Deep Drawing Parts

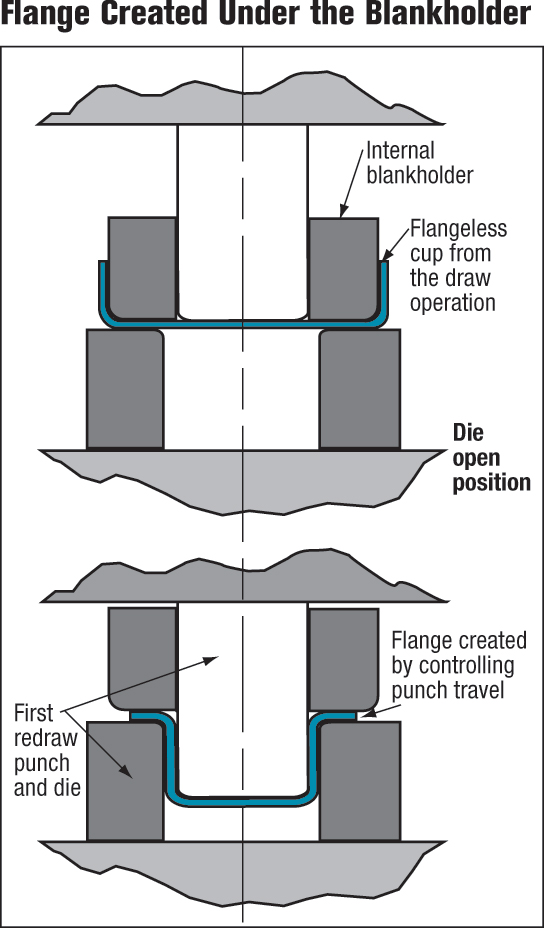

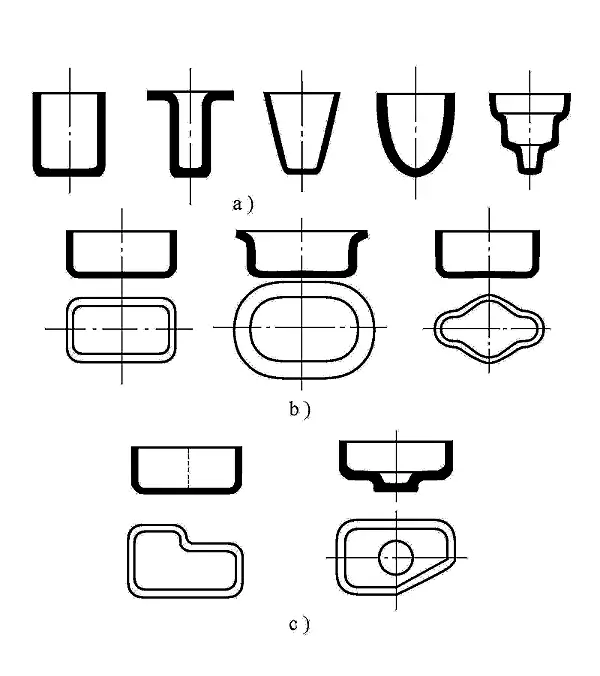

Deep Drawing Parts - Tailored to your needs, we expand our machine capabilities according to project requirements. Deep drawn parts are found in countless applications for many industries including consumer. Web deep drawn parts at national die company, we produce high volume deep drawn components for a variety of industries, including aerospace components, automotive components, and more. Web 1 2 3 4 metal forming processes deep drawing hydroforming metal spinning / spin forming secondary operations (value added services) anodizing blanking cnc machining forming heat treating heliarc® welding iriditing light assembly metal spinning painting (wet and powder) piercing spot welding swedging trimming. Automatic stamping presses from 180 to 800 kn ; Web deep drawn parts are generally defined as components with lengths measuring greater than or equal to one half (1/2) of their diameter. The press is then activated to force the punch against the die with up to 400 tons of force. The sheet metal, or metal blank, is placed on the die and secured. Example of deep drawn parts. Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. The process is repeated until the component achieves the desired size and shape. Deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. The sheet metal, or metal blank, is placed on the die and secured. Web deep drawn parts are generally defined as components with lengths measuring greater. Web deep drawn parts are generally defined as components with lengths measuring greater than or equal to one half (1/2) of their diameter. The process is considered deep drawing when the depth of the drawn part exceeds. Example of deep drawn parts. Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs. The press is then activated to force the punch against the die with up to 400 tons of force. Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. Automatic stamping presses from 180 to 800 kn ; Deep drawing is a sheet metal forming process in which a. Web 1 2 3 4 metal forming processes deep drawing hydroforming metal spinning / spin forming secondary operations (value added services) anodizing blanking cnc machining forming heat treating heliarc® welding iriditing light assembly metal spinning painting (wet and powder) piercing spot welding swedging trimming. Web deep drawn parts are generally defined as components with lengths measuring greater than or equal. The sheet metal, or metal blank, is placed on the die and secured. Web 1 2 3 4 metal forming processes deep drawing hydroforming metal spinning / spin forming secondary operations (value added services) anodizing blanking cnc machining forming heat treating heliarc® welding iriditing light assembly metal spinning painting (wet and powder) piercing spot welding swedging trimming. Here at pmp,. The sheet metal, or metal blank, is placed on the die and secured. The process is considered deep drawing when the depth of the drawn part exceeds. Hydraulic presses from 300 to 3200 kn Prospect machine products deep draw metal stamping. Beading burnishing chamfering coining embossing extruding flange forming ironing Example of deep drawn parts. Beading burnishing chamfering coining embossing extruding flange forming ironing Hydraulic presses from 300 to 3200 kn Tailored to your needs, we expand our machine capabilities according to project requirements. Web welcome to our deep draw shop. Tailored to your needs, we expand our machine capabilities according to project requirements. The press is then activated to force the punch against the die with up to 400 tons of force. Hydraulic presses from 300 to 3200 kn Beading burnishing chamfering coining embossing extruding flange forming ironing Web deep drawn parts at national die company, we produce high volume. [1] it is thus a shape transformation process with material retention. Deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. The sheet metal, or metal blank, is placed on the die and secured. Here at pmp, we tailor our deep drawing expertise in our metal forming technology to. Web welcome to our deep draw shop. Web deep drawn parts are generally defined as components with lengths measuring greater than or equal to one half (1/2) of their diameter. The sheet metal, or metal blank, is placed on the die and secured. Transfer presses from 60 to 1250 kn; It allows for superior quality components, produced at high speeds,. Transfer presses from 60 to 1250 kn; Web welcome to our deep draw shop. The process is considered deep drawing when the depth of the drawn part exceeds. Beading burnishing chamfering coining embossing extruding flange forming ironing Here at pmp, we tailor our deep drawing expertise in our metal forming technology to our customers’ needs & best practices. Automatic stamping presses from 180 to 800 kn ; The process is repeated until the component achieves the desired size and shape. Tailored to your needs, we expand our machine capabilities according to project requirements. Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It allows for superior quality components, produced at high speeds, and often at lower costs than competing methods. Example of deep drawn parts. Web 1 2 3 4 metal forming processes deep drawing hydroforming metal spinning / spin forming secondary operations (value added services) anodizing blanking cnc machining forming heat treating heliarc® welding iriditing light assembly metal spinning painting (wet and powder) piercing spot welding swedging trimming. Hydraulic presses from 300 to 3200 kn The sheet metal, or metal blank, is placed on the die and secured. Web deep drawn parts at national die company, we produce high volume deep drawn components for a variety of industries, including aerospace components, automotive components, and more. [1] it is thus a shape transformation process with material retention.

Deep Draw Process for Precision Metal Components TransMatic TransMatic

Deep drawing of sheet metal

best deep drawing process, by chris YouTube

Deep Drawing from A to Z MetalForming Magazine Article

Deep Drawing Process Sinoway Industry Metal Parts

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

Deep Drawing of Sheet Metal Stoeckli Metall AG Metalworking Center

Deep Drawing New England Metalform, Inc., Precision Metal Stamped

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

The Ultimate Guide to Metal Deep Drawing MachineMfg (2022)

Deep Drawn Parts Are Found In Countless Applications For Many Industries Including Consumer.

Deep Drawing Is A Type Of Metal Forming Process Where Parts Are Produced By Punching Sheet Metal Into A Formed Die.

Prospect Machine Products Deep Draw Metal Stamping.

The Press Is Then Activated To Force The Punch Against The Die With Up To 400 Tons Of Force.

Related Post: