Cold Rolled, High Yield), H02 (Half Hard), H03 (Three Quarter Hard), And H04 (Hard).

Related Post: