Grinding Wheel Color Chart

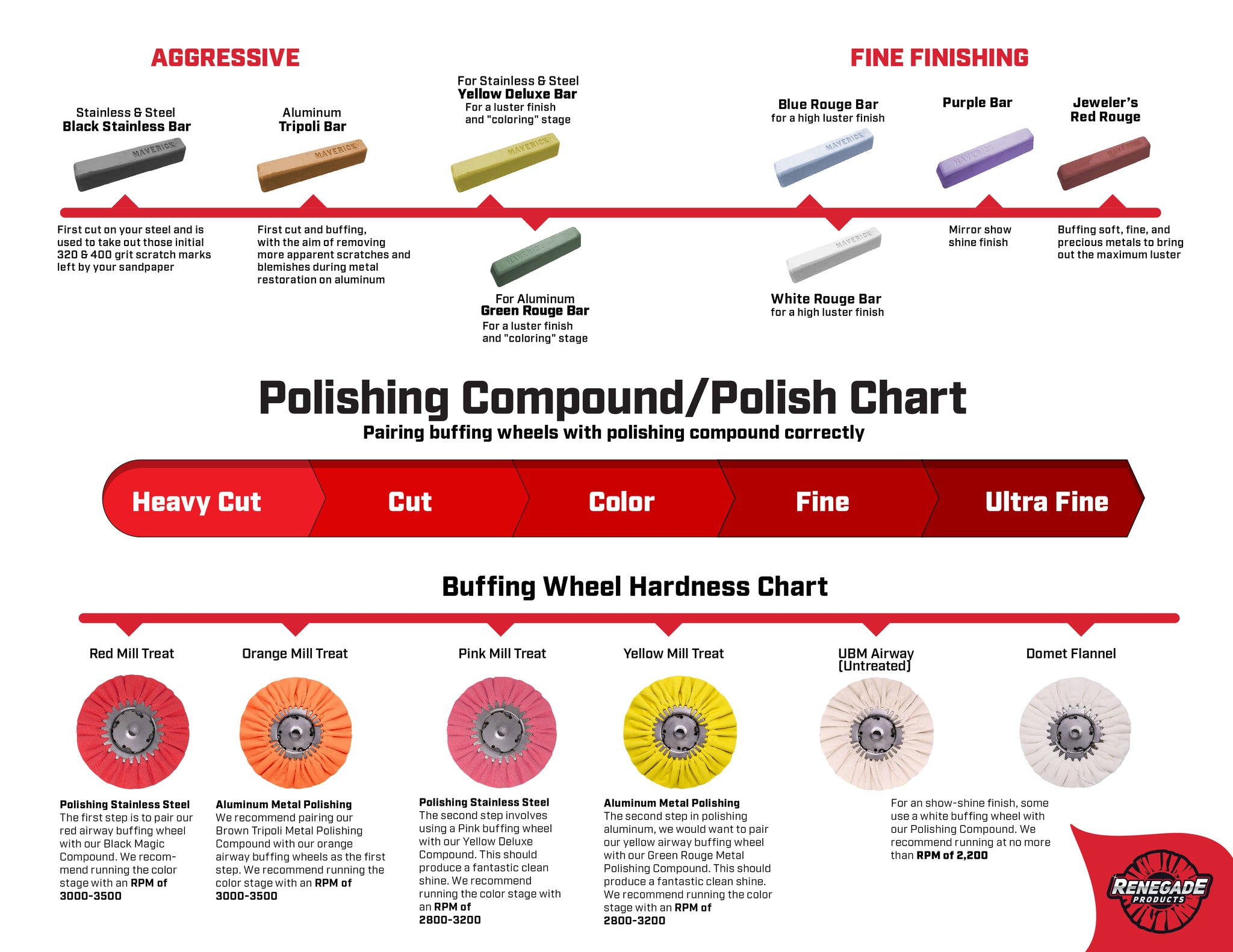

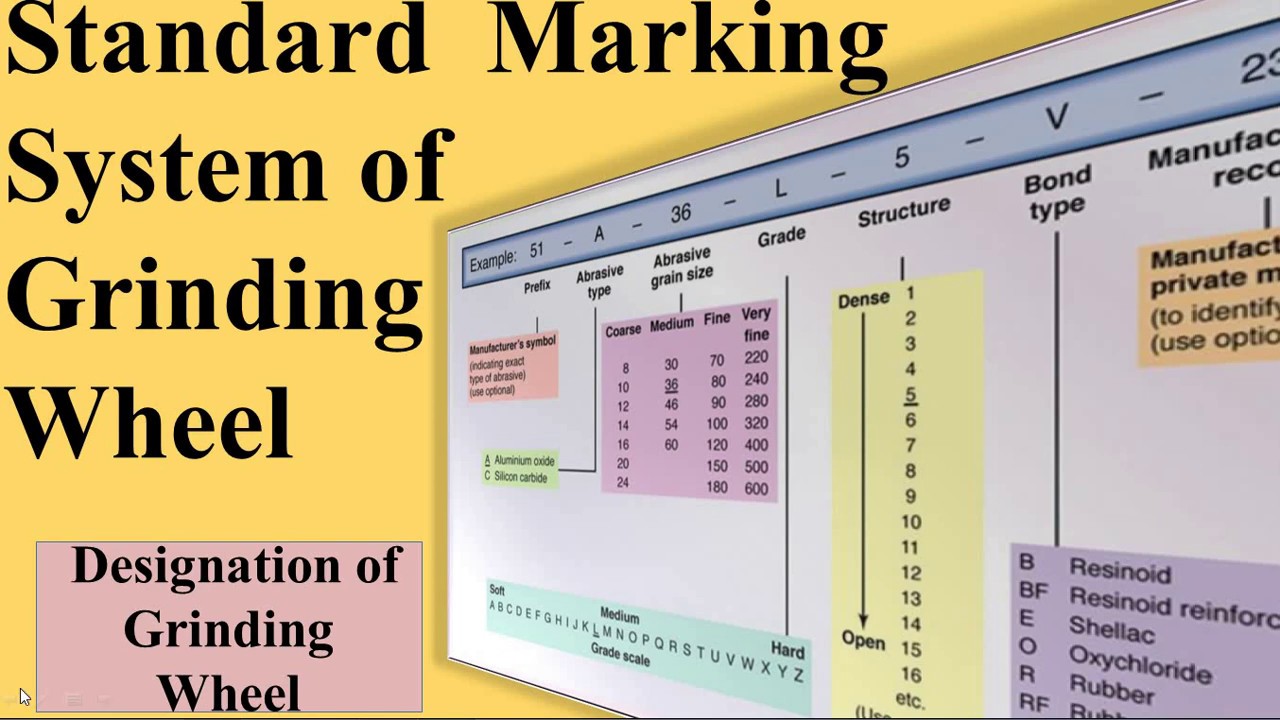

Grinding Wheel Color Chart - 30, 36, 46, 54, 60. Use at 90oto wheel face. Web grinding wheel segments are generally used to grind flat stock or flat surfaces within a workpiece for anything from heavy stock removal to precision grinding. Unfortunately the color of the grinding wheel does not. Grinding wheels with different grain sizes. Hardness is dependent on the grit type, the material being ground, the amount of stock. Buffing compounds are used for, coloring, creating luster,. 80, 100, 120, 150, 180. What material will you be grinding. Web the amount of abrasive bond in the grinding wheel determines its grade or hardness. Web grinding wheel segments are generally used to grind flat stock or flat surfaces within a workpiece for anything from heavy stock removal to precision grinding. Web master branded grinding wheels are manufactured to en 12413 and provide consistently high quality under iso 9001. Buffing compounds are used for, coloring, creating luster,. Use at 90oto wheel face. Web different abrasive. Unfortunately the color of the grinding wheel does not. 80, 100, 120, 150, 180. (1) in a figure shown dimension of grinding wheel ∅105×1.2×16mm. Hardness is dependent on the grit type, the material being ground, the amount of stock. Web master branded grinding wheels are manufactured to en 12413 and provide consistently high quality under iso 9001. The a refers to the abrasive. What material will you be grinding. Usually,there are items on the lables. B, d, e, f, g, h. Web slower = softer. Web the amount of abrasive bond in the grinding wheel determines its grade or hardness. Web different abrasive grains have different colors, diamond is golden color, cbn is black color, aluminum oxide has white (white aluminum oxide), pink (pink. Web master branded grinding wheels are manufactured to en 12413 and provide consistently high quality under iso 9001. Usually,there are items. Web the amount of abrasive bond in the grinding wheel determines its grade or hardness. Grinding wheels with different grain sizes. Hardness is dependent on the grit type, the material being ground, the amount of stock. At slower wheel speeds, there is a higher force per abrasive particle causing the grain and/or bond to break down quicker. Web slower =. (1) in a figure shown dimension of grinding wheel ∅105×1.2×16mm. Buffing compounds are used for, coloring, creating luster,. There are various types of. 30, 36, 46, 54, 60. Grinding wheels with different grain sizes. See below for an easy guide to choosing the right buffing compound for your project. Use at 90oto wheel face. It also covers what colors are. The a refers to the abrasive. There are various types of. Web the amount of abrasive bond in the grinding wheel determines its grade or hardness. Web read the label on the grinding wheels. Web grinding wheel composition 8 abrasive 9 grit size 10 hardness 11 structure 11 binder 11 how grinding wheels work. Web in this post we will show you a color chart that displays the different buffing wheels. Web different abrasive grains have different colors, diamond is golden color, cbn is black color, aluminum oxide has white (white aluminum oxide), pink (pink. Web in this guide to grinding wheels, we discuss a few grinding wheel types, as well as their materials, design and benefits for specific applications. Web selecting the right grinding wheel there are nine main factors. Web in this post we will show you a color chart that displays the different buffing wheels and buffing compounds that we manufacture. Now we specified grinding wheel through figure one by one. At slower wheel speeds, there is a higher force per abrasive particle causing the grain and/or bond to break down quicker. Web different abrasive grains have different. See below for an easy guide to choosing the right buffing compound for your project. The product range is extensive covering vitrified and resin. Grinding wheels with different grain sizes. Web selecting the right grinding wheel there are nine main factors to be considered when selecting a grinding wheel for any application: I, j, k, l, m, n. Web read the label on the grinding wheels. Unfortunately the color of the grinding wheel does not. Web in this guide to grinding wheels, we discuss a few grinding wheel types, as well as their materials, design and benefits for specific applications. Buffing compounds are used for, coloring, creating luster,. The a refers to the abrasive. At slower wheel speeds, there is a higher force per abrasive particle causing the grain and/or bond to break down quicker. B, d, e, f, g, h. Web master branded grinding wheels are manufactured to en 12413 and provide consistently high quality under iso 9001. 8, 10, 12, 14, 18, 20, 24. Web in this post we will show you a color chart that displays the different buffing wheels and buffing compounds that we manufacture. Hardness is dependent on the grit type, the material being ground, the amount of stock.

How to read a grinding wheel's specification Forture Tools

BUFFING WHEEL COLOR CHART Renegade Products USA

Grit chart of grinding wheels Forture Tools

Pinterest

Norton Grinding Wheels Chart

Grinding Wheel Basics Norton Abrasives

Bibielle UK Grinding Wheels

Cutting and Grinding Wheels Application Guide Archives Extreme

How to read a grinding wheel's specification Forture Tools

Standard Marking System of Grinding Wheel Designation of Grinding

There Are Various Types Of.

(1) In A Figure Shown Dimension Of Grinding Wheel ∅105×1.2×16Mm.

Web Grinding Wheel Segments Are Generally Used To Grind Flat Stock Or Flat Surfaces Within A Workpiece For Anything From Heavy Stock Removal To Precision Grinding.

Web The Amount Of Abrasive Bond In The Grinding Wheel Determines Its Grade Or Hardness.

Related Post: