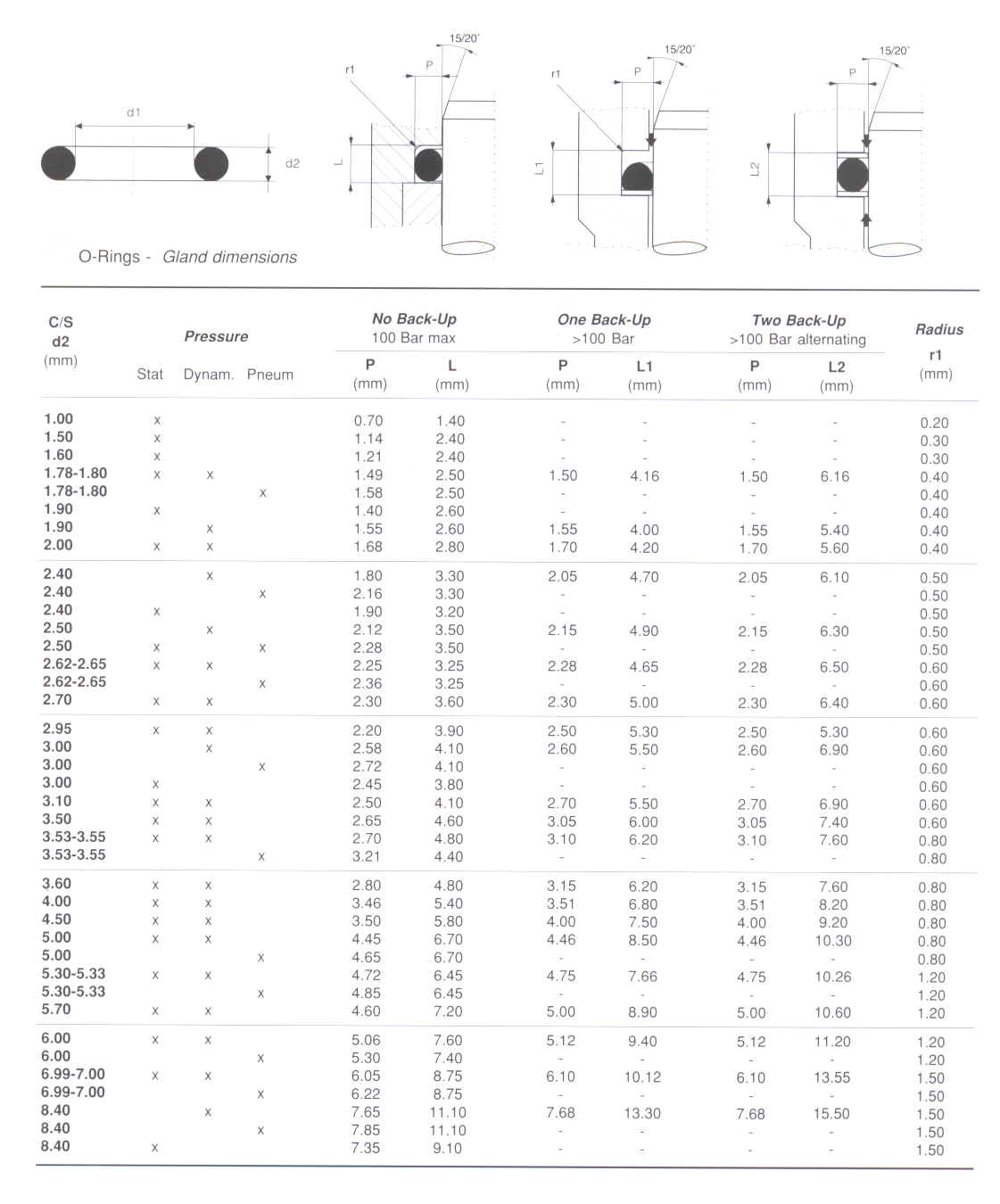

O Ring Groove Dimensions Chart

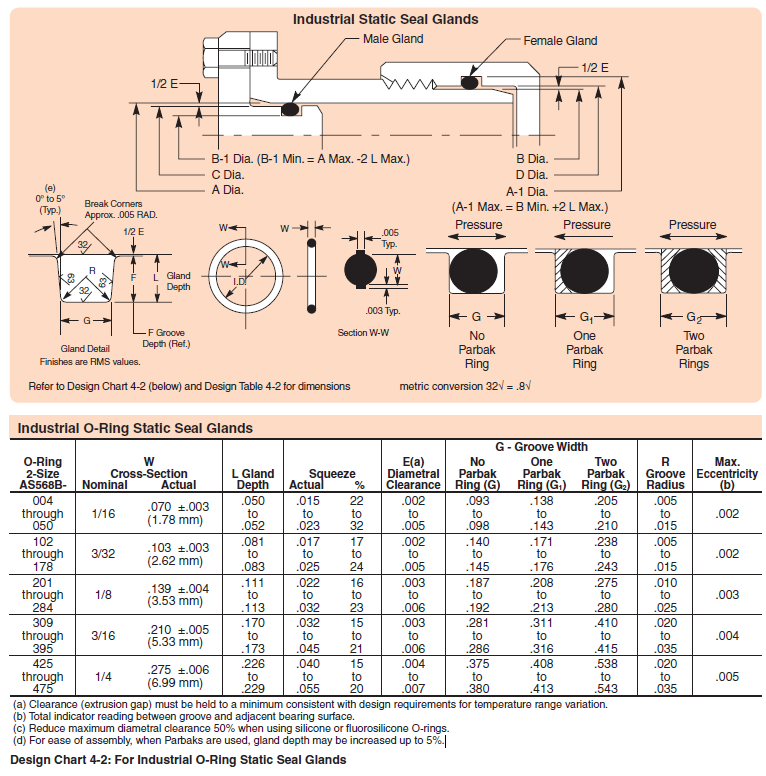

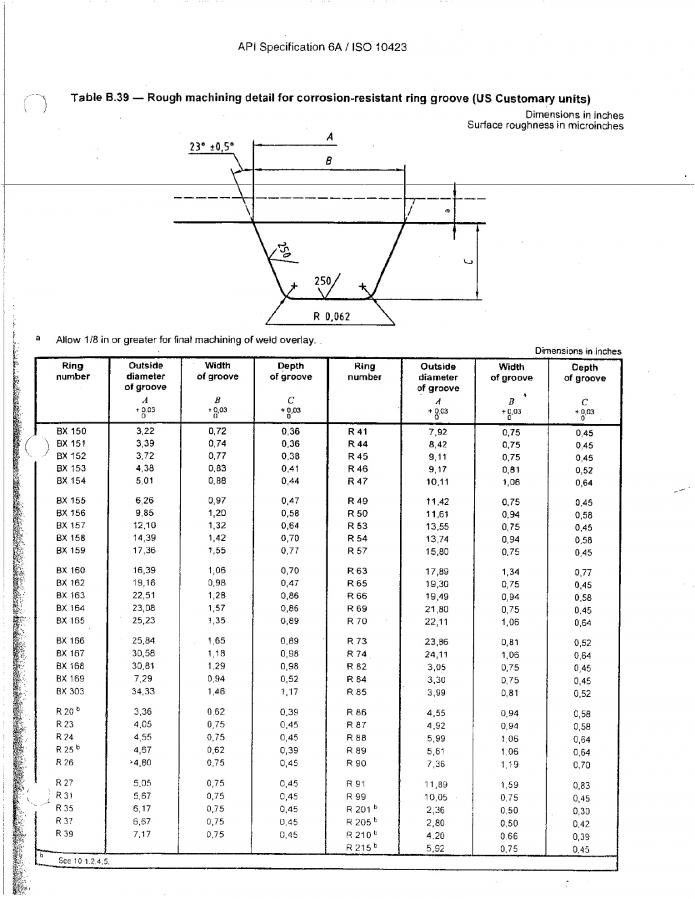

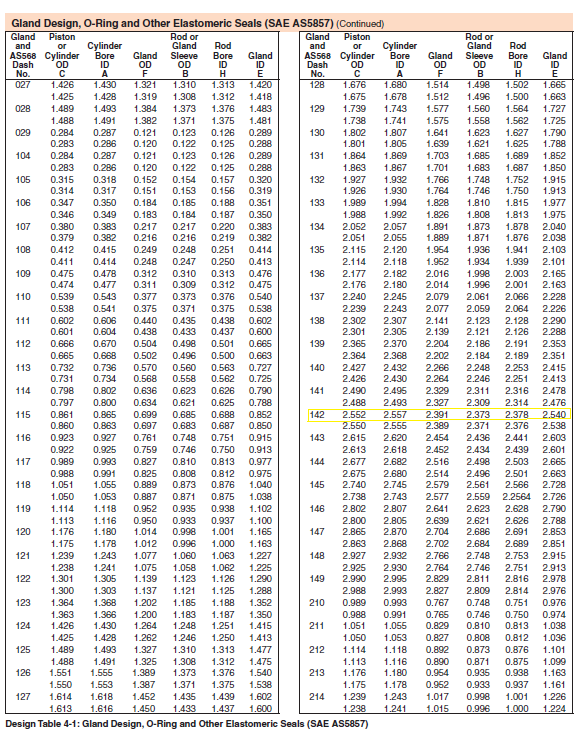

O Ring Groove Dimensions Chart - * these designs require considerable installation stretch. X = surface finish in μ ra. Web this chart provides dimensions for standard (an) shrinkage materials only. For more information on shrinkage rates, see the appendix. • nitrile nbr 70 and 90 shore a, We have included static, dynamic, and pneumatic applications. Web the following information is a guide for o’ring groove dimensions for both static and reciprocating dynamic applications. Contact us today to receive a quote or samples. The guidelines are for the nominal condition. The minimum and maximum conditions should also be checked. Web learn more about the three main types of standard groove designs at seal & design. Most of these sizes are readily available from eriks stock in: O (h ) = mean o.d. For more information on shrinkage rates, see the appendix. The minimum and maximum conditions should also be checked. • nitrile nbr 70 and 90 shore a, Clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. Generally surface finish for sealing surfaces are as follows… 63rms maximum: Web the following information is a guide for o’ring groove dimensions for both static and reciprocating dynamic applications. Surface finishes up to 64 to. Most of these sizes are readily available from eriks stock in: Web the following information is a guide for o’ring groove dimensions for both static and reciprocating dynamic applications. Web learn more about the three main types of standard groove designs at seal & design. The minimum and maximum conditions should also be checked. Contact us today to receive a. Five degree sloping sides are easier to machine and are suitable for lower pressures. Clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. The minimum and maximum conditions should also be checked. Total indicator reading between groove and adjacent bearing surface. O (h ) = mean o.d. The minimum and maximum conditions should also be checked. Total indicator reading between groove and adjacent bearing surface. The info is based on 70 shore a durometer hardness only. O (h ) = mean o.d. Clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. Contact us today to receive a quote or samples. • nitrile nbr 70 and 90 shore a, Web the following information is a guide for o’ring groove dimensions for both static and reciprocating dynamic applications. Total indicator reading between groove and adjacent bearing surface. Surface finishes up to 64 to 125 rms with no burrs, nicks, or scratches are. The info is based on 70 shore a durometer hardness only. Generally surface finish for sealing surfaces are as follows… 63rms maximum: Web the following information is a guide for o’ring groove dimensions for both static and reciprocating dynamic applications. The calculator takes all relevant parameters into account like: For more information on shrinkage rates, see the appendix. We have included static, dynamic, and pneumatic applications. The guidelines are for the nominal condition. Surface finishes up to 64 to 125 rms with no burrs, nicks, or scratches are. X = surface finish in μ ra. These correspond to as568a dimensions. Clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. Surface finishes up to 64 to 125 rms with no burrs, nicks, or scratches are. The info is based on 70 shore a durometer hardness only. Generally surface finish for sealing surfaces are as follows… 63rms maximum: X = surface finish in μ. Five degree sloping sides are easier to machine and are suitable for lower pressures. Web this chart provides dimensions for standard (an) shrinkage materials only. X = surface finish in μ ra. The calculator takes all relevant parameters into account like: We have included static, dynamic, and pneumatic applications. Most of these sizes are readily available from eriks stock in: X = surface finish in μ ra. We have included static, dynamic, and pneumatic applications. Clearance (extrusion gap) must be held to a minimum consistent with design requirements for temperature range variation. For more information on shrinkage rates, see the appendix. Web the following information is a guide for o’ring groove dimensions for both static and reciprocating dynamic applications. The info is based on 70 shore a durometer hardness only. The calculator takes all relevant parameters into account like: Total indicator reading between groove and adjacent bearing surface. Surface finishes up to 64 to 125 rms with no burrs, nicks, or scratches are. These correspond to as568a dimensions. Contact us today to receive a quote or samples. The guidelines are for the nominal condition. Web this chart provides dimensions for standard (an) shrinkage materials only. Generally surface finish for sealing surfaces are as follows… 63rms maximum: * these designs require considerable installation stretch.

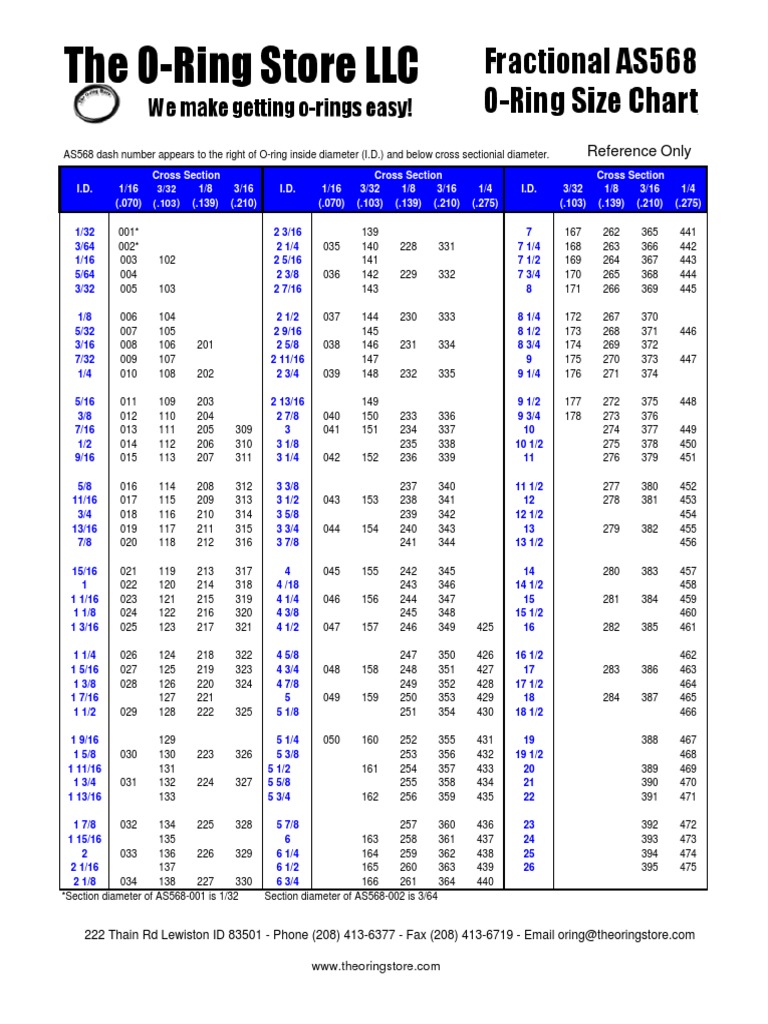

O'ring Sizing Chart

Oring Groove Size Chart

Printable O Ring Size Chart

Metric O Ring Groove Size Chart Chart Examples

Basic Applications Metric ORing Groove Design Reference

O Ring Groove Size Chart

Sae code 61 o ring groove dimensions Knowledge Yuyao Jiayuan

o ring groove size chart pdf Ranee Ojeda

O Ring Groove Dimensions Chart

O'ring Groove Size Chart

• Nitrile Nbr 70 And 90 Shore A,

O (H ) = Mean O.d.

The Minimum And Maximum Conditions Should Also Be Checked.

Web Learn More About The Three Main Types Of Standard Groove Designs At Seal & Design.

Related Post: