Oil Burner Electrode Adjustment Chart

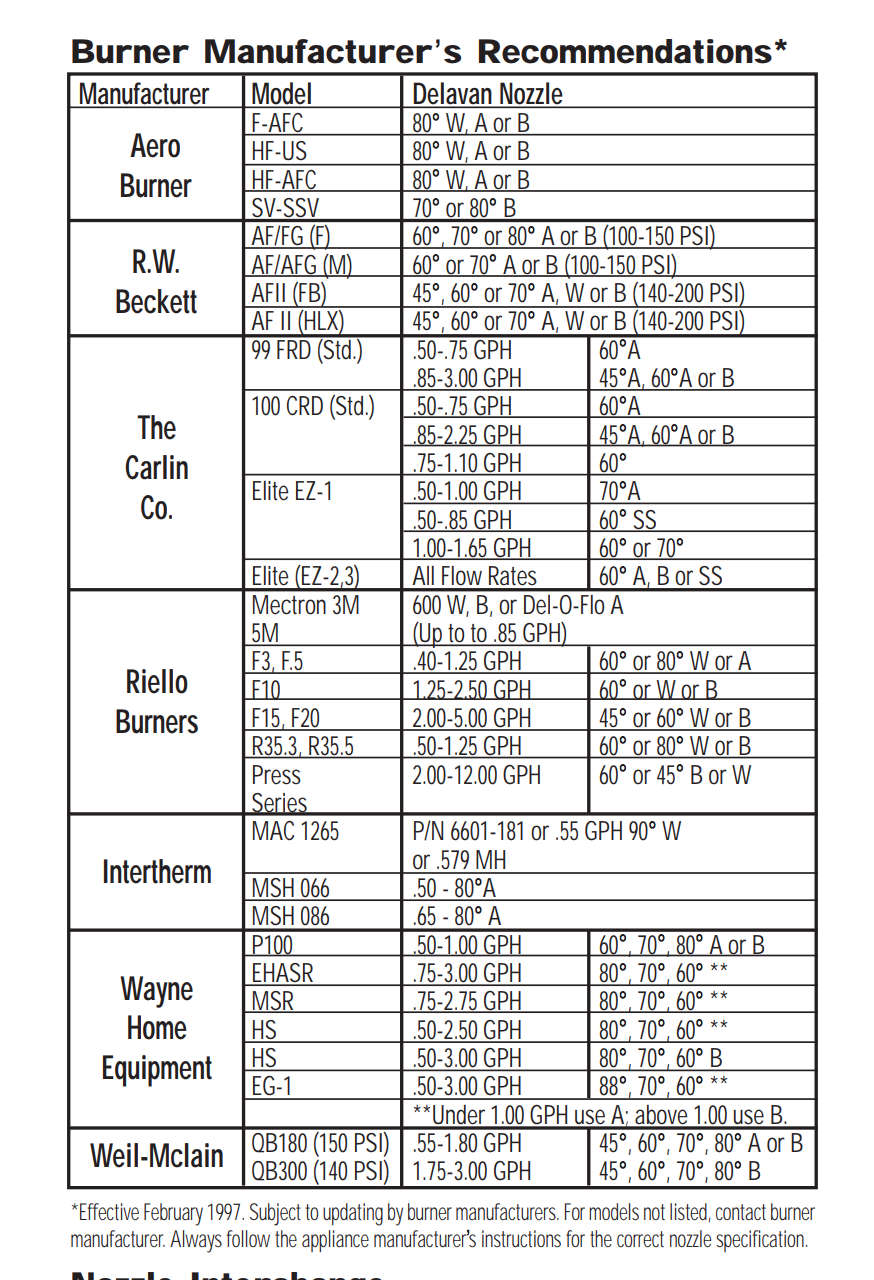

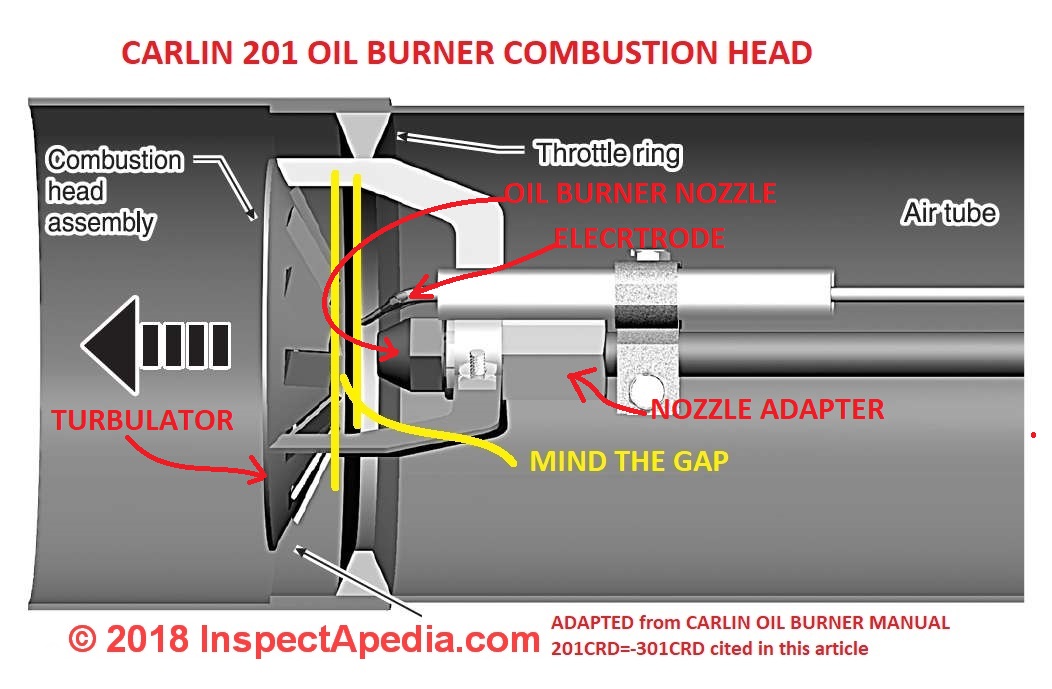

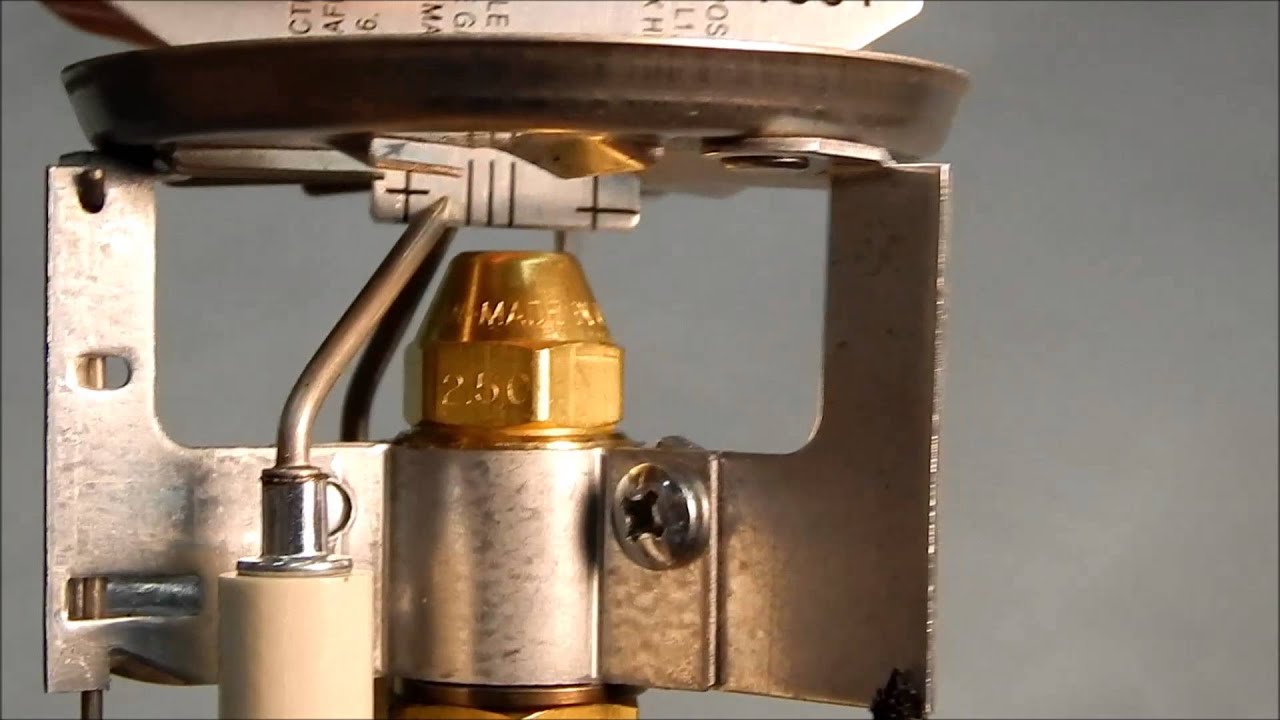

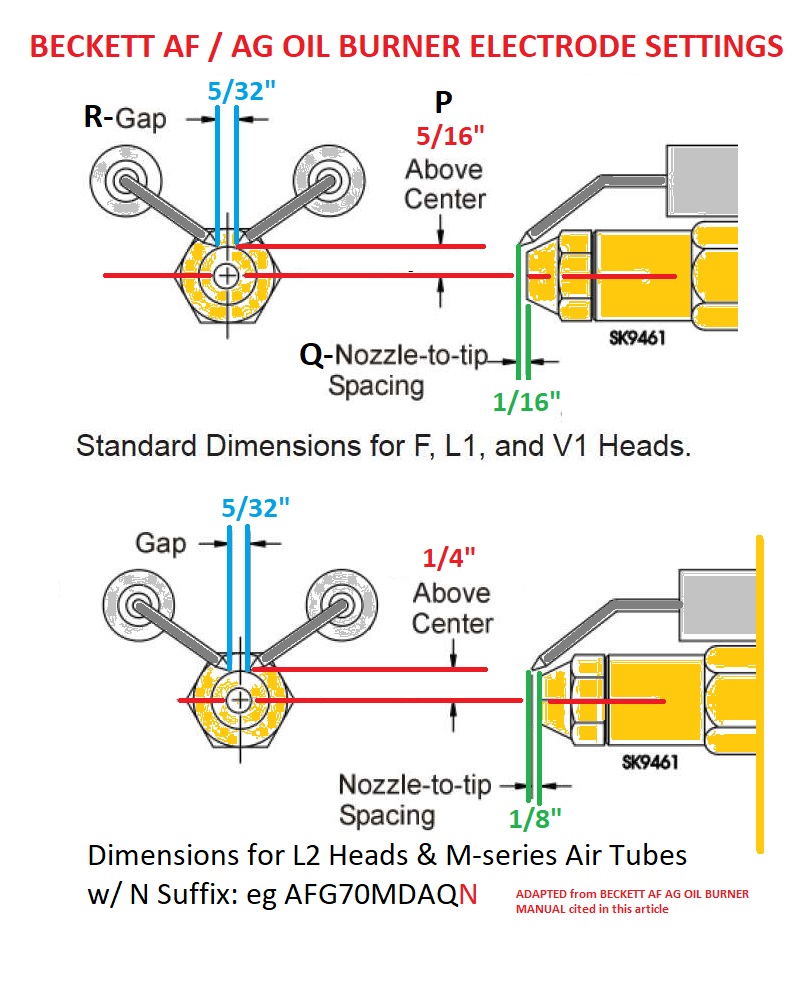

Oil Burner Electrode Adjustment Chart - Web oil burner electrode settings guide & measurements: Web view and download riello 40 f10 installation & operating manual online. Specific applications may require testing more than one nozzle to obtain both clean combustion and a good. Web this video shows you how to adjust the electodes in an oil burner and how to replace an oil nozzle. Web f, fbx, l and v head settings are set by aligning the electrode tip with the 5/16″ cross marks. The standard cautionary notes apply: Oil burner ignition electrode gap & positions. Make sure the retention head is securely against the stops in the retention ring when the check the electrode tip settings. The slightly negative pull overfire removes combustion products from the chamber and out the flue. These burners may appear to be basically identical, but there are differences in design and performance. Move the escutcheon plate 1/16’’ forward for an afii burner with the fbx airtube combination. Typically, or whatever the manufacturer specifies. We discuss the setting of the gap and position of oil burner ignition electrodes. Attach air tube ( if not already installed ) • carefully check and realign electrode tips after replacing nozzle, The stack dra, measured near the. Attach air tube ( if not already installed ) • carefully check and realign electrode tips after replacing nozzle, An oil burner adjustment template provided by beckett corporation and shown just below summarizes the adjustment of the ignition electrodes & their positioning for beckett oil burners. For more details, refer to “ connect fuel lines ” on page 7. Fuel. Web critical that all oil fired heating equipment be installed using combustion efficiency test equipment and the burners be set to the appliance manufacturers recommended settings. Web • verify that the burner fuel unit is compatible with the oil supply system. Web oil nozzle selection — conversion burners if oil nozzle selection information for the application is not available from. Web the important ‘z’ dimension is the distance from the face of the nozzle to the fl at face of the head (or heat shield, if applicable). One stage kerosene and light oil burner. Set the electrode tip gap spacing (5/32”) by adjusting the tips to meet the two outside marks. Make sure you turn off the system, and be. Attach air tube ( if not already installed ) • carefully check and realign electrode tips after replacing nozzle, We discuss the setting of the gap and position of oil burner ignition electrodes. The burner meets protection level of ip 40, en 60529. The stack dra, measured near the appliance flue connection, should be slightly higher than the overfire reading. If the condition still appears unsafe, contact the fire department. Whether you are installing a new burner, solving a problem, or conducting an annual service call, you eventually get to the point where you have to adjust the burner. Make sure the retention head is securely against the stops in the retention ring when the check the electrode tip settings.. (1) use wet pac ceramic liner to line the inside of chamber, (2) adjust burner (see finaladjustments column). Make sure the retention head is securely against the stops in the retention ring when the check the electrode tip settings. The “z” dimension is now set. The standard cautionary notes apply: The stack dra, measured near the appliance flue connection, should. Web each situation calls for proper burner adjustment. An oil burner adjustment template provided by beckett corporation and shown just below summarizes the adjustment of the ignition electrodes & their positioning for beckett oil burners. One stage kerosene and light oil burner. Web view and download riello 40 f10 installation & operating manual online. Make sure you turn off the. Web view and download riello 40 f10 installation & operating manual online. We discuss the setting of the gap and position of oil burner ignition electrodes. If the condition still appears unsafe, contact the fire department. Specific applications may require testing more than one nozzle to obtain both clean combustion and a good. Web remove the nlea and gauge. For more details, refer to “ connect fuel lines ” on page 7. One stage kerosene and light oil burner. Set the electrode tip gap spacing (5/32”) by adjusting the tips to meet the two outside marks. The slightly negative pull overfire removes combustion products from the chamber and out the flue. Web the beckett nx oil burner uses standard. The “z” dimension is now set. One stage kerosene and light oil burner. (1) use wet pac ceramic liner to line the inside of chamber, (2) adjust burner (see finaladjustments column). Adjust the escutcheon plate to the mark on the housing. The standard cautionary notes apply: Web each situation calls for proper burner adjustment. These burners may appear to be basically identical, but there are differences in design and performance. Web adjusting electrodes in your oil burner is something normally done by a professional, however it is not rocket science. 40 f10 burner pdf manual download. Web oil nozzle selection — conversion burners if oil nozzle selection information for the application is not available from appliance documents, you can use table 1, page 4, for an initial nozzle selection for the application. Attach air tube ( if not already installed ) • carefully check and realign electrode tips after replacing nozzle, Web oil burner electrode settings guide & measurements: Web the following diagram will show you the 5/16” standard specifications: Move the escutcheon plate 1/16’’ forward for an afii burner with the fbx airtube combination. The burner meets protection level of ip 40, en 60529. We discuss the setting of the gap and position of oil burner ignition electrodes.

Oil Burner maintenance setting electrodes and replacing nozzle YouTube

Oil Burning Temperature Chart A Visual Reference of Charts Chart Master

Oil Burner Electrode Assembly Inspection, Cleaning, Adjustment

Frost Fighter Heaters How to Set the Electrode Gaps (IDF Oil/Diesel

Oil Burner Electrode Adjustment Chart

Oil Burner Electrode Adjustment Chart

Oil Burner Electrode Assembly Inspection, Cleaning, Adjustment

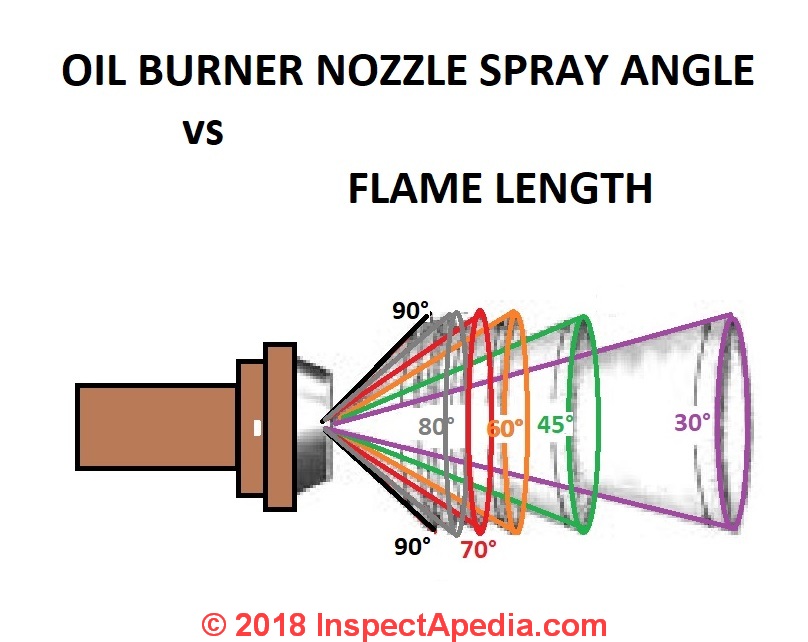

Oil Burner Electrode & Nozzle Guide Nozzle types, patterns, selection

How to Adjust the Electrode (Points) Gap On Riello Oil Fired Burners

Prepare burner & site, Check/adjust "z" dimension "f" head Beckett

Please Review The Comparison Chart Below:

Web The Important ‘Z’ Dimension Is The Distance From The Face Of The Nozzle To The Fl At Face Of The Head (Or Heat Shield, If Applicable).

Web Critical That All Oil Fired Heating Equipment Be Installed Using Combustion Efficiency Test Equipment And The Burners Be Set To The Appliance Manufacturers Recommended Settings.

Make Sure The Retention Head Is Securely Against The Stops In The Retention Ring When The Check The Electrode Tip Settings.

Related Post: