Ewma Control Chart

Ewma Control Chart - It makes possible the faster detection of small to moderate shifts in the process average. The weights decrease exponentially going backward in time. Web the ewma control chart can be made sensitive to small changes or a gradual drift in the process by the choice of the weighting factor, λ. Web the primary purpose of the ewma control chart is to detect small shifts or to detect when the process has drifted off target. The cumulative sum chart, the moving average and the exponentially weighted moving average charts. Use the ewma chart when you have one sample and want to detect small shifts in performance. Set between 0 and 1. Web this research presents a new adaptive exponentially weighted moving average control chart, known as the coefficient of variation (cv) ewma statistic to study the relative process variability. Web this international standard covers ewma control charts as a statistical process control technique to detect small shifts in the process mean. Web multivariate ewma control chart. Web the ewma control chart can be made sensitive to small changes or a gradual drift in the process by the choice of the weighting factor, λ. Set between 0 and 1. It weights observations in geometrically decreasing order so that the most recent observations contribute highly while the oldest observations contribute very little. Web definition of control limits for. Qi macros will do the math and draw the graph for you. Web the control limits on the ewma chart are derived from the average range (or moving range, if n=1), so if the range chart is out of control, then the control limits on the ewma chart are meaningless. Web how to make an ewma control chart. Web click. The two previous charts highlight 2 extremes of monitoring charts. Set between 0 and 1. Web the ewma control chart differs from the similar cusum chart by using the additional weighting factor, which allows the adjustment of shift sensitivity. It makes possible the faster detection of small to moderate shifts in the process average. Use the ewma chart when you. Some advanced monitoring strategies involve the simultaneous use of multiple control chart types, such as cusum, ewma, and shewhart charts, to maximize the likelihood of detecting any process abnormalities, regardless of their magnitude. It weights observations in geometrically decreasing order so that the most recent observations contribute highly while the oldest observations contribute very little. Web cusum, ma and ewma. Ewma charts have a built in mechanism for incorporating information from all previous subgroups, weighting the information from the closest subgroup with a higher weight. • two effective alternatives to the shewhart control charts are the cumulative sum (cusum) control chart and the exponentially weighted moving average (ewma) control chart. Web in this study, we introduce an adaptive exponentially weighted. Use smaller weightings to discern smaller shifts. When to use an alternate control chart. Web click on qi macros menu > control charts (spc) > special> ewma. Web the ewma control chart differs from the similar cusum chart by using the additional weighting factor, which allows the adjustment of shift sensitivity. Web an exponentially weighted moving average (ewma) chart is. When to use an alternate control chart. Web like a cusum chart, an ewma chart is an alternative to a shewhart individuals or x chart and provides quicker responses to shifts in the process mean then either an individuals or x chart because it incorporates information from all previously collected data. The weights decrease exponentially going backward in time. Some. Web cusum, ma and ewma control charts. Where 0 < l ≤ 1. Based on user experience and preference. Web • major disadvantage of shewhart control charts is that it only uses the information about the process contained in the last plotted point. The two previous charts highlight 2 extremes of monitoring charts. Web • major disadvantage of shewhart control charts is that it only uses the information about the process contained in the last plotted point. Web the control limits on the ewma chart are derived from the average range (or moving range, if n=1), so if the range chart is out of control, then the control limits on the ewma chart. Determine whether the process mean is in control. Use smaller weightings to discern smaller shifts. The model for a univariate ewma chart is given by: Set between 0 and 1. Web this research presents a new adaptive exponentially weighted moving average control chart, known as the coefficient of variation (cv) ewma statistic to study the relative process variability. The center line for the control chart is the target value or \ (\mbox {ewma}_0\). Web the ewma control chart can be made sensitive to small changes or a gradual drift in the process by the choice of the weighting factor, λ. Z i = λ x i + ( 1 − λ) z i − 1, i = 1, 2,., n, where z i is the i th ewma, x i is the the i th observation, z 0 is the average from the historical data, and 0 < λ ≤ 1. If there are any, then the special causes must be eliminated. The cumulative sum chart, the moving average and the exponentially weighted moving average charts. It makes possible the faster detection of small to moderate shifts in the process average. In this publication we will compare the ewma control chart to the individuals control, show how to calculate the ewma statistic and the control limits, and discuss the weighting factor, ?, used in the calculations. Shewhart charts cannot detect small shifts. Web the primary purpose of the ewma control chart is to detect small shifts or to detect when the process has drifted off target. • two effective alternatives to the shewhart control charts are the cumulative sum (cusum) control chart and the exponentially weighted moving average (ewma) control chart. Web the ewma control chart differs from the similar cusum chart by using the additional weighting factor, which allows the adjustment of shift sensitivity. When to use an alternate control chart. Web this international standard covers ewma control charts as a statistical process control technique to detect small shifts in the process mean. (setting the ewma weighting factor w = 1 yields a shewhart control chart.) Web the control limits on the ewma chart are derived from the average range (or moving range, if n=1), so if the range chart is out of control, then the control limits on the ewma chart are meaningless. Web multivariate ewma control chart.

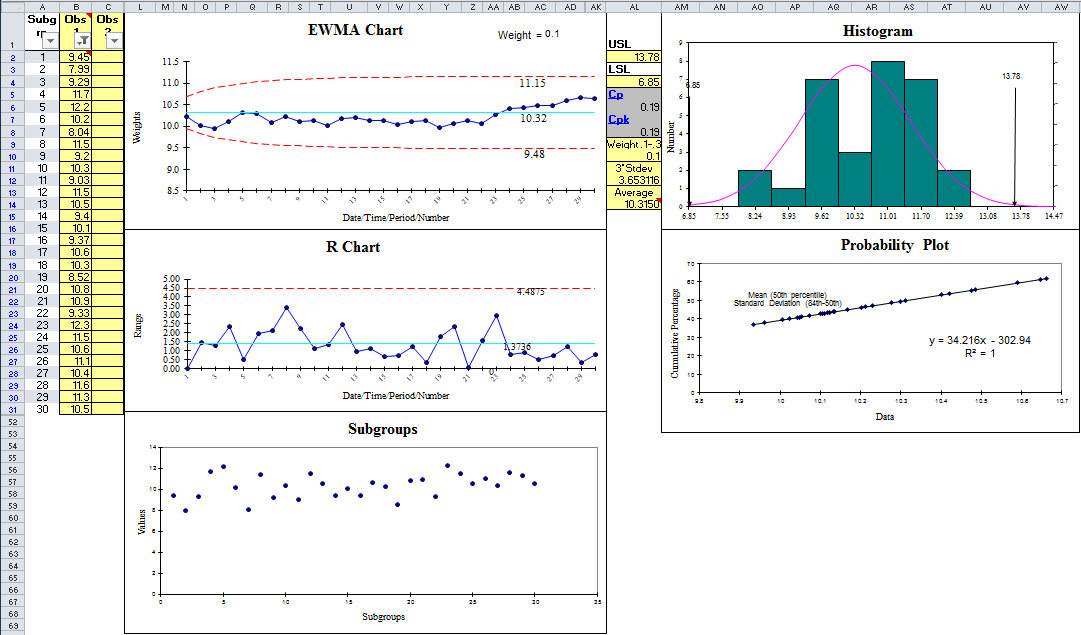

Example of an EWMA control chart (Montgomery, 2020). Download

EWMA Chart Template Exponentially Weighted Moving Average QI Macros

(a) Fuzzy EWMA chart (b) Conventional EWMA control chart Download

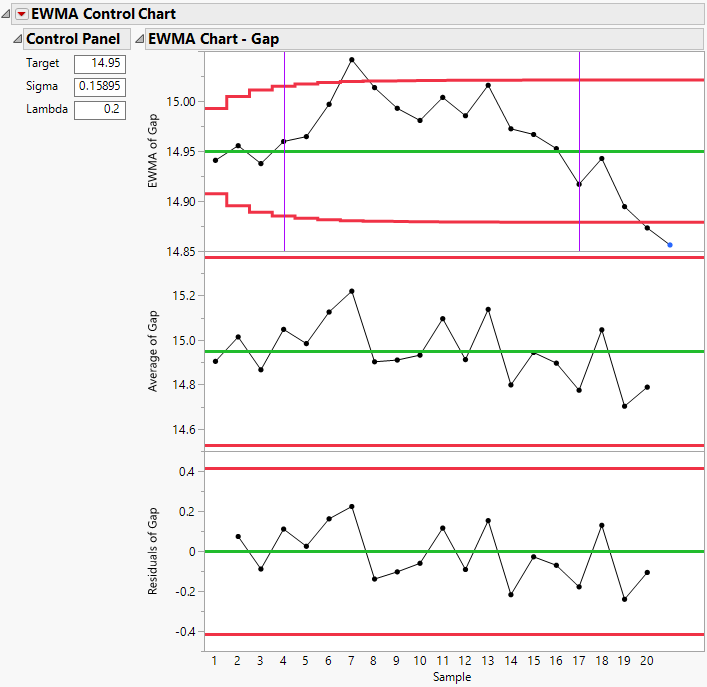

Example of the EWMA Control Chart Platform

Jendela Statistika Peta Kendali EWMA (Exponential Weighted Moving

Shewhart control chart, exponentially weighted moving average (EWMA

EWMA control chart for monthly temperature in peninsular zone

EWMA Control Charts with Timevarying Control Limits dashed lines show

(PDF) Optimized EWMA Control Charts in Function of Intrusion Detection

EWMA control charts for drip irrigation with different hydraulic heads

Web Like A Cusum Chart, An Ewma Chart Is An Alternative To A Shewhart Individuals Or X Chart And Provides Quicker Responses To Shifts In The Process Mean Then Either An Individuals Or X Chart Because It Incorporates Information From All Previously Collected Data.

Based On User Experience And Preference.

We Also Need To Define A Starting Value Of Z 0 Before The First Sample Is Taken.

Each Plotted Point Incorporates Information From All The Previous Subgroups Or Observations Based On The Weight That You Specify.

Related Post: