Flux Core Wire Size Chart

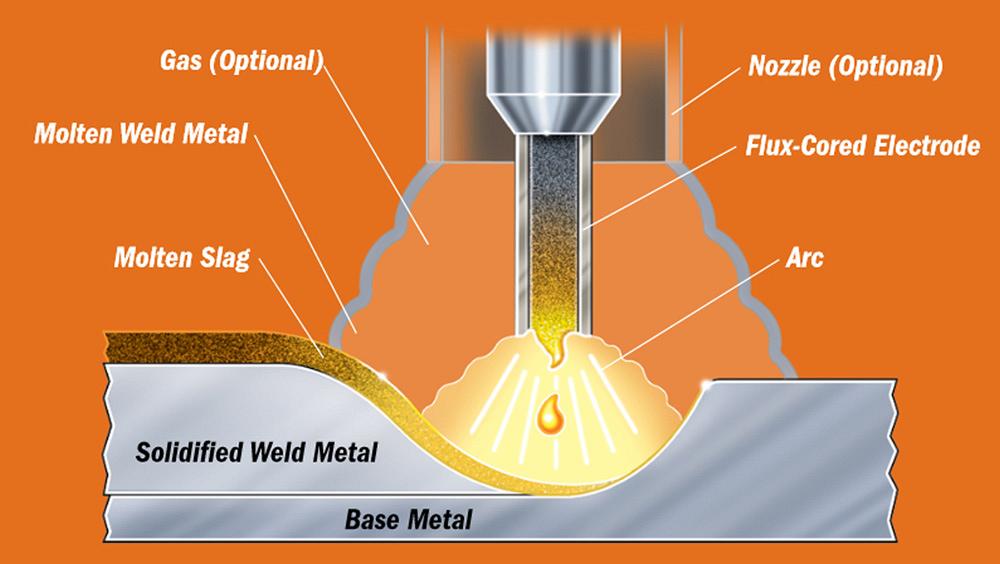

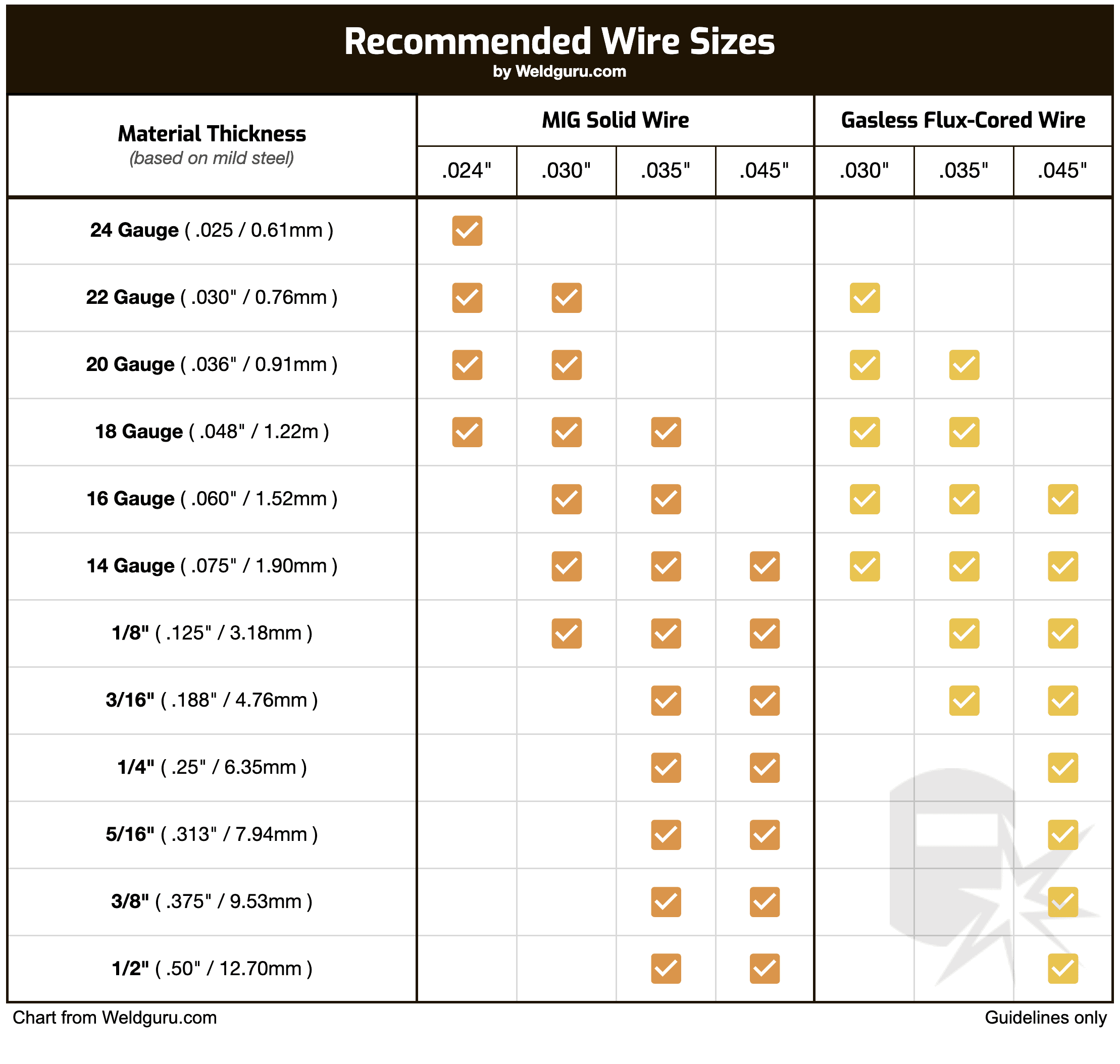

Flux Core Wire Size Chart - What diameter flux core wire are you using? What material are you welding? What is self shielded flux cored wire? If you were also looking for a special wire for a mig welder, you end up at the right spot because we have a detailed guide. In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. In this case, the number 6 means that the wire contains additional deoxidizers that help when welding rusty or dirty metal. The last digit indicates the chemical additives added to the wire, which affect the resulting bead and the polarity. Web the flux core mig welding wire speed and voltage chart offers precise guidance on optimal voltage and wire speed settings in mig welding. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. Flux core welding settings chart. The last digit indicates the chemical additives added to the wire, which affect the resulting bead and the polarity. Web what is this thing called flux? Let's talk to andy next and hear his story. And gives your hot metal the protection it needs from. The flux is a chemical compound that melts in the heat of your welding arc. Understanding the different types and sizes of flux core wire is essential for. Let's listen to brad's story next. The last digit indicates the chemical additives added to the wire, which affect the resulting bead and the polarity. In making a mig wire purchase, your. The last digit indicates the chemical additives added to the wire, which affect the resulting bead and the polarity. What material are you welding? Web this chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. What is this slag from your flux. Web table of contents. What types flux core wire are there? .30 vs.35 flux core wire? Web a general rule of thumb is you need 1 amp of power for every 0.001 inches of steel. What is this slag from your flux core wire welding? What's inside flux core wire? The compounds turn to gas in your arc’s heat. What's the difference between.030 and.035 welding wire? Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. Web the most common sizes for welding on sheet metal are 0.35 and 0.45. Mig welding has different qualities and types of wires that have unique features. In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. What about your metal and your flux core wire? What's the difference between.030 and.035 welding wire? It differs from mig welding in that it doesn’t require an external shielding. If you were also looking for a special wire for a mig welder, you end up at the right spot because we have a detailed guide. And gives your hot metal the protection it needs from. Flux core welding settings chart. Mig & flux core welding wire types with key specifications (guide with chart) updated: Mig welding has different qualities. Web a general rule of thumb is you need 1 amp of power for every 0.001 inches of steel. Mig welding has different qualities and types of wires that have unique features. What is this slag from your flux core wire welding? Web in this post, you will learn everything you need to know about choosing between.030 and.035 flux core. Web the flux core mig welding wire speed and voltage chart offers precise guidance on optimal voltage and wire speed settings in mig welding. Web in this post, you will learn everything you need to know about choosing between.030 and.035 flux core wire size. Web mig flux core wire has been around since the 1950s, and at this point, it. Web the size of the flux core wire used for welding depends on the thickness of the metal being welded and the desired penetration and bead size. What about your metal and your flux core wire? Its low hydrogen content makes it suitable for highly demanding applications, ensuring the weld’s integrity and durability. What diameter flux core wire are you. What's the difference between.030 and.035 welding wire? And gives your hot metal the protection it needs from. Its low hydrogen content makes it suitable for highly demanding applications, ensuring the weld’s integrity and durability. Mig welding has different qualities and types of wires that have unique features. What types flux core wire are there? The compounds turn to gas in your arc’s heat. Let's listen to brad's story next. What material are you welding? It differs from mig welding in that it doesn’t require an external shielding gas, such as carbon dioxide or argon, to protect the weld pool from contamination. Web what is this thing called flux? Web the size of the flux core wire used for welding depends on the thickness of the metal being welded and the desired penetration and bead size. This chart is essential for achieving proper weld quality and avoiding common welding defects. What is this slag from your flux core wire welding? Flux core wire speed and voltage chart. Web in this post, you will learn everything you need to know about choosing between.030 and.035 flux core wire size. In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed.

Flux Cored Wires Self Shielded vs Gas Shielded

Understanding the Basics of FluxCored Wires Fabricating and Metalworking

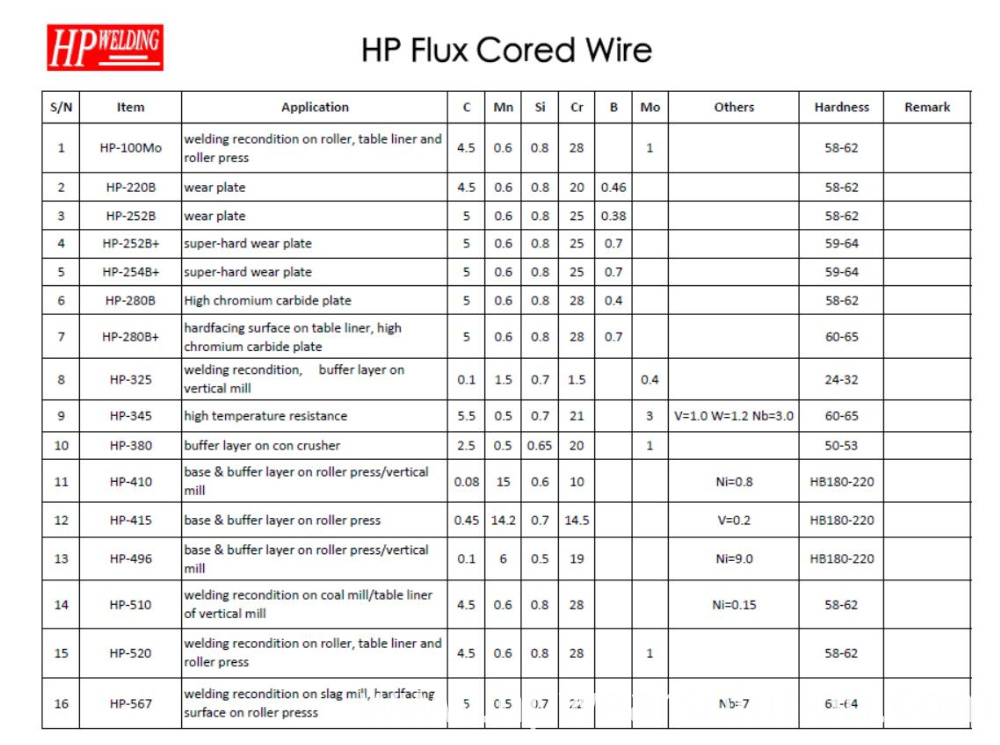

Flux Cored Welding Wires China Manufacturer

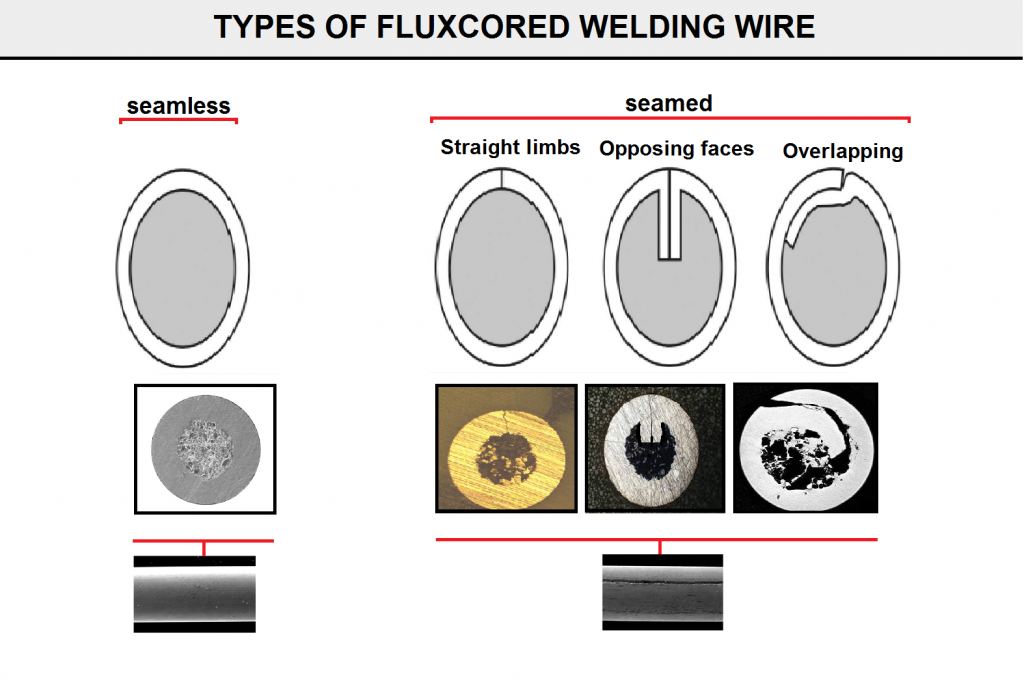

Flux Cored Welding Wire Manufacturing from A to Z by WESPEC

Getting to Know Fluxcored Wires The Fabricator

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

Flux Core Wire Types & Sizes All You Need To Know

What flux core wires to keep on hand? Welding Site

MIG + Flux Core Welding Wire Size Chart Beginner Welding Guide

Flux Core Wire Size Chart

Web Table Of Contents.

What Diameter Flux Core Wire Are You Using?

Understanding The Different Types And Sizes Of Flux Core Wire Is Essential For.

Web Table Of Contents.

Related Post: