Oxyacetylene Cutting Tip Size Chart

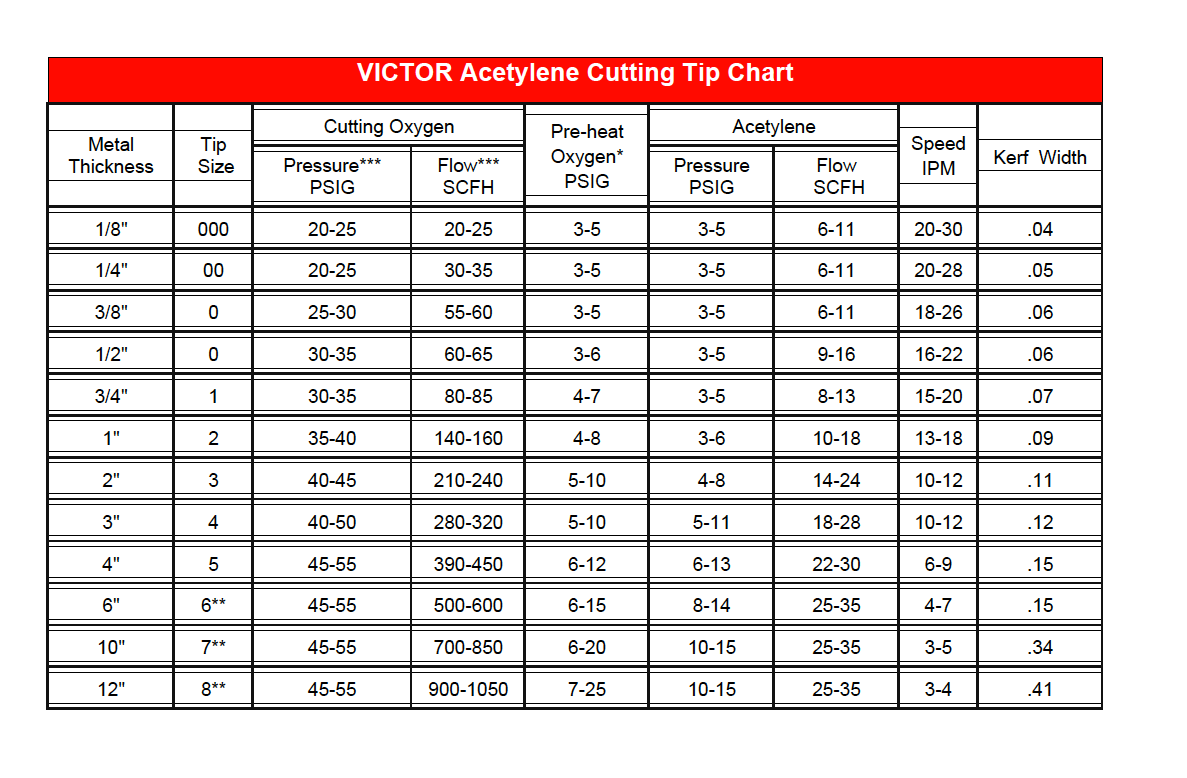

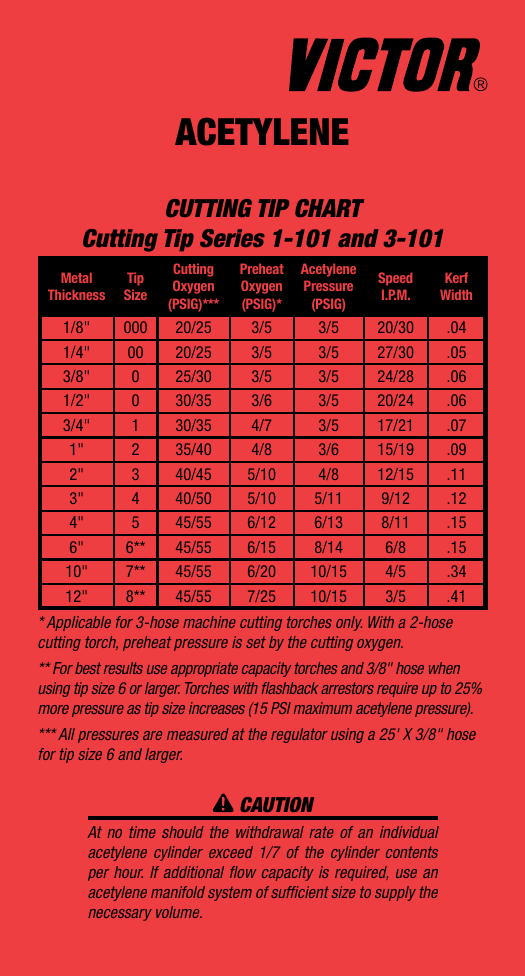

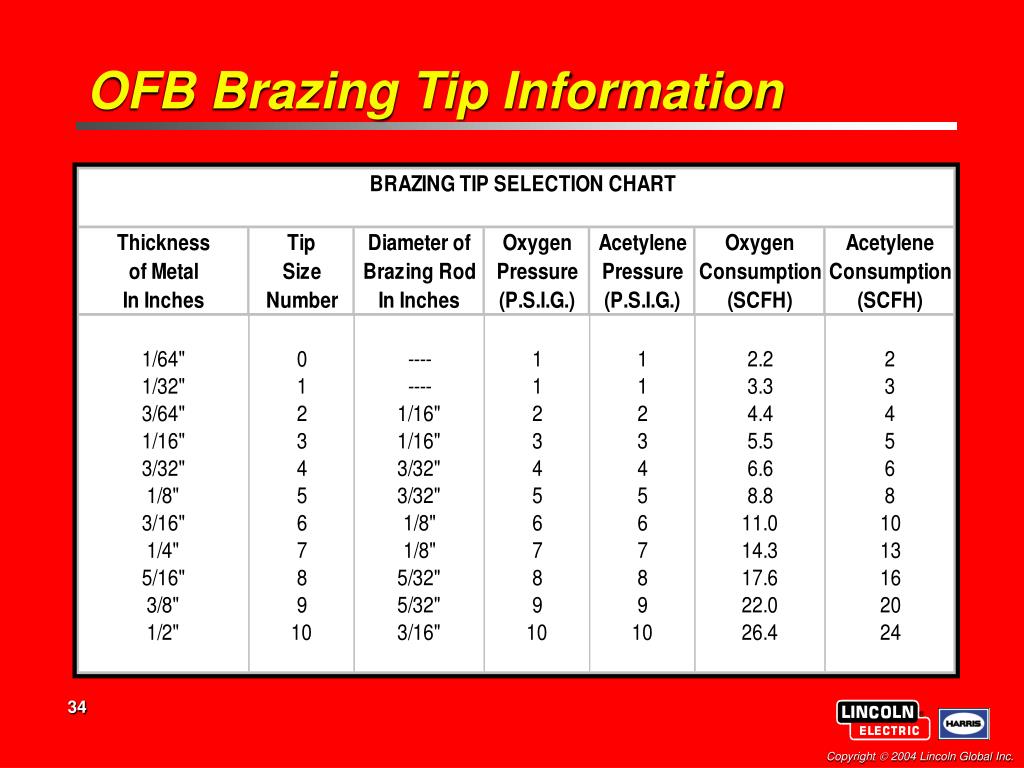

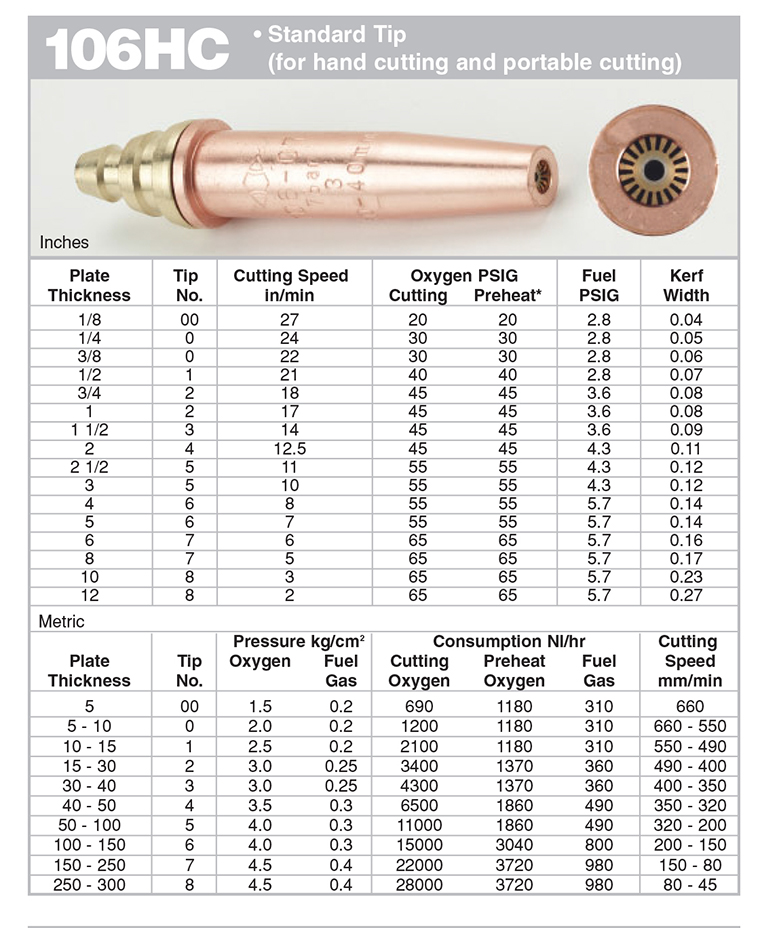

Oxyacetylene Cutting Tip Size Chart - Oxy acetylene cutting settings are crucial for achieving clean and precise cuts in metal fabrication. Tip sizes are often labeled differently depending on the manufacturer, as companies have no industry standards to follow. Type 41 oxy/acetylene cutting nozzles. Web cutting tip chart cutting tip series gpn and hpn metal thickness tip size cutting oxygen (psig)*** preheat oxygen (psig)* preheat fuel gas (psig) speed i.p.m. Cutting oxygen pressure psig*** preheat oxygen pressure psig* cutting gas pressure psig: Tip number purpose capacity (width x depth) pressure − psig at regulator consumption − scfh drill size in. Welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal pressures of acetylene and oxygen. Setting the correct working pressures. There are a number of different types. Once your torch is set up correctly, you can start using it for cutting various types of metal. To begin cutting metal, place your tip a few inches away from where you want to start your cut and turn on your preheat flame until it melts through the metal surface. Selecting the correct welding attachment/ nozzles. The tip size is determined by the orifice for cutting oxygen gas. The larger the number, the larger the hole in the. This means a thin plate requires a tip with a small nozzle to make a precision cut. Selecting the correct welding attachment/ nozzles. Welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal pressures of acetylene and oxygen. Proper adjustment of oxygen and acetylene pressures, as well as the cutting tip. There are a number of different types. This means a thin plate requires a tip with a small nozzle to make a precision cut. Use the right tip size for every job. Make use of correct welding & cutting technique. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches. Welding tips have one hole and cutting tips have a centrally located hole with a number of Select a tip based on metal thickness 3. Oxy acetylene cutting settings are crucial for achieving clean and precise cuts in metal fabrication. There are a number of different types. The tip of a welding or cutting torch is where the action is. Use the right tip size for every job. Selecting the correct welding attachment/ nozzles. Setting the correct working pressures. Fits airco® 3790, 4690, 4700, 4800, 5700, 5800, 1100, 3000, 9000 and 9500 torches. Metal tip size thickness victor cutting equipment. This means a thin plate requires a tip with a small nozzle to make a precision cut. Adjust to the correct flame setting. Make use of correct welding & cutting technique. Tables show approximate gas pressures for welding or cutting. Use the right tip size for every job. Web airco® 144/alc 802 style cutting tips. Fits airco® 3790, 4690, 4700, 4800, 5700, 5800, 1100, 3000, 9000 and 9500 torches. For general hand or machine cutting. It’s important to note that these settings may vary based on the manufacturer’s recommendations and the thickness of the material you are cutting. The tip size is determined by the orifice for cutting. Tips are available in a variety of shapes and sizes to fit most any welding job and are identified by number. It’s important to note that these settings may vary based on the manufacturer’s recommendations and the thickness of the material you are cutting. Web a low number indicates a small tip size, while a high number indicates a large. Web a low number indicates a small tip size, while a high number indicates a large tip size. Web do not use in cutting attachments. Web 1 to 11 of 11 results. Oxy acetylene cutting settings are crucial for achieving clean and precise cuts in metal fabrication. For general hand or machine cutting. Oxy acetylene cutting settings are crucial for achieving clean and precise cuts in metal fabrication. Adjust to the correct flame setting. Make use of correct welding & cutting technique. The larger the number, the larger the hole in the tip and the thicker the metal that can be welded or cut. Web 8 steps to making a quality cut 1. Tables show approximate gas pressures for welding or cutting. Cutting oxygen pressure psig*** preheat oxygen pressure psig* cutting gas pressure psig: Welding tips have one hole and cutting tips have a centrally located hole with a number of Sc and mc series special purpose tips for hand torches and cutting assemblies − acetylene. Web using your torch. Tip number purpose capacity (width x depth) pressure − psig at regulator consumption − scfh drill size in. Kerf width 1/8 000 20/25 3/5 3/5 20/30.04 1/4 00 20/25 3/5 3/5 27/30.05 3/8 0 25/30 3/5 3/5 24/28.06 1/2 0 30/35 3/6 3/5 20/24.06 3/4 1 30/35 4/7 3/5 17/21.07 1 2. This means a thin plate requires a tip with a small nozzle to make a precision cut. There are a number of different types. Web cutting tip chart cutting tip series gpn and hpn metal thickness tip size cutting oxygen (psig)*** preheat oxygen (psig)* preheat fuel gas (psig) speed i.p.m. Proper adjustment of oxygen and acetylene pressures, as well as the cutting tip size, directly impact the efficiency and quality of the cutting process. Tips are available in a variety of shapes and sizes to fit most any welding job and are identified by number. Adjust to the correct flame setting. Web airco® 144/alc 802 style cutting tips. Welding tips usually produce positive pressure (higher than 1 pound per square inch [psi]) and are used at equal pressures of acetylene and oxygen. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches.SÜA Oxy/Acetylene Cutting Tips Replacement for 6290 Select Qtty and

OxyAcetylene Welding Tips Model WJ Compatible with "J" Series Victor

Airco AFH / AFS Cut Chart American Torch Tip

Oxyacetylene Torch Settings Chart

Oxy Acetylene Victor Welding Tip Chart

Oxy Acetylene Cutting Tip Size Chart

Selecting the Right Cutting Tip RonSon's Torch Repairs & Sales Ltd.

acetylene Victor Technologies

Oxy Acetylene Tip Chart

Oxy Acetylene Torch Tip Chart

Web The Oxygen Pressure Typically Ranges From 30 To 40 Psi (Pounds Per Square Inch), While The Acetylene Pressure Should Be Set Between 5 And 15 Psi.

For General Hand Or Machine Cutting.

The Thicker The Metal, The Bigger The Nozzle Or Tip Size Will Generally Be Required.

The Tip Size Is Determined By The Orifice For Cutting Oxygen Gas.

Related Post: