End Mill Size Chart

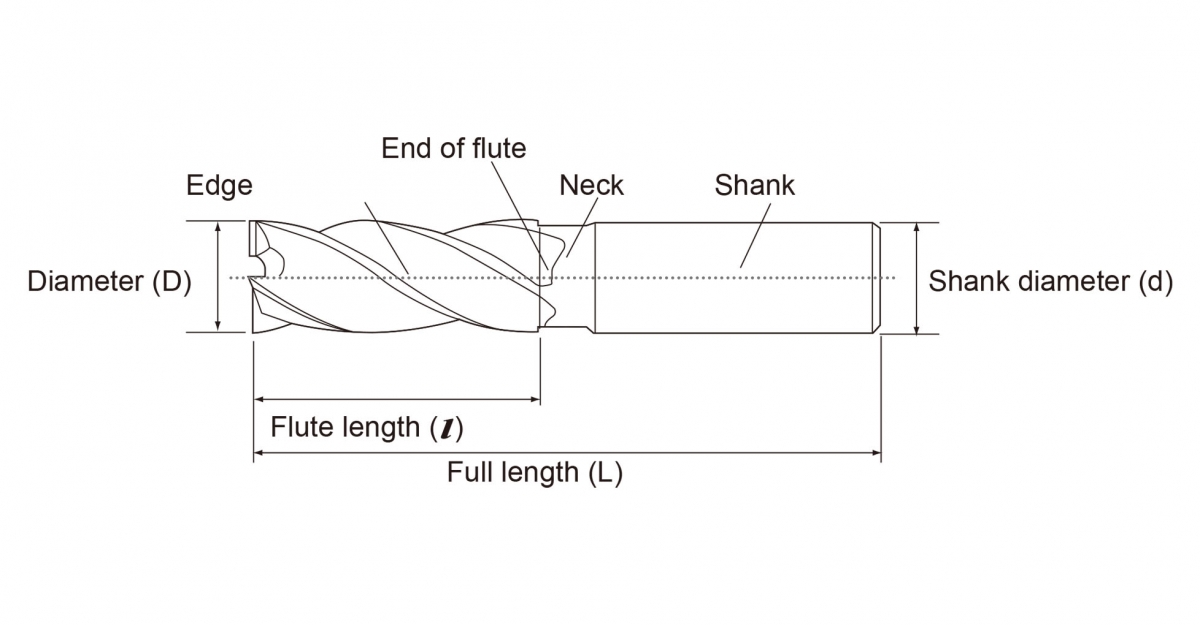

End Mill Size Chart - Find your perfect milling bit at 6g tools and have it shipped today. Web end mills, htpm, speeds and feeds, slotting and side cutting, metric. Web din 844 end mill standard sizes. Web 1/8 inch (3.175mm): For smaller taper machining centers or less rigid conditions, please adjust parameters accordingly on diameters greater than 12mm. Note 2) if the depth of cut is smaller than this table, feed rate can be increased. 5 7 7 8 8 11 13 13 16 19 19 22 22 26 26 26 26 32 32 32 32 38 38 38 38 45 45 45 45 45 45 45 53. Achieve 50% greater chip loads and 20% to 40% higher speeds than conventional end mills. Pvd/cvd coatings & surface finishes. Web chamfer size —.010—.020 — —.020. In stock and ready to ship. Web din 844 end mill standard sizes. An end mill size chart can help you quickly determine the cutting diameter and other dimensions of the tool. Note 3) when drilling, please. Versatile enough for many types of cuts and milling operations, this size offers a good balance between strength and precision. Web end mill sizes author: End mills cut rotationally in a horizontal, or lateral (side to side) direction whereas a drill bit only cuts straight down, vertically into the material. Find your perfect milling bit at 6g tools and have it shipped today. A chart of all standard end mill sizes including inch, metric, and micro. Web according to the. Ball end mill sizes created date: Note 3) when drilling, please. Feed to be reduced by approximately 50% if loc (length of cut) is over 3xd. The size of an end mill not only determines the. Choose from our selection of metric end mills in a wide range of styles and sizes. Web chamfer size —.010—.020 — —.020. An end mill size chart can help you quickly determine the cutting diameter and other dimensions of the tool. The above recommendations are based on ideal conditions; Endmills are available in a wide variety of lengths, diameters, flutes and types, and are chosen according to the material they are cutting and the surface finish. It can be used with different materials, too. The size of an end mill not only determines the. Apply coatings for higher feeds, speeds and tool life. Web understanding the spectrum of end mill sizes is crucial for every machinist, manufacturer, and hobbyist involved in milling operations. Also available in pdf format to download for future reference. Grinding accuracy & qc technology. The size of an end mill not only determines the. Ball end mill sizes created date: What size of end mill should i use? Versatile enough for many types of cuts and milling operations, this size offers a good balance between strength and precision. This size is perfect for detailed work on small objects, such as engraving words or tiny designs into jewelry or circuit boards. Variable helix end mills reduce chatter and vibration. 5 7 7 8 8 11 13 13 16 19 19 22 22 26 26 26 26 32 32 32 32 38 38 38 38 45 45 45 45 45. A chart of all standard end mill sizes including inch, metric, and micro. Each of these features has a direct influence on how the end mill will behave during a machining operation and on the cutting possibilities in terms of performance and shapes. For smaller taper machining centers or less rigid conditions, please adjust parameters accordingly on diameters greater than. Web chamfer size —.010—.020 — —.020. Pvd/cvd coatings & surface finishes. This measurement is important to note when choosing a tool to ensure that the shank is the correct size for the holder being used. Web din 844 end mill standard sizes. Allowance/deviations (es/el) tolerances (t d /t d) normal length of engagement. Apply coatings for higher feeds, speeds and tool life. Web here is a chart of standard end mill sizes which includes ball end mill sizes. It can be used with different materials, too. Ball end mill sizes created date: Variable helix end mills reduce chatter and vibration. Web end mill sizes author: This size is perfect for detailed work on small objects, such as engraving words or tiny designs into jewelry or circuit boards. Note 3) when drilling, please. Web this chart references all the standard end mill tool sizes in american measurements. Web february 15, 2021 by sherry deperno. Web din 844 end mill standard sizes. Pvd/cvd coatings & surface finishes. It can be used with different materials, too. Note 2) if the depth of cut is smaller than this table, feed rate can be increased. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Versatile enough for many types of cuts and milling operations, this size offers a good balance between strength and precision. End mills cut rotationally in a horizontal, or lateral (side to side) direction whereas a drill bit only cuts straight down, vertically into the material. 5 7 7 8 8 11 13 13 16 19 19 22 22 26 26 26 26 32 32 32 32 38 38 38 38 45 45 45 45 45 45 45 53. Choose from our selection of metric end mills in a wide range of styles and sizes. Web according to the five most common end mill types, we will introduce how to read the specification sheet one by one, and the precautions to help you quickly find the size you need! Each of these features has a direct influence on how the end mill will behave during a machining operation and on the cutting possibilities in terms of performance and shapes.

Standard Length Endmills (Ball End) Peak Toolworks

Kennametal Solid Carbide End Mill Tool Selection Guide Fractional Sizes

Radius 1/32 Shank Dia 3/8 Largest Dia 7/16 Overall Length 2 1

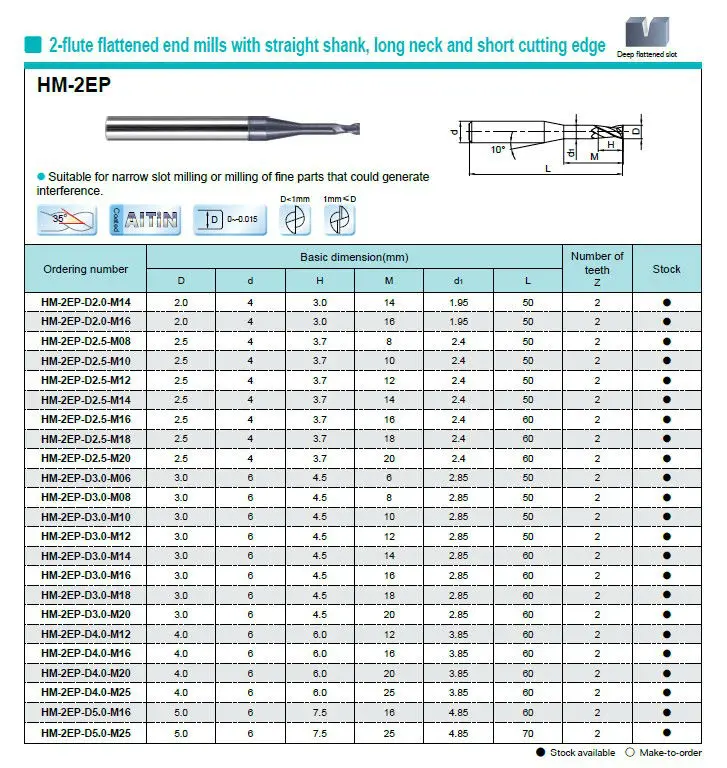

End Mill Cutter Sizes;2flute Flattened End Mills With Straight Shank

end mill cutter sizes;2flute flattened end mills with straight shank

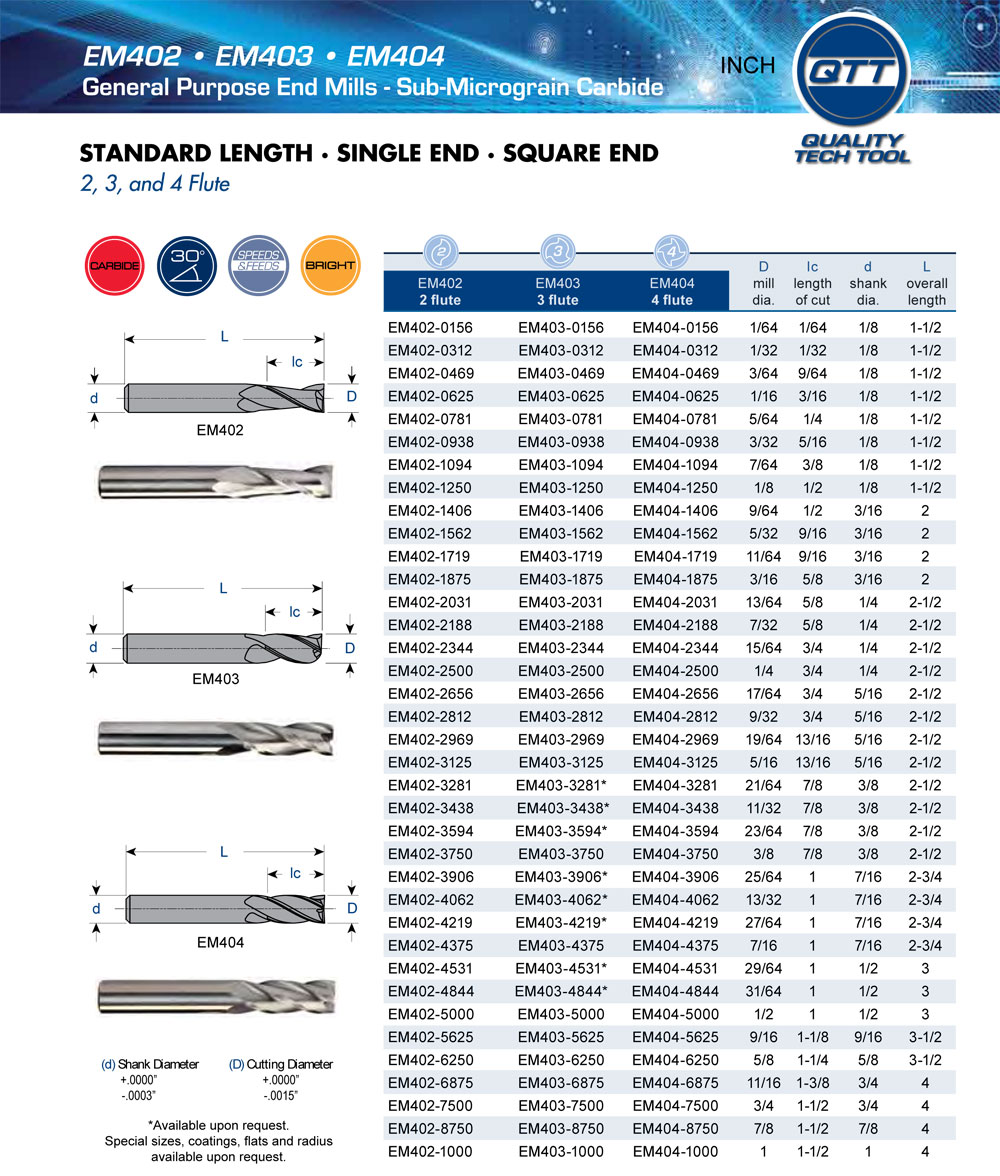

General Purpose End Mills Inch Quality Tech Tool

ball end mill size chart Kristle Hartmann

Standard Size Carbide End Mill Carbide Rounding Corner Radius End Mill

Standard End Mill Sizes Chart

End Mill Size Standards Chart & IntroductionSPEED TIGER

This Measurement Is Important To Note When Choosing A Tool To Ensure That The Shank Is The Correct Size For The Holder Being Used.

End Mills Are Available In Metric Sizes And Follow End Mill Size Standards To Ensure Compatibility With Cnc Machinery.

Also Available In Pdf Format To Download For Future Reference.

Variable Helix End Mills Reduce Chatter And Vibration.

Related Post: