Gear Pattern Chart

Gear Pattern Chart - Web we can determine how gears mesh by changing how close the pinion gear is to the ring gear centerline. Pulling off a proper differential setup comes down to precise adjustments. Five cut ring & pinion gears (face milled): We live in a global economy and the parts we are working with, oem or aftermarket, are being sourced all over the world. Web the toe of the gear tooth is the portion of the tooth surface at the end towards the center. Even if you farm this work out to a specialist, you should understand what’s involved. Web there are two types of gears which are determined by the machining method. Web pressure angle is the leaning angle of a gear tooth, an element determining the tooth profile. ( gear tooth contact pattern )in this video i'm going to show you how to correctly read a differ. One is manufactured by face hobbing, while the other one is manufactured by face milling. We live in a global economy and the parts we are working with, oem or aftermarket, are being sourced all over the world. See manufacturer or the gearset for exact specifications and special instructions before attempting to adjust the ring and pinion. The coast pattern will move deeper toward the tooth flank and slightly toward the heel. Web this chart. Used gearing may not display the round, even contact pattern found in new gear sets. Web this chart illustrates different patterns and adjustments. Web the toe of the gear tooth is the portion of the tooth surface at the end towards the center. This video was created to give people a basic understanding of how to read gear patterns when.. Reading contact patterns can be daunting when looking at the average gear installation guide. Most generally, gear teeth are equally spaced around the periphery of the gear. Web ring and pinion gear teeth are cut with the drive faces positioned closer to vertical and the coast faces at a steeper angle. The drive faces are also typically convex, curving outward. The drive faces are also typically convex, curving outward while coast sides are concave, curving inward. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Recently, the pressure angle (α) is usually set to 20°,. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Specified in catalog for most applications. ( gear tooth contact pattern )in this video i'm going to show you how to correctly read a differ. Reading contact patterns can be daunting when looking at the average gear installation. Web this chart illustrates different patterns and adjustments. Five cut ring & pinion gears (face milled): The top land of a gear tooth is the surface of the top of the tooth. Web ring gear contact pattern interpretation of face hobbed (uniform tooth depth) gear teeth. One is manufactured by face hobbing, while the other one is manufactured by face. The heel of the gear tooth is the portion of the tooth surface at the outer end. Web how to read a differential gear pattern: The prospect of installing and adjusting driveline ring & pinion gears can be intimidating for shops that don’t routinely perform this task. Web gear tooth patterns are harbingers… they can foretell whether your ring and. Web we can determine how gears mesh by changing how close the pinion gear is to the ring gear centerline. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the toe. Web we can determine how gears mesh by changing how close the pinion gear is to the. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Web how to read a differential gear pattern: Web pattern should range from just clear of the toe end to about 3/8” off the toe end.. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Web tooth height is measured from the top or crown of each tooth to the bottom or root of each gear tooth. The top land of. Web the toe of the gear tooth is the portion of the tooth surface at the end towards the center. Pulling off a proper differential setup comes down to precise adjustments. ( gear tooth contact pattern )in this video i'm going to show you how to correctly read a differ. The drive faces are also typically convex, curving outward while coast sides are concave, curving inward. Five cut ring & pinion gears (face milled): Reading contact patterns can be daunting when looking at the average gear installation guide. (important gear terminology and gear nomenclature in fig 2.2) reference line. Bearing preload, total turning preload, and ring gear backlash. Web ring gear contact pattern interpretation of face hobbed (uniform tooth depth) gear teeth. Specified in catalog for most applications. Used gearing may not display the round, even contact pattern found in new gear sets. Even if you farm this work out to a specialist, you should understand what’s involved. You must first determine the type of gear that you have in order to know which gear pattern chart to use as described in this bulletin. The heel of the gear tooth is the portion of the tooth surface at the outer end. Web this chart illustrates different patterns and adjustments. The gear may have a “pocket” at the heel end of pattern.

Repair Guides

10 Speed Shift Pattern

Differential Gear Patterns

Weber_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth

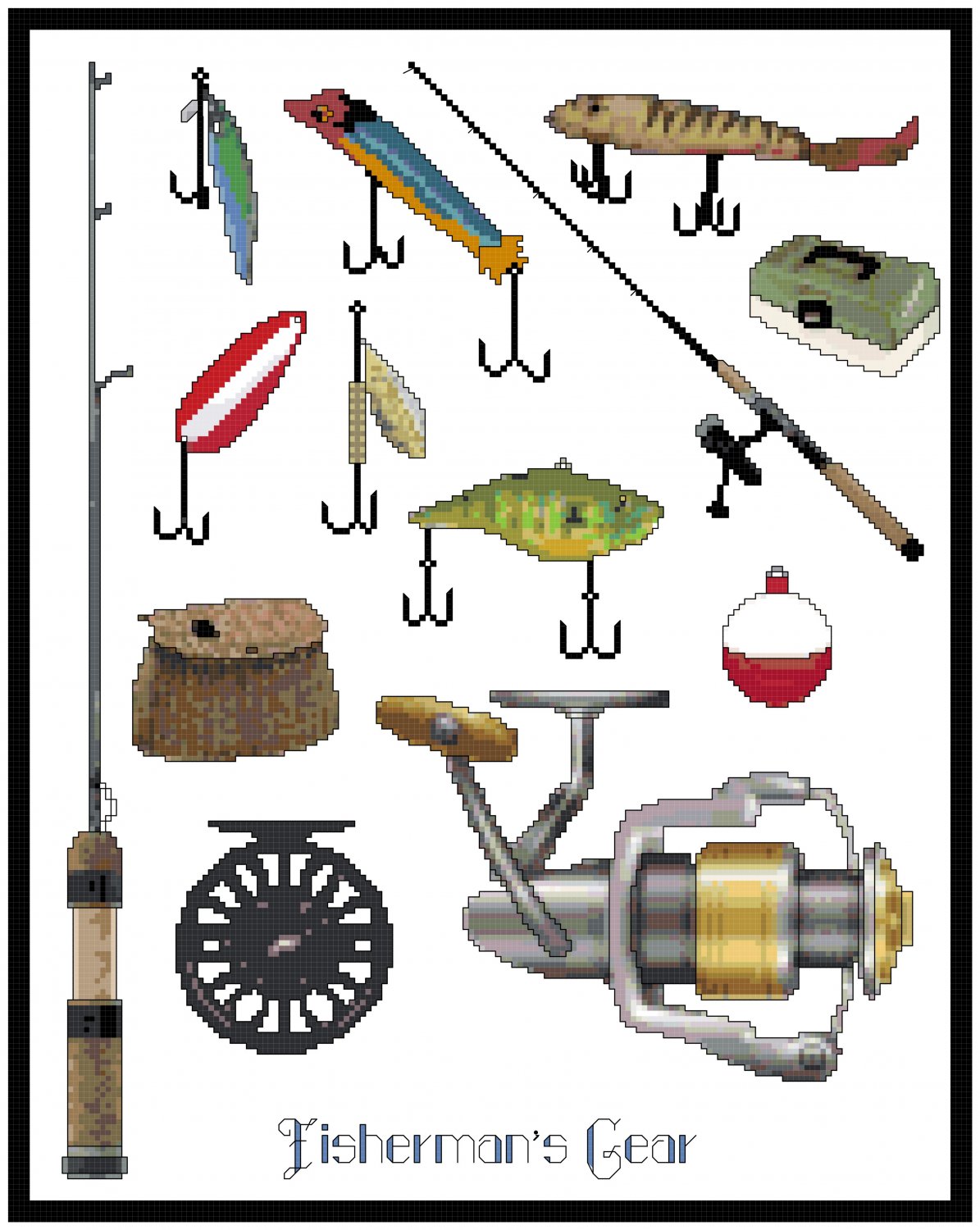

Fisherman's Gear Pattern Chart Graph

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Differential Installation Instructions West Coast Differentials

Can You Install Your Own Gears at Home?

Gear Diametrical Pitch Chart Jeff Thompson

How to Set up Your Rear Gear Correctly RacingJunk News

Web Ring And Pinion Gear Pattern Is One Of The Most Valuable Tools For Determining If A Differential Is Properly Set Up.

Web There Are Two Types Of Gears Which Are Determined By The Machining Method.

Proper Ring Gear To Pinion Gear Contact Pattern Is Critical For Quiet And Trouble Free Gear Set Operation.

Web Gear Tooth Patterns Are Harbingers… They Can Foretell Whether Your Ring And Pinion Gear Set Is Going To Live A Long And Prosperous Life Or If It’s Doomed To An Impending Catastrophic Failure.

Related Post: