Eye Bolt Rating Chart

Eye Bolt Rating Chart - Web regular, shoulder, lag, and machinery. They are used for a wide variety of material lifting applications and may either pivot or swivel. This standard specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load handling equipment). Web forged eye bolt capacity and strength chart to show rated load capacities, proof load and breaking strength of a selected forged threaded eye bolt. Web collared eyebolt working load chart. Check with the bolt manufacturer to confirm exact weight capacity limits, but following is a helpful table that shows how much weight most eye. Maximum (metric threads) recommended when used. Load limits are based on a safety factor of 5 to 1. Angular lifts will significantly lower working load limits and should be avoided whenever possible. Din 580 technical delivery conditions. Web the working load limits for regular forged eye bolts can be found on our forged eye bolt working load limits page. Web quenched & tempered • design factor 5/1. Web din 580 minimum breaking forces. Maximum (metric threads) recommended when used. Furnished with standard hot dip galvanized hex nuts. Maximum (metric threads) recommended when used. Screw eyes are sold by industry trade sizes (e.g. The eye bolt is inserted through a hole and secured on the back side with a nut. Web an eye bolt size chart will help you figure out which bolt to use based on the weight capacity. Web forged eye bolt capacity and strength chart. Any angle beyond vertical (axial lift ) will reduce the rating capacity refer to load charts. Working in pairs loads for inclined for collared loading eyebolts. Standard forged eye bolts should not be used with angular lifts. They are used for a wide variety of material lifting applications and may either pivot or swivel. Web collared eyebolt working load chart. Screw eyes are sold by industry trade sizes (e.g. Working in pairs loads for inclined for collared loading eyebolts. Maximum pair of eyebolts load (w) when to be the lifted by a angle between sling legs is: Any angle beyond vertical (axial lift ) will reduce the rating capacity refer to load charts. Web working load limits for eye bolts. Web forged eye bolt sizes chart according to asme b18.15 for plain and shoulder eye bolts. Wire eye bolts should never be used with angular lifts. Web quenched & tempered • design factor 5/1. All bolts hot dip galvanized after threading (unc). The chart will pinpoint the. Check with the bolt manufacturer to confirm exact weight capacity limits, but following is a helpful table that shows how much weight most eye. Web collared eyebolt working load chart. Web some important notes from the asme b18.15: Web working load limits for eye bolts are based on a straight vertical lift in a gradually increasing manner. Working in pairs. Load limits are based on a safety factor of 5 to 1. Web table according to din 444: Web this standard specifies the characteristics of eye bolts made of steel and stainless steel and provides information for their correct use in hoist operations (as part of slings and as a load suspension device). Angular lifts will significantly lower working load. All the information provided on this website is provided on an “as is” and “as commonly used in production” basis and you agree that you use such information entirely at your own risk. Web in case you didn’t already know, an eye bolt’s “rated capacity” describes how heavy of a load a single eye bolt can support when the load. They are used for a wide variety of material lifting applications and may either pivot or swivel. Angular lifts will significantly lower working load limits and should be avoided whenever possible. Web working load limits for eye bolts are based on a straight vertical lift in a gradually increasing manner. Web din 580 minimum breaking forces. These fittings are made. Web din 580 minimum breaking forces. Web regular, shoulder, lag, and machinery. Before inserting any eye bolts on your working surface, decide whether it’ll be at an angle or not. Eye bolts are such tools. Standard forged eye bolts should not be used with angular lifts. Web in case you didn’t already know, an eye bolt’s “rated capacity” describes how heavy of a load a single eye bolt can support when the load is angled at 0 degrees through the eye bolt’s shank. Wire eye bolts should never be used with angular lifts. Maximum (metric threads) recommended when used. Web regular, shoulder, lag, and machinery. Web working load limits for eye bolts are based on a straight vertical lift in a gradually increasing manner. 112), which correspond to a specific wire diameter, inside eye diameter and length. The chart will pinpoint the. All bolts hot dip galvanized after threading (unc). Web working load limits for eye bolts are based on a straight vertical lift in a gradually increasing manner. Load limits are based on a safety factor of 4 to 1. Web learn more about our eye bolts including eye bolt capacity and eye bolt sizes. They are used for a wide variety of material lifting applications and may either pivot or swivel. Loads should always be applied to eye bolts in the plane of the eye, not at an angle to this plane. Web the eye bolt (otherwise known as a lifting eye bolt or eyelet) is a type of bolt with a loop at one end. Maximum pair of eyebolts load (w) when to be the lifted by a angle between sling legs is: Web din 580 minimum breaking forces.

Stainless steel eye bolt sizes mserlstatus

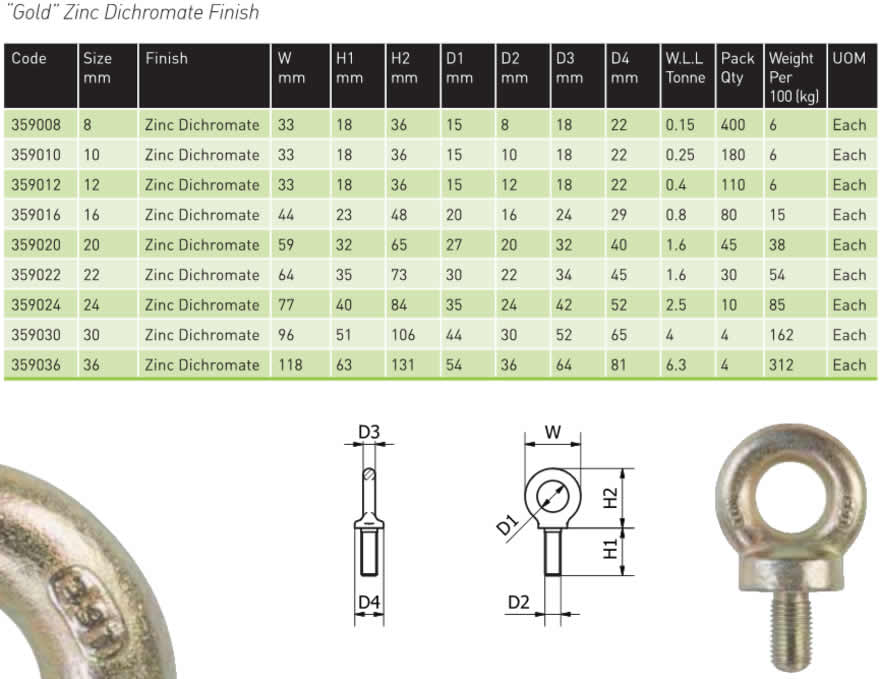

Eye Bolts All About Lifting & Safety

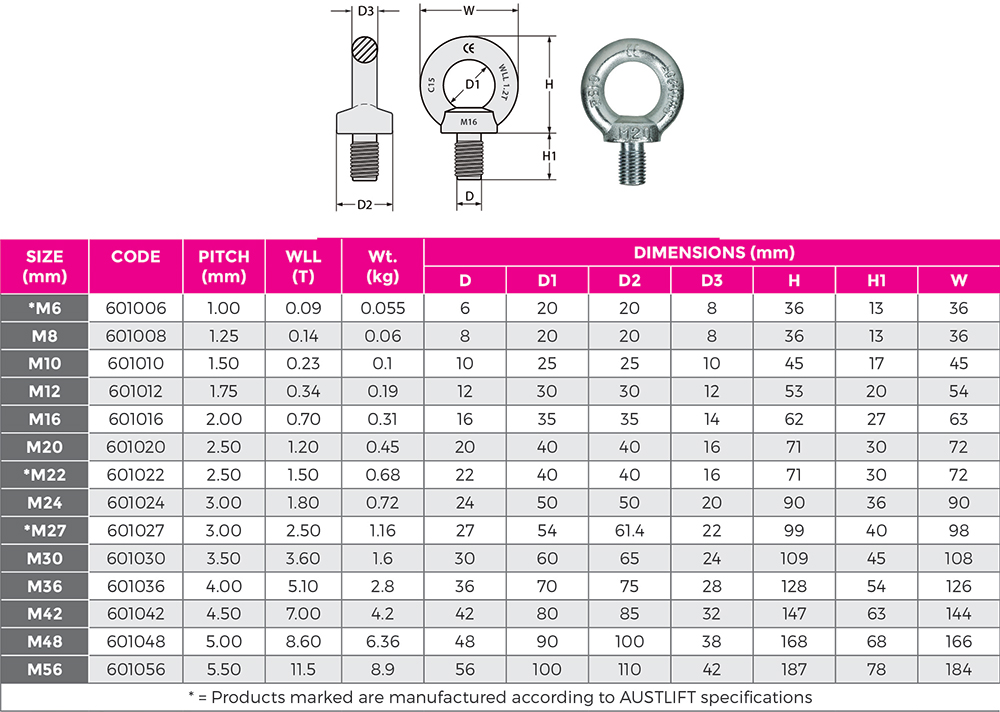

AUSTLIFT Eye Bolt DIN580 Zinc The Lifting Guys

Eye Bolt Manufacturer In India and Lifting Eye Bolts Anchor

Eye Bolt Rating and Specifications Screw Building Engineering

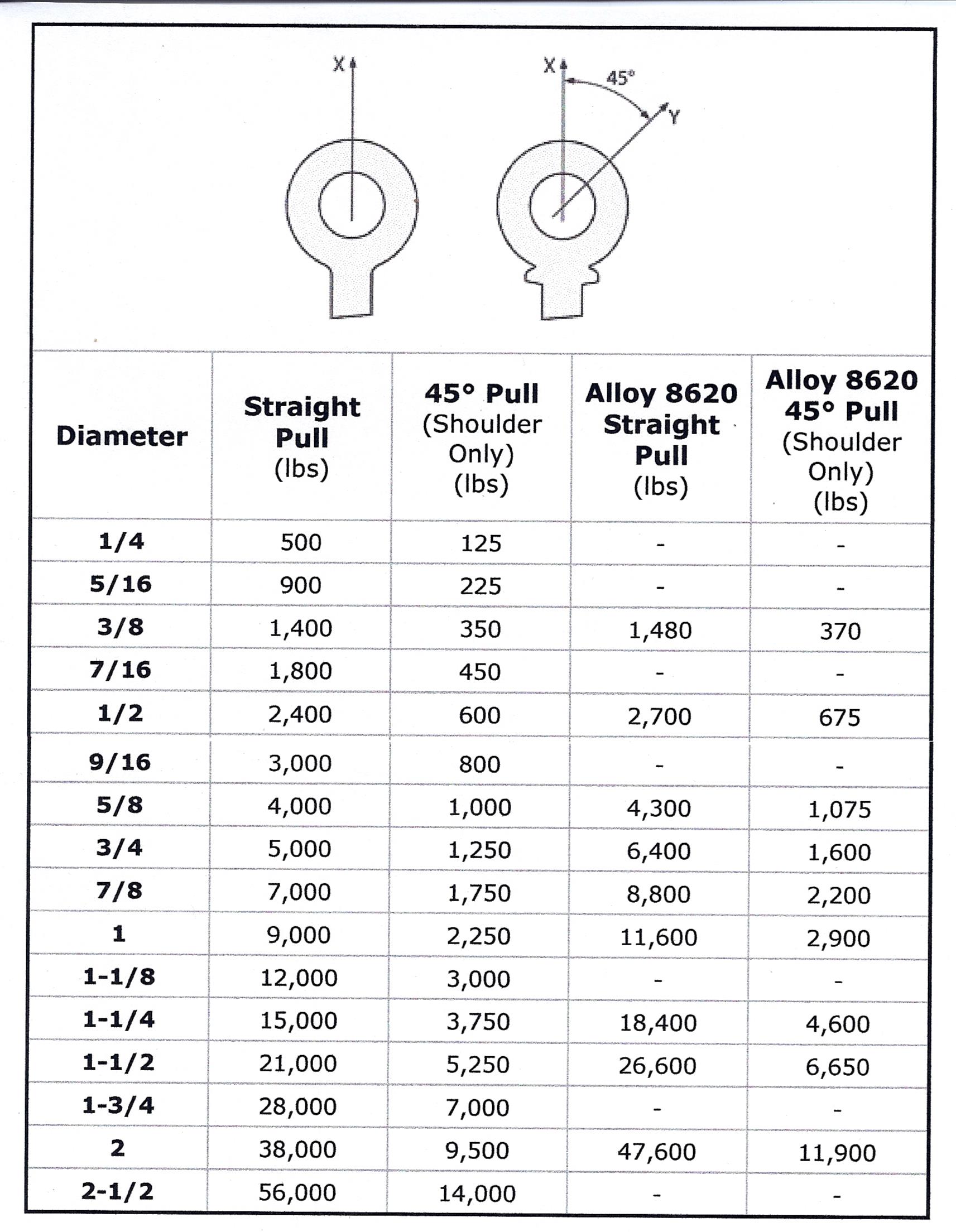

Eye Bolt Load Chart

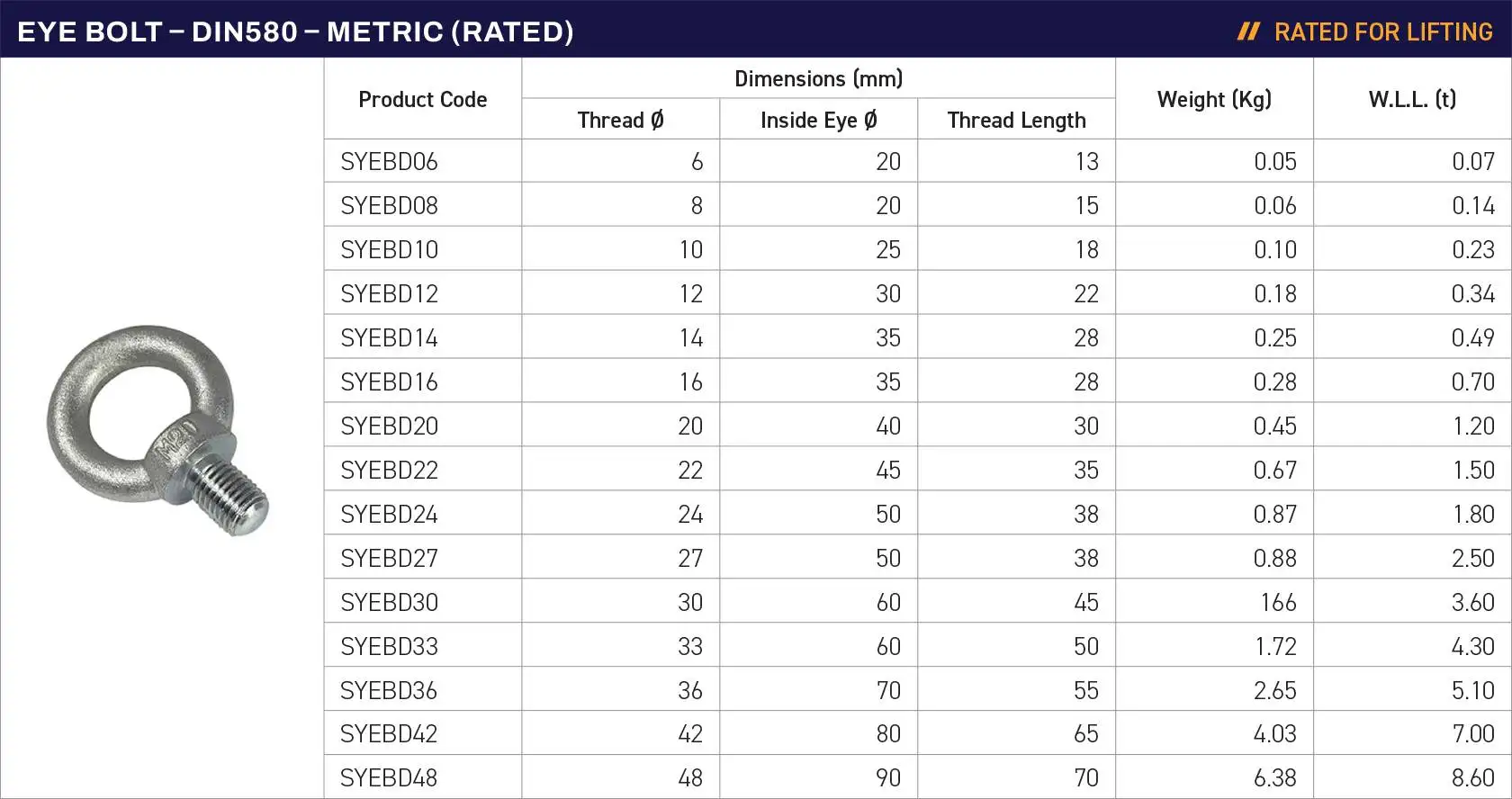

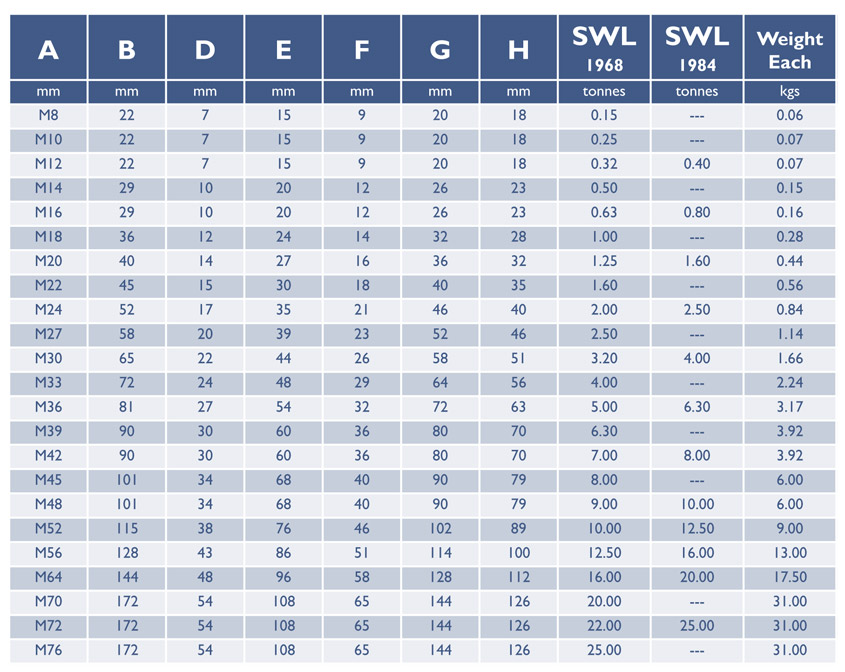

Eye Bolt DIN580 Metric Rated Chain & Rigging Supplies

Eye Bolt Load Chart

Eye Bolt Size Chart Pdf A Visual Reference of Charts Chart Master

Stainless Steel Eye Bolt With Shoulder & Ring SS Eye Bolt Screw Anchor

The Eye Bolt Is Inserted Through A Hole And Secured On The Back Side With A Nut.

All The Information Provided On This Website Is Provided On An “As Is” And “As Commonly Used In Production” Basis And You Agree That You Use Such Information Entirely At Your Own Risk.

Web Quenched & Tempered • Design Factor 5/1.

Furnished With Standard Hot Dip Galvanized Hex Nuts.

Related Post: