Hdpe Pipe Fusion Time Chart

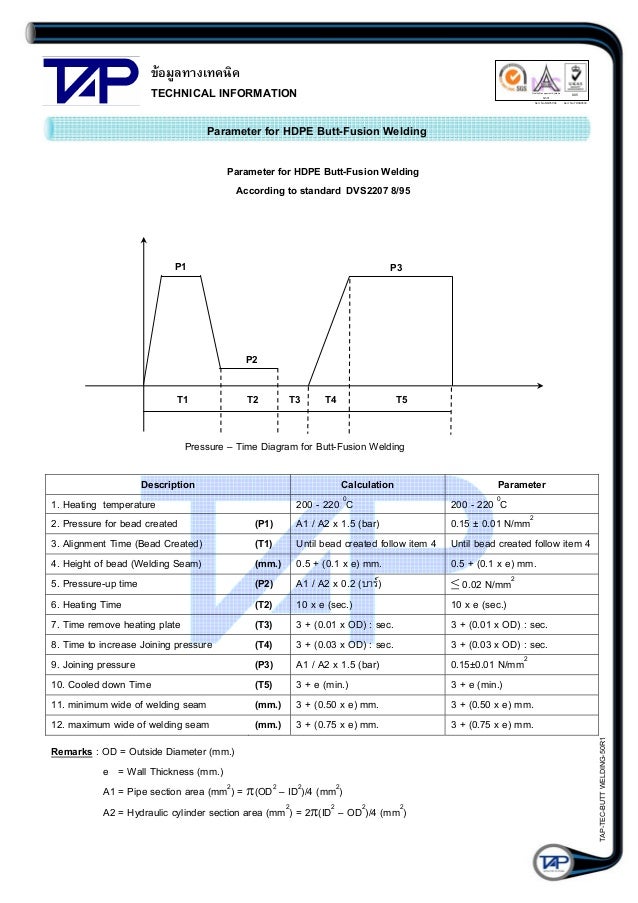

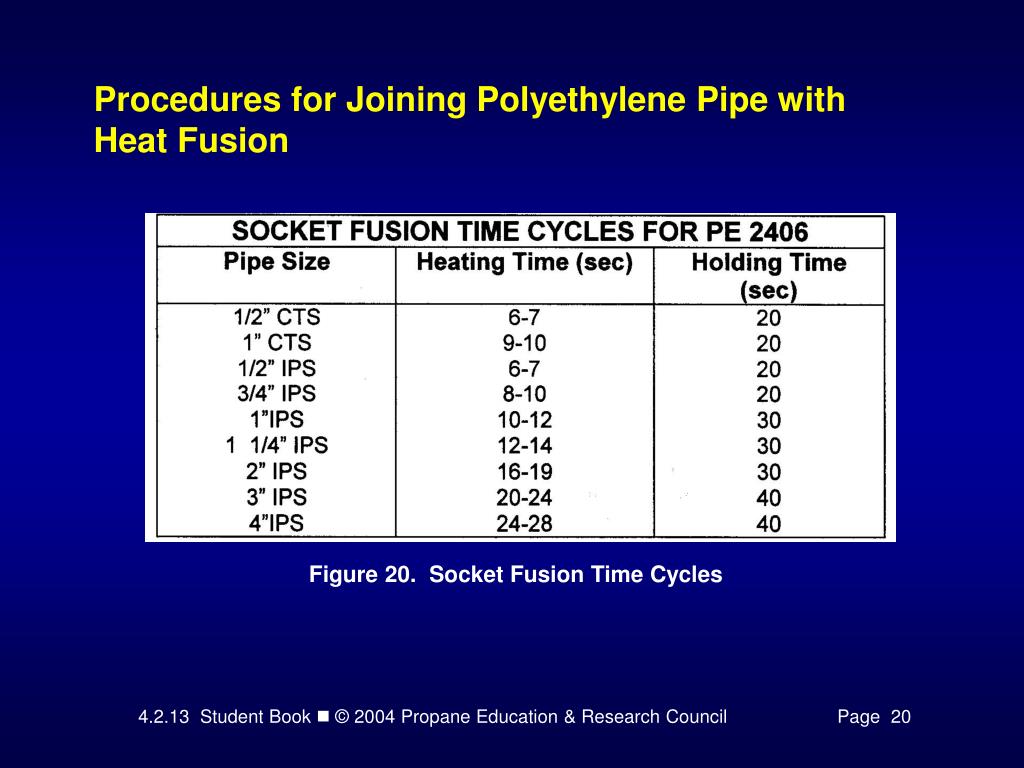

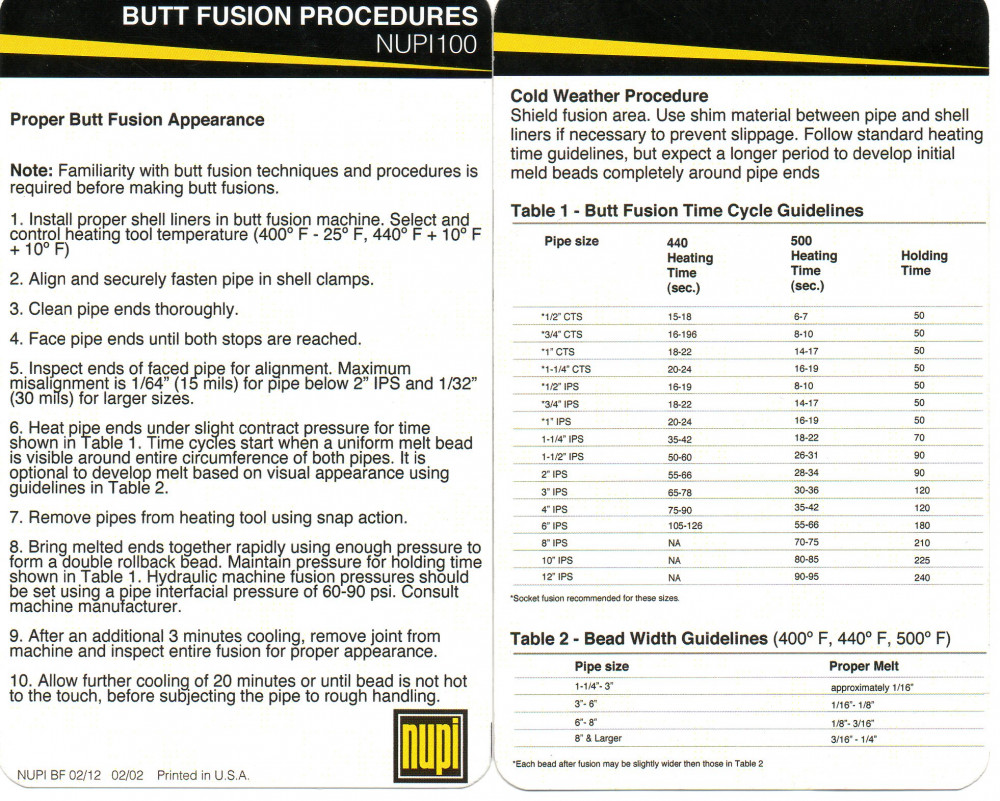

Hdpe Pipe Fusion Time Chart - Web this procedure is applicable for butt fusion joining mdpe to mdpe, hdpe to hdpe, and mdpe to hdpe pipes where pipe or fitting ends do not exceed one standard dimension ratio (sdr) difference. During the revision process, these changes were not evaluated for. Web this paper presents the effect of fusion procedure on the fusion performance of the thermal butt fusion in the safety class iii buried hdpe piping per various tests performed, including. As the molten materials cool, they mix and fuse into a permanent, monolithic joint. There are three types of heat fusion joints currently used in the industry: This better clarified the cool time required for pipes of all. The minimum time before the joint can be pressurized to 150% of moap and the main can be tapped. Plastic pipes & fittings, including hdpe, mdpe, ppr, pp, pb and pvdf. Of a quality electric heating plate, and electric controller and a comfortable nylon plastic handle. Apply heat for the amount of time shown on the table and. This better clarified the cool time required for pipes of all. There are three types of heat fusion joints currently used in the industry: The procedures outlined in this document are qualified for use with uponor infra’s sclairpipe and wehogas product lines. Web because of its value, it is very important to weld pipe together properly to get the most. The jackman series of socket fusion tools offer innovative solutions for heating and joining. This better clarified the cool time required for pipes of all. Butt, saddle and socket fusion. To complete this task, you must have operator qualification (oq) certification under tasks: As the molten materials cool, they mix and fuse into a permanent, monolithic joint. The minimum time before the joint can be pressurized to 150% of moap and the main can be tapped. Web this paper presents the effect of fusion procedure on the fusion performance of the thermal butt fusion in the safety class iii buried hdpe piping per various tests performed, including. Web a standardized chart depicting hdpe pipe sizes serves as. The minimum time before the joint can be pressurized to 150% of moap and the main can be tapped. This document outlines the procedures for joining polyethylene pipe & fittings by butt fusion. Web the butt fusion technique described in this document refers to the method by which the square cut end of two pipes are first cleaned, then heated. Web 4.3 the socket fusion, butt fusion, and saddle fusion procedures in this practice are suitable for joining pe gas pipe and fittings, pe water pipe and fittings, and pe general purpose pipes and fittings made to pe product specifications from organizations such as astm, awwa, api, and iso that are used in pressure, low pressure and non. Socket fusion. Figure 6 pipe wall), used to convey ‘essential cooling water’ to a nuclear power plant steam turbine’s condenser. The procedures outlined in this document are qualified for use with uponor infra’s sclairpipe and wehogas product lines. The minimum time the fitting must remain clamped after the fusion cycle is complete. To complete this task, you must have operator qualification (oq). This guide will explain how to most efficiently weld hdpe pipe and get the most out of an investment and to have sturdy, solid fuses in the field. The jackman series of socket fusion tools offer innovative solutions for heating and joining. Web a standardized chart depicting hdpe pipe sizes serves as a guide for project planning and execution. Apply. As the molten materials cool, they mix and fuse into a permanent, monolithic joint. Web this manual describes procedures and guidelines for joining performance pipe products using butt fusion, saddle fusion and socket fusion joining techniques. The procedures outlined in this document are qualified for use with uponor infra’s sclairpipe and wehogas product lines. Our pressure pipe is used in. The minimum time the fitting must remain clamped after the fusion cycle is complete. Butt, saddle and socket fusion. Web 4.3 the socket fusion, butt fusion, and saddle fusion procedures in this practice are suitable for joining pe gas pipe and fittings, pe water pipe and fittings, and pe general purpose pipes and fittings made to pe product specifications from. Time before pressure test & tapping: Web because of its value, it is very important to weld pipe together properly to get the most value out of a length of pipe. Of a quality electric heating plate, and electric controller and a comfortable nylon plastic handle. All procedures and guidelines in this document are in alignment with astm f2620 standard. The procedures outlined in this document are qualified for use with uponor infra’s sclairpipe and wehogas product lines. Place the heater adapter between the pipe and the fitting. These charts typically list the nominal pipe size (nps) or outside diameter (od) with corresponding wall thicknesses, which are critical for determining the pipe’s capacity and strength. All procedures and guidelines in this document are in alignment with astm f2620 standard practice for heat fusion joining of polyethylene pipe and fittings. This document outlines the procedures for joining polyethylene pipe & fittings by butt fusion. Web connect the fusion unit to the pipe. Socket fusion pipe heating welder. Web because of its value, it is very important to weld pipe together properly to get the most value out of a length of pipe. To properly fuse pipe the fusion pressure must be adjusted so the pipe manufacturers recommended interfacial pressure is achieved. Web the butt fusion technique described in this document refers to the method by which the square cut end of two pipes are first cleaned, then heated by pressing the pipes against a hot plate after which the plate is removed and the molten pipe ends then pressed together and allowed to cool. Of a quality electric heating plate, and electric controller and a comfortable nylon plastic handle. Plastic pipes & fittings, including hdpe, mdpe, ppr, pp, pb and pvdf. Our pressure pipe is used in many types of applications such as potable water, sewer, drain, mining, irrigation, slip lining, and reclaimed water. During the revision process, these changes were not evaluated for. Apply heat for the amount of time shown on the table and. Web this manual describes procedures and guidelines for joining performance pipe products using butt fusion, saddle fusion and socket fusion joining techniques.![How to fuse polyethylene butt joints together? [with graphics]](https://www.finishing.com/61/6107.png)

How to fuse polyethylene butt joints together? [with graphics]

Energy management system Hdpe pipe welding procedure

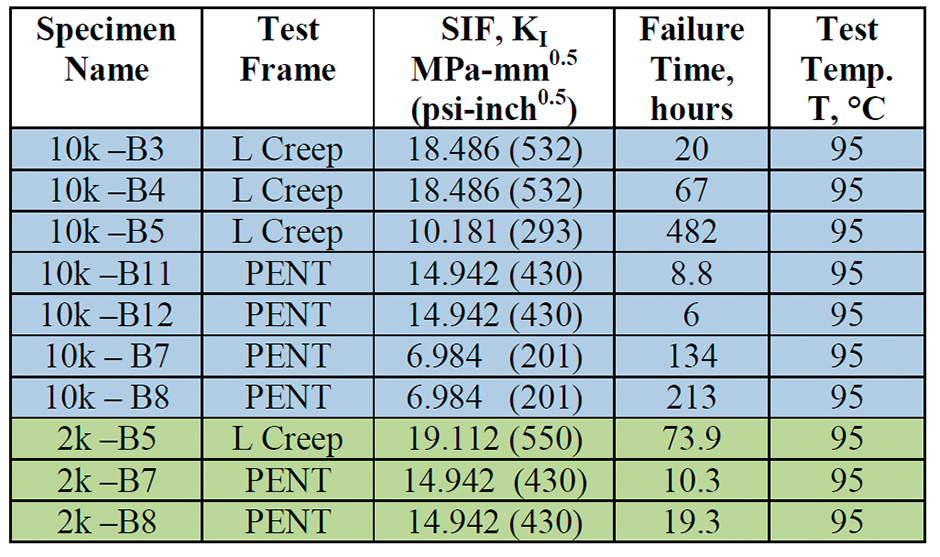

A Fracture Mechanics Approach to Service Life Prediction of HDPE Fusion

High Country Fusion HDPE Pipe DIPS Chart by FRED Issuu

PPT 4.2.13 PowerPoint Presentation, free download ID479602

Table 1 from Effect of joint contamination on the quality of buttfused

Schematic showing butt fusion welding method of HDPE pipes in different

Normes de tuyaux et daccessoires en polyéthylène

Product Information B & D Mfg., Inc.

Product Information B & D Mfg., Inc.

The Minimum Time The Fitting Must Remain Clamped After The Fusion Cycle Is Complete.

To Complete This Task, You Must Have Operator Qualification (Oq) Certification Under Tasks:

Time Before Pressure Test & Tapping:

Web This Paper Presents The Effect Of Fusion Procedure On The Fusion Performance Of The Thermal Butt Fusion In The Safety Class Iii Buried Hdpe Piping Per Various Tests Performed, Including.

Related Post: