Deep Draw Manufacturing

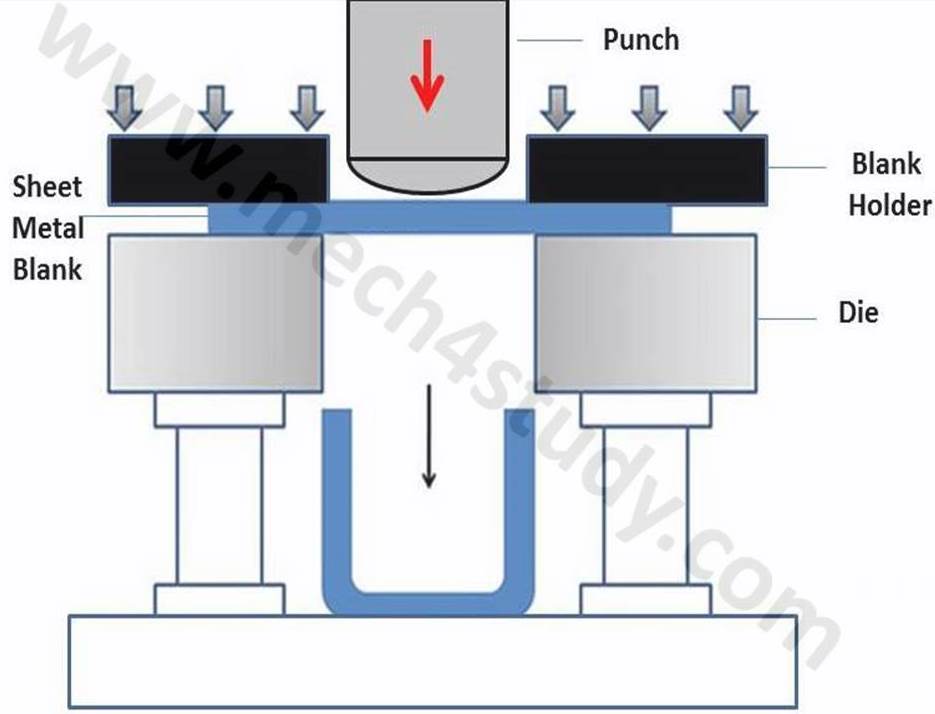

Deep Draw Manufacturing - Serving global customers in aerospace, medical, battery, electronic and industrial markets for. This is particularly true in cases where specific parts have complex geometries or require a high degree of precision and accuracy. Manufacturing processes our manufacturing processes and stamping services include: Including aerospace, electronics, and medical. Large quantities of products are easily manufactured through deep drawing complex. This is accomplished by drawing a flat metal blank into a die cavity (or several cavities in a series of steps) with a punch until the metal has been shaped into the desired form. Web deep drawing is the process of forming sheet metal by using a punch to radially draw the metal into a forming die. Deep drawn parts are created from a single sheet of metal rapid cycle times: Web ⅛ to 12 inches (3.1 mm to 305 mm) in diameter up to 12 inches (305 mm) in length.002 to.187 inches (.05 to 6.35 mm) in thickness material we can source and work with a variety of metals and metal alloys to create finished deep drawn parts. Web specialists in deep drawing, deep draw metal stamping & deep drawn enclosures. We also specialize in stainless steel & cold rolled steel enclosures. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. 3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is. Including aerospace, electronics, and medical. [1] it is thus a shape transformation process with material retention. The process is repeated until the component achieves the desired size and shape. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Some of. Some of the materials we typically employ include: Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web deep drawing manufacturing processes offers significant cost efficiency over other manufacturing methodologies. 2] it is combination of metal forming process & sheet. Defects, both in shape and location, are dimensionally deviant and constitute a significant difficulty for companies that produce large quantities of their products. Including aerospace, electronics, and medical. [1] it is thus a shape transformation process with material retention. Web deep drawing is one of the most common methods in sheet metal forming and is highly valuable for large quantities. [1] it is thus a shape transformation process with material retention. Web at demsey manufacturing, we are a global manufacturer of precision quality stamped, formed, and deep drawn parts. Serving global customers in aerospace, medical, battery, electronic and industrial markets for. Shallow draw stamping deep draw stamping metal stamping progressive die tooling transfer press tooling Norpin manufactures quality seamless metal. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Web 1] deep drawing is the process of converting blank of sheet metal into a cylindrical containers with a flat or hemispherical base. Large quantities of products are easily manufactured through. Web ⅛ to 12 inches (3.1 mm to 305 mm) in diameter up to 12 inches (305 mm) in length.002 to.187 inches (.05 to 6.35 mm) in thickness material we can source and work with a variety of metals and metal alloys to create finished deep drawn parts. Including aerospace, electronics, and medical. Web deep draw stamping is considered a. Web deep draw stamping is considered a viable solution for the production of parts because: Web deep drawing is one of the most common methods in sheet metal forming and is highly valuable for large quantities or long run production orders. Web ⅛ to 12 inches (3.1 mm to 305 mm) in diameter up to 12 inches (305 mm) in. Web deep drawing may be a viable production solution for any manufacturing process that requires one or more of the following: Web deep draw manufacturing is a metal forming process that takes a flat metal blank and is carried through a series of operations using a punch… metal forming versus plastic forming The sheet metal, or metal blank, is placed. Deep drawn parts create seamless shapes from a single piece of sheet metal you can attain a high volume due to the process’s rapid cycle times deep drawing offers exact detailing and is highly accurate with its. Including aerospace, electronics, and medical. 3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing. The process is considered deep drawing when the depth of the drawn part exceeds its diameter. View our catalog or call us today for more information. 3] if the ratio of height to diameter of the product is greater than 0.5 then this drawing operation is known as deep drawing. Shallow draw stamping deep draw stamping metal stamping progressive die tooling transfer press tooling Web deep drawing may be a viable production solution for any manufacturing process that requires one or more of the following: The press is then activated to force the punch against the die with up to 400 tons of force. The deep drawing process saves you time and money through the efficient use of material and the. The mechanical action of the punch in combination with the hollow die applies both tensile and compressive forces. Manufacturing processes our manufacturing processes and stamping services include: Web deep draw stamping is considered a viable solution for the production of parts because: This is particularly true in cases where specific parts have complex geometries or require a high degree of precision and accuracy. Defects, both in shape and location, are dimensionally deviant and constitute a significant difficulty for companies that produce large quantities of their products. Web deep drawing is the process of forming sheet metal by using a punch to radially draw the metal into a forming die. Web deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. 2] it is combination of metal forming process & sheet metal process. Web specialists in deep drawing, deep draw metal stamping & deep drawn enclosures.

What Is Involved in the Deep Drawn Manufacturing Process? Hudson

Deep Draw Process for Precision Metal Components TransMatic TransMatic

DeepDrawn Process Our DeepDrawing Process

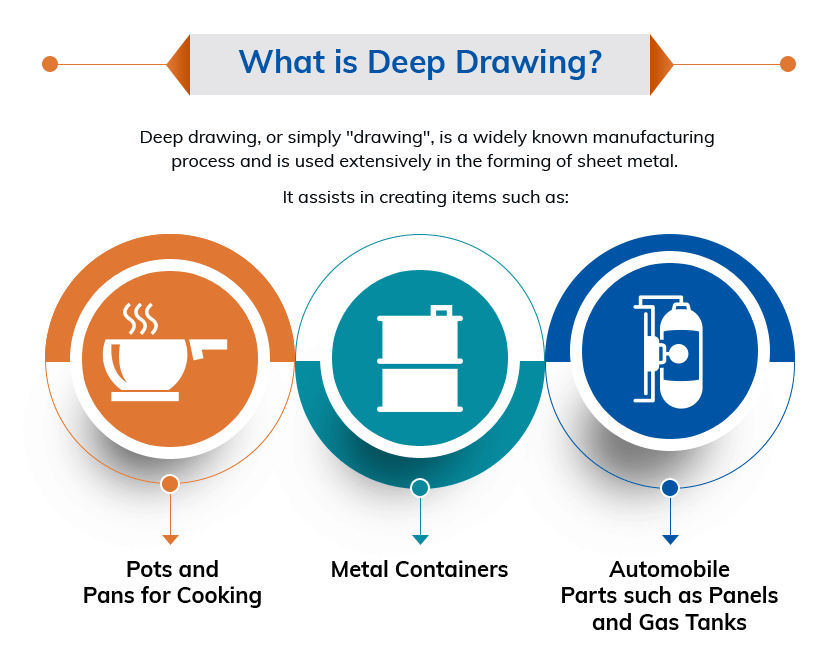

What is Deep Drawing? Process, Diagram, Advantages & Applications

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

What is Deep Drawing Process? Mech4study

Deep Drawn Methodology and Its Benefits

What is Deep Drawing Process? Mech4study

LESSONS LEARNED DEEP DRAW STAMPING Duggan Manufacturing

Deepdrawn manufacturing process for MDI cans YouTube

Some Of The Materials We Typically Employ Include:

Large Quantities Of Products Are Easily Manufactured Through Deep Drawing Complex.

This Is Accomplished By Drawing A Flat Metal Blank Into A Die Cavity (Or Several Cavities In A Series Of Steps) With A Punch Until The Metal Has Been Shaped Into The Desired Form.

[1] It Is Thus A Shape Transformation Process With Material Retention.

Related Post: