Mig Welding Gas Flow Rate Chart Lpm

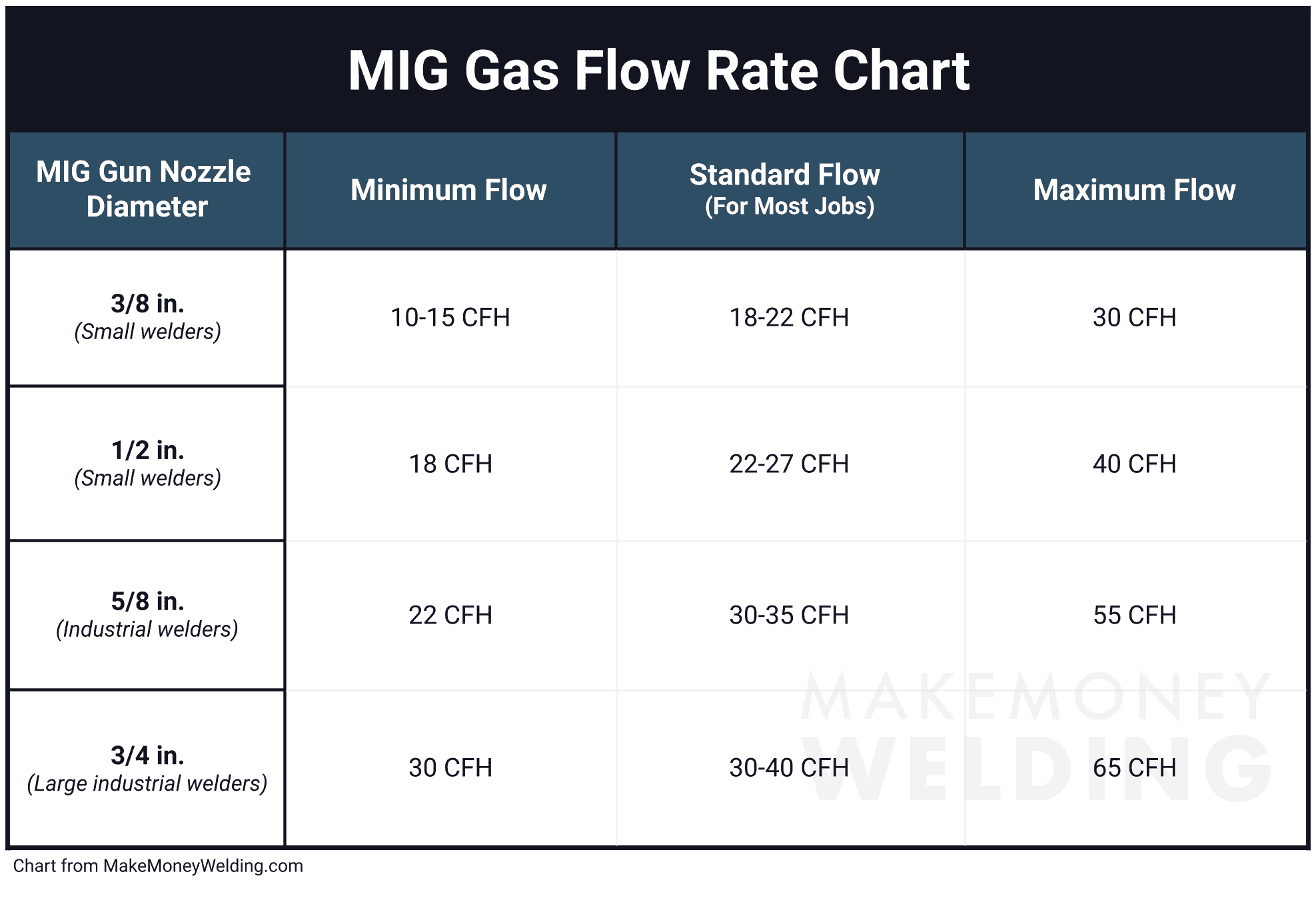

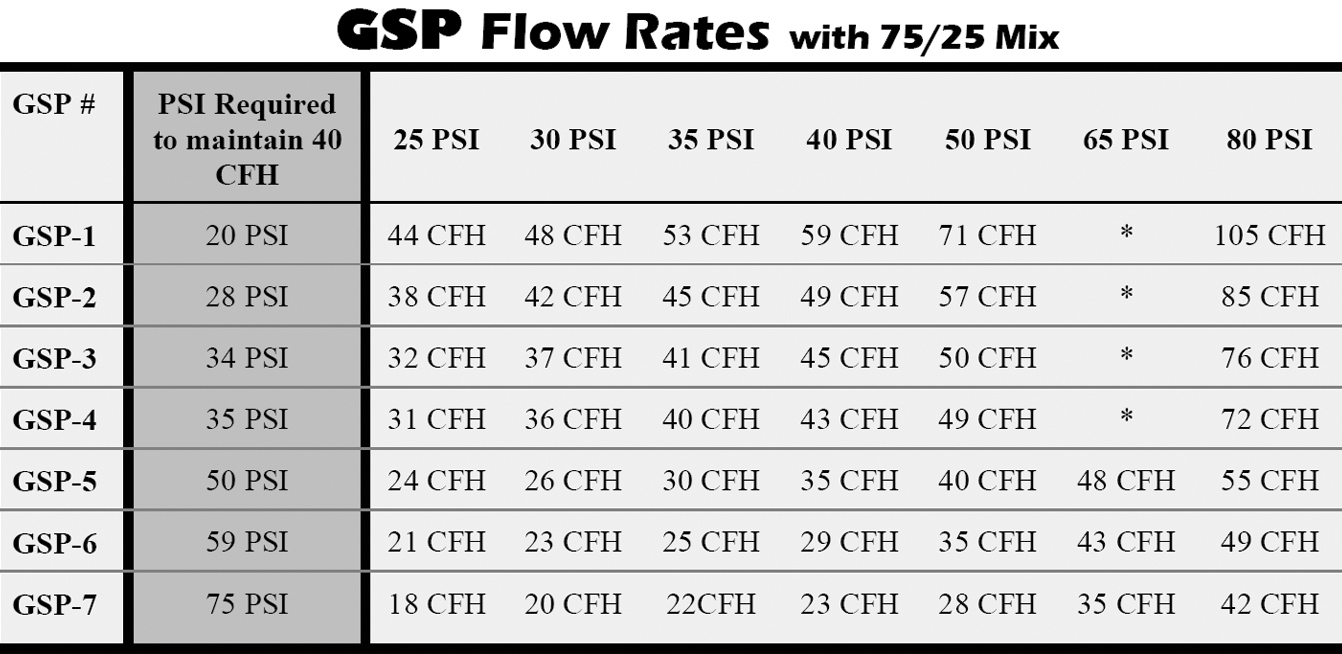

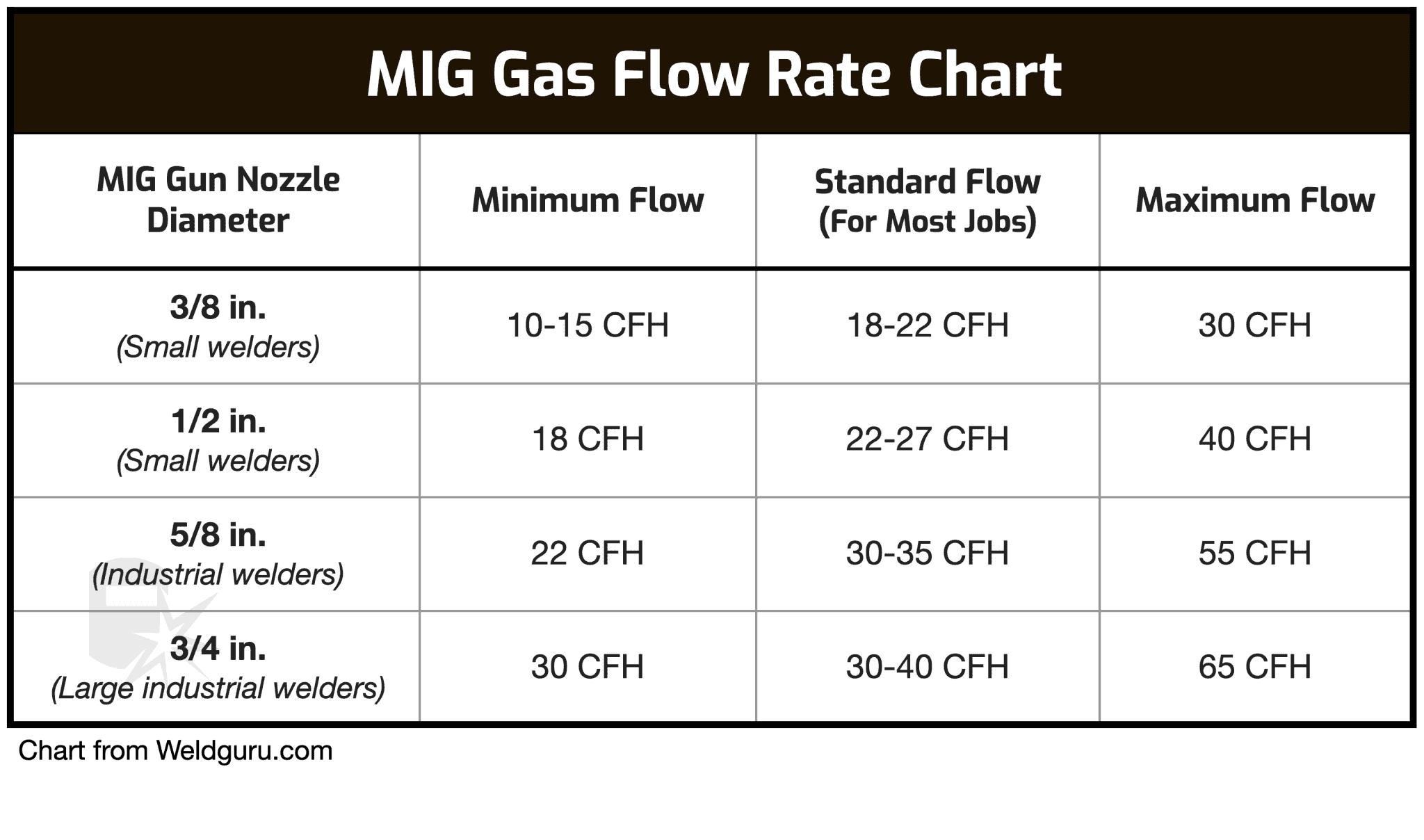

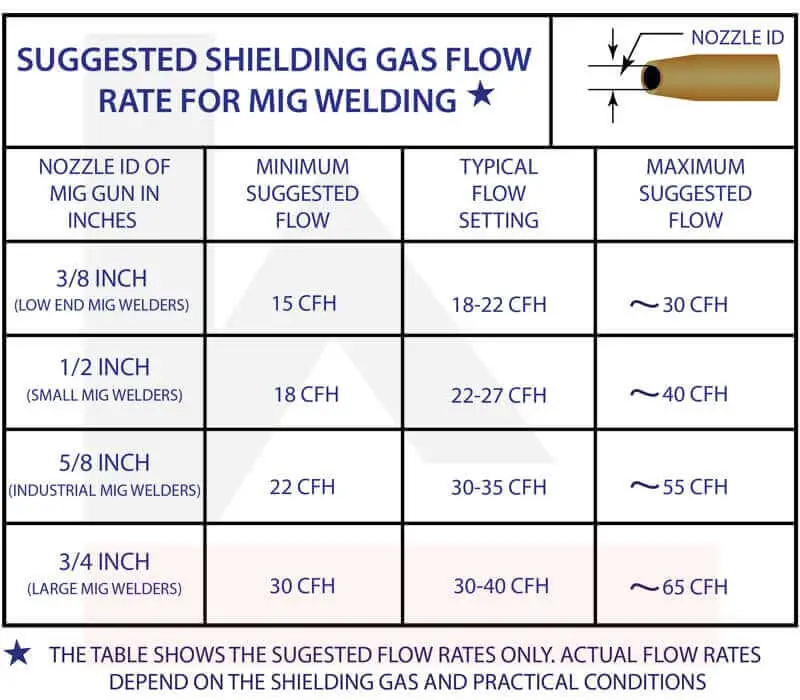

Mig Welding Gas Flow Rate Chart Lpm - Web setting mig shielding gas flow rates. This chart can help figure out what flow rate you need based on the size ( the welders ). Web how do you control gas flow rate? Using a pea shooter flow indicator to check the shielding gas flow rate at the nozzle is the most accurate method. Have a question about converting cfh to psi? 10 lpm is a good starting point. The second is gasless, and the filler metal used has a flux core, which protects the weld instead of gas. In this article we will look at how to determine the ideal welding gas flow rate. Do you have questions about choosing the right welding gas for your diy welding projects? My gas supplier says that's way too high and you need the gas to be barely audible. In many cases, other gases such as oxygen (o 2 ), nitrogen (n 2 ), and hydrogen (h 2) may be added to modify arc characteristics, the molten weld pool, or the weld. Depends on material and tungsten protrusion for me. 10 lpm is a good starting point. Web how do you control gas flow rate? Web typical gas flow. Web unlike oxyfuel welding and cutting, mig gas flow rates are very low. My gas usage seems high, i go for 10 l/m which is what i read is needed. Do you have questions about choosing the right welding gas for your diy welding projects? Click to see why you can't! Web aim for a gas flow rate ranging from. Web you don't need a flow chart, just set it between 12 and 15 ltr/min and use the same flow for whatever you're doing unless you are running well into spray transfer and you may need to tweet it up to around 18. Using a pea shooter flow indicator to check the shielding gas flow rate at the nozzle is. Use this web page to find information about setting mig shielding gas flow rates, reducing waste and improving weld quality. My gas supplier says that's way too high and you need the gas to be barely audible. 10 lpm is a good starting point. See web page with suggested flow rate chart. Using a pea shooter flow indicator to check. The gas flow rate gauge: Web best mig welding gas. Showcased in cfh (cubic feet per hour) if you have a standard gas regulator, opening the valve will release the gas, moving the needles inside the gauge to represent the gas. The role of welding gas. My gas usage seems high, i go for 10 l/m which is what i. Web how do you control gas flow rate? Showcased in psi (pounds per square inch) ideally, the pressure for mig welding should range from 3 to 8 psi. Showcased in cfh (cubic feet per hour) if you have a standard gas regulator, opening the valve will release the gas, moving the needles inside the gauge to represent the gas. The. Whether you’re mig welding mild steel, aluminum or stainless, choosing the right shielding gas for the base material is an important first step in getting good results. Click to see why you can't! Web you don't need a flow chart, just set it between 12 and 15 ltr/min and use the same flow for whatever you're doing unless you are. Web unlike oxyfuel welding and cutting, mig gas flow rates are very low. 10 lpm is a good starting point. Web understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. My gas usage seems high, i go for 10 l/m which is what i read is needed. This chart can. Web setting mig shielding gas flow rates. Can anyone give me an idea of what sort of flow rate i should be using for car panel migging ? The role of welding gas. I have an argon/co2 reg but i'm not sure what setting i should be on litres per min. As to how much it depends on your machine. Argon (ar), helium (he), and carbon dioxide (co 2 ). In many cases, other gases such as oxygen (o 2 ), nitrogen (n 2 ), and hydrogen (h 2) may be added to modify arc characteristics, the molten weld pool, or the weld. Web min & max mig gas flow rate chart the graph below illustrates the minimum and maximum. However, to start, let's revisit the role of welding gas. 10 lpm is a good starting point. Web understand the gas pressure settings for mig welding, helping you find the perfect flow rate for your welding application. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. Web setting mig shielding gas flow rates. The first (and most common) is with gas. Web unlike oxyfuel welding and cutting, mig gas flow rates are very low. In this article we will look at how to determine the ideal welding gas flow rate. Whether you’re mig welding mild steel, aluminum or stainless, choosing the right shielding gas for the base material is an important first step in getting good results. Can anyone give me an idea of what sort of flow rate i should be using for car panel migging ? Measuring this flow is typically done in cfh (cubic feet per hour) or lpm (liters per minute). I'm doing bodywork at the moment. Web how do you control gas flow rate? Click to see why you can't! The gas is used to shield the weld metal from any outside contaminants when welding. We need a lot less flow in tig welding.

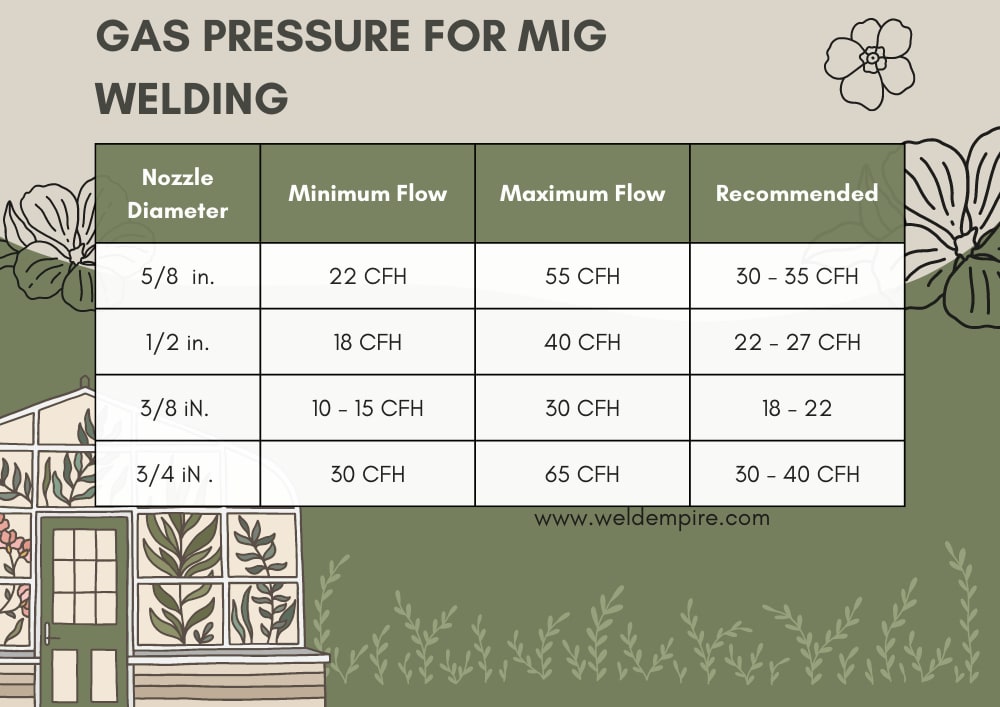

MIG Welding Gas Pressure Settings

MIG Welding Gas Pressure Settings (with Charts), 50 OFF

Mig Welding Gas Flow Rate Chart Lpm

MIG Welding Gas Pressure Settings (with Charts)

Mig Welding Gas Flow Rate Chart

MIG Flow Rate Chart Welding Gases

How to Optimize MIG Welding Shielding Gas Pressure

What Should Be the Gas Pressure for MIG Welding? Weld Empire

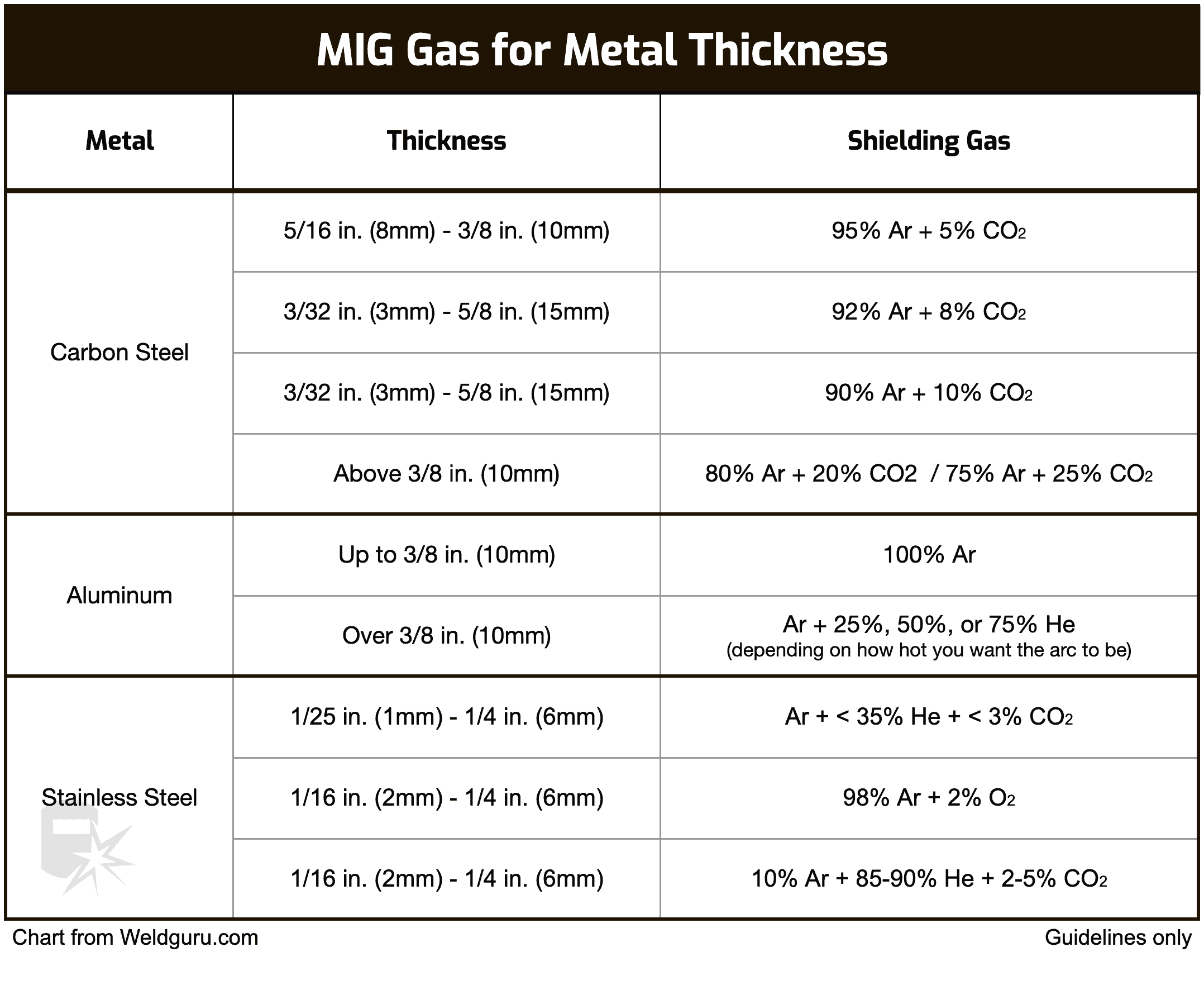

Best Gas for MIG Welding What to Use (with Chart)

MIG Welding Gas Pressure Settings (with Charts)

Web The Correct Gas Flow Rate In Mig Welding Ranges Between 15 To 25 Cfh.

Web Three Pure Gases Form The Foundation For Shielding Arc Welding Processes:

There Are Two Ways To Mig Weld.

Web Tungsten Diameter And Cup Size.

Related Post: