Grain Drill Calibration Chart

Grain Drill Calibration Chart - Additionally, it is useful to check actual seeding rates by maintaining records of seed used and acres drilled over the years. When divided by 43,560 square feet (an acre) we get a calibration area of.069 acre. Consult seed chart for starting point. Calibrate the drill for a driving distance of 200 feet. Web we have designed a simple and straightforward calibration method that can be applied across a wide range of grain drill types and manufacturers. Flags to mark stopping and starting points 3. Drill settings can be chosen based on the wheat chart inside the grain bin of each drill. John deere 1910/1890 combination air drill calibration video There is no better way to be sure a your drill is planting at the desired rate than to calibrate it before planting! Find a detailed guide and a fact sheet on seed drill calibration. Web since the rate of seeding any oats with a grain drill will vary considerably with the degree of cleanness of the oats, the most satisfactory method of determining an accurate drill setting for any particular lot of seed is by a calibration test. Web we have designed a simple and straightforward calibration method that can be applied across a. There is no better way to be sure a your drill is planting at the desired rate than to calibrate it before planting! Calibrate the drill for a driving distance of 200 feet. Also, calibration can give producers confidence in their planting operation as. Web learn how to calibrate your grain or seed drill for different crops and varieties using. Web getting the correct amount of seed planted with a grain drill requires calibrating the drill before planting begins. Flags to mark stopping and starting points 3. John deere 1910/1890 combination air drill calibration video Determine the area seeded when driving the calibration distance. Additionally, it is useful to check actual seeding rates by maintaining records of seed used and. Turn drive tire 25 times. Web since the rate of seeding any oats with a grain drill will vary considerably with the degree of cleanness of the oats, the most satisfactory method of determining an accurate drill setting for any particular lot of seed is by a calibration test. Find out how to adjust the seed meter, measure the seeding. We have designed a simple and straightforward calibration method that can be applied across a wide range of grain drill types and manufacturers. Turn drive tire 25 times. Make sure the seed tubes are free of any debris or insects by blowing compressed air or running a wire through them. Remove seed hose and secure a bag/cup to catch seed.. Drill settings can be chosen based on the wheat chart inside the grain bin of each drill. Web the seeding rate chart provided by the drill manufacturer is a good starting point in obtaining desired seeding rates, but actual results will vary depending upon a number of variables including, mechanical condition of the drill, variety and seed lot, seed size,. Web we have designed a simple and straightforward calibration method that can be applied across a wide range of grain drill types and manufacturers. We have designed a simple and straightforward calibration method that can be applied across a wide range of grain drill types and manufacturers. The right place, the right time, the right rate. Web start right to. Also, calibration can give producers confidence in their planting operation as. Gram scale with 0.1 gram accuracy plastic sandwich bags 5. Web “with a scale on the grain drill or air seeder, you simply plant a known amount of acres, look at how much weight you’ve distributed over that number of acres and do a simple calculation to see if. Web getting the correct amount of seed planted with a grain drill requires calibrating the drill before planting begins. This involves minimal math, but does require a table that can be found. Grain drill width (ft) row spacing (in) landoll 5211 10 7.5 great plains 1006 nt 10 7.5 john deere 450 8 6.0 international 5100 15 7.0 john deere. Lower row units to engage. Web the seeding rate chart provided by the drill manufacturer is a good starting point in obtaining desired seeding rates, but actual results will vary depending upon a number of variables including, mechanical condition of the drill, variety and seed lot, seed size, and the addition of seed treatments and or inoculants. Seeding rate (pounds. Web grain drill fertilizer calibration table 1. Find a detailed guide and a fact sheet on seed drill calibration. Calibrate the drill using a driving distance of 200 feet. Consult seed chart for starting point. The right place, the right time, the right rate. John deere 1910/1890 combination air drill calibration video Find out how to adjust the seed meter, measure the seeding rate, and check the seed delivery system. Getting the correct seeding rate is important for high yielding wheat. Tape measure (150 feet) 2. Web since the rate of seeding any oats with a grain drill will vary considerably with the degree of cleanness of the oats, the most satisfactory method of determining an accurate drill setting for any particular lot of seed is by a calibration test. Seeding rate (pounds per acre) =. Web start right to end right: Web learn how to check the seeding rate of your grain drill using a seeding chart, a bag or cup, or a vacuum. Jim johnson, noble foundation soils and crops consultant, demonstrates. Drill settings can be chosen based on the wheat chart inside the grain bin of each drill. Pour 1 to 2 pounds of fertilizer into the empty grain cups.

MF30 drill calibration The Farming Forum

case grain drill settings Yesterday's Tractors

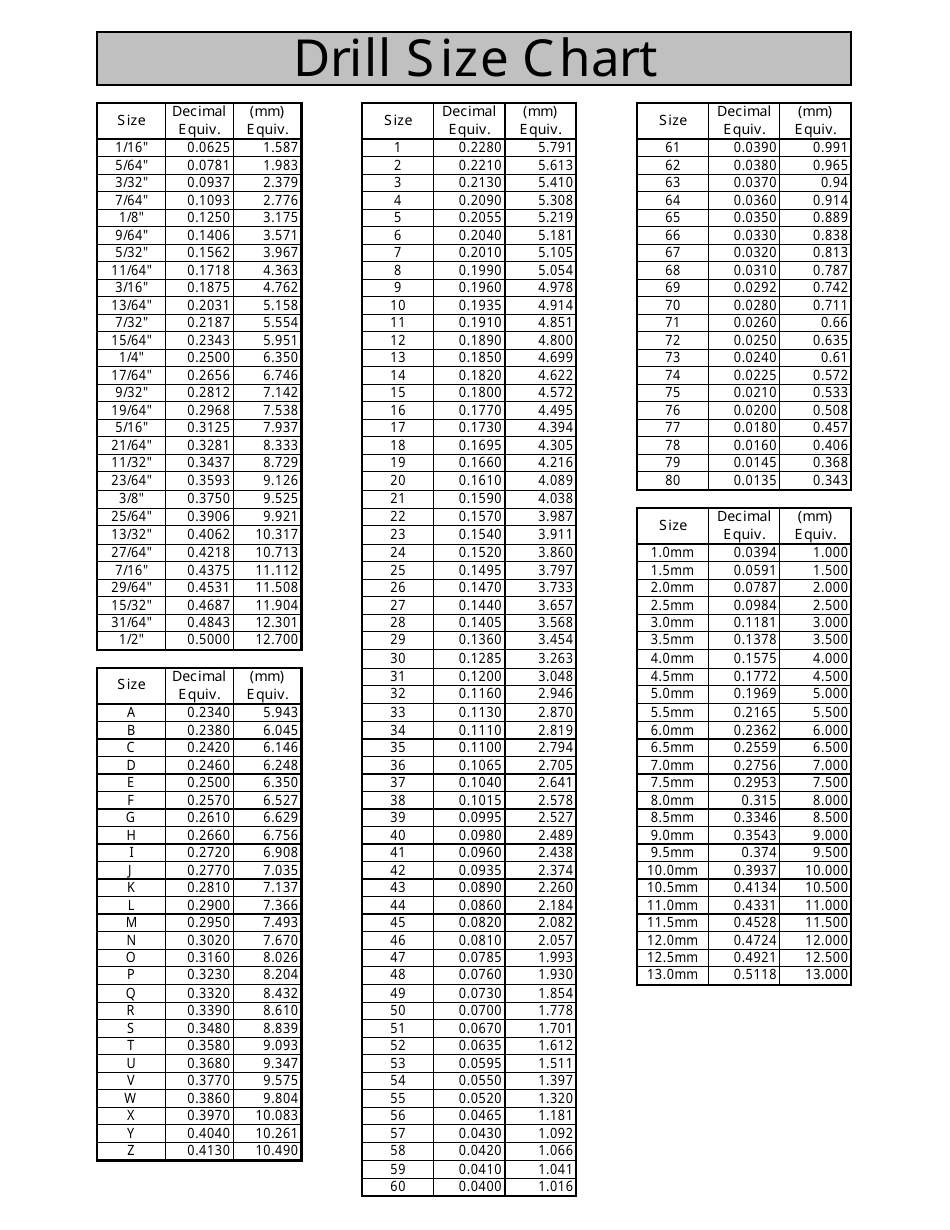

Printable Drill Chart

Preparing and Calibrating a NoTill or Conventional Drill for

How to Calibrate a Grain Drill YouTube

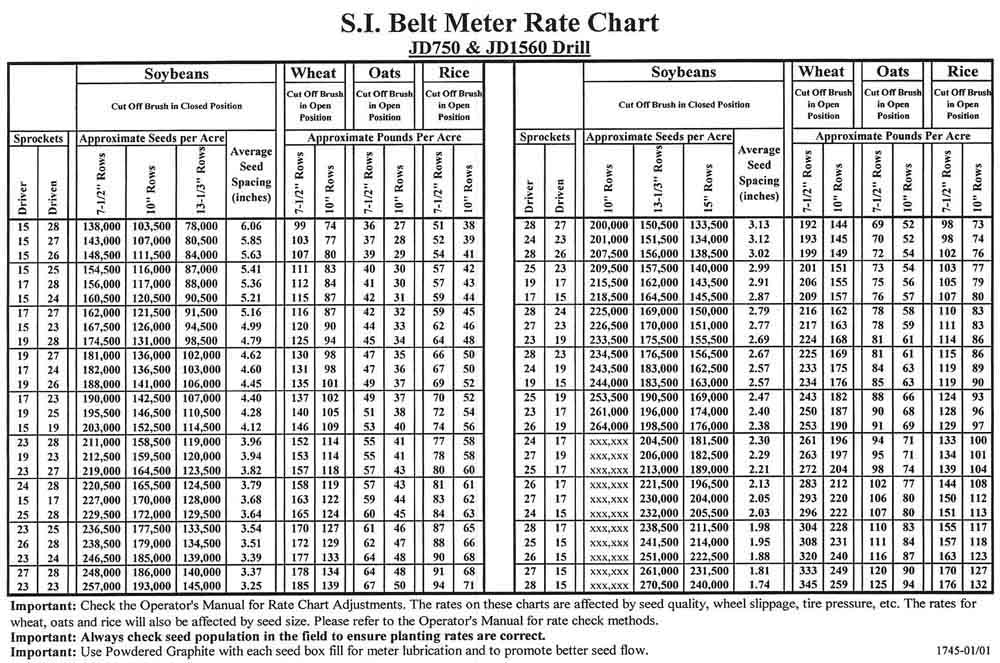

Gallery of viewing a thread 750 drill setting si meters john deere

How to calibrate a grain drill

Calibration of Grain Drills YouTube

Calibrating a seed drill Seed drill, Soil and water conservation, Drill

tye grain drill parts diagram GavynHoward

Web We Have Designed A Simple And Straightforward Calibration Method That Can Be Applied Across A Wide Range Of Grain Drill Types And Manufacturers.

Web The Seeding Rate Chart Provided By The Drill Manufacturer Is A Good Starting Point In Obtaining Desired Seeding Rates, But Actual Results Will Vary Depending Upon A Number Of Variables Including, Mechanical Condition Of The Drill, Variety And Seed Lot, Seed Size, And The Addition Of Seed Treatments And Or Inoculants.

Make, Model, Width And Row Spacing Of The Grain Drills Used In The Study.

We Have Designed A Simple And Straightforward Calibration Method That Can Be Applied Across A Wide Range Of Grain Drill Types And Manufacturers.

Related Post: