Drag Chain Conveyor Drawing

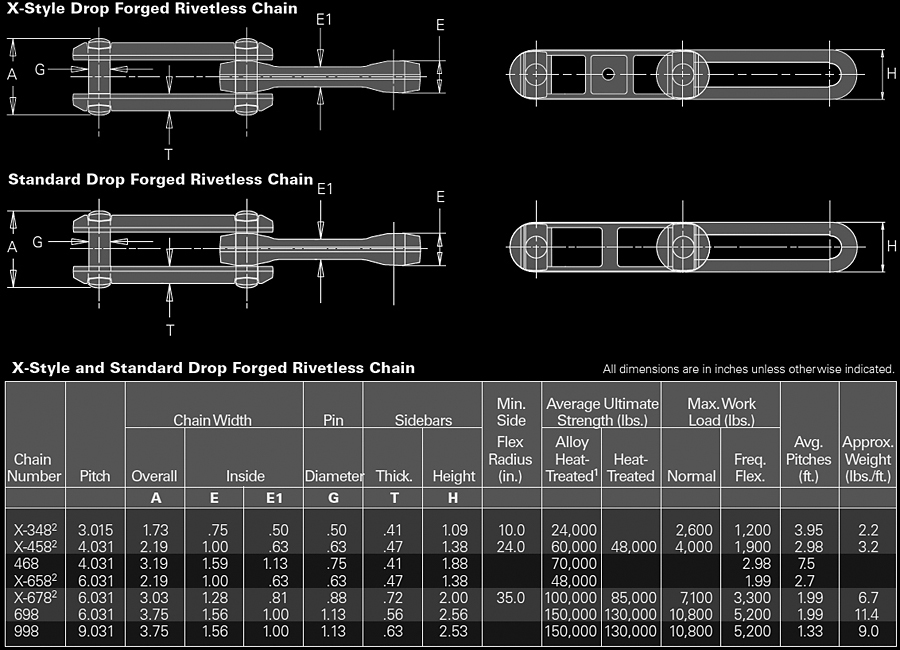

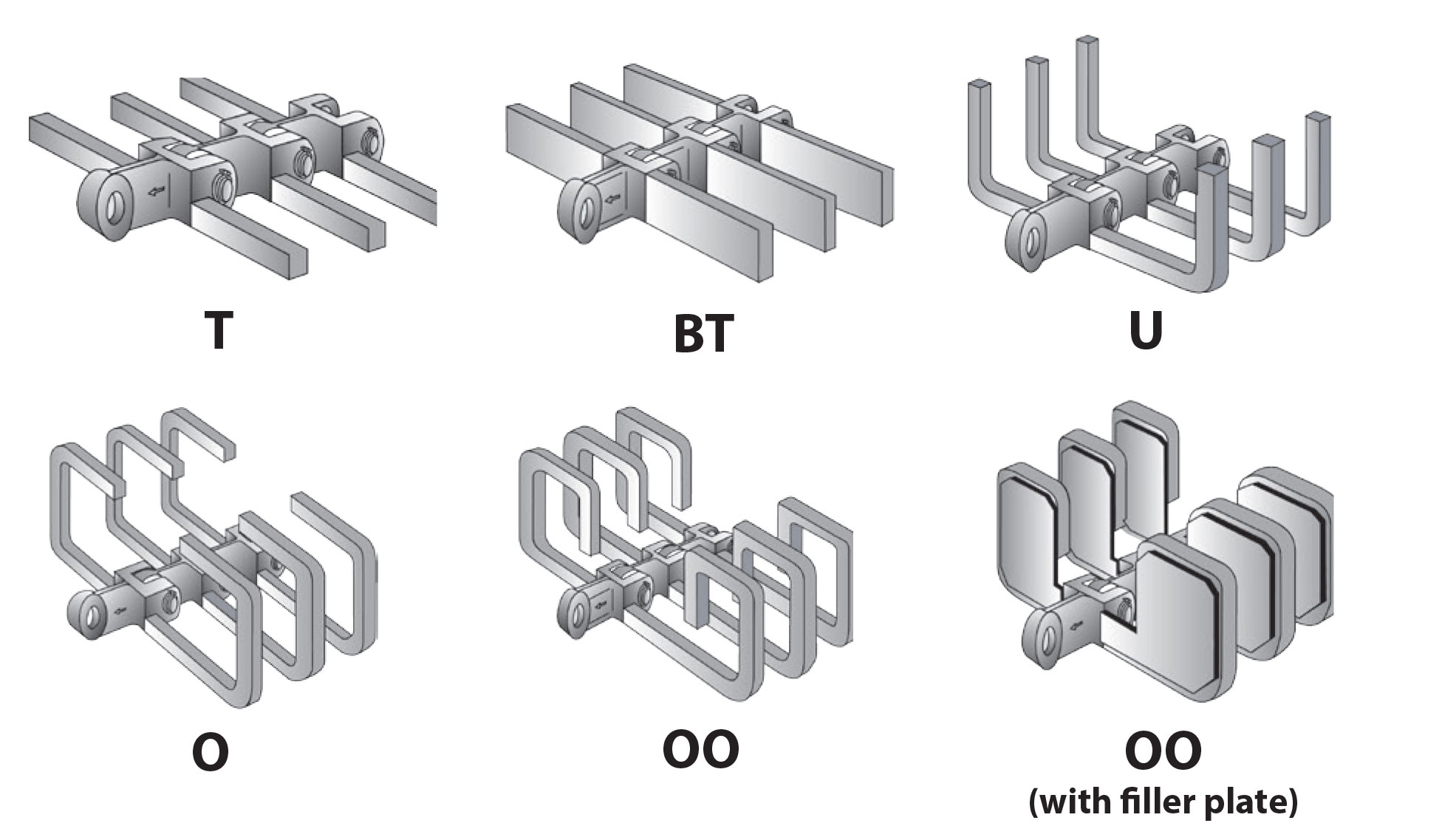

Drag Chain Conveyor Drawing - Be&e’s drag conveyors, however, are uniquely designed so their chains run in dedicated channels outside the material path: The “trs” drag chain conveyors are used for horizontal, inclined or vertical conveying of countless types of bulk materials. Web in this in this comprehensive guide, we will explore the inner workings of drag chain conveyors, discuss their advantages, examine their key applications across various industries, delve into design considerations, offer maintenance best. 206 downloads 20 likes 1 comments. Here are four advantages of the. The chain and flights are housed in a trough assembly that consists of a material. Web choose from our selection of drag conveyor chain, including ansi roller chain and links, ansi attachment chain and links, and more. It has a heavy duty construction. Configurations can include multiple inlets and discharges, optimized puck design, and many other options to make sure it’s the right conveyor for you. Web luxme technology special merits luxme link chain design acts as a universal joint during product conveying and can turn in multiple directions and planes. Web drag conveyors consist of evenly spaced rounded or rectangular flights mounted on a continuous chain that travels around a drive and a tail sprocket. We offer some examples of common drag conveyor layouts on our designs pages. Gschwendt r advanced conveyor technology. Various industries served include automotive, electronics, marine and medical. Web browse and download thousands of cad drawing. We offer some examples of common drag conveyor layouts on our designs pages. Web download the model according to the specified sizing parameters in either 3d or 2d format. Web most drag chain conveyors run chains along the bottom pan and return rails. No chains or paddles drag on the floors and no ar rails. The design, layout configurations, service. Web most drag chain conveyors run chains along the bottom pan and return rails. Drag conveyors can efficiently convey a variety of bulk materials with low to. In stock and ready to ship. The rugged welded construction permits high speeds, minimal lubrication and easy. Web luxme technology special merits luxme link chain design acts as a universal joint during product. Thousands of free, manufacturer specific cad drawings, blocks and details for download in multiple 2d and 3d formats organized by masterformat. Gschwendt r advanced conveyor technology. Various industries served include automotive, electronics, marine and medical. Welded steel drag chains are designed for drag conveyors where r ugged and demanding environments exist. Be&e’s drag conveyors, however, are uniquely designed so their. Drag conveyors can efficiently convey a variety of bulk materials with low to. Web choose from our selection of drag conveyor chain, including ansi roller chain and links, ansi attachment chain and links, and more. The design, layout configurations, service duty rating, size of the drive, and type of chain and flight assembly are all components that make a significant. Hollow bearing pin chain hollow pin conveyor chain offers the facility for fixing attachments to the outer links using bolts through the hollow pin and attachment, this method of fixing being suitable for use in most normal circumstances. Our l path line of drags was designed to handle materials at inclines greater. Various industries served include automotive, electronics, marine and. But why does this mater? Dassault systèmes 3d contentcentral is a free library of thousands of high quality 3d cad models from hundreds of suppliers. Custom manufacturer of drag chain conveyors made from mild steel and stainless steel. Web download the model according to the specified sizing parameters in either 3d or 2d format. Web drag conveyors consist of evenly. Web vertical conveyors 21 installation drawing 23 accessories 25 4 since 1919 ga m b a rot ta s.r.l. The “trs” drag chain conveyors are used for horizontal, inclined or vertical conveying of countless types of bulk materials. The chain and flights are housed in a trough assembly that consists of a material. Gschwendt r advanced conveyor technology. Web tubular. Web drag conveyor chain guides. Web incline drag chain conveyors are ideal for conveying grain from pits to legs, underground or overhead—wherever high capacities are required. Here are four advantages of the design: Various industries served include automotive, electronics, marine and medical. Millions of users download 3d and 2d cad files everyday. No chains or paddles drag on the floors and no ar rails. But why does this mater? Here are four advantages of the. Thousands of free, manufacturer specific cad drawings, blocks and details for download in multiple 2d and 3d formats organized by masterformat. Welded steel drag chains are designed for drag conveyors where r ugged and demanding environments exist. The chain and flights are housed in a trough assembly that consists of a material. 206 downloads 20 likes 1 comments. Web drag conveyors are commonly used for bulk material handling, specifically for moving flowable bulk materials horizontally, vertically and on various inclines. Welded steel drag chains are designed for drag conveyors where r ugged and demanding environments exist. Dassault systèmes 3d contentcentral is a free library of thousands of high quality 3d cad models from hundreds of suppliers. Available with single or multiple chain strands, drag chain conveyors are designed to pull materials like coal, wood, tdf, lime and other materials vertically while still working to maintain particle. We offer some examples of common drag conveyor layouts on our designs pages. But the actual layout is tailored to your existing or desired placement of your equipment. Drag conveyors can efficiently convey a variety of bulk materials with low to. But why does this mater? Web luxme technology special merits luxme link chain design acts as a universal joint during product conveying and can turn in multiple directions and planes. Millions of users download 3d and 2d cad files everyday. Web imagine a chain being driven by an electric motor to get a sense of how drag chain conveyors operate. No chains or paddles drag on the floors and no ar rails. Web in this in this comprehensive guide, we will explore the inner workings of drag chain conveyors, discuss their advantages, examine their key applications across various industries, delve into design considerations, offer maintenance best. Configurations can include multiple inlets and discharges, optimized puck design, and many other options to make sure it’s the right conveyor for you.

Drag Chain Conveyor Operation Understanding the Functional Differences

.jpg)

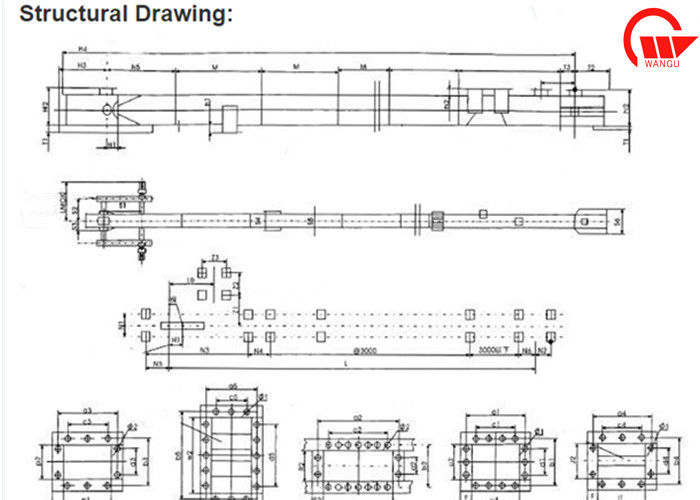

The Design of Drag Chain Conveyor for Rice Hull conveying

Custom Simple Structure Drag Chain Conveyor , TGMC Series Redler Chain

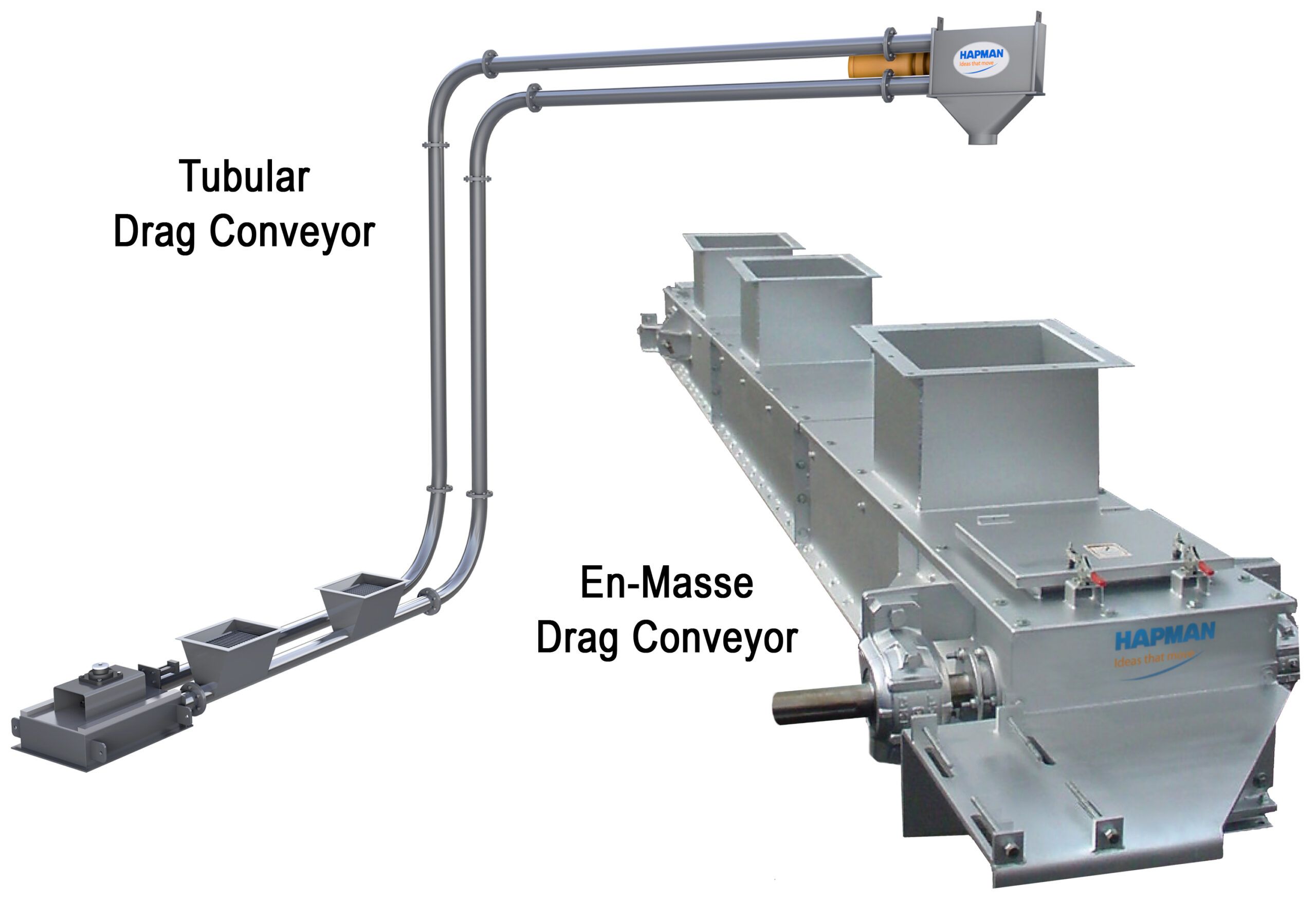

Drag Conveyors Hapman

Drag Chain Conveyors

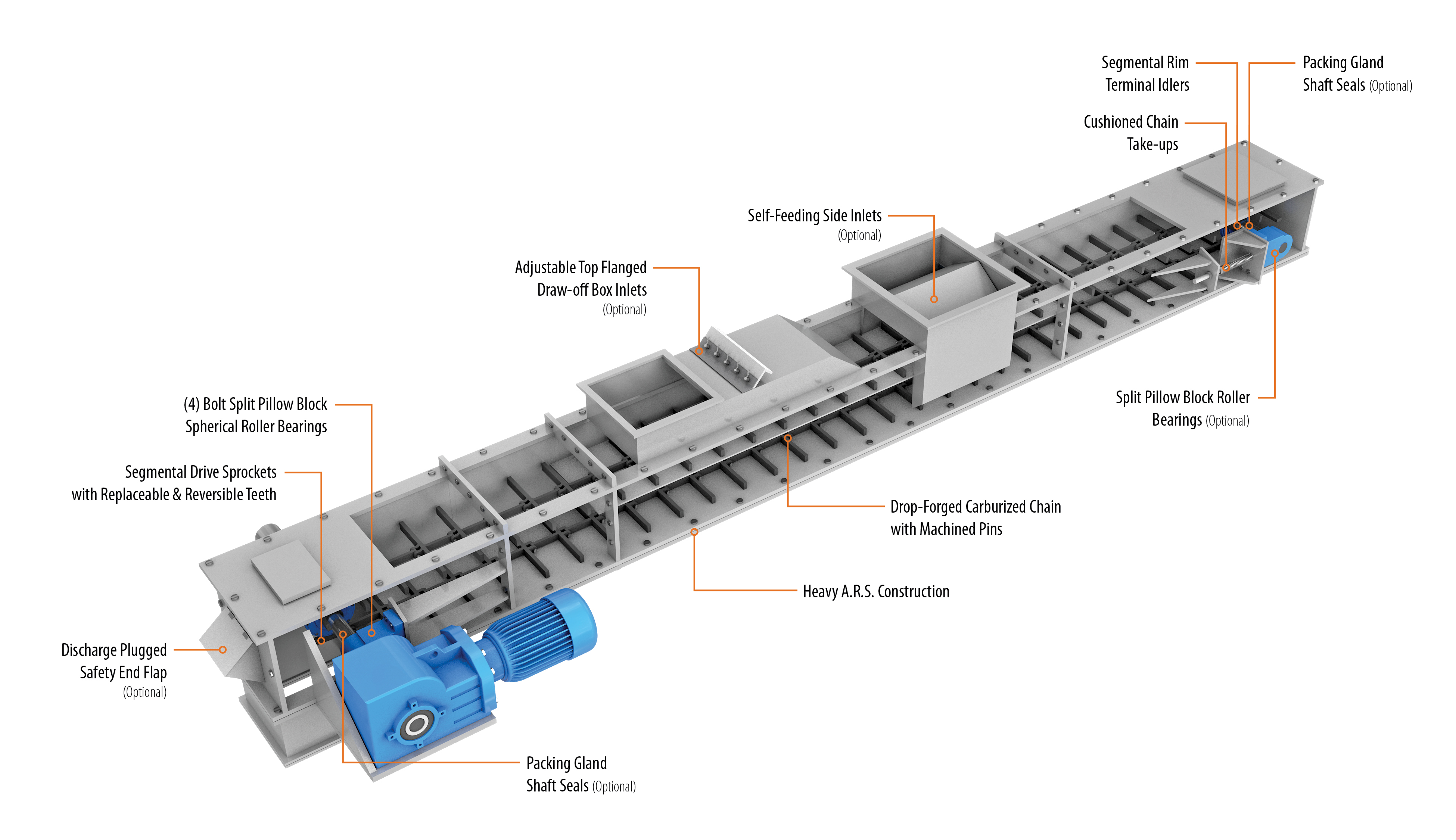

Tech Brief Drag Chain Conveyor Operation CDM Systems, Inc.

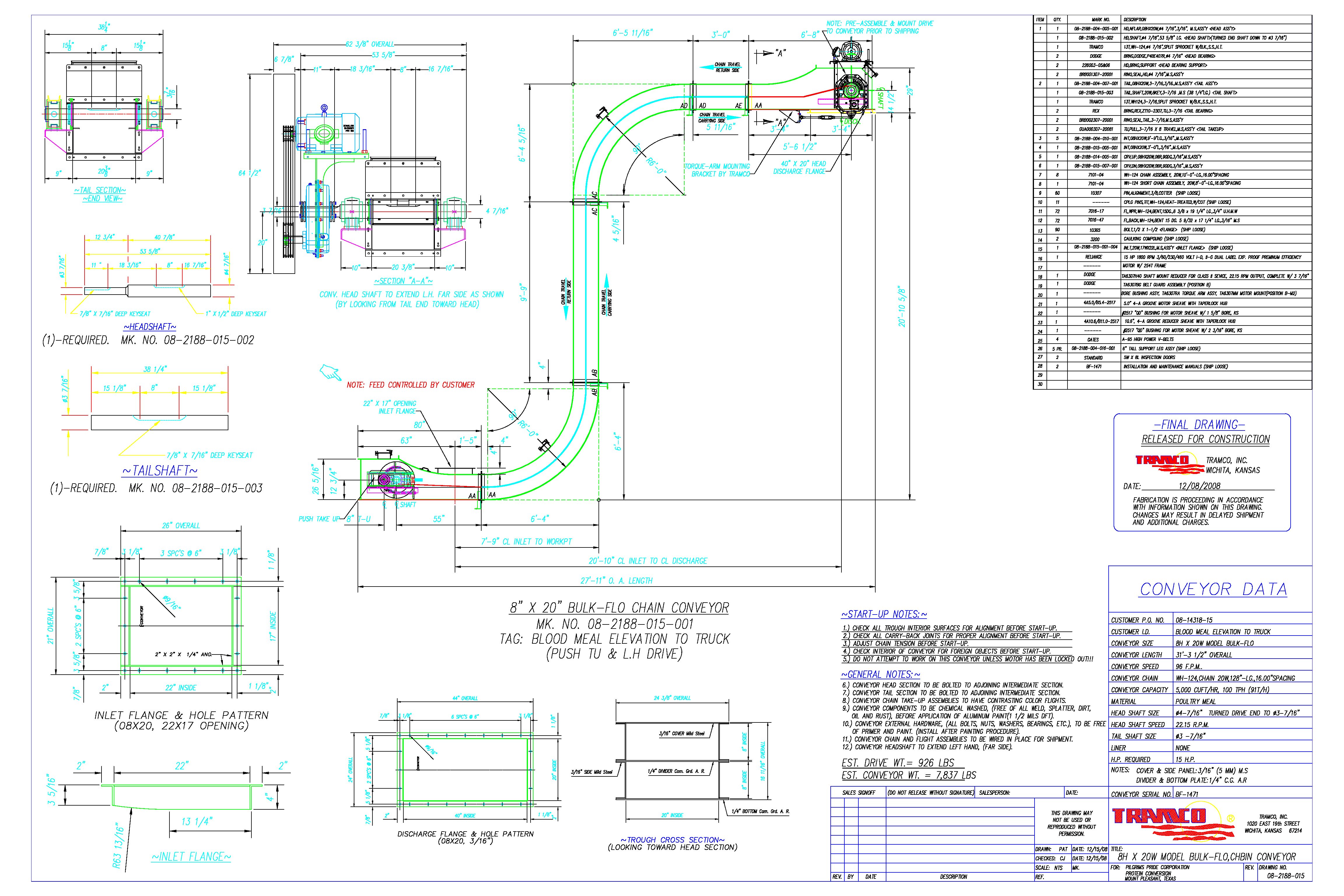

8” HIGH X 20” WIDE “Z” TYPE MODEL BULKFLO RAPAT DRAG CHAIN CONVEYOR

Custom Simple Structure Drag Chain Conveyor , TGMC Series Redler Chain

All About Drag Conveyors Types, Design, and Uses

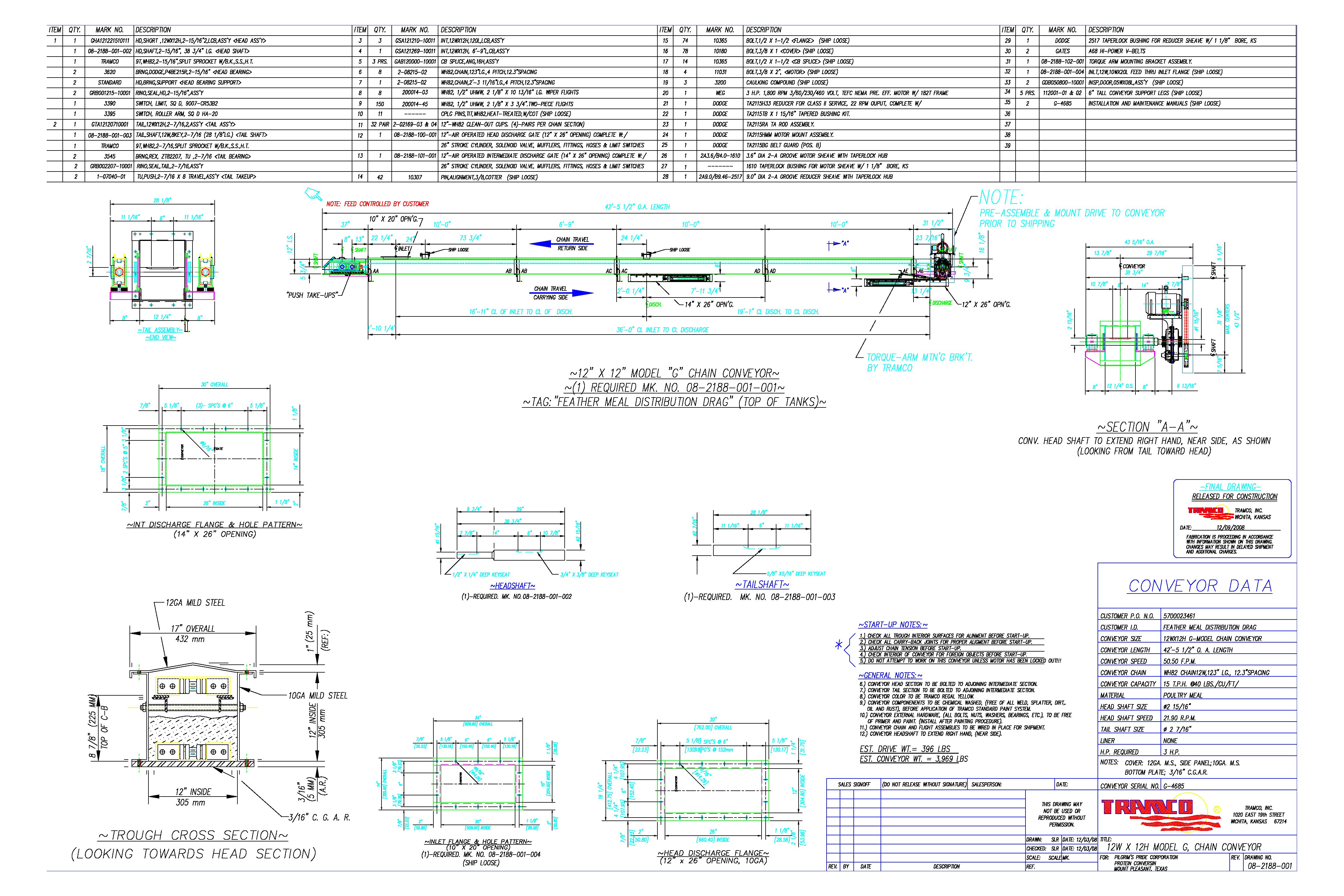

12” WIDE X 12” HIGH X 42’5.5” OVERALL LENGTH MODEL G RAPAT DRAG CHAIN

Web Drag Chain Conveyor Systems.

Various Industries Served Include Automotive, Electronics, Marine And Medical.

Web Most Drag Chain Conveyors Run Chains Along The Bottom Pan And Return Rails.

Be&E’s Drag Conveyors, However, Are Uniquely Designed So Their Chains Run In Dedicated Channels Outside The Material Path:

Related Post: