Flux Core Settings Chart

Flux Core Settings Chart - This chart is essential for achieving proper weld quality and avoiding common welding defects. The lincoln 140 settings chart blue column. 20 ( voltage), 375 ( wire speed) 8 mm material thickness: Here's a guide to setting it up the right. 20 ( voltage), 280 ( wire speed) 4.8mm material thickness : A flux core mig welding wire speed and voltage chart can significantly simplify the setup process for different welding jobs. They are the same welder. Web chart usage for various welding jobs. When setting up a for flux cored arc welding machine there is no simple answer! Web settings based on butt welds. Web how to setup flux core mig welder detailed guide. 20 ( voltage), 280 ( wire speed) 4.8mm material thickness : 20.5 ( voltage), 335 ( wire speed) 6.4mm material thickness : So the example giving is 1/8 or.125 thick steel. For different welding positions and welding types the wire parameters happen to be different every time. **co2 gas is economical and has deeper penetration on steel, but may be too hot for thin metal. A flux core mig welding wire speed and voltage chart can significantly simplify the setup process for different welding jobs. Marketed and sold by different lincoln distribution partners. 75% argon / 25% co2 is better on thin steels, produces less spatter and. Web here goes a chart for 0.045 flux core vertical settings depending on several welding positions. 20 ( voltage), 375 ( wire speed) 8 mm material thickness: Web how to setup flux core mig welder detailed guide. .023/.024 the number is 3.5. Yield strength represents the maximum force applied before the piece deforms plastically. Web for.045 wire the number is 1. For different welding positions and welding types the wire parameters happen to be different every time. We talk about safety equip. Web 59k views 9 months ago. The lincoln 140 setting chart yellow column. Web good for outdoor windy conditions. Everything you need to know to get your flux core or mig welder setup correctly! Marketed and sold by different lincoln distribution partners. Use it as a guideline to achieve proper penetration and weld strength. The lincoln 140 settings chart blue column. Web settings based on butt welds. So the example giving is 1/8 or.125 thick steel. This chart is essential for achieving proper weld quality and avoiding common welding defects. Yield strength represents the maximum force applied before the piece deforms plastically. Web 59k views 9 months ago. For.035 wire the number is 1.6. Web chart usage for various welding jobs. Web a flux core welding amperage chart specifies the required amperage based on the wire diameter and material thickness. 20 ( voltage), 280 ( wire speed) 4.8mm material thickness : Flux core welding, or fcaw, is a versatile welding method that’s both portable and effective for various. **co2 gas is economical and has deeper penetration on steel, but may be too hot for thin metal. 20 ( voltage), 280 ( wire speed) 4.8mm material thickness : We talk about safety equip. Web here goes a chart for 0.045 flux core vertical settings depending on several welding positions. For.035 wire the number is 1.6. This chart is essential for achieving proper weld quality and avoiding common welding defects. Joint design, fitup, backup, position, bead size and stickout may alter conditions. Web 59k views 9 months ago. Web chart usage for various welding jobs. The lincoln 140 settings chart blue column. The lincoln 140 settings chart blue column. 1/16 flux core wire settings. 75% argon / 25% co2 is better on thin steels, produces less spatter and better bead appearance. We talk about safety equip. They are the same welder. Yield strength represents the maximum force applied before the piece deforms plastically. The lincoln 140 setting chart green column. Refer to the chart to determine each job’s optimal wire speed and voltage settings, ensuring consistent and reliable welds. 20.5 ( voltage), 335 ( wire speed) 6.4mm material thickness : Web good for outdoor windy conditions. It gives a basic guideline on how to setup you welder depending on electrode size and shielding gas. Everything you need to know to get your flux core or mig welder setup correctly! They are the same welder. Web here goes a chart for 0.045 flux core vertical settings depending on several welding positions. So the example giving is 1/8 or.125 thick steel. .023/.024 the number is 3.5. Flux core welding, or fcaw, is a versatile welding method that’s both portable and effective for various metal thicknesses and outdoor conditions. There is some nuance to it. Here's a guide to setting it up the right. Tensile strength represents the maximum force applied to the weld before it fails, and it is measured in pounds per square inch (psi) or megapascals (mpa). Web settings based on butt welds.

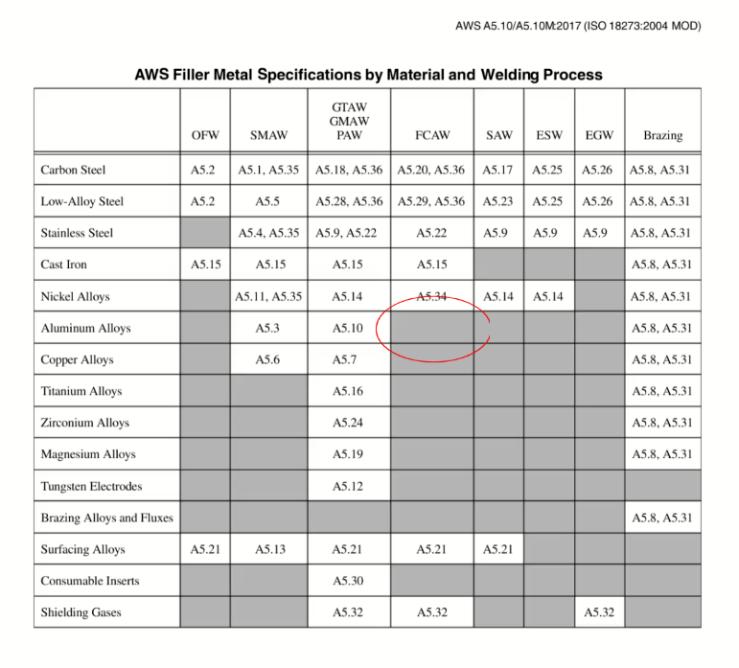

Flux Core Aluminum Welding Wire What You Need to Know WelditU

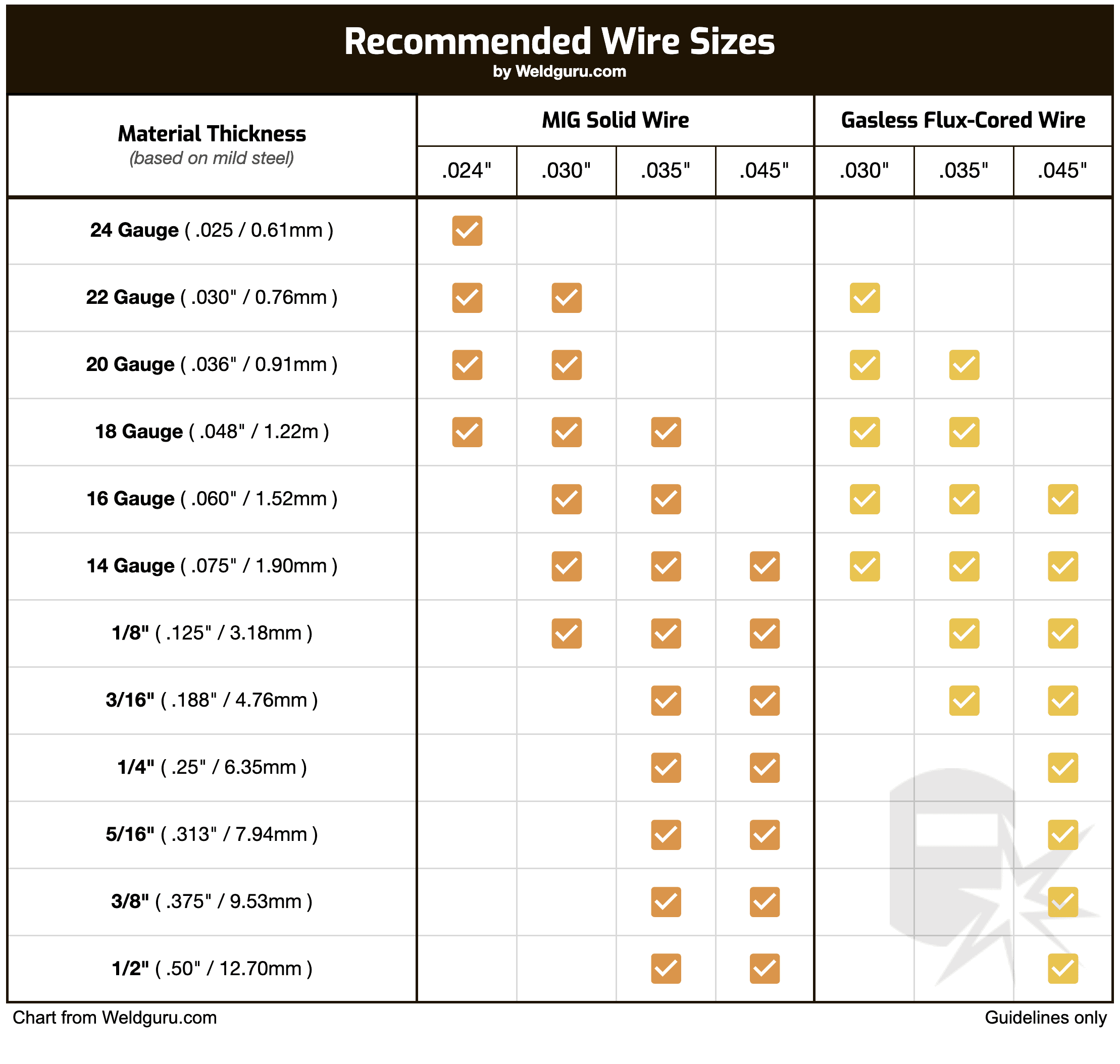

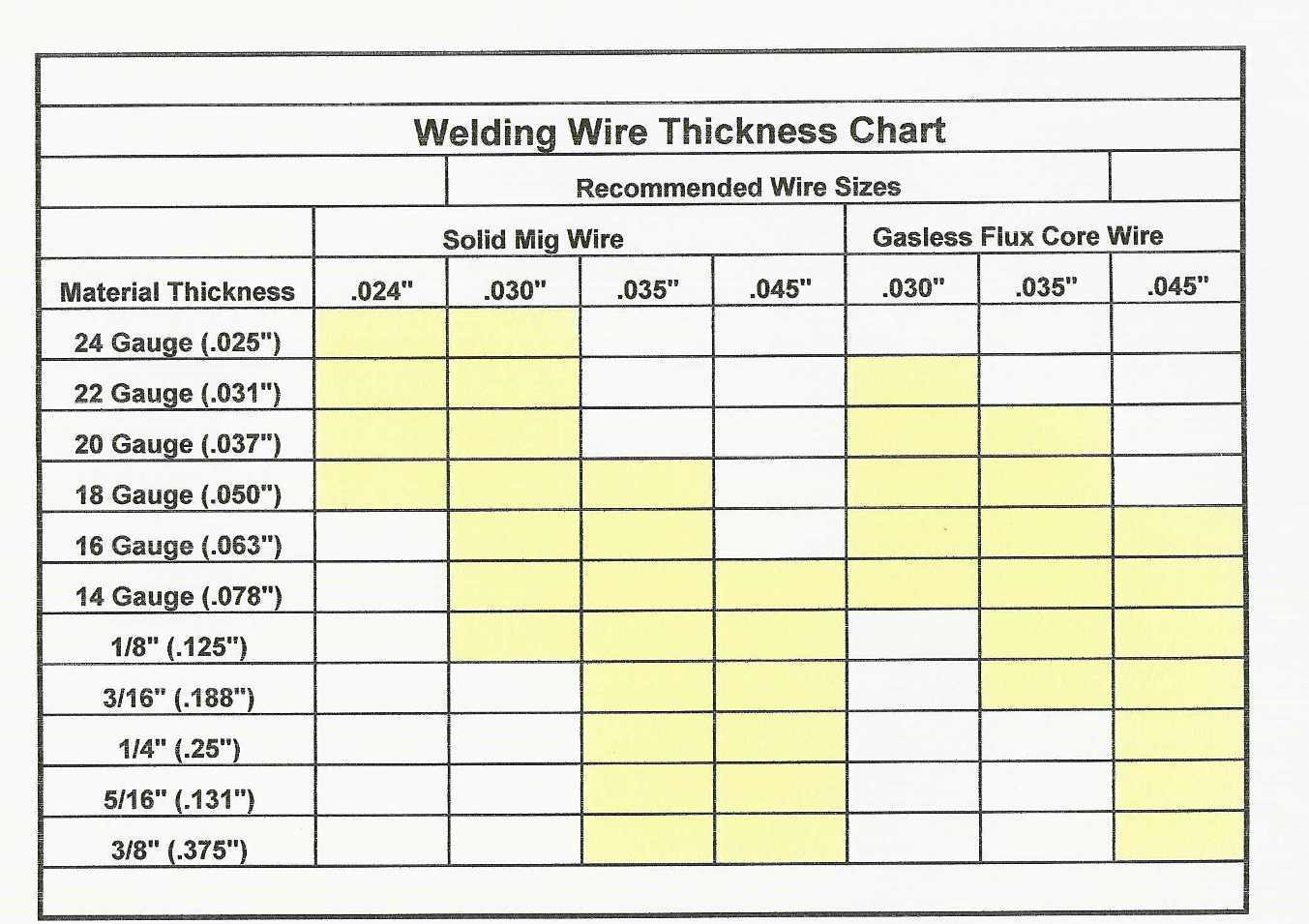

Flux Core Wire Size Chart

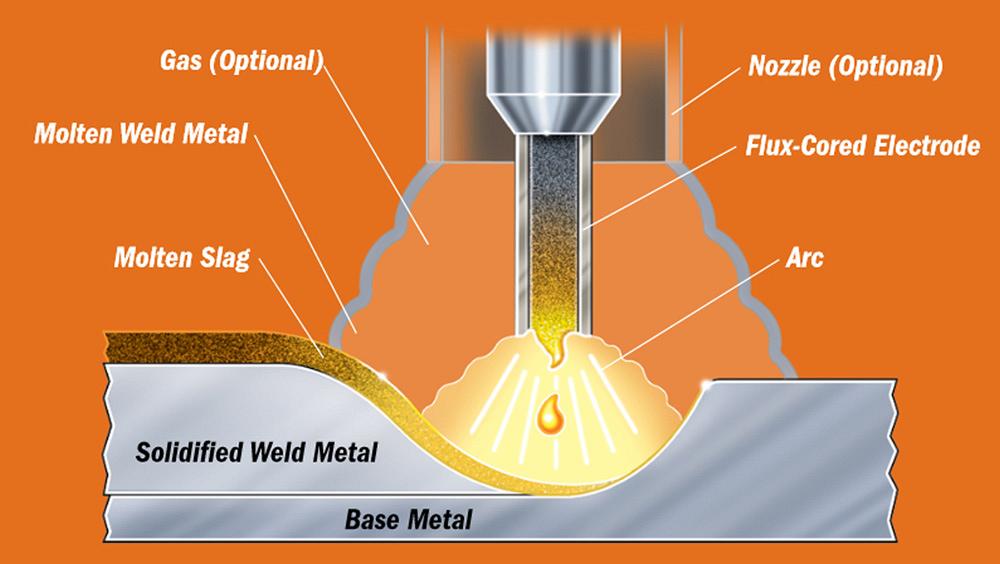

Understanding the Basics of FluxCored Wires Fabricating and Metalworking

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

What flux core wires to keep on hand? Welding Site

newbe initial review of yeswelder mig205ds using 110v flux core

instructions on welding in auto floor pan Grumpys Performance Garage

Flux Core Settings Chart

Getting to Know Fluxcored Wires The Fabricator

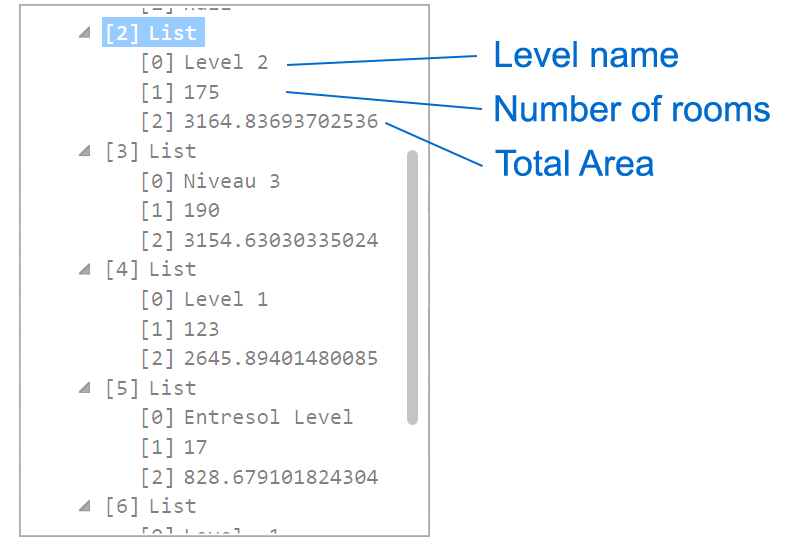

MIG FluxCored Welding Calculator Electrical Components

Web This Is A Millermatic 250 Fcaw Setting Chart.

Web A Flux Core Welding Amperage Chart Specifies The Required Amperage Based On The Wire Diameter And Material Thickness.

For Different Welding Positions And Welding Types The Wire Parameters Happen To Be Different Every Time.

Marketed And Sold By Different Lincoln Distribution Partners.

Related Post: