Oxy Acetylene Welding Pressure Chart

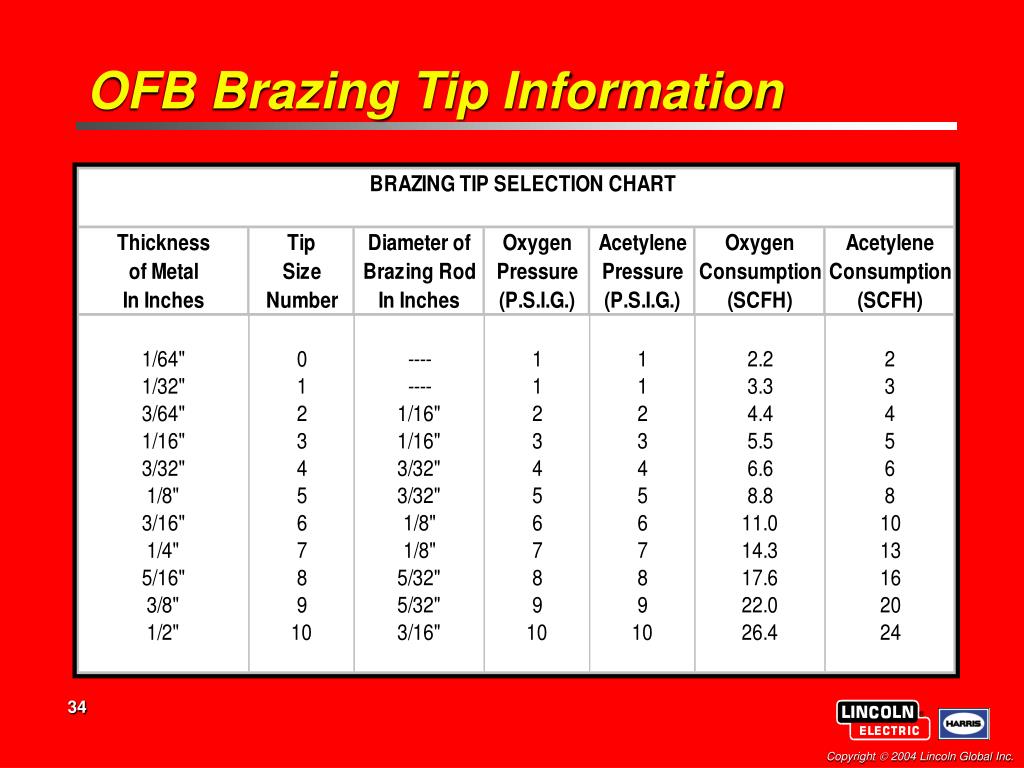

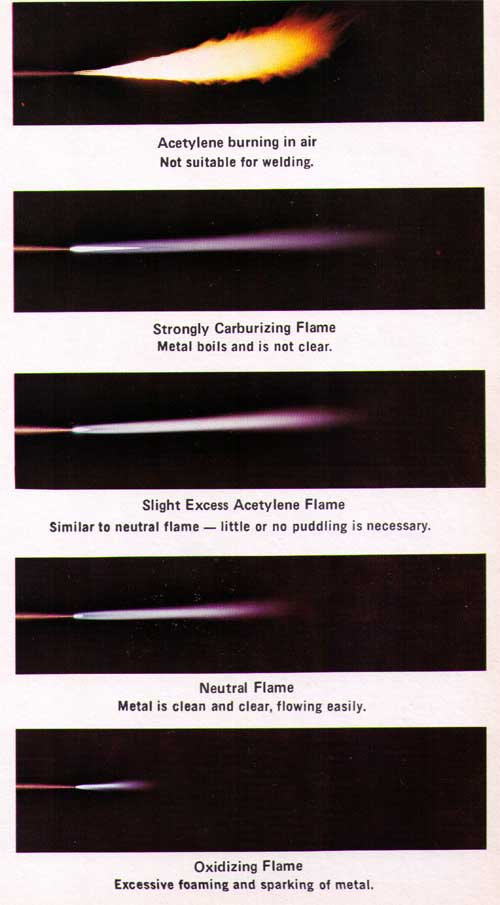

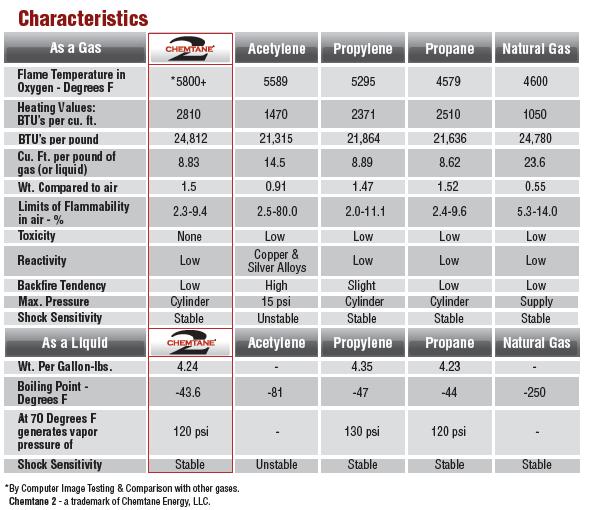

Oxy Acetylene Welding Pressure Chart - 0 1780 *** pressures shown above only apply to full cylinders *** author: Fasten oxygen and acetylene cylinders in an upright position. Web oxy acetylene welding set up and pressure settings chart : Web the following guides should help you. 7.1 filler rod and flux selection chart 23 7.2 how to improve weld quality 24 8.0 joining processes 28 8.1 welding28 8.2 braze welding 28. These recommended practices for oxyacetylene welding include the latest procedures to be used in conjunction with oxyacetylene equipment and the latest safety recommendations. Web the blowpipe is therefore designed to accommodate different sizes of 'swan neck copper nozzle which allows the correct intensity of flame to be used. Lightweight & heavy duty swagged oxy/acet gas welding nozzles. If you have a cylinder cart, place both the oxygen and acetylene cylinders into it. It is an intricate process that requires a great degree of skill, focus and patience, but don’t be discouraged. Kerf width 1/8 000 20/25 3/5 3/5 20/30.04 1/4 00 20/25 3/5 3/5 27/30.05 3/8 0 25/30 3/5 3/5 24/28.06 1/2 0 30/35 3/6 3/5 20/24.06 3/4 1 30/35 4/7 3/5 17/21.07 Web regulator to give the correct working pressure (see chart on page 13), this ensures that any air or oxygen is purged from the hose. The recommended setting. Web oxy acetylene welding set up and pressure settings chart : Open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. The mixing of the gases (oxygen and acetylene) happens in the welding torch. Web the following guides should help you. If not,. Web the blowpipe is therefore designed to accommodate different sizes of 'swan neck copper nozzle which allows the correct intensity of flame to be used. Repeat the procedure for the oxygen side. The relationship between material thickness, blowpipe nozzle size and welding speed, is shown in the chart. Web acetylene pressure range psig: Web oxy acetylene welding set up and. The relationship between material thickness, blowpipe nozzle size and welding speed, is shown in the chart. Tip number purpose capacity (width x depth) pressure − psig at regulator consumption − scfh drill size in. Web advanced welding supply company industrial gas information acetylene pressure temperature oxygen pressure 355. Fasten oxygen and acetylene cylinders in an upright position. Complete lists of. Web regulator to give the correct working pressure (see chart on page 13), this ensures that any air or oxygen is purged from the hose. 7.1 filler rod and flux selection chart 23 7.2 how to improve weld quality 24 8.0 joining processes 28 8.1 welding28 8.2 braze welding 28. Web with the pressure in a full acetylene cylinder at. Kerf width 1/8 000 20/25 3/5 3/5 20/30.04 1/4 00 20/25 3/5 3/5 27/30.05 3/8 0 25/30 3/5 3/5 24/28.06 1/2 0 30/35 3/6 3/5 20/24.06 3/4 1 30/35 4/7 3/5 17/21.07 It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal. This is accomplished by using an adjustable pressure reducing. If not, they should be securely fastened with a chain to a workbench, a wall, or a post. Web the following guides should help you. First, we must clean the nozzle because if the head of the nozzle is dirty will cause a flame bad. Web oxy acetylene welding set up and pressure settings chart : Web with the pressure. Web the blowpipe is therefore designed to accommodate different sizes of 'swan neck copper nozzle which allows the correct intensity of flame to be used. Fasten oxygen and acetylene cylinders in an upright position. 0 1780 *** pressures shown above only apply to full cylinders *** author: If not, they should be securely fastened with a chain to a workbench,. Repeat the procedure for the oxygen side. Web these recommended practices for oxyacetylene welding include the latest procedures to be used in conjunction with oxyacetylene equipment and the latest safety recommendations. Mm oxygen acetylene oxygen acetylene cutting preheat. Cylinder into is suitable for the gas and pressure involved. Open regulator oxygen and acetylene, set until the pressure matches with what. Open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Kerf width 1/8 000 20/25 3/5 3/5 20/30.04 1/4 00 20/25 3/5 3/5 27/30.05 3/8 0 25/30 3/5 3/5 24/28.06 1/2 0 30/35 3/6 3/5 20/24.06 3/4 1 30/35 4/7 3/5 17/21.07 With. If you have a cylinder cart, place both the oxygen and acetylene cylinders into it. If not, they should be securely fastened with a chain to a workbench, a wall, or a post. This is accomplished by using an adjustable pressure reducing regulator. Mm oxygen acetylene oxygen acetylene cutting preheat. Ensure that any accessories (such as hoses These recommended practices for oxyacetylene welding include the latest procedures to be used in conjunction with oxyacetylene equipment and the latest safety recommendations. It is an intricate process that requires a great degree of skill, focus and patience, but don’t be discouraged. The mixing of the gases (oxygen and acetylene) happens in the welding torch. Web the following guides should help you. Web with the pressure in a full acetylene cylinder at 250 psig and a full oxygen cylinder at 2200 psig, a way is needed to lower these cylinder pressures to desired working pressures for use in the torch. There are two pressure gauges on each cylinder. Kerf width 1/8 000 20/25 3/5 3/5 20/30.04 1/4 00 20/25 3/5 3/5 27/30.05 3/8 0 25/30 3/5 3/5 24/28.06 1/2 0 30/35 3/6 3/5 20/24.06 3/4 1 30/35 4/7 3/5 17/21.07 Complete lists of equipment are available from individual manufacturers. Sc and mc series special purpose tips for hand torches and cutting assemblies − acetylene. With the right information and proper application you. Lightweight include dh type oxy acetylene nozzles (not pictured) heavy duty includes type 3, 4 & 5 torches.

Oxy Acetylene Victor Welding Tip Chart

Oxy Acetylene Cutting Pressure Chart

Oxy Acetylene Pressure Settings Chart Best Picture Of Chart

OxyAcetylene Welding Tips Model W1 Compatible with 100 Series Victor

Oxy Acetylene Torch Tip Chart

oxygen and acetylene pressure settings

oxygen and acetylene pressure settings

Oxyacetylene Torch Settings Chart

Oxyacetylene Cutting Pressure Chart

Oxy Acetylene Welding Rod Chart

Cylinder Into Is Suitable For The Gas And Pressure Involved.

Web Regulator To Give The Correct Working Pressure (See Chart On Page 13), This Ensures That Any Air Or Oxygen Is Purged From The Hose.

Tip Number Purpose Capacity (Width X Depth) Pressure − Psig At Regulator Consumption − Scfh Drill Size In.

The Relationship Between Material Thickness, Blowpipe Nozzle Size And Welding Speed, Is Shown In The Chart.

Related Post: