Hdpe Fusion Temperature Chart

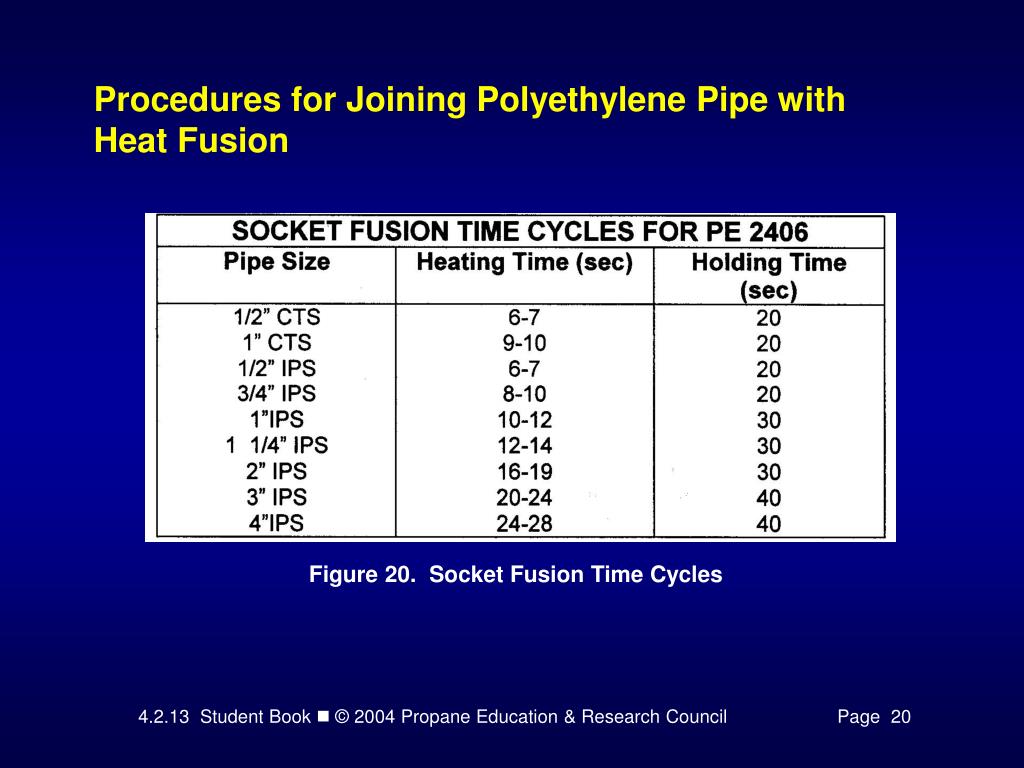

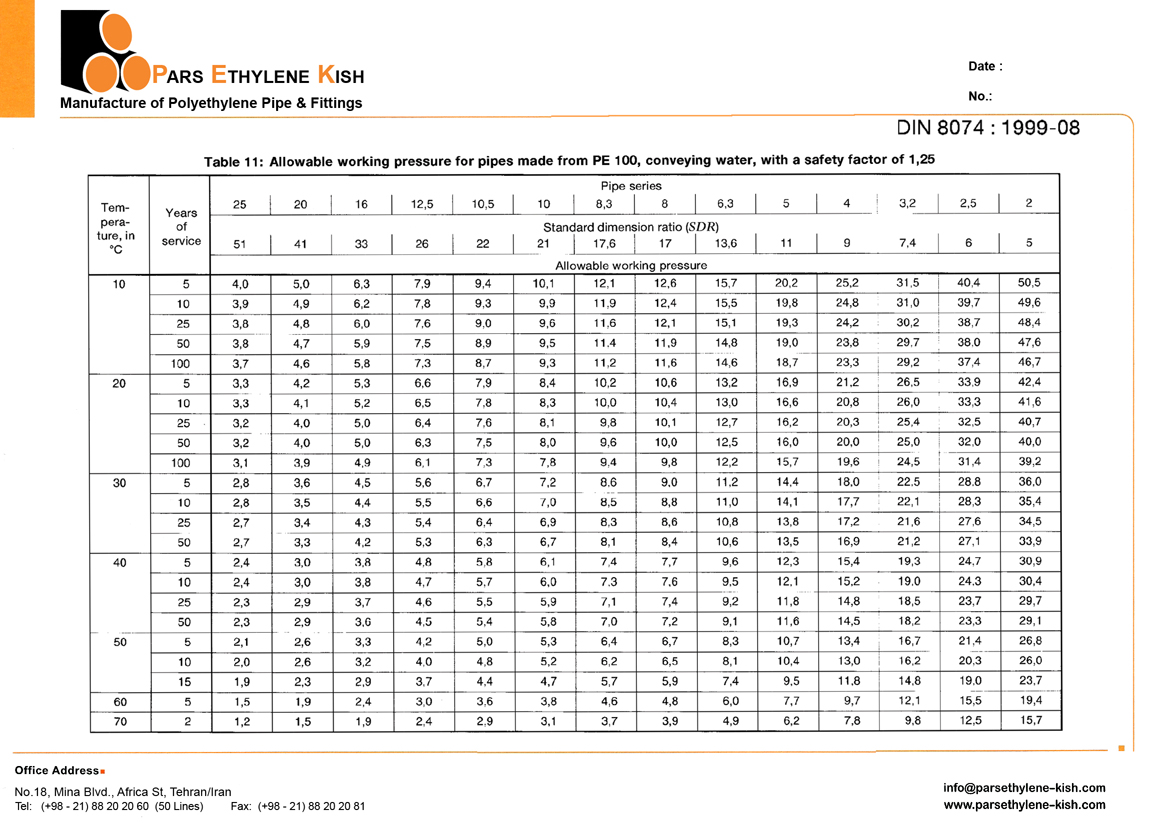

Hdpe Fusion Temperature Chart - Web • check the heater temperature and clean heater surfaces. Web butt fusion is the most important and widely used method of connection for hdpe pipes larger than 110 mm. It is a method of jointing pipe ends by way of heating and cooling. Place the heater adapter between the pipe and the fitting. Heat or thermal fusion is the best way to join hdpe pipes. Web don’t leave your fusions to chance. The butt welding machines used to weld pe. Web thus, mcelroy included three temperatures for its testing matrix: Web butt fusion can be successfully performed over a broad range of weather and temperature conditions. Items that are in stock are typically shipped within 24 hours. * click “start” on the datalogger to begin recording. Web intuitively, factors that could significantly affect the joint core temperature of the pipe during the fusion cooling cycle are the heater temperature, the heat soak time, the open/close. The minimum time the fitting must remain clamped after the fusion cycle is complete. Has a large inventory of hdpe fittings and. Web a typical qualified temperature range for installation is 14°f minimum to 113°f maximum. Web butt fusion can be successfully performed over a broad range of weather and temperature conditions. Web butt fusion is the most important and widely used method of connection for hdpe pipes larger than 110 mm. Web connect the fusion unit to the pipe. Place the. Socket fusion pipe heating welder. The butt welding machines used to weld pe. • set the heater into the machine between pipe ends. The minimum time the fitting must remain clamped after the fusion cycle is complete. Web thus, mcelroy included three temperatures for its testing matrix: • set the heater into the machine between pipe ends. Web butt fusion is the most important and widely used method of connection for hdpe pipes larger than 110 mm. The welding temperature ranges from 200. The butt welding machines used to weld pe. It is a method of jointing pipe ends by way of heating and cooling. Quickly and easily determine the correct fusion pressure, temperatures, and time for your job using mcelroy’s free mccalc ®. The minimum time the fitting must remain clamped after the fusion cycle is complete. It is a method of jointing pipe ends by way of heating and cooling. Web this manual describes procedures and guidelines for joining performance pipe products using. Web a typical qualified temperature range for installation is 14°f minimum to 113°f maximum. • set the heater into the machine between pipe ends. Web what is the best way to connect hdpe pipes? The minimum time the fitting must remain clamped after the fusion cycle is complete. It is a method of jointing pipe ends by way of heating. Time before pressure test & tapping: Web butt fusion is the most important and widely used method of connection for hdpe pipes larger than 110 mm. Web a typical qualified temperature range for installation is 14°f minimum to 113°f maximum. Items that are in stock are typically shipped within 24 hours. The butt welding machines used to weld pe. Place the heater adapter between the pipe and the fitting. * click “start” on the datalogger to begin recording. Web connect the fusion unit to the pipe. Items that are in stock are typically shipped within 24 hours. It is a method of jointing pipe ends by way of heating and cooling. Web a typical qualified temperature range for installation is 14°f minimum to 113°f maximum. Web connect the fusion unit to the pipe. However, some weather, wind and temperature conditions can affect. The minimum time the fitting must remain clamped after the fusion cycle is complete. It is a method of jointing pipe ends by way of heating and cooling. Time before pressure test & tapping: Place the heater adapter between the pipe and the fitting. Web this document outlines the procedures for joining polyethylene pipe & fittings by butt fusion. Web thus, mcelroy included three temperatures for its testing matrix: Web butt fusion can be successfully performed over a broad range of weather and temperature conditions. The minimum time the fitting must remain clamped after the fusion cycle is complete. Web this manual describes procedures and guidelines for joining performance pipe products using butt fusion, saddle fusion and socket fusion joining techniques. The butt welding machines used to weld pe. The minimum time before the. Web thus, mcelroy included three temperatures for its testing matrix: Web don’t leave your fusions to chance. Quickly and easily determine the correct fusion pressure, temperatures, and time for your job using mcelroy’s free mccalc ®. Web butt fusion is the most important and widely used method of connection for hdpe pipes larger than 110 mm. Some manufacturers have lower and/or higher temperature limits and. Socket fusion pipe heating welder. • set the heater into the machine between pipe ends. * click “start” on the datalogger to begin recording. Place the heater adapter between the pipe and the fitting. It is a method of jointing pipe ends by way of heating and cooling. Web what is the best way to connect hdpe pipes? Web butt fusion can be successfully performed over a broad range of weather and temperature conditions.

High Country Fusion HDPE Pipe DIPS Chart by FRED Issuu

Municipal P&F Distributors

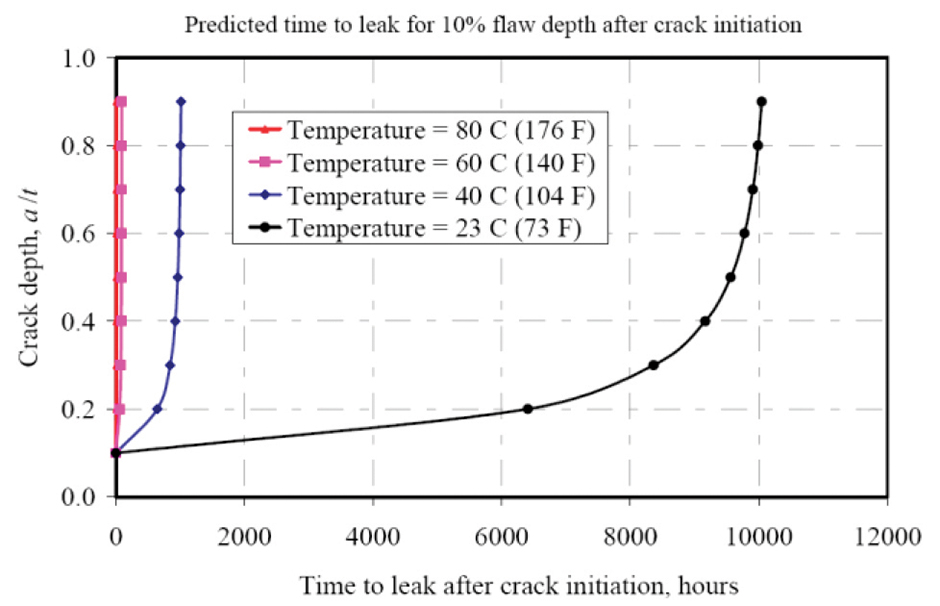

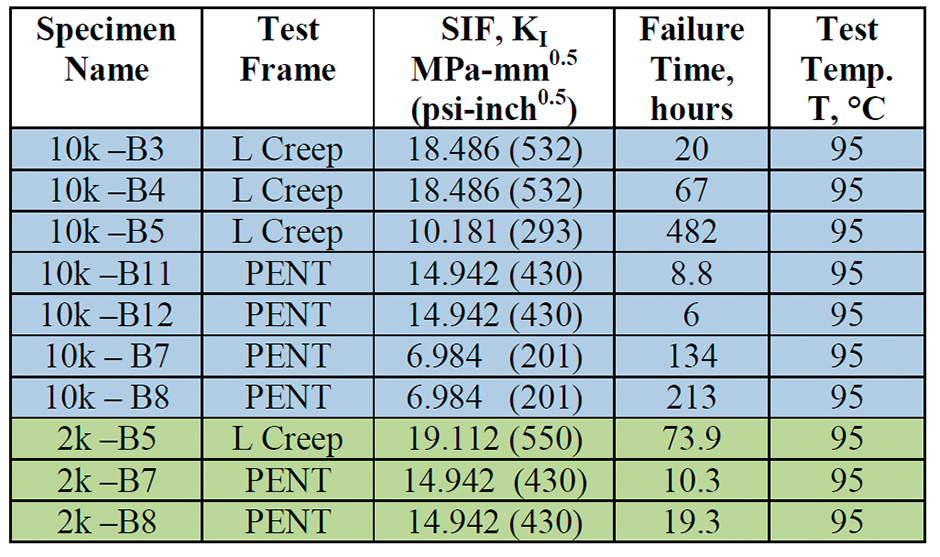

A Fracture Mechanics Approach to Service Life Prediction of HDPE Fusion

PPT 4.2.13 PowerPoint Presentation, free download ID479602

Hdpe Pipe Charts PDF Gas Technologies Gases

Schematic showing butt fusion welding method of HDPE pipes in different

A Fracture Mechanics Approach to Service Life Prediction of HDPE Fusion

![How to fuse polyethylene butt joints together? [with graphics]](https://www.finishing.com/61/6107.png)

How to fuse polyethylene butt joints together? [with graphics]

6 inch hdpe pipe Polyethylene agricultural pipe

Effect of temperature on thermal conductivity of LDPE and HDPE

Web A Typical Qualified Temperature Range For Installation Is 14°F Minimum To 113°F Maximum.

Items That Are In Stock Are Typically Shipped Within 24 Hours.

The Welding Temperature Ranges From 200.

Web Intuitively, Factors That Could Significantly Affect The Joint Core Temperature Of The Pipe During The Fusion Cooling Cycle Are The Heater Temperature, The Heat Soak Time, The Open/Close.

Related Post: