Driveline Angle Chart

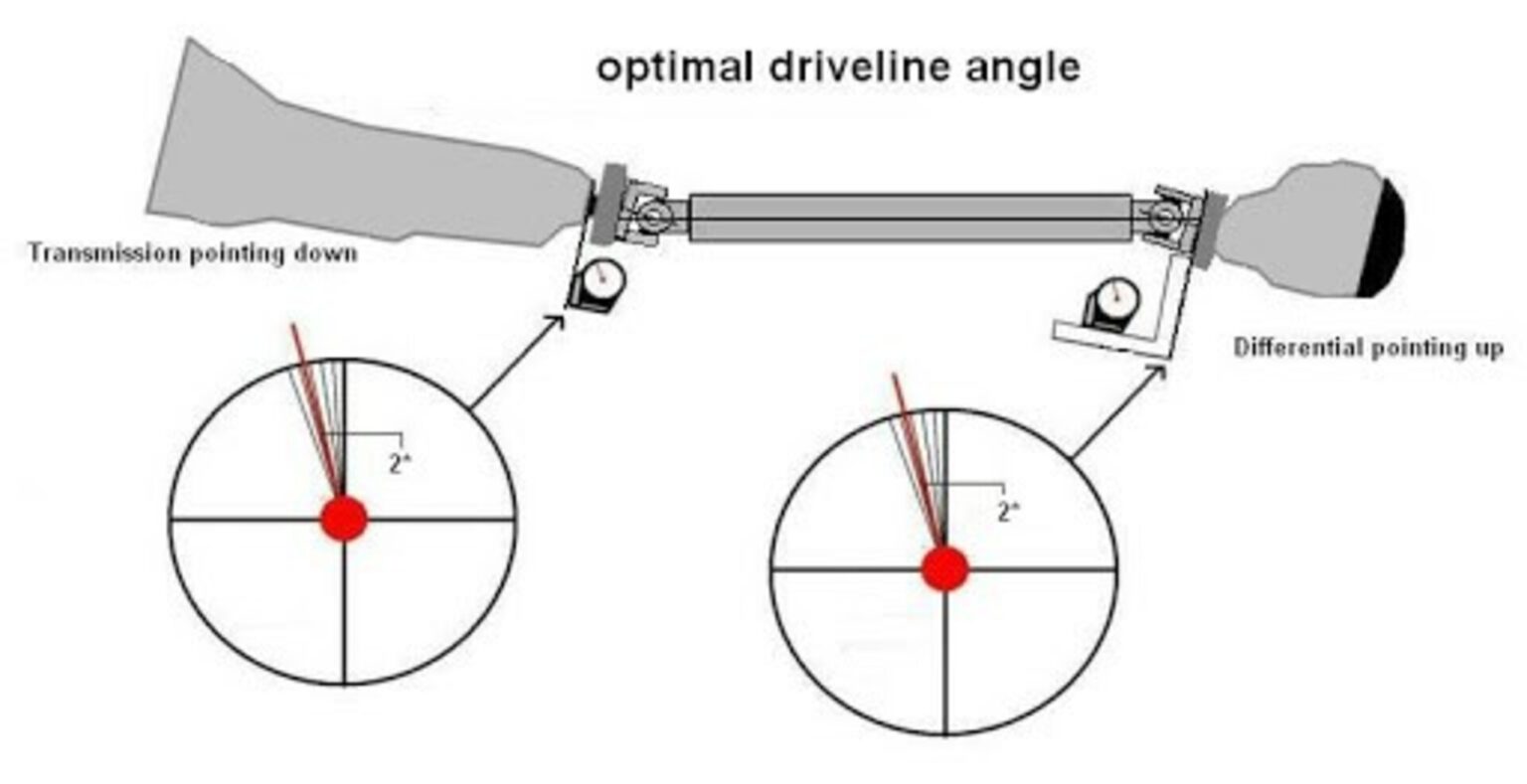

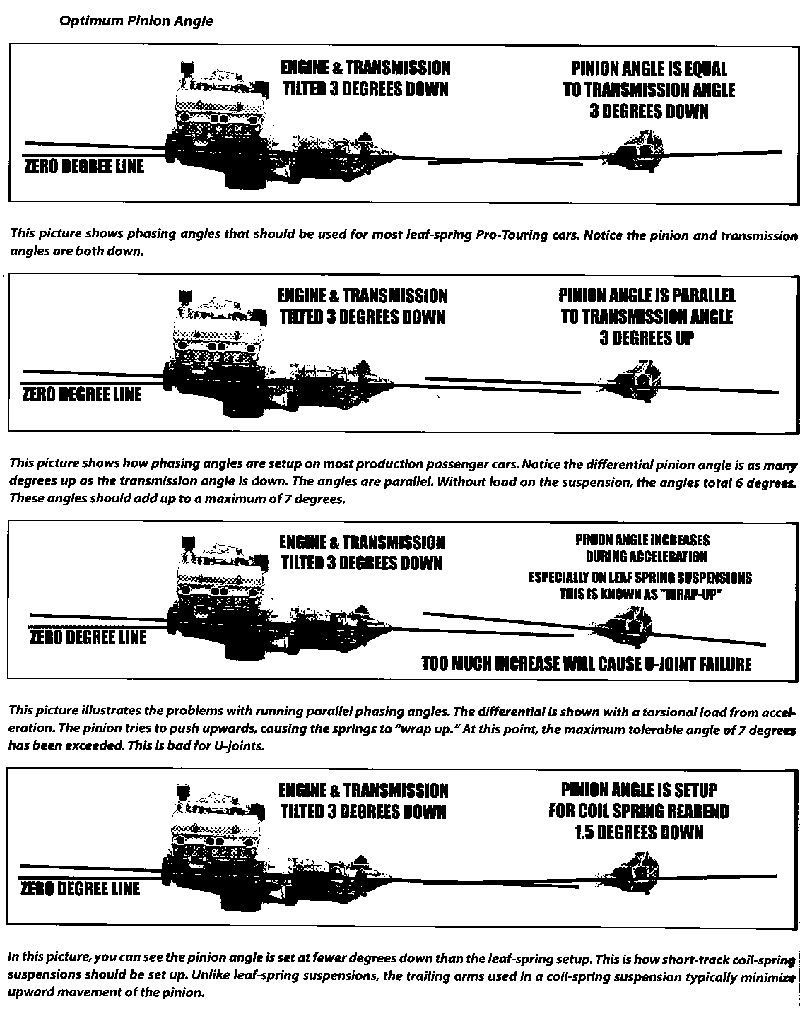

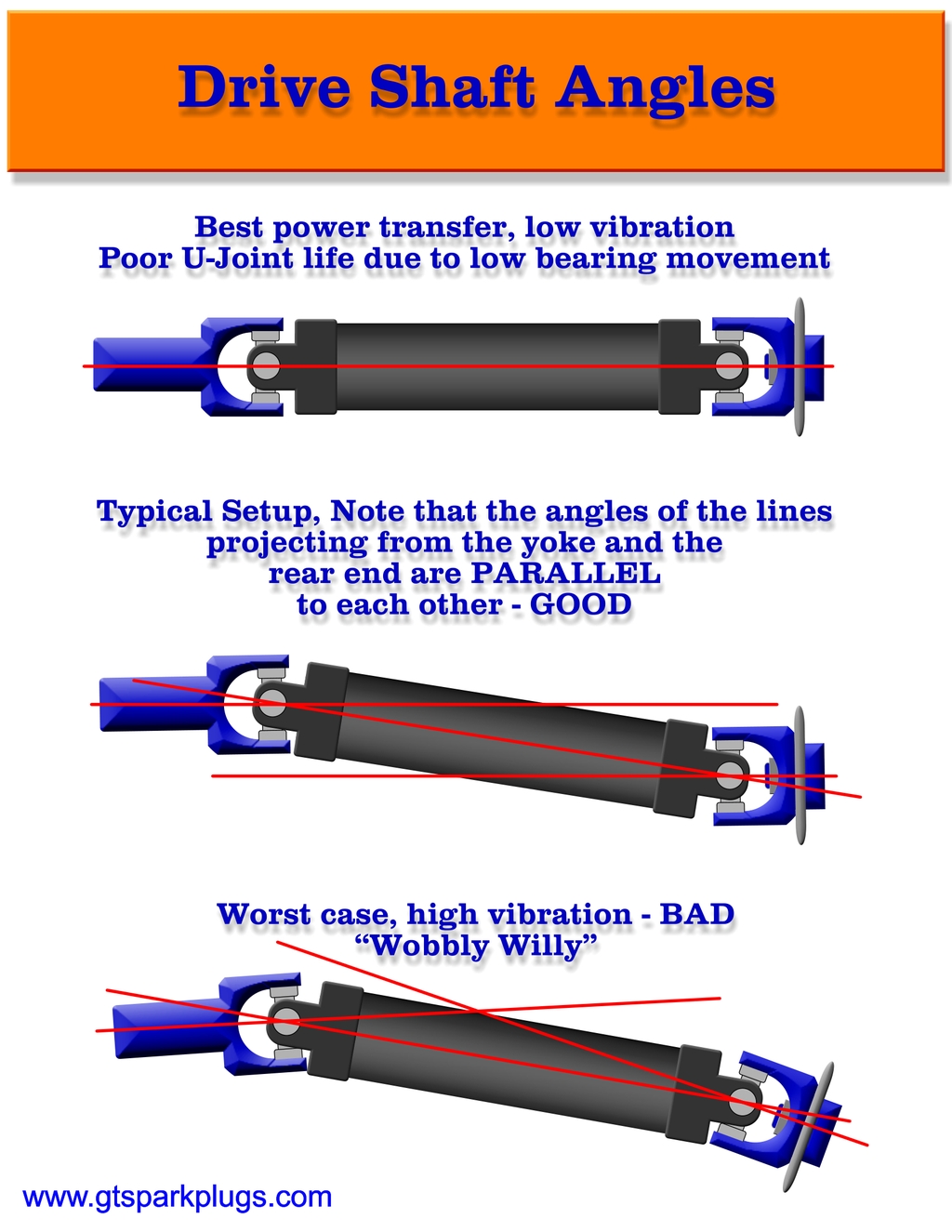

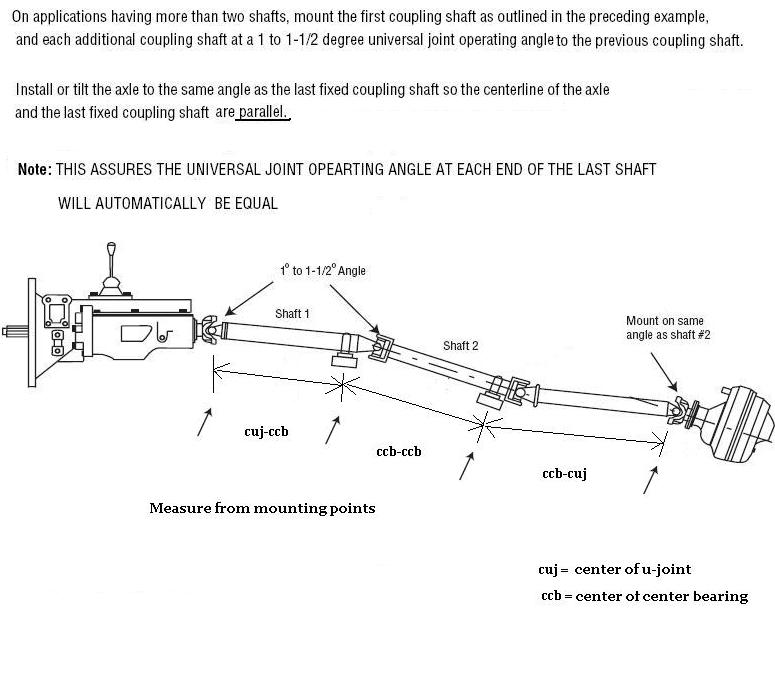

Driveline Angle Chart - Web how to perfectly set up your drive shaft angles! 40k views 1 year ago. Web measuring driveline operating angles. Web if your drive shaft is 20 and your transfer case is 5 degrees up, your joint angle is 25 degrees. Web the anglemaster can be used wherever there is a need for a precise measurement of angles and slopes. Web specifically we are focusing on drive shaft angle on lifted trucks and jeeps. Web the spicer website also includes a chart of values for vibration free performance, showing driveshaft rpm vs operating angle when the operating angles. The step 2 driveshaft angle is. The drive line working angle should not. For each of the following values, enter angle (to the nearest 1/4 degree) and slope (up or down). This video offers a quick tutorial that can. There should be a minimum of ½° to allow the needles to rotate. Place an angle finder on the bearing cap and take note of the reading. Web driveline angles should be equal to or within 1° of each other. Select the number of shafts in your application. There should be a minimum of ½° to allow the needles to rotate. This video offers a quick tutorial that can. 1.4k views 2 years ago. Dsopnsrtoegh4fa l3u1i6 i 1 50t0 0lr il0547i, ma p 4 2 39ulh5 2. Web driveline angles should be equal to or within 1° of each other. This video offers a quick tutorial that can. Web to find the working angles follow these steps: 1.4k views 2 years ago. By using your smartphone as a measuring device, the app will. See charts, diagrams and examples of one plane and two plane angles,. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. For each of the following values, enter angle (to the nearest 1/4 degree) and slope (up or down). Select the number of shafts in your application. The information below is a step by step guide on how to use the. This video offers a quick. Measure the angles of each. Web how to perfectly set up your drive shaft angles! Web driveline angles should be equal to or within 1° of each other. This is a textbook layout and if you can. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. Dsopnsrtoegh4fa l3u1i6 i 1 50t0 0lr il0547i, ma p 4 2 39ulh5 2. This is a textbook layout and if you can. High angle (45°) interaxle driveshafts are available in c2045, c2055, spl170, spl250 and 1710 series only. Web specifically we are focusing on drive shaft angle on lifted trucks and jeeps. The information below is a step by step. The drive line working angle should not. Web to find the working angles follow these steps: When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. For each of the following values, enter angle (to the nearest 1/4 degree) and slope (up or down). Web please use the above chart to check your driveshaft angle. This is a textbook layout and if you can. Select the number of shafts in your application. Measure the angles of each. The drive line working angle should not. For each of the following values, enter angle (to the nearest 1/4 degree) and slope (up or down). Measure the angles of each. See charts, diagrams and examples of one plane and two plane angles,. Place an angle finder on the bearing cap and take note of the reading. High angle (45°) interaxle driveshafts are available in c2045, c2055, spl170, spl250 and 1710 series only. Web measuring driveline operating angles. 40k views 1 year ago. 1.4k views 2 years ago. Web driveline angles should be equal to or within 1° of each other. Shims are available in different corrective. There should be a minimum of ½° to allow the needles to rotate. Rotate the driveshaft 90° and repeat step one. See charts, diagrams and examples of one plane and two plane angles,. In order to determine the slopes you will need to have some. Web driveline angles should be equal to or within 1° of each other. Web the spicer website also includes a chart of values for vibration free performance, showing driveshaft rpm vs operating angle when the operating angles. Web how to perfectly set up your drive shaft angles! Putting the thick edge to the front raises the pinion. Web please use the above chart to check your driveshaft angle the picture above shows a simple driveline and how its angles are laid out. When checking driveshaft angles, be sure all tires are inflated to their normal operating pressure. For each of the following values, enter angle (to the nearest 1/4 degree) and slope (up or down). Web measuring driveline operating angles. Shims are available in different corrective. Web specifically we are focusing on drive shaft angle on lifted trucks and jeeps. Place an angle finder on the bearing cap and take note of the reading. Dsopnsrtoegh4fa l3u1i6 i 1 50t0 0lr il0547i, ma p 4 2 39ulh5 2. Web to find the working angles follow these steps:

Mastering Driveline Angles for Optimal Performance

Classic Car Pinion Angle Why It Is Important Classic Auto Advisors

Driveline angles CorvetteForum Chevrolet Corvette Forum Discussion

Driveline Geometry » Tom Mackie Racing

Drive Shaft Angles GTSparkplugs

driveline angle worksheet

How To Measure Oliver's Driveshafts

Technical Driveline angles The H.A.M.B.

Driveline Angle Worksheet

Driveline Geometry 101 Tom Wood's Custom Drive Shafts

This Video Offers A Quick Tutorial That Can.

Web The Anglemaster Can Be Used Wherever There Is A Need For A Precise Measurement Of Angles And Slopes.

Read If You Want To Fully Understand Why Drive Line Geometry Is Important And How It Affects The Type.

Web How To Use The Driveline Operating Angle Calculator.

Related Post: