Lathe Feed Rate Chart

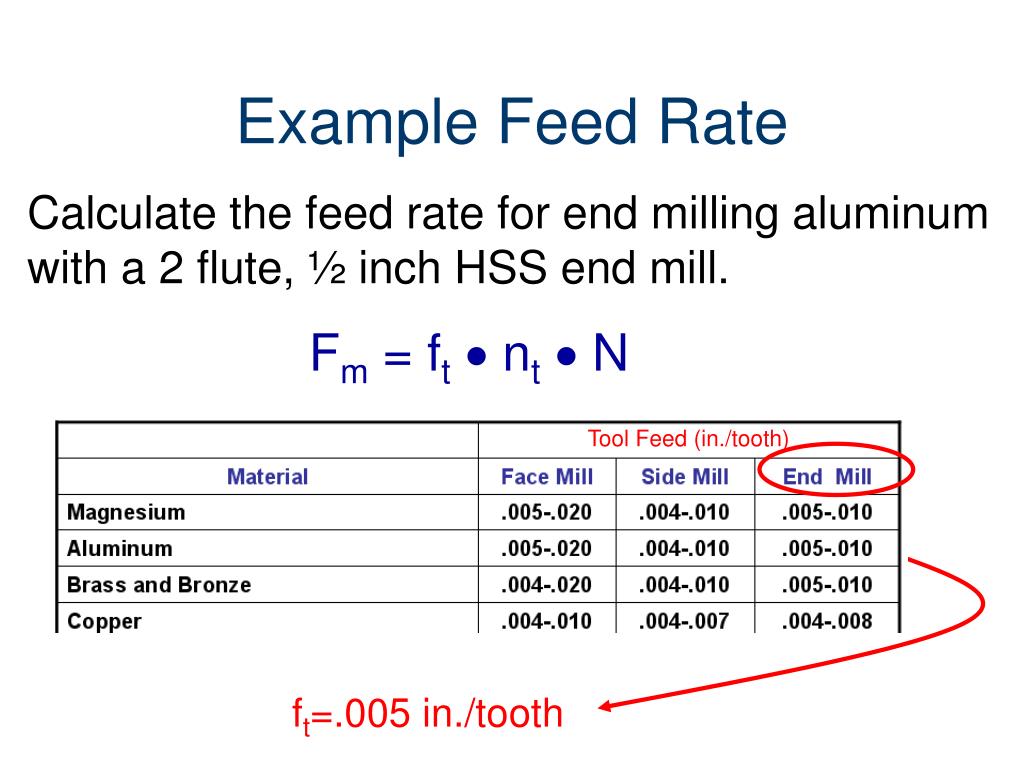

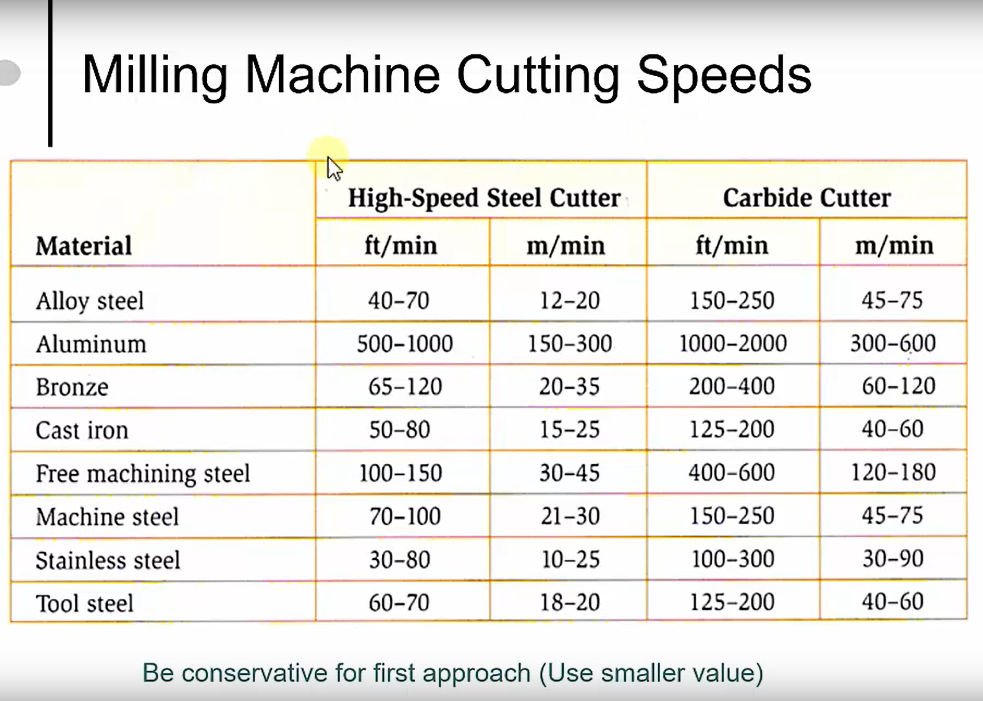

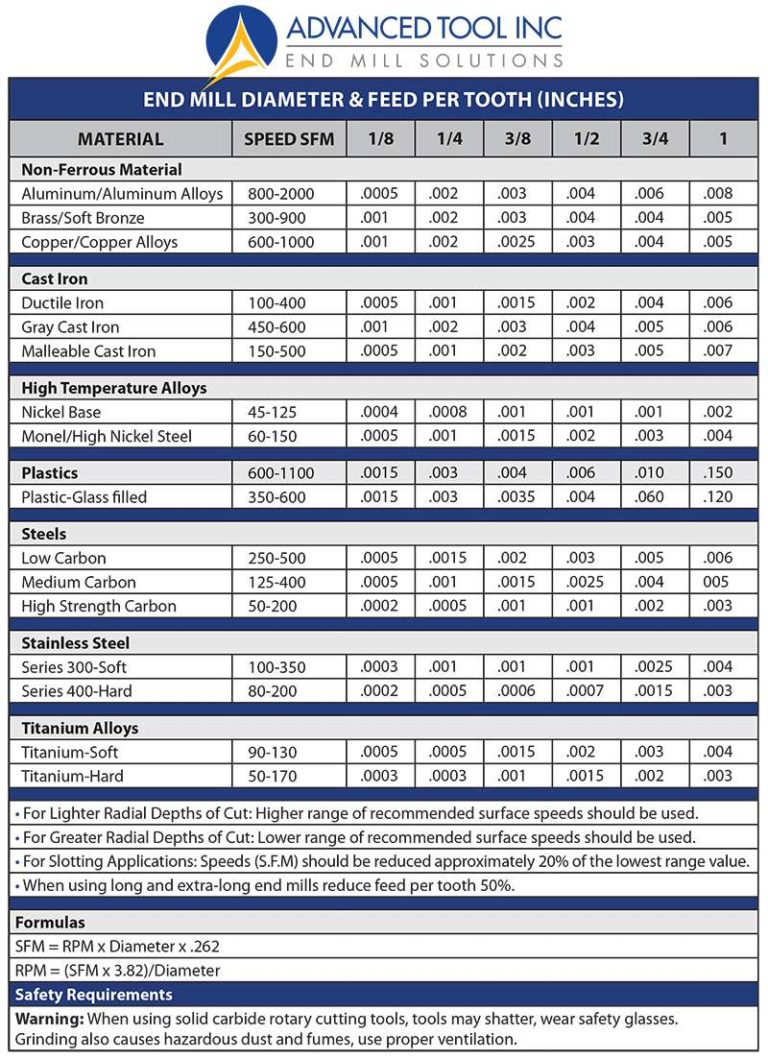

Lathe Feed Rate Chart - Interrelationship of theory and practice. Ipm (inches / minute) feed rate formula = chip load *. Web the rpm calculated in the turning (lathe) speed and feed calculator refers to the spindle speed in turning process, and the ipm refers to feed rate. Web 1) select your material in the iso colored chart with respect to material description and hardness (hb). Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Web lathe speeds and feeds. Formula to determine feed rate. Web feed rate defines the speed at which a cutting tool moves through a workpiece during machining. Rpm = of the tool or workpiece. It supports all of the following machine tool operations: For milling, turning, drilling, grooving, and parting off. Feed rate = rpm x chip load x number of teeth. Rpm = of the tool or workpiece. This calculator will determine speeds and feed rates for machining operations on mill or lathes. Web calculate the spindle speed, feed rate, and cut time for a turning operation based on the cut diameter,. Feed rate, spindle speed (rpm), cutting speed (surface speed), and chip load. Web calculate the spindle speed, feed rate, and cut time for a turning operation based on the cut diameter, cutting speed, and cutting feed. The tool’s depth of cuts and the rate at which it is cutting can be used to. Web a lathe feeds and speeds chart. The tool’s depth of cuts and the rate at which it is cutting can be used to. These charts can be found in your machinery’s handbook , a textbook or in a chart given to you by your tool salesperson. Interrelationship of theory and practice. Web the feed rate (ipm) is multiplied by the radial and axial depths of cut. Web calculate the spindle speed, feed rate, and cut time for a turning operation based on the cut diameter, cutting speed, and cutting feed. Optimal feed rates are crucial for achieving high precision, efficiency, and. These charts can be found in your machinery’s handbook , a textbook or in a chart given to you by your tool salesperson. The chart. Effects of feed rate and speed. Successful turning requires knowledge of many factors, workholding, materials, tooling available, and much more. Use the widget to embed the calculator on. Surface speed / cutting speed: These charts can be found in your machinery’s handbook , a textbook or in a chart given to you by your tool salesperson. Successful turning requires knowledge of many factors, workholding, materials, tooling available, and much more. The exact rpm is not always. To learn what is sfm and how to go from sfm to. Web a lathe feeds and speeds chart is a handy tool that provides the necessary information regarding the appropriate feed rate and spindle rpms to optimize machining performance.. These charts can be found in your machinery’s handbook , a textbook or in a chart given to you by your tool salesperson. The chart includes a range of materials, cutting operations, and corresponding. Web recommended cutting speeds are given in charts. Use the widget to embed the calculator on. Optimal feed rates are crucial for achieving high precision, efficiency,. Web feed rate defines the speed at which a cutting tool moves through a workpiece during machining. Use the recommended insert chip groove based on your selection. Web recommended cutting speeds are given in charts. Ipm (inches / minute) feed rate formula = chip load *. Feed rate = rpm x chip load x number of teeth. Feed rate is the speed at which the cutting tool advances along the workpiece to remove material. Web calculate the spindle speed, feed rate, and cut time for a turning operation based on the cut diameter, cutting speed, and cutting feed. Use the widget to embed the calculator on. How to calculate feed rate and rpm. Determine the spindle speed. How to calculate feeds and speeds the right way to maximize your results. Sfm (see table below for sfm values). Feed rate is the speed at which the cutting tool advances along the workpiece to remove material. Web lathe feed rate calculator. Web recommended cutting speeds are given in charts. Web the feed rate (ipm) is multiplied by the radial and axial depths of cut to produce the rate of removal. These charts can be found in your machinery’s handbook , a textbook or in a chart given to you by your tool salesperson. Use the widget to embed the calculator on. Web lathe speeds and feeds. Web the rpm calculated in the turning (lathe) speed and feed calculator refers to the spindle speed in turning process, and the ipm refers to feed rate. Feed rate, spindle speed (rpm), cutting speed (surface speed), and chip load. Formula to determine feed rate. For milling, turning, drilling, grooving, and parting off. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. The exact rpm is not always. Effects of feed rate and speed. This calculator will determine speeds and feed rates for machining operations on mill or lathes. The tool’s depth of cuts and the rate at which it is cutting can be used to. To learn what is sfm and how to go from sfm to. Web speed (rpm) = (surface feet per minute x 3.82) / diameter of the tool. Web first is the formula to find the rpm, rpm = sfm* x 3.82 / diameter of the tool (* sfm = surface feet per minute) you can also use the rpm calculator below.

Lathe Surface Speed Chart

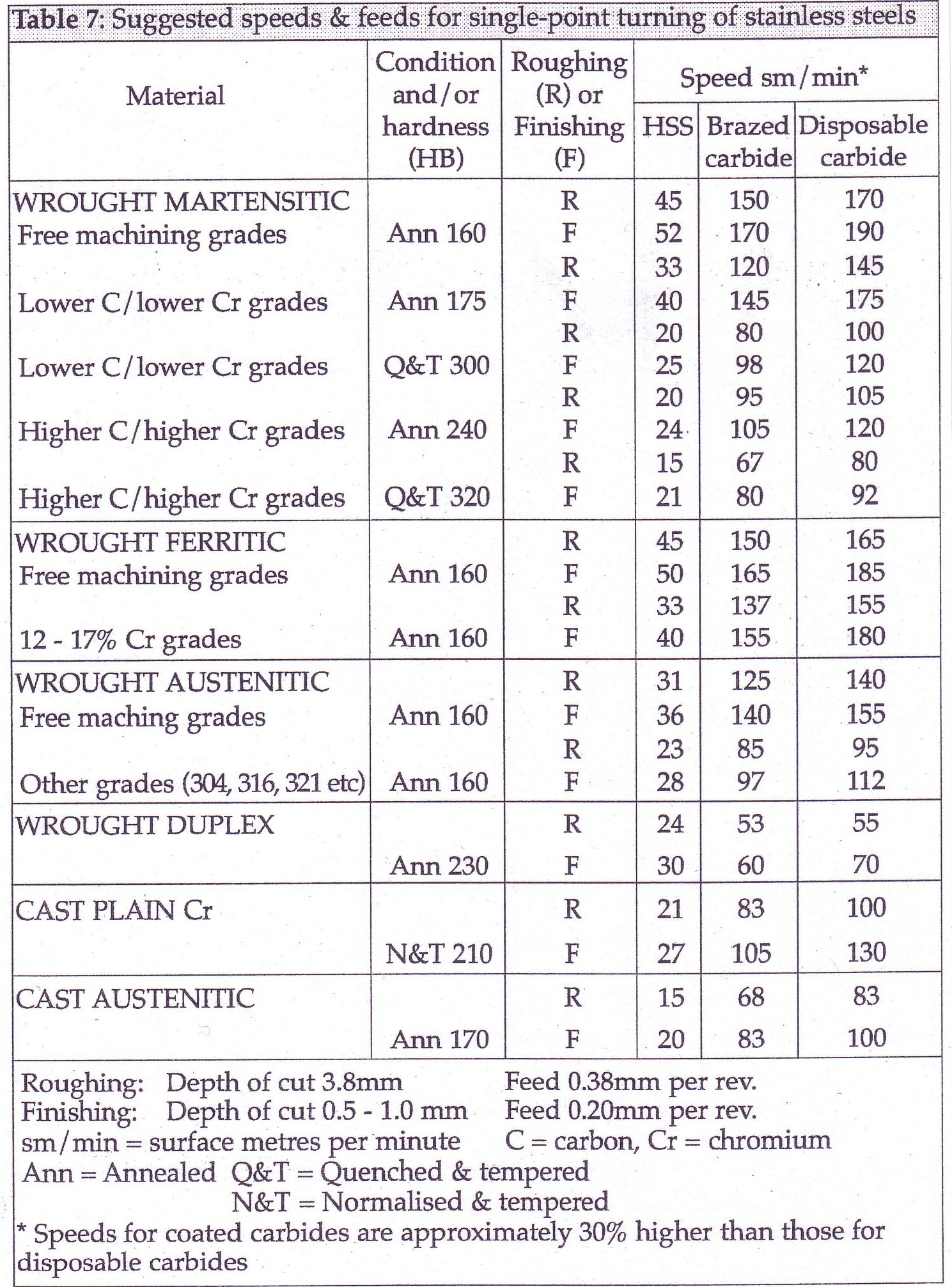

Speeds and feeds for turning stainless steels British Stainless Steel

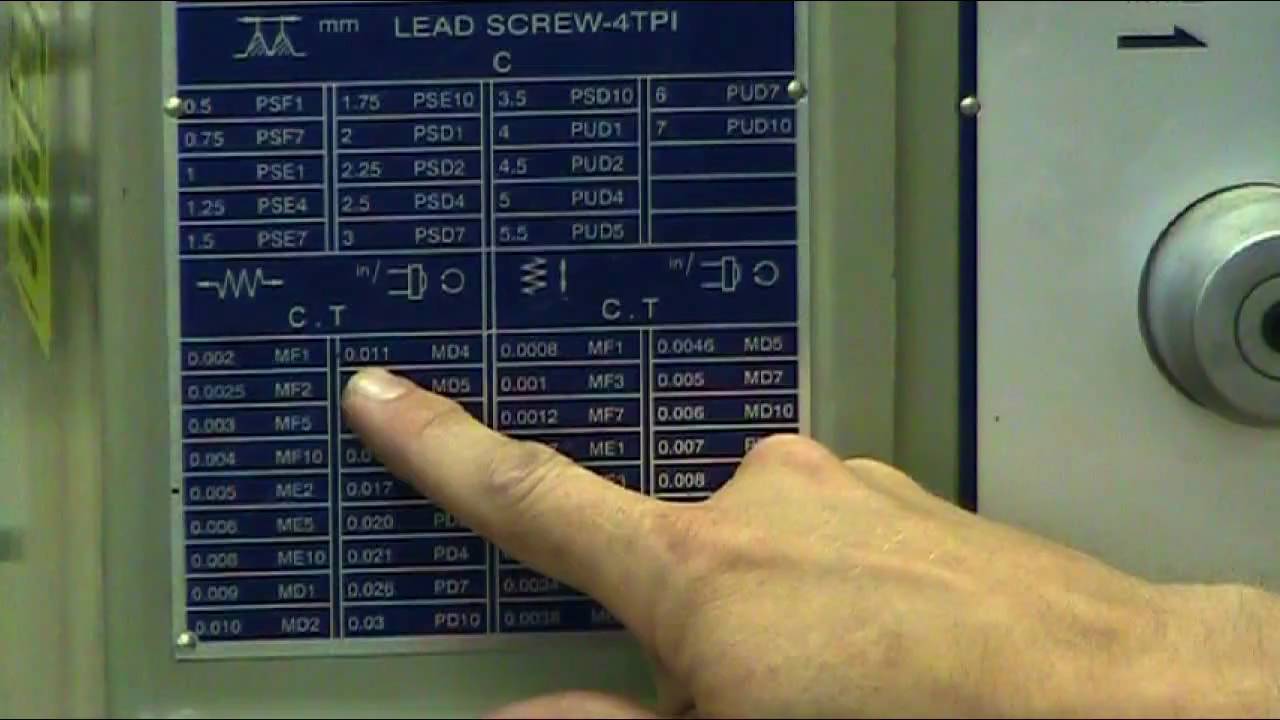

Threading and feed chart for IZH1i611P lathe YouTube

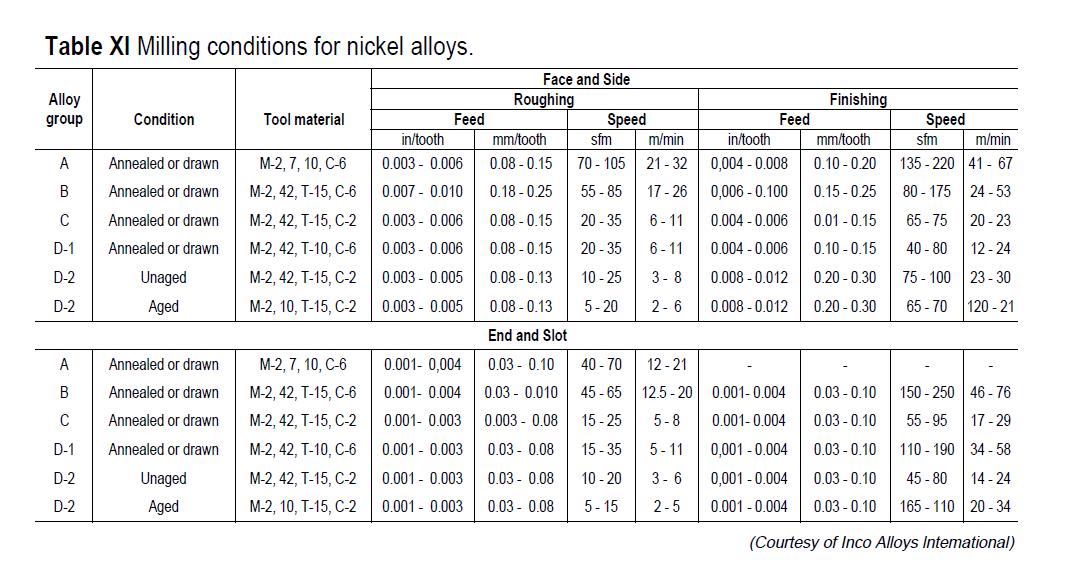

Feeds & Speeds Charts Lexington Cutter

Lathe Speeds And Feeds Chart

PPT Speeds and Feeds PowerPoint Presentation, free download ID6311492

Setting the Feed Rate on the Lathe YouTube

Machinist Tables for Lathes and Mills from American Machine Tools Company

Cnc router feeds and speeds for cutting 6063 aluminum naalogic

Feed And Speed Chart

> Ipt (Inches / Revolution) Feed Rate:

Feed Rate = Rpm X Chip Load X Number Of Teeth.

Web Lathe Feed Rate Calculator.

Sfm (See Table Below For Sfm Values).

Related Post: