Machining Surface Finish Chart

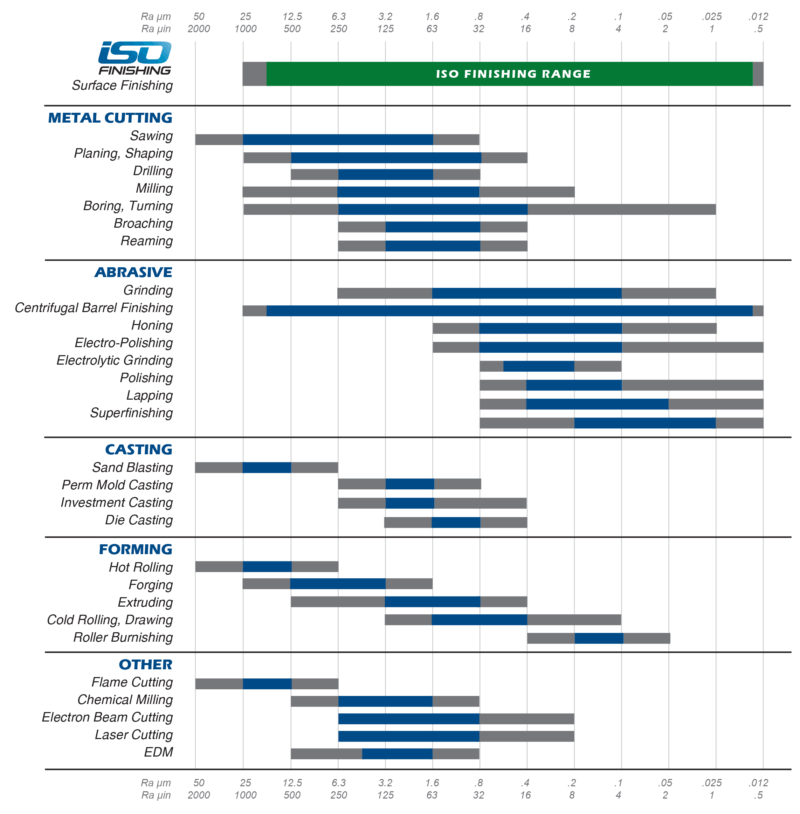

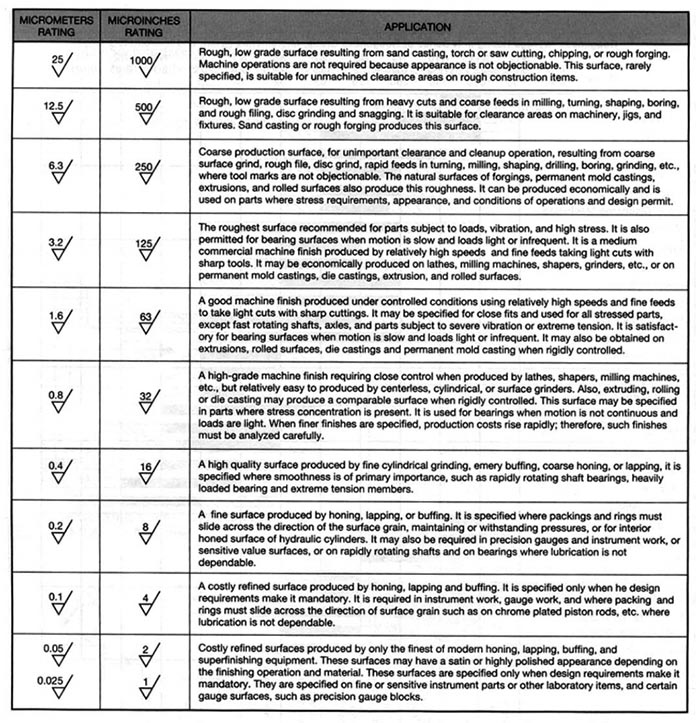

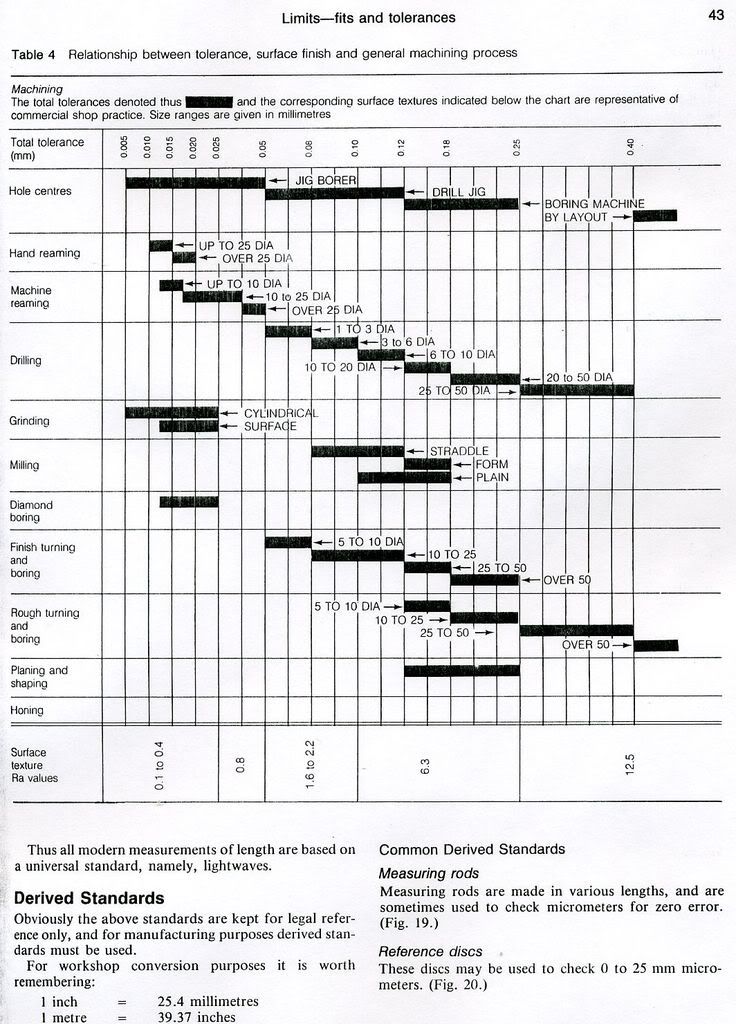

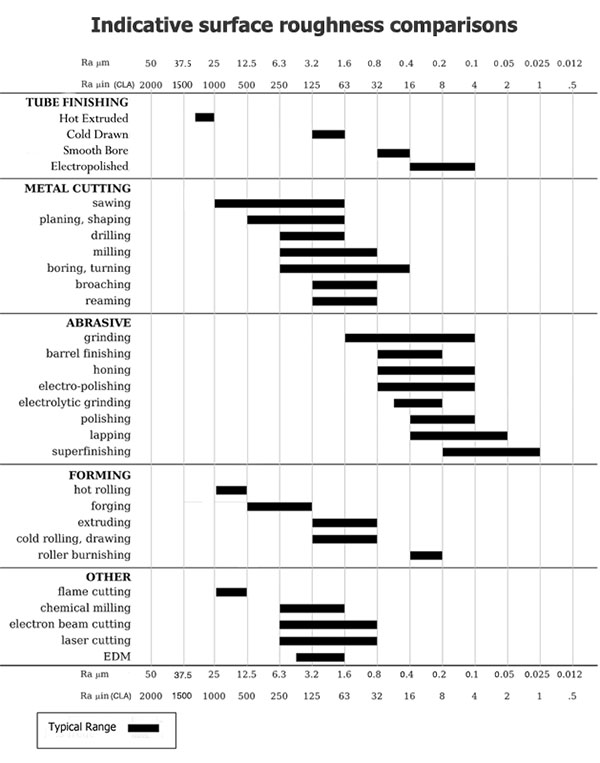

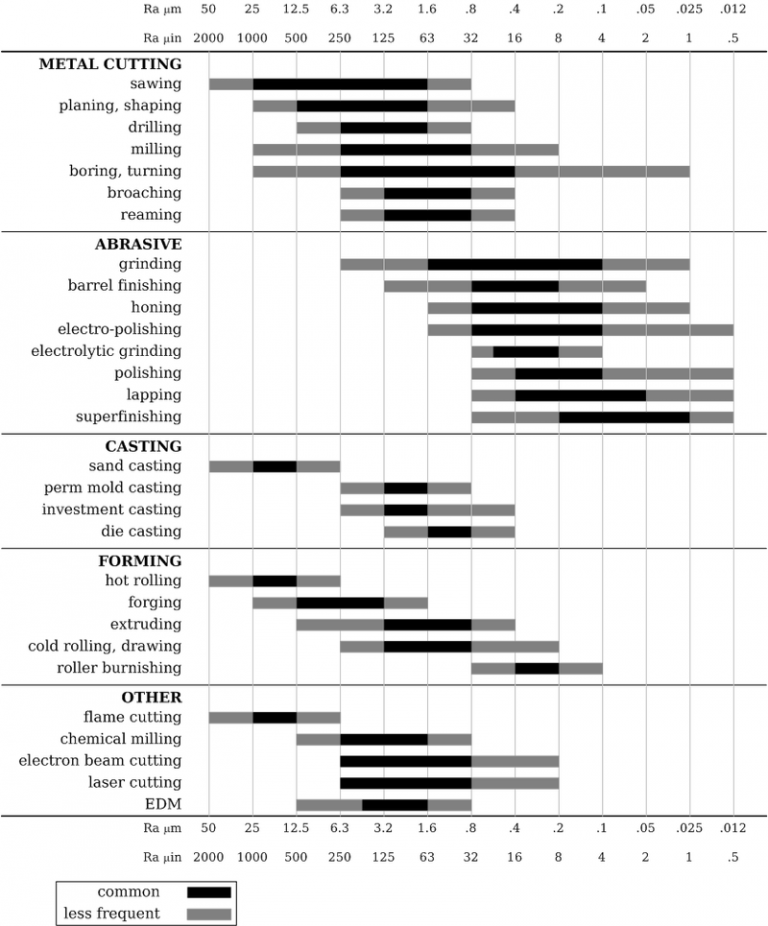

Machining Surface Finish Chart - Web there are a variety of surface finishes charts that can be used to help machining operations. A comprehensive understanding of these factors enables machinists to optimize surface finish and minimize defects. Improve mating properties, wear resistance, fatigue strength, contact stiffness, vibration and noise of mechanical parts. Understanding surface finish symbols and ra values is essential for quality control. Web the machining surface finish chart provides important instructions for gauging standard surface finish characteristics. Web this diagram shows how waviness, lay, and roughness are related to each other: Improves conductivity and adds surface electrical conductions. Several factors influence surface finish in cnc machining. As you venture into the realm of machining surface finishes, keep these key points in mind: Machine surface finish chart provides you with the comparison of average surface roughness produced by each machining process. The ra chart illustrates the average roughness of a machined surface. Surface finish plays a critical role in part performance and aesthetics. Web the machining surface finish chart provides important instructions for gauging standard surface finish characteristics. Improve mating properties, wear resistance, fatigue strength, contact stiffness, vibration and noise of mechanical parts. Surface roughness is the measurement of the relative. The most common type is the roughness chart which shows a graphical representation of the roughness of a surface. We will highlight how surface finish data impacts the performance and quality of machined components. Web understanding how to interpret and utilize a surface finish machining chart is essential for optimizing machining operations. A comprehensive understanding of these factors enables machinists. Web the following charts and tables convert surface finish or roughness between selected industry standard units. Check how injection moulding surface finish can be defined and used as a functional or aesthetical feature. These charts serve as a comprehensive reference tool, outlining the different surface finish options achievable through various machining processes. The most common type is the roughness chart. Rt = roughness, total in microns. As you venture into the realm of machining surface finishes, keep these key points in mind: The most common type is the roughness chart which shows a graphical representation of the roughness of a surface. By understanding and interpreting this chart, manufacturers can make informed decisions regarding machining processes and material selection. Understanding surface. Web the following charts and tables convert surface finish or roughness between selected industry standard units. These charts serve as a comprehensive reference tool, outlining the different surface finish options achievable through various machining processes. Web surface finish is a term that describes the texture, shape, and other properties of the surface of a manufactured object. Web by better understanding. We will highlight how surface finish data impacts the performance and quality of machined components. Web this diagram shows how waviness, lay, and roughness are related to each other: It provides a visual guide to different surface finishes, with notations and surface roughness values. Manufacturers consistently reference it to guarantee product quality during the manufacturing process. Surface roughness average ra. Machine surface finish chart provides you with the comparison of average surface roughness produced by each machining process. Web understanding how to interpret and utilize a surface finish machining chart is essential for optimizing machining operations. Web surface finish specification and comparison. Web surface finish chart by machining technology in the chart below, you can find the lowest surface roughness. Check how injection moulding surface finish can be defined and used as a functional or aesthetical feature. Web surface finish chart by machining technology in the chart below, you can find the lowest surface roughness (best surface finish) that the main machining processes can achieve. Web the machining surface finish chart offers important guidelines for measuring standard surface finish parameters.. Web surface finish is a term that describes the texture, shape, and other properties of the surface of a manufactured object. N = new iso (grade) scale numbers. Tips for improving surface finish. Web the machining surface finish chart offers important guidelines for measuring standard surface finish parameters. These charts serve as a comprehensive reference tool, outlining the different surface. The most common type is the roughness chart which shows a graphical representation of the roughness of a surface. N = new iso (grade) scale numbers. Several factors influence surface finish in cnc machining. Let's explore some common machine finish charts and their significance: A comprehensive understanding of these factors enables machinists to optimize surface finish and minimize defects. Understanding surface finish symbols and ra values is essential for quality control. Machining processes like grinding, milling, turning or drilling produce different surface roughness on a specific material after processing. How to measure surface roughness. Surface roughness is the measurement of the relative smoothness of a surface’s profile, calculated via the microscopic deviations in a surface's true form. Cover or eliminate surface defects. Web understanding how to interpret and utilize a surface finish machining chart is essential for optimizing machining operations. Web there are a variety of surface finishes charts that can be used to help machining operations. Web machining surface finish chart. Web surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. As you venture into the realm of machining surface finishes, keep these key points in mind: It is typically defined in terms of its roughness, waviness, and lay. Web below is a comprehensive machining surface finish chart for your reference: Web by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and performance of manufactured applications. It can also refer to how the surface was treated, such as machining, grinding, or sanding. Web how do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? Web surface finish specification and comparison.

Surface Roughness Chart Comparison ISO Finishing

Complete Guide to Surface Finish Charts, RA, RZ, Measurements, Callouts

Machine Surface Finish Chart

Surface Finish Destiny Tool

What is Surface Finish? Units, Symbols & Chart

Selecting right surface roughness for CNC machining Xometry Europe

Complete Guide to Surface Finish Charts, RA, RZ, Measurements, Callouts

Machining Surface Finish Chart & Specifications Moseys Production

Surface Finish Machinng Chart PDF PDF Surface Roughness Machining

The Only Surface Finishing Chart (and Guide) You'll Ever Need

It Provides A Visual Guide To Different Surface Finishes, With Notations And Surface Roughness Values.

Rt = Roughness, Total In Microns.

Ra Ranges And Corresponding Surface Finishes.

Web Get A Specific Texture Or Appearance To Have Outstanding Looks For A Product.

Related Post: