Jic Fitting Size Chart

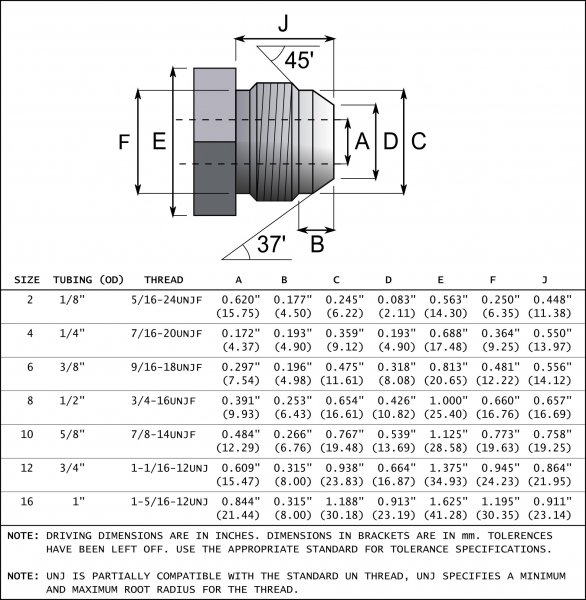

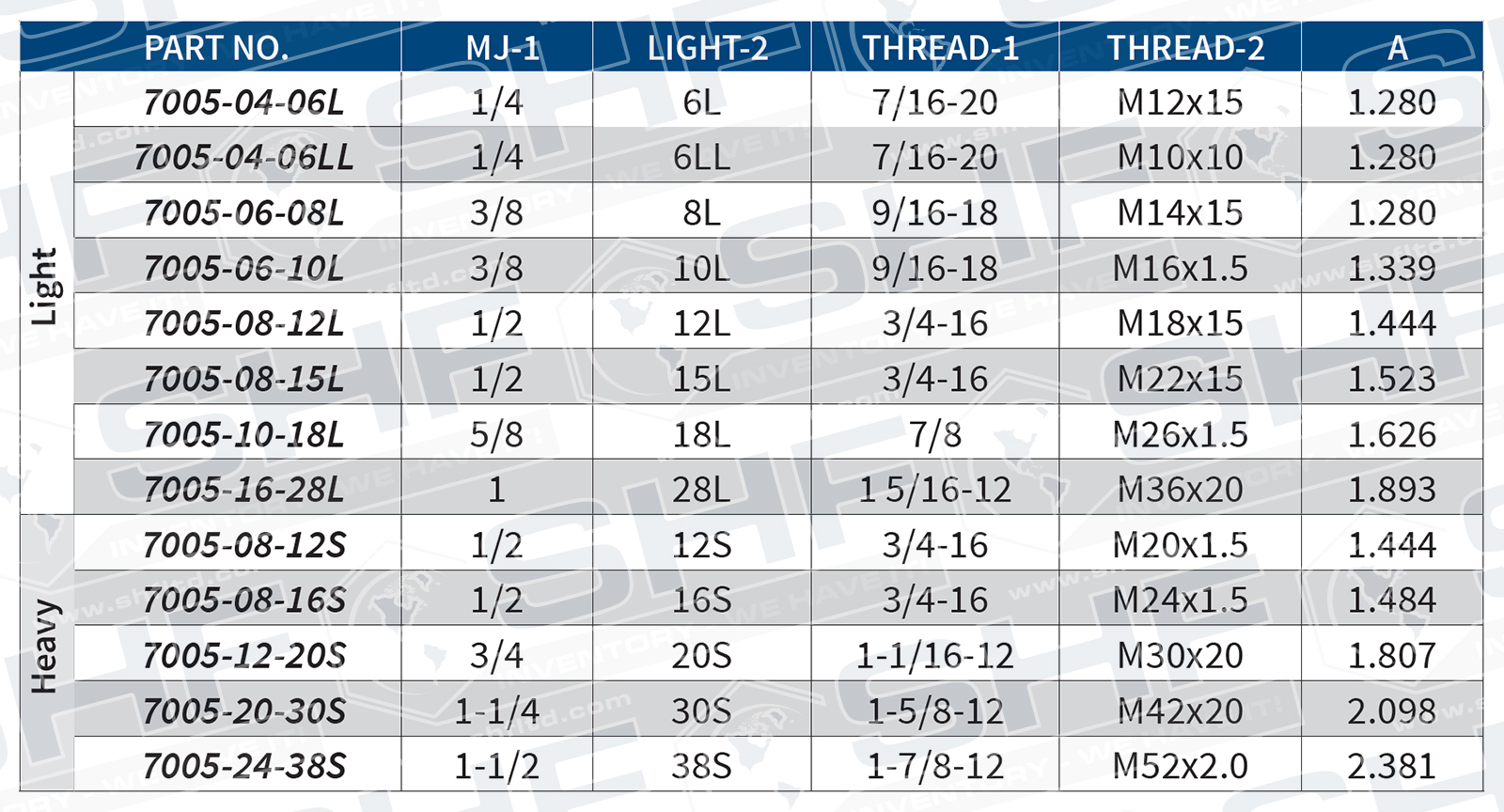

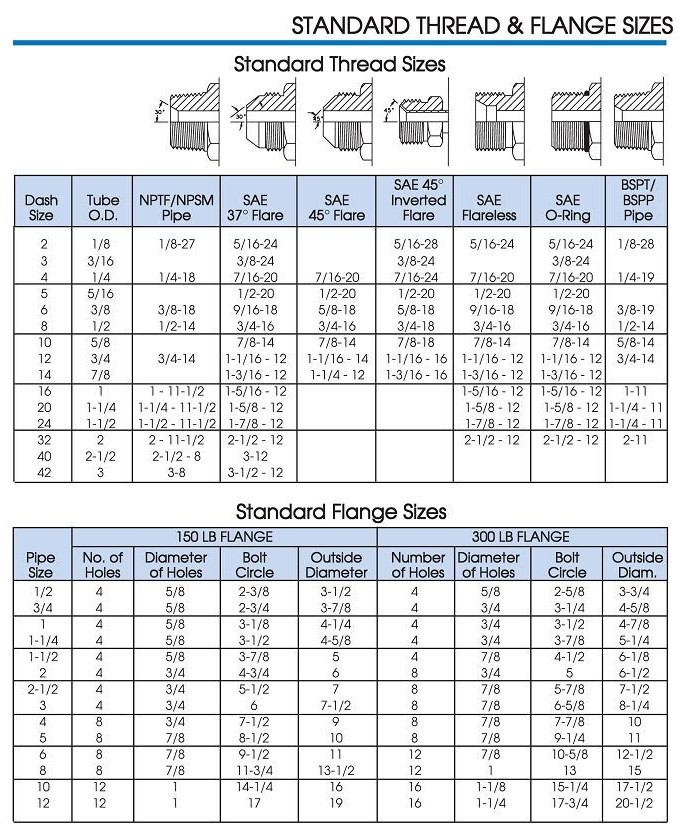

Jic Fitting Size Chart - Series 23 / 24 / p23 / p12 / p24 / p25 / 26 connectors. Assembly procedure (drawing as follow) get ready tube with applicable length. This connection is widely used in hydraulic systems. Please contact us today at. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. 1/8 3/16 1/4 5/16 3/8 1/2 5/8 3/4 1 1¼. A seal is achieved by threading in the jic male flared connection with the female coned connection. Web thread size chart (male) for most accurate sizing results when printing, change the page scaling setting to 'none'. When the straight threads are engaged, the 37° male seat seals on the 37° female flare seat. By forcing the flare against the cone during the torquing process, the nose cone is slightly deformed and Web ensure the fitting size matches your tubing or hose and verify the thread size to prevent improper sealing and leaks. Web jic fitting dimensions standard. Assembly procedure (drawing as follow) get ready tube with applicable length. Each has its own tube sizes and thread dimensions as shown in the following table: Web dash size 2345678 10 12 14 16. In this article we cover jic pipe fittings, commonly known as sae/iso 37° flare fittings. 1/8 to 2 in fitting materials: The sleeve not only absorbs vibration, but acts as a support to the flare during assembly and helps reduce the risk of twisting the tube. Web here is the jic fittings chart. Series 23 / 24 / p23 /. Din 2353 l (light) and din 2353 s (heavy) classes. Series 23 / 24 / p23 / p12 / p24 / p25 / 26 connectors. When the straight threads are engaged, the 37° male seat seals on the 37° female flare seat. To choose the thread size, you need to measure the male thread's outside diameter (od) or the female. The o’ring boss male will mate with an o’ring boss female only. Form the end of the tube to 37 degrees by using flaring tool. Web thread size chart (male) for most accurate sizing results when printing, change the page scaling setting to 'none'. A seal is achieved by threading in the jic male flared connection with the female coned. Web refer to this thread size chart, and ensure accurate measurement of jic fittings by comparing the thread o.d., thread i.d., and jic flare measurements for each fitting type. 1/8 3/16 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 1 1¼ 1½22½ 3 hose i.d. Web jic fittings size chart for identifying the correct size of bulkhead fitting adapter for. A seal is achieved by threading in the jic male flared connection with the female coned connection. Din 2353 l (light) and din 2353 s (heavy) classes. Web jic adapter specifications male flared fittings include a conical nose with external threads for clamping. Web jic fitting dimensions standard. 1/8 3/16 1/4 5/16 3/8 1/2 5/8 3/4 1 1¼. Web jic fittings come in various sizes, from 1/8 inch to 2 inches, and the thread size is expressed in inches. 1/8 to 2 in fitting materials: By forcing the flare against the cone during the torquing process, the nose cone is slightly deformed and For optional leakage control in medium and high pressure hydraulic systems. This connection is widely. The o’ring boss male will mate with an o’ring boss female only. The acronym jic stands for joint industry council, are compression fittings machined with a 37 degree flare seating surface and parallel threads. For optional leakage control in medium and high pressure hydraulic systems. Web dash size 2345678 10 12 14 16 20 24 32 40 48 tube o.d.. Web jic fittings size chart for identifying the correct size of bulkhead fitting adapter for skid steer quick couplers. In this article we cover jic pipe fittings, commonly known as sae/iso 37° flare fittings. Web here is the jic fittings chart. 45°, 90°, straight, cross, and tee A flared fitting or tube assembly is tightened against the cone with a. Stainless steel, steel, and brass type approval certificates korean register Web refer to this thread size chart, and ensure accurate measurement of jic fittings by comparing the thread o.d., thread i.d., and jic flare measurements for each fitting type. Din 2353 l (light) and din 2353 s (heavy) classes. 45°, 90°, straight, cross, and tee Npt, or national pipe thread. The sleeve not only absorbs vibration, but acts as a support to the flare during assembly and helps reduce the risk of twisting the tube. Web jic fittings come in various sizes, from 1/8 inch to 2 inches, and the thread size is expressed in inches. For optional leakage control in medium and high pressure hydraulic systems. Web the 37° jic connection consists of three pieces: Assembly procedure (drawing as follow) get ready tube with applicable length. Web ensure the fitting size matches your tubing or hose and verify the thread size to prevent improper sealing and leaks. Din 2353 l (light) and din 2353 s (heavy) classes. The nut, the sleeve, and the fitting in a range of sizes from 1/8” up to 2”. Form the end of the tube to 37 degrees by using flaring tool. 45°, 90°, straight, cross, and tee A 37° fitting body will accept both inch and metric tube by changing the sleeve. Each has its own tube sizes and thread dimensions as shown in the following table: This connection is widely used in hydraulic systems. The o’ring boss male will mate with an o’ring boss female only. Npt, or national pipe thread taper, is a standard that originated in north america and is widely used in various industries. Please contact us today at.Jic Hydraulic Fittings Size Chart Images and Photos finder

AN and JIC Fittings

Hose Size Chart

Hydraulic Hose Fittings Chart

Tabla de tallas de accesorios JIC de rosca SAE Conocimiento Fábrica

7005 Male JIC x Male DIN Metric SHF, Inc.

Jic Fitting Size Chart Pdf

When Can AN Fitting Be Substituted for JIC?

Jic Fittings Size Chart

Npt Thread Chart Pdf vietmanager

Web Refer To This Thread Size Chart, And Ensure Accurate Measurement Of Jic Fittings By Comparing The Thread O.d., Thread I.d., And Jic Flare Measurements For Each Fitting Type.

When The Straight Threads Are Engaged, The 37° Male Seat Seals On The 37° Female Flare Seat.

1/8 To 2 In Fitting Materials:

By Forcing The Flare Against The Cone During The Torquing Process, The Nose Cone Is Slightly Deformed And

Related Post: