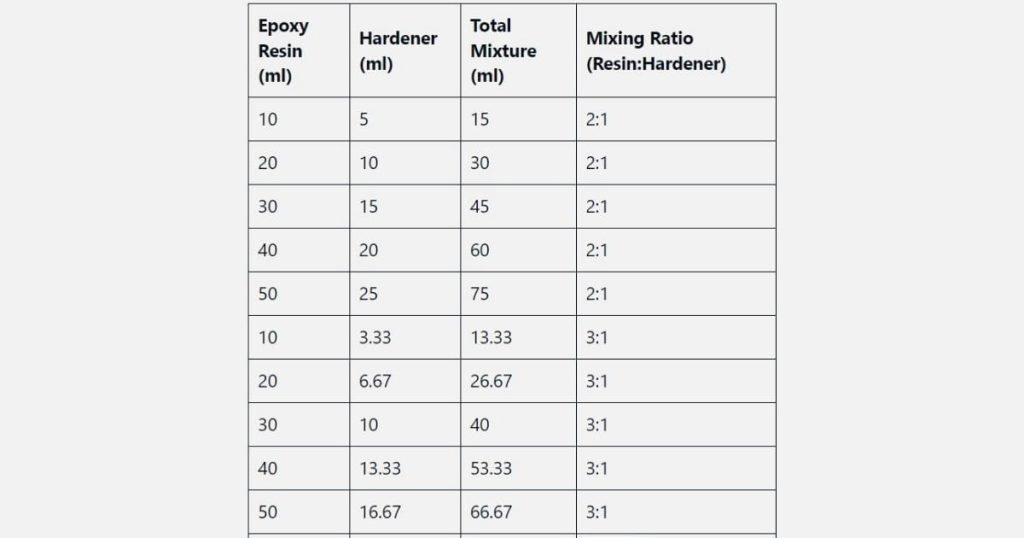

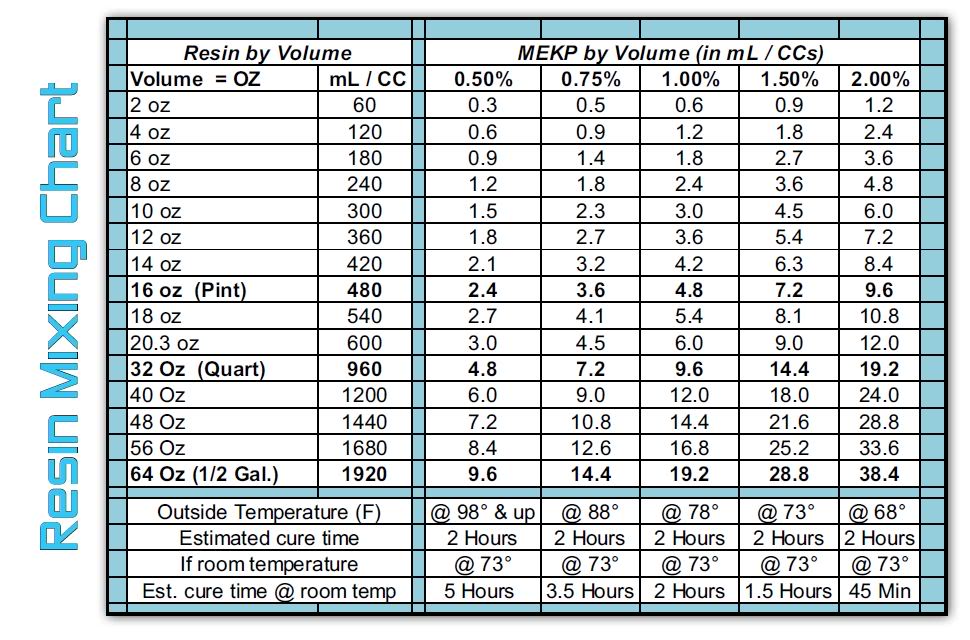

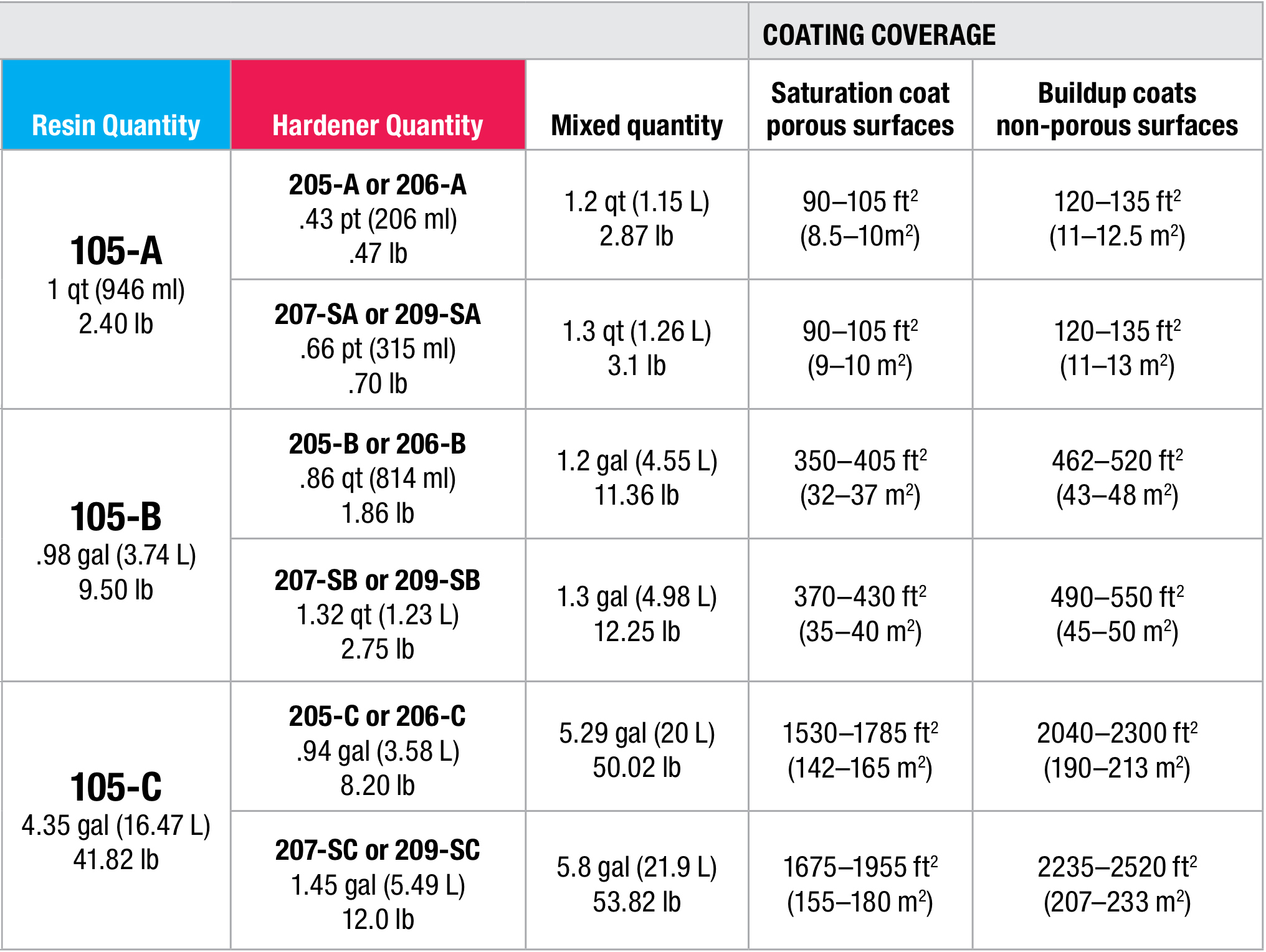

Epoxy Resin Mixing Ratio Chart

Epoxy Resin Mixing Ratio Chart - Buy only high quality epoxy. Web determine and follow the correct mixing ratio. For this reason, we would add the kr stirrer to the above list, as it deals better with thicker epoxies. Things to consider while mixing. Resin (part a) hardener (part b) project volume. Web mix ratio by volume. Total required quantity of epoxy resin incl. With the 3:2 mix an extra oz. Using the mix ratio on the technical data sheet, weigh out the part a to be blended to the nearest gram (g). Epoxy resin comes in two parts: The effect of ambient temperature. Total required quantity of epoxy resin incl. Web determine and follow the correct mixing ratio. With the 3:2 mix an extra oz. Web our epoxy resin calculator will help you determine the optimum mixing ratio. Here is a simple explanation on how to use the graduated marks on our standar. How to use the epoxy calculator? So you can be sure that your projects turn out just as planned. To calculate the amount you will need, in metric, you will need work out the size of the volume you wish to fill, convert that to. Web this makes it very important to consult your epoxy resin mixing ratio chart to ensure that you're getting the proper mix on each product that you're applying in the field, as each product may have different viscosities. Web mix ratio by volume. Things to consider while mixing. Web our epoxy resin calculator will help you determine the optimum mixing. Web our epoxy resin calculator will help you determine the optimum mixing ratio. The right tool for epoxy resin mixing. Web the correct entropy resins epoxy mix ratio can be measured by volume, weight or using our mini pumps. Web determine and follow the correct mixing ratio. Web the ratio of resin and hardener needed to make epoxy resin does. Web epoxy resins can be measured by weight, but due to the nature of specific gravity of the resin it is important to follow the ratio guide, and the use of electronic scales is essential. Entropy resins technical advisor, don gutzmer, explains where to find the proper mix ratio for. That is a mix ration of 1.58:1. Contains the resin. Resin (part a) hardener (part b) project volume. Web measuring by volume vs. Entropy resins technical advisor, don gutzmer, explains where to find the proper mix ratio for. Temperature below 68 degrees fahrenheit: Cooler temperatures can thicken the resin, slowing down the curing process, while warmer conditions can cause the resin to set too quickly. Epoxy resin comes in two parts: Resin (part a) hardener (part b) project volume. Web hardner weight = (hardner ratio / (resin ratio + hardner ratio)) x desired weight. The effect of ambient temperature. Web the ratio of resin and hardener needed to make epoxy resin does depend on the product you are using, and every different product should have. Epoxy resin mixing by volume instead of weight. Web epoxy resins can be measured by weight, but due to the nature of specific gravity of the resin it is important to follow the ratio guide, and the use of electronic scales is essential. Place your clean container (see above) on. How to calculate 2 part epoxy resin ratio? Here, you'll. This point is step one in mixing importance. A resin and a hardener. To calculate the amount you will need, in metric, you will need work out the size of the volume you wish to fill, convert that to the capacity and finally convert to the required weight: Web result of the calculation: Warm up the epoxy resin before processing. Here is a simple explanation on how to use the graduated marks on our standar. Web determine and follow the correct mixing ratio. Careful mixing of the components. Of part a means you actually used 19 oz. Epoxy resin mixing by volume instead of weight. Always mix in the exact ratio specified by the manufacturer. So you can be sure that your projects turn out just as planned. Of part a and 12 oz. Place your clean container (see above) on. Contains the resin and the hardener. That is a mix ration of 1.58:1. Cooler temperatures can thicken the resin, slowing down the curing process, while warmer conditions can cause the resin to set too quickly. Make sure you used resin and hardener, and not all resin or all hardener. Buy only high quality epoxy. Determine how much artresin you'll need. This point is step one in mixing importance. Double check the proper mix ratio was used. With the 3:2 mix an extra oz. Web determine and follow the correct mixing ratio. The right tool for epoxy resin mixing. These calculators will help you determine the exact mixing proportions by volume.

resin charts Google Search Epoxy resin diy, Diy resin crafts, Resin

How to measure and mix epoxy resin and hardener in five easy steps

How To Mix Epoxy? Epoxy Resins Art

West System Epoxy Guides The Fibreglass Shop

How To Measure And Mix Epoxy Resin And Hardener ArtResin

Epoxy Resin Mixing Ratio Chart

Epoxy Resin Coverage Chart

Resin comparison chart Epoxy resin diy, Resin crafts, Diy resin art

How to Calculate Epoxy Resin Epoxy Resin Calculator YouTube

MIX RATIO RESIN RESEARCH EPOXY shapehouse

Web Table Of Contents.

Mix Your Artresin For 3 Minutes.

Upon Mixing, Be Sure To Scrape Sides And Bottom Of Mixing Container To Ensure All Resin And Hardener Are Fully Blended.

Total Required Quantity Of Epoxy Resin Incl.

Related Post: