Corrosion Resistance Chart For Metals

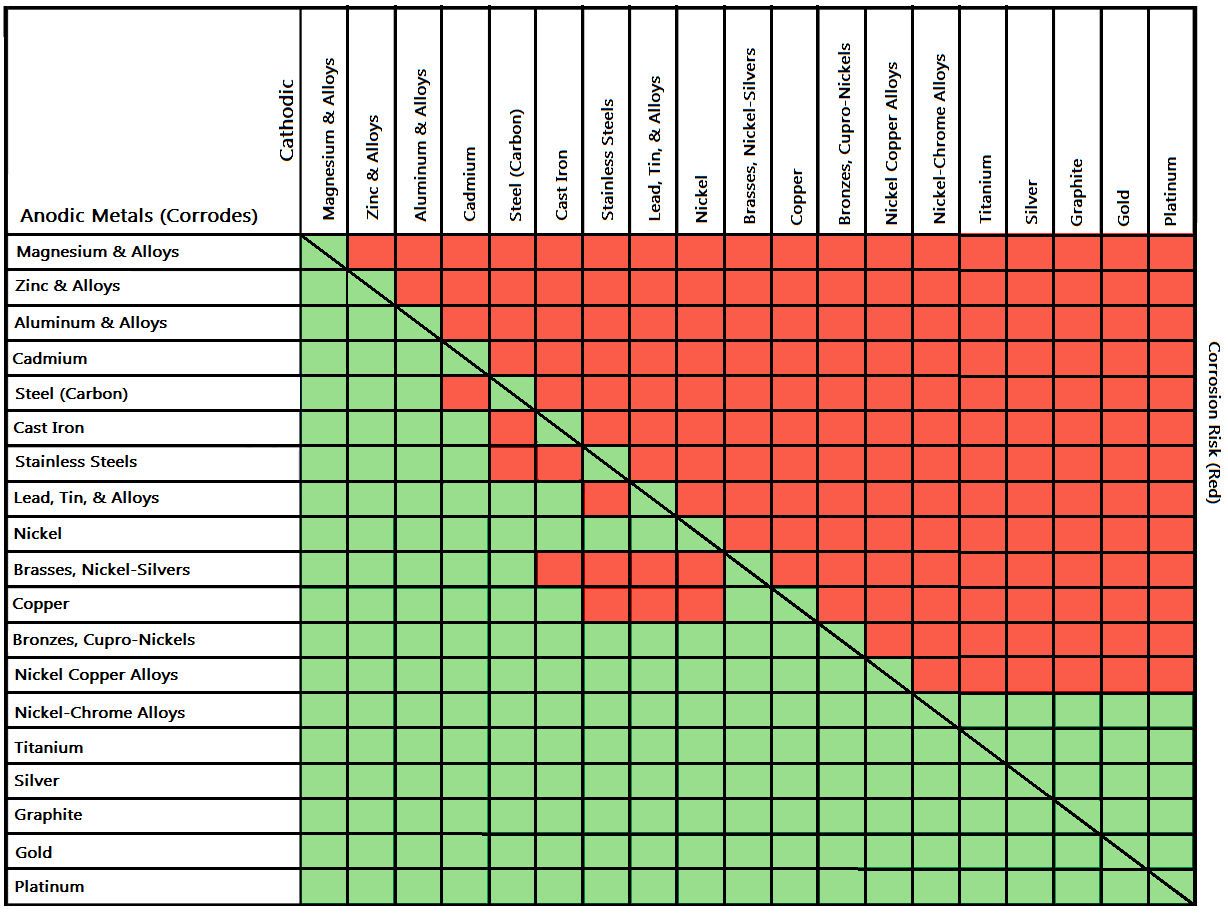

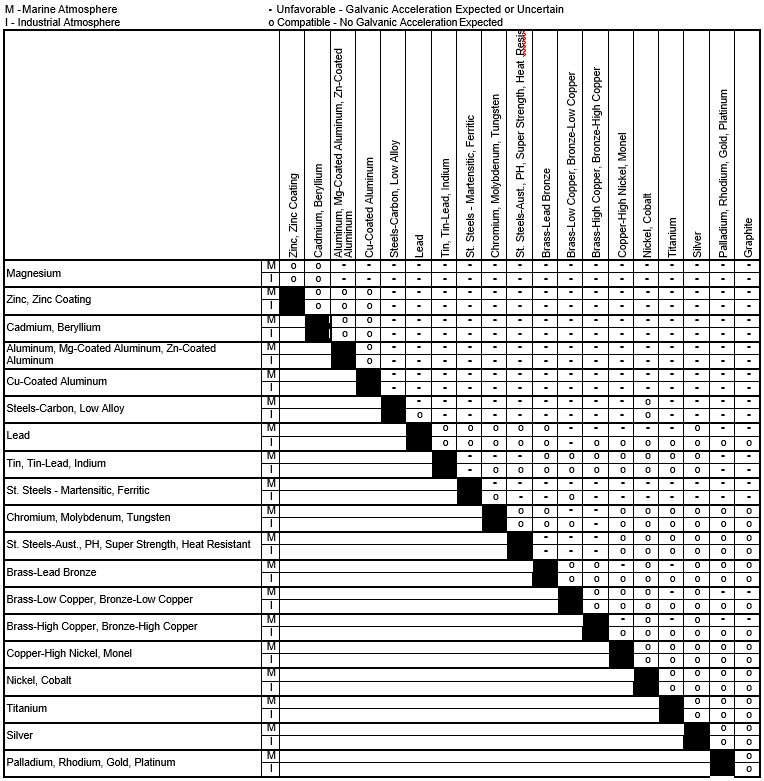

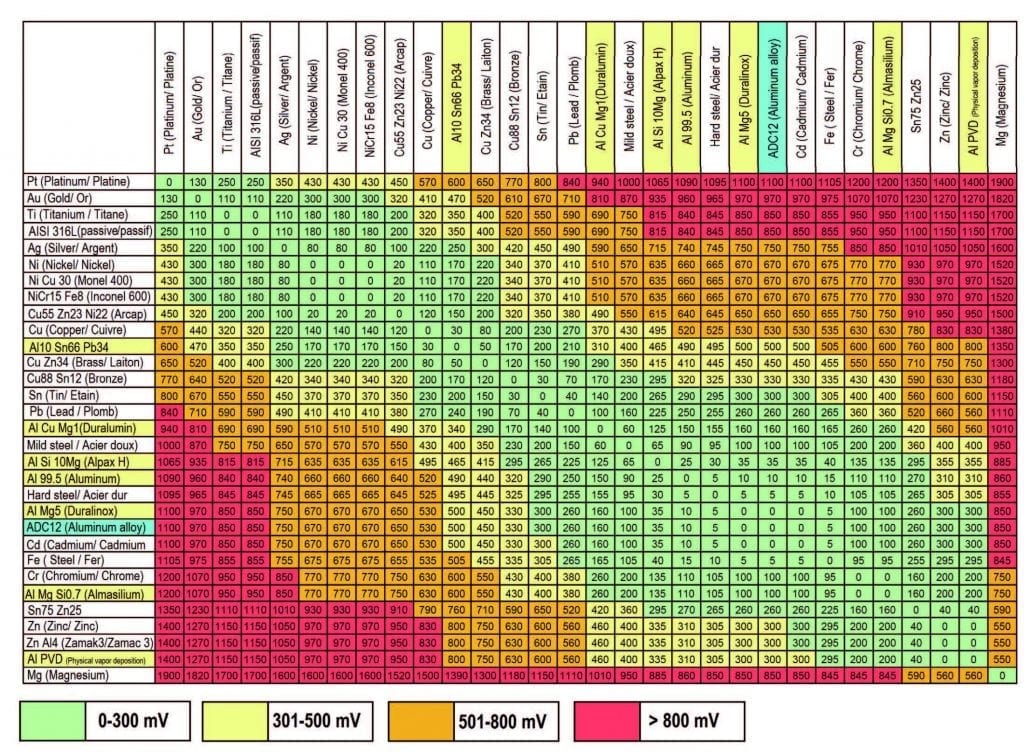

Corrosion Resistance Chart For Metals - Web common metals and their corrosion resistance to aggressive fluids like acids, bases and more. Protective coatings chemical resistance guide. Corrosion and degradation depend on many parameters: Web corrosion resistance of metals and alloys: It can help with the selection of flow control components and tubing samples for evaluation and testing. As you can see on the graph, a small amount of chromium already gives significant corrosion resistance, and above 10%, the effect flattens. Web its composition includes nickel, molybdenum, chromium, nitrogen, and manganese, offering excellent resistance to general corrosion, pitting, and crevice corrosion, and stress corrosion cracking (scc), while maintaining weldability. Web these ratings may be used as a guide in selecting materials for many flowserve product components, including pipe, casings, covers, impellers, and valve bodies.critical components such as plugs, shafts, and mag drive containment shells. Contact a corrosion specialist to determine the best material for your application. Corrosion is an inherent concern with every metal, with every metal coating, and in every environment. Service conditions (concentrations, temperatures, tramp chemical contaminants, etc) can vary greatly. 190 detroit street • cary, illinois 60013 • phone: The application of special finishes for the prevention of corrosion, abrasion and erosion has been the subject of study. Corrosion is an inherent concern with every metal, with every metal coating, and in every environment. Since failure due to corrosion. The alloys near the bottom are cathodic and unreactive; ** this chart is intended to be used only as guide and provides only overall comparison of the corrosion resistance of the metals/alloys in the chemicals noted. Those at the top are most anodic. Web corrosion properties of carbon steel, brass, cast iron, copper, titanium, aluminium, bronze. Corrosion is an inherent. As you can see on the graph, a small amount of chromium already gives significant corrosion resistance, and above 10%, the effect flattens. This can be used in the same way as the corrosion handbook. Protective coatings chemical resistance guide. Web common metals and their corrosion resistance to aggressive fluids like acids, bases and more. Web the “galvanic series of. We strongly urge corrosion testing! Therefore, instead of uniform corrosion rate, more complex. Web common metals and their corrosion resistance to aggressive fluids like acids, bases and more. Web its composition includes nickel, molybdenum, chromium, nitrogen, and manganese, offering excellent resistance to general corrosion, pitting, and crevice corrosion, and stress corrosion cracking (scc), while maintaining weldability. Web use our chemical. Web chemical resistance of a material does not necessarily indicate the suitability of a fitting in a given application due to variables such as improper clamp and coupling application, special hose construction, gasket material, etc. The table below indicates the approximate corrosion resistance of selected metals to a range of common chemicals. As you can see on the graph, a. Joinings (e.g weldings, soldering) mechanical stress of materials. Web corrosion criteria based on laboratory tests are commonly expressed in grams per square meter per hour. Web corrosion resistance of metals and alloys: For all metals this entity corresponds with approximately mm/per year (1 g/m2h = 1,1 mm/year) because the specifi c gravity (7.7 to 8.1) for all metal is similar.. Web the “galvanic series of metals and alloys” chart above provides a realistic and practical ranking of metallic electrical potentials. 190 detroit street • cary, illinois 60013 • phone: Web these ratings may be used as a guide in selecting materials for many flowserve product components, including pipe, casings, covers, impellers, and valve bodies.critical components such as plugs, shafts, and. Web chemical resistance of a material does not necessarily indicate the suitability of a fitting in a given application due to variables such as improper clamp and coupling application, special hose construction, gasket material, etc. Those at the top are most anodic. Protective coatings chemical resistance guide. Web reducing acids and caustics, and increases resistance to stress corrosion cracking particularly. Web chemical resistance of a material does not necessarily indicate the suitability of a fitting in a given application due to variables such as improper clamp and coupling application, special hose construction, gasket material, etc. Web they should be used as a guide only in determining your electrical heating element requirements. The alloys near the bottom are cathodic and unreactive;. Web corrosion properties of carbon steel, brass, cast iron, copper, titanium, aluminium, bronze. Web in corrosion resistant alloys (cras), the rate of localized corrosion can exceed that of uniform corrosion by orders of magnitude. Therefore, instead of uniform corrosion rate, more complex. Web corrosion tables and diagrams (corrosion handbook) the corrosion tables show the anticipated resistance of a range of. Web corrosion resistance of metals and alloys: Contact a corrosion specialist to determine the best material for your application. Web use our chemical compatibility chart as guide for evaluating the resistance of polymer and metal materials to a wide range of chemicals found in industrial, commercial, laboratory and medical applications. Therefore, instead of uniform corrosion rate, more complex. Web corrosion criteria based on laboratory tests are commonly expressed in grams per square meter per hour. Web common metals and their corrosion resistance to aggressive fluids like acids, bases and more. Web the chart on the left shows the corrosion rate in mpy (millimeters per year) as a function of the chromium content. Those at the top are most anodic. Corrosion is an inherent concern with every metal, with every metal coating, and in every environment. Web in corrosion resistant alloys (cras), the rate of localized corrosion can exceed that of uniform corrosion by orders of magnitude. As you can see on the graph, a small amount of chromium already gives significant corrosion resistance, and above 10%, the effect flattens. Web the “galvanic series of metals and alloys” chart above provides a realistic and practical ranking of metallic electrical potentials. This chart is provided for reference only. Web corrosion properties of carbon steel, brass, cast iron, copper, titanium, aluminium, bronze. Since failure due to corrosion may have dramatic consequences, grabber ensures our products meet corrosion resistance. *corrosion resistance of above alloys depends on media concentration, operating temperature, flow rate and other variables.

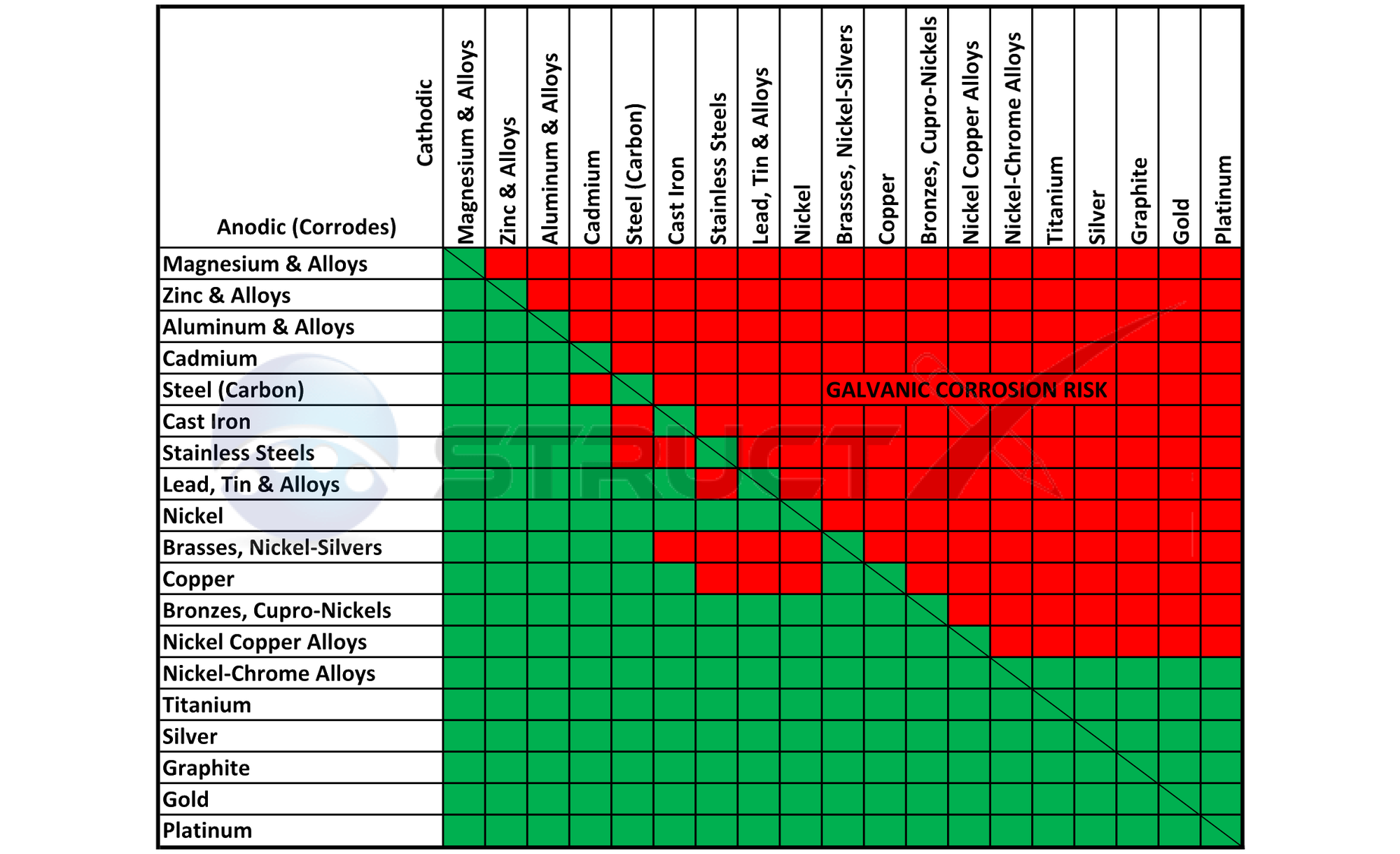

Galvanic Corrosion Common Questions Answered

![Galvanic Corrosion [with Chart] EngineerExcel](https://engineerexcel.com/wp-content/uploads/2023/03/galvanic-corrosion-chart.png)

Galvanic Corrosion [with Chart] EngineerExcel

Facility Focus Advantages of Titanium in Corrosion Resistance — CSCAA

Corrosion Resistance Table For Metals bmpcentral

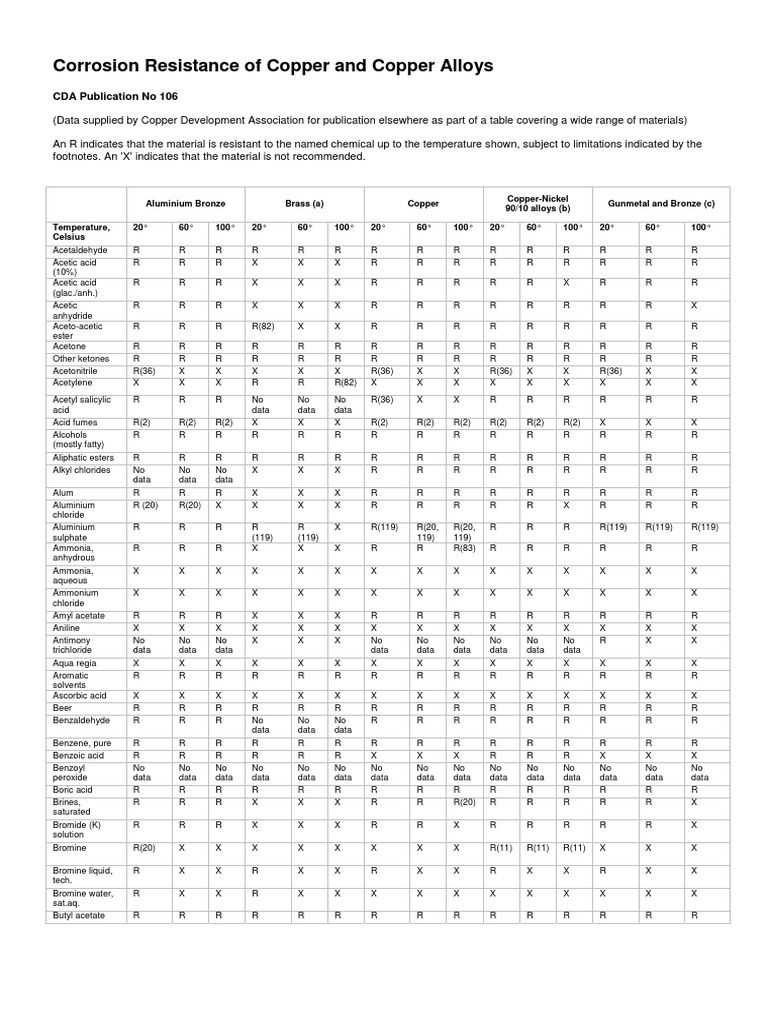

Corrosion Resistance Chart (Copper and Copper Alloy).pdf Brass

Galvanic Corrosion Chart Dissimilar Metals Video Bokep Ngentot

La résistance à la corrosion de l'aluminium JPC France

Corrosion Resistant Metals Materials Selection Guide Swagelok

Aluminum Corrosion Resistance Chart

Material Applications Corrosion Resistant Alloy Comparison Part 2

Protective Coatings Chemical Resistance Guide.

A Comprehensive Guide | Machinemfg.

A Major Problem In Process Industry Is Corrosion Of Metals In Pipes, Valves And Other Parts Of The Constructions.

For More Information, Visit Www.grabberpro.com.

Related Post: