Eye Bolt Capacity Chart

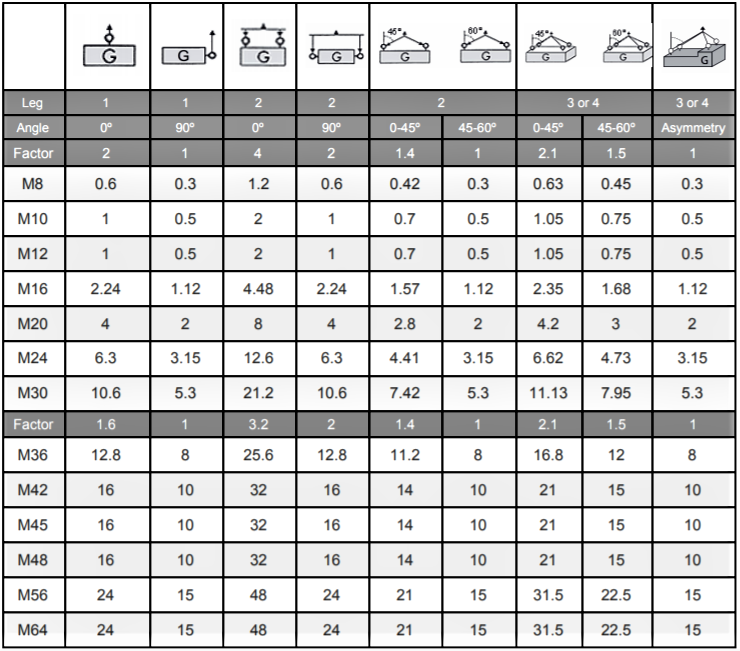

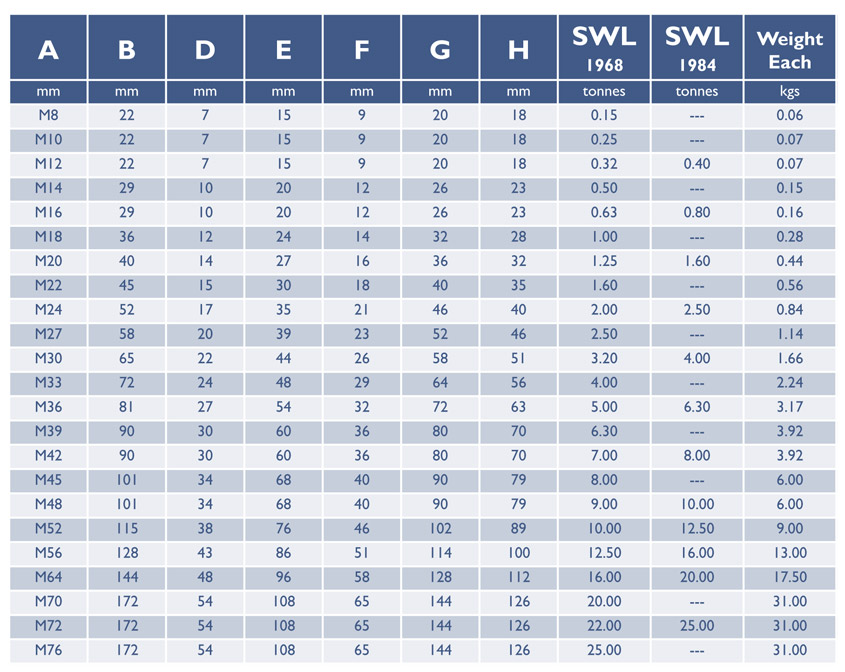

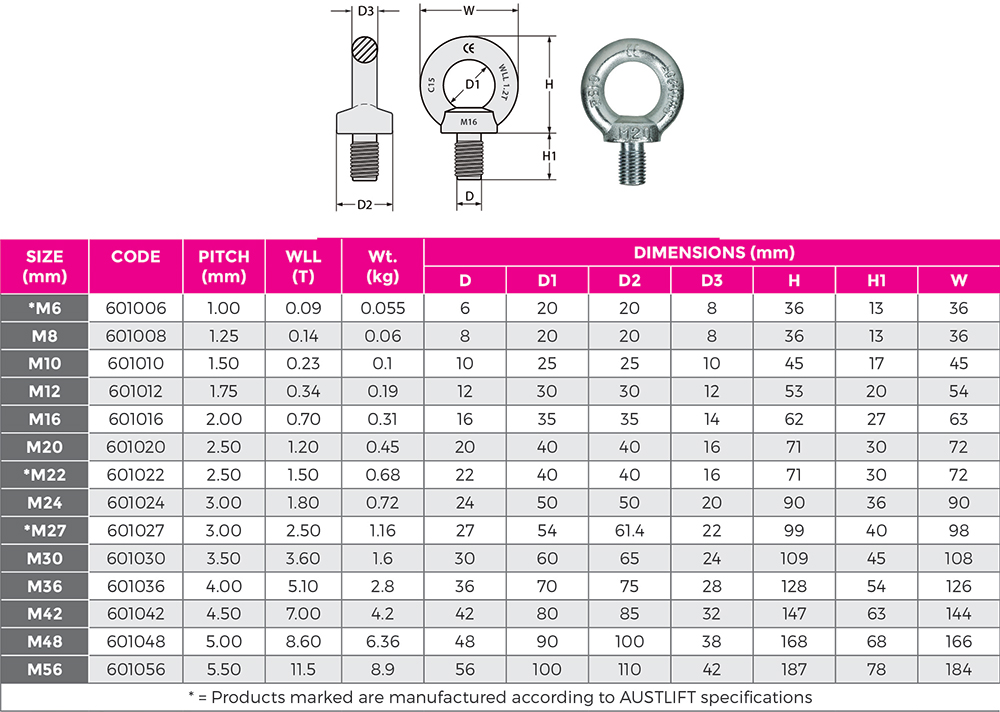

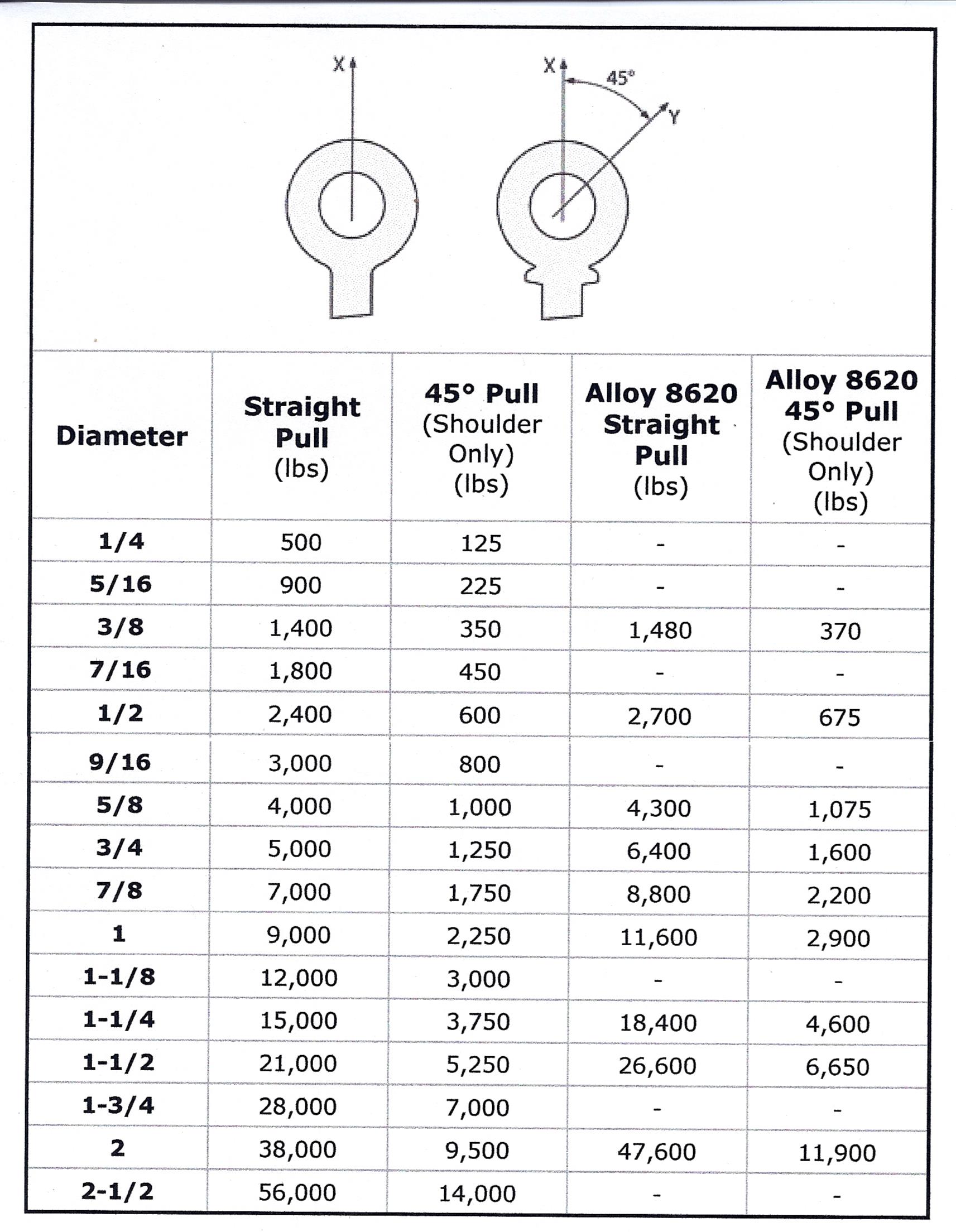

Eye Bolt Capacity Chart - Working in pairs loads for inclined for collared loading eyebolts. Our guide will explain what eye bolts are, the different types, their uses, sizes, and lifting capacity. When the load is applied to the eye in this direction it will bend. Eye bolts are such tools. It is important to ensure proper alignment of. Eye bolt working load chart (straight pull, no angle) The minimum threaded shank length of eyebolts must be one thread diameter to attain the rated capacity. Web this is a ½” x 6 shoulder eye bolt and a ½” x 6 stainless steel lag eye bolt. The larger the diameter of the shank, the larger the working load limit. Web the following charts and information will assist you: Web din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load handling equipment). Three times allowance load with same bolt size. Eye bolt working load chart (straight pull, no angle) No greater load should be applied to an eyebolt than the. When the load is applied to the eye in this direction it will bend. Web all dimensions are according to asme b18.15 standard. ・compared with chi, swivel lifting eye bolt has approx. Working in pairs loads for inclined for collared loading eyebolts. Web the following guidelines of lifting eye bolts din 580 have to be observed in addition to the. Before inserting any eye bolts on your working surface, decide whether it’ll be at an angle or not. It is important to ensure proper alignment of. Web din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load handling equipment). The eye. When the load is applied to the eye in this direction it will bend. Our guide will explain what eye bolts are, the different types, their uses, sizes, and lifting capacity. Web this standard specifies the characteristics of eye bolts made of steel and stainless steel and provides information for their correct use in hoist operations (as part of slings. Web the following charts and information will assist you: The length of the thread of the assembly hole must be equal to the length of the thread of the pin of the eyebolt; Maximum (metric threads) recommended when used. Web sling strength at 45° is 71% of vertical sling capacity. Maximum pair of eyebolts load (w) when to be the. Web din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load handling equipment). Eye bolt working load chart (straight pull, no angle) Maximum (metric threads) recommended when used. The eye bolt must be of fully screwed in to achieve a perfect. When the load is applied to the eye in this direction it will bend. Web all dimensions are according to asme b18.15 standard. The eye bolt (otherwise known as a lifting eye bolt or eyelet) is a type of bolt with a loop at one end. Maximum (metric threads) recommended when used. Web the following charts and information will assist. Eye bolts according to this standard can be used in a temperature range from −20 ° c to +200 ° c without any restriction of the load. Web the following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table: Our guide will explain what eye bolts are,. Web sling strength at 45° is 71% of vertical sling capacity. The eye bolt must be of fully screwed in to achieve a perfect contact between the two mating faces. Web all dimensions are according to asme b18.15 standard. There shall be no debris or contaminants present in the thread or underside of collar. When the load is applied to. Web the following guidelines of lifting eye bolts din 580 have to be observed in addition to the load values given in the above table: Web the following charts and information will assist you: Maximum (metric threads) recommended when used. Web ・can safely use swivel lifting eye bolt even when the lifting work from side direction, beveled direction or under. Web this standard specifies the characteristics of eye bolts made of steel and stainless steel and provides information for their correct use in hoist operations (as part of slings and as a load suspension device). There are certain tools whose proper selection and use go beyond making your job faster and easier and actually affect workplace safety. The larger the diameter of the shank, the larger the working load limit. Web this is a ½” x 6 shoulder eye bolt and a ½” x 6 stainless steel lag eye bolt. No greater load should be applied to an eyebolt than the rated capacity listed. The eye bolt must be of fully screwed in to achieve a perfect contact between the two mating faces. The chart will pinpoint the detailed lengths and diameters in your eye bolt. When the load is applied to the eye in this direction it will bend. Web working loading limits for lifting eyes are based on a straight vertical lift in a gradually increasing manner, and should never be used for angular lifts. Meets or exceeds all requirements of asme b30.26 including identification, ductility, design factor, proof load and temperature requirements. The length of the thread of the assembly hole must be equal to the length of the thread of the pin of the eyebolt; The 6” measurement refers to the length of the shank. Topics covered in this guide. Web the working load limits for regular forged eye bolts can be found on our forged eye bolt working load limits page. Maximum (metric threads) recommended when used. Web din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load handling equipment).Eye Bolt Capacity Chart

Eye Bolts A Complete Guide

Metric Eye Bolt Sizes Chart

Stainless Steel Eye Bolt With Shoulder & Ring SS Eye Bolt Screw Anchor

Stainless Steel Eye Bolt With Shoulder & Ring SS Eye Bolt Screw Anchor

Eye Bolt Size Chart Pdf A Visual Reference of Charts Chart Master

Eye Bolt Rating and Specifications Screw Building Engineering

Swivel Eye Bolt Capacity Chart

Eye Bolt DIN580 Zinc Austlift

Eye Bolt Load Chart

Web An Eye Bolt Size Chart Will Help You Figure Out Which Bolt To Use Based On The Weight Capacity.

Selecting The Right Tool For The Job Can Make A Huge Difference In Productivity And Quality Of Work.

It Is Important To Ensure Proper Alignment Of.

Web ・Can Safely Use Swivel Lifting Eye Bolt Even When The Lifting Work From Side Direction, Beveled Direction Or Under Tensile Condition Which Are Dangerous With The Conventional Eye Bolt Of Chi.

Related Post: