Mig Wire Size Chart

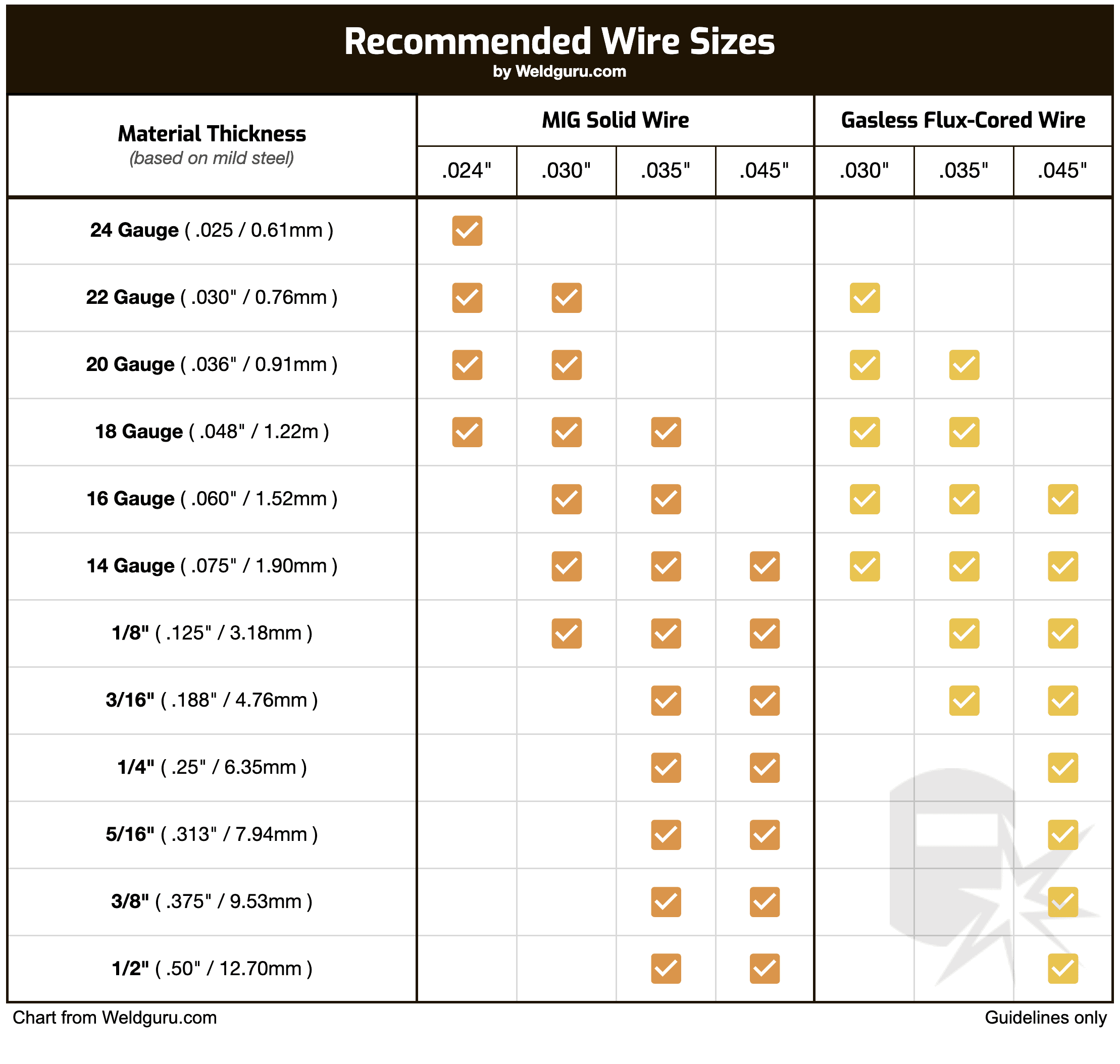

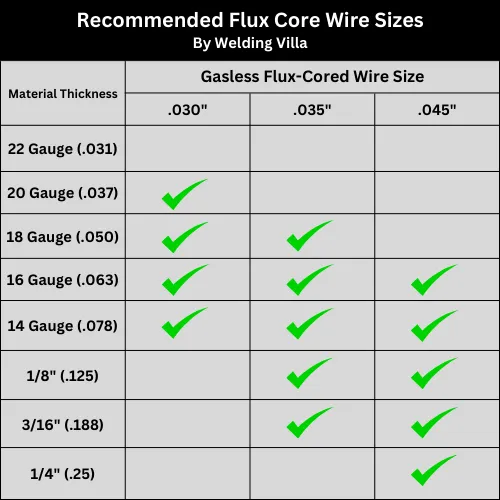

Mig Wire Size Chart - This calculator is intended as a guide to initial power and wire feed settings for people new to welding. But they both use the same wire feed mechanism and serve as filler metal, and consumable electrode in arc welding processes. Standard sizes range from 0.023 to 0.045 inches for welding various metal gauges. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes. Check with your machine manufacturer for any information that. These are all things to consider when deciding which type of welder you’ll need. Adjusting them optimizes welding performance and quality. Mig welding is a process used to join metal pieces together. The diy guide > mig > tutorial > mig settings calculator. Are you welding indoors or outdoors? There are various charts from various manufacturers, which. Standard sizes range from 0.023 to 0.045 inches for welding various metal gauges. Web a general rule of thumb is you need 1 amp of power for every 0.001 inches of steel. For most fabrication shops the.035 with is the most common. We will also provide a mig wire size chart to. How thick is the metal you want to weld? There are various charts from various manufacturers, which. Web esab's mig wire selection guide will help you make the right choice for the types of welds you want to make and the machines in your shop. Select proper wire size according to amperage. Web the welding wire size chart is a. Web a mig wire size chart provides recommended wire diameters for different metal thicknesses. We will also provide a mig wire size chart to help you select the appropriate wire size for your welding project. How thick is the metal you want to weld? Standard sizes range from 0.023 to 0.045 inches for welding various metal gauges. In making a. Web mig welding wire size. There are various charts from various manufacturers, which. The most common sizes most welders use are: Web how big is the job? Web in this article, we will guide you through the basics of mig wire sizes and how to select the right size for your welding project. The amp range overlaps, giving you various options for each current setting. Your mig welding wire size will determine the amperage setting used. Quick guide for selecting mig wire size and welder amperage for your application. When you’re trying to get into stainless steel welding, there’s nothing more frustrating than the realization that you have no idea what it is. The ultimate mig welding guide. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes. We will also provide a mig wire size chart to help you select the appropriate wire size for your welding project. .125 inch = 125 amps. When you’re trying to get into stainless steel welding, there’s nothing more frustrating than the. Navigating the complexities of mig welding requires a deep understanding of its two pivotal parameters: Check with your machine manufacturer for any information that. Web typical mig welding electrodes are a solid wire ranging from a thickness of.023 to.045. For most fabrication shops the.035 with is the most common. Web esab's mig wire selection guide will help you make the. Table of wire speed for mig welding. The diy guide > mig > tutorial > mig settings calculator. Web mig welding wire size. The most common sizes most welders use are: Since you don't want to change wire, select one for your most commonly used thicknesses. This calculator is intended as a guide to initial power and wire feed settings for people new to welding. Web this chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. Web mig welding wire size. Web a mig welding wire speed and. .125 inch = 125 amps. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes. When you’re trying to get into stainless steel welding, there’s nothing more frustrating than the realization that you have no idea what it is you’re getting into. Mig welding is a process used to join metal pieces together. But they both. So, how many amps does it take to weld 3/8 steel? Check with your machine manufacturer for any information that. There are dozens of stainless steel mig wires on the market, each with its own list of pros and cons. Web a mig welding wire speed chart offers insights into appropriate wire speeds for various material thicknesses and types in mig welding. When you’re trying to get into stainless steel welding, there’s nothing more frustrating than the realization that you have no idea what it is you’re getting into. Your mig welding wire size will determine the amperage setting used. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Web a mig wire size chart provides recommended wire diameters for different metal thicknesses. We will also provide a mig wire size chart to help you select the appropriate wire size for your welding project. Selecting the appropriate mig wire size is crucial for successful welding. Web in this article, we will guide you through the basics of mig wire sizes and how to select the right size for your welding project. How thick is the metal you want to weld? The most common sizes most welders use are: We will also provide a mig wire size chart to help you select the appropriate wire size for your welding project. The settings in the calculator suit me (a diy welder). Web mig welding wire size.

Important MIG Welder Settings You Need to Know (with Chart)

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

MIG Welding Wire Charts Work,work,work...I love it!

MIG welder settings explained Amperage & Wire Speed

MIG Welding Wire Essentials A Guide to Types & Uses

Mig welding how to set up your welder from a to z Artofit

Mig Welding Settings Chart Metric Pdf

MIG & Flux Core Welding Wire Types With Detail Chart

mig wire selection Grumpys Performance Garage

How To MIG Weld Aluminum Beginners Guide (with Chart)

Web Typical Mig Welding Electrodes Are A Solid Wire Ranging From A Thickness Of.023 To.045.

Web How Big Is The Job?

Some Are Much Thicker For Heavy Industrial Applications.

In Making A Mig Wire Purchase, Your Last Decision Involves The Quantity Of Wire And How It’s Housed.

Related Post: