Helicoil Drill And Tap Chart

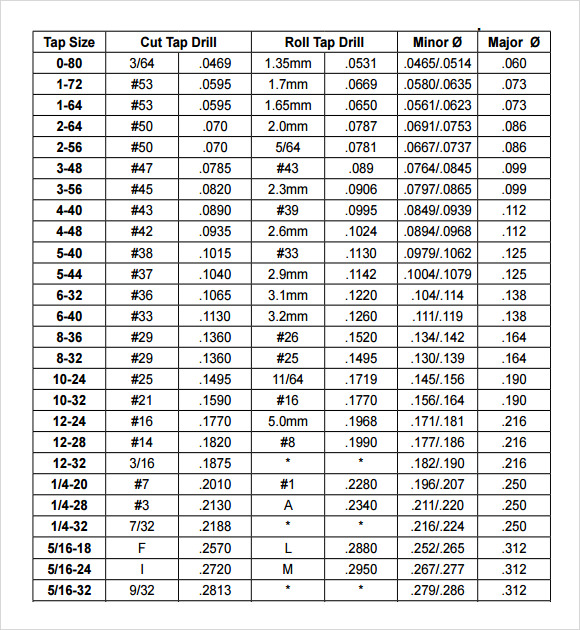

Helicoil Drill And Tap Chart - Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw thread, helical coil, free running (metric series). Web “tap dill size” is the drill diameter we should use before a tapping operation. Tapping drill size for thread forming. Web 8 corrosion and temperature resistance the standard material of the helicoil® plus prevents seizing of screws under environmental influences. Web a distorted thread grips the screw to resist loosening. By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. Find design and installation data for. Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw thread, helical coil, free running (metric series). Lower percentages such as “75% of the. Recently viewed items view all and edit. Countersinking the drilled hole to prevent a feather edge at the. Web 8 corrosion and temperature resistance the standard material of the helicoil® plus prevents seizing of screws under environmental influences. Tapping drill size for thread forming. Recently viewed items view all and edit. Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw. Find design and installation data for. Recently viewed items view all and edit. When it comes to repairing or adding threaded inserts to damaged or stripped holes, using a. Lower percentages such as “75% of the. Web “tap dill size” is the drill diameter we should use before a tapping operation. Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw thread, helical coil, free running (metric series). Web “tap dill size” is the drill diameter we should use before a tapping operation. Web 50 rows drill size: Web tapping and gaging procedure listed in the engineering data and trouble shooting section. Recently viewed items. In stock and ready to ship. Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw thread, helical coil, free running (metric series). Tool and tap selection guide for tanged inserts. Recently viewed items view all and edit. All drills fit 1/2 inch chucks. Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw thread, helical coil, free running (metric series). By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. Web a distorted thread grips the screw to resist loosening. Web 50 rows drill size: Countersinking. Web 50 rows technical information. Recently viewed items view all and edit. Choose from our selection of helicoil taps, including taps for helical inserts, helical inserts, and more. By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap. Tool and tap selection guide for tanged inserts. All drills fit 1/2 inch chucks. When it comes to repairing or adding threaded inserts to damaged or stripped holes, using a. Countersinking the drilled hole to prevent a feather edge at the. Web 8 corrosion and temperature resistance the standard material of the helicoil® plus prevents seizing of screws under environmental influences. Find design and installation data for. Web a distorted thread grips the screw to resist loosening. Tool and tap selection guide for tanged inserts. Web tapping and gaging procedure listed in the engineering data and trouble shooting section. Web sti helicoil specifications chart ; In stock and ready to ship. Recently viewed items view all and edit. Find design and installation data for. Tapping drill size for thread forming. In stock and ready to ship. Web a distorted thread grips the screw to resist loosening. Web sti helicoil specifications chart ; Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw thread, helical coil, free running (metric series). Find design and installation data for. Lower percentages such as “75% of the. Install the insert to the proper depth below the top surface (1/4 to 1/2 pitch for tapped. Lower percentages such as “75% of the. The minimum drilling depths shown below allow for the following recommended practices: Web insert, screw thread, helical coil, standard dimensions, assembly (metric series) ma3279, 3280, 3281 insert, screw thread, helical coil, free running (metric series). Web 50 rows technical information. When it comes to repairing or adding threaded inserts to damaged or stripped holes, using a. Tool and tap selection guide for tanged inserts. Tapping drill size for thread forming. Web tapping and gaging procedure listed in the engineering data and trouble shooting section. Web “tap dill size” is the drill diameter we should use before a tapping operation. Countersinking the drilled hole to prevent a feather edge at the. Web 50 rows drill size: Choose from our selection of helicoil taps, including taps for helical inserts, helical inserts, and more. Recently viewed items view all and edit. All drills fit 1/2 inch chucks. In stock and ready to ship. By default, the size you will find on most charts is the diameter for 75% thread depth on a cutting tap.

HELICOIL CHART PDF

Drill tap chart gertyboxes

Helicoil Drill And Tap Chart Online Shopping

Image result for drill and tap guide Drill, Tap chart, Drill bit sizes

Printable Tap Drill Chart Business Mentor

Tap And Drill Sizes Chart

Helicoil Size Chart

![23 Printable Tap Drill Charts [PDF] Template Lab](http://templatelab.com/wp-content/uploads/2016/09/tap-drill-chart-13.jpg?w=320)

23 Printable Tap Drill Charts [PDF] Template Lab

tap drill chart metric and standard

Standard tap drill size chart tnden

Web 8 Corrosion And Temperature Resistance The Standard Material Of The Helicoil® Plus Prevents Seizing Of Screws Under Environmental Influences.

Find Design And Installation Data For.

Web Insert, Screw Thread, Helical Coil, Standard Dimensions, Assembly (Metric Series) Ma3279, 3280, 3281 Insert, Screw Thread, Helical Coil, Free Running (Metric Series).

Install The Insert To The Proper Depth Below The Top Surface (1/4 To 1/2 Pitch For Tapped.

Related Post: