Pile Cage Drawing

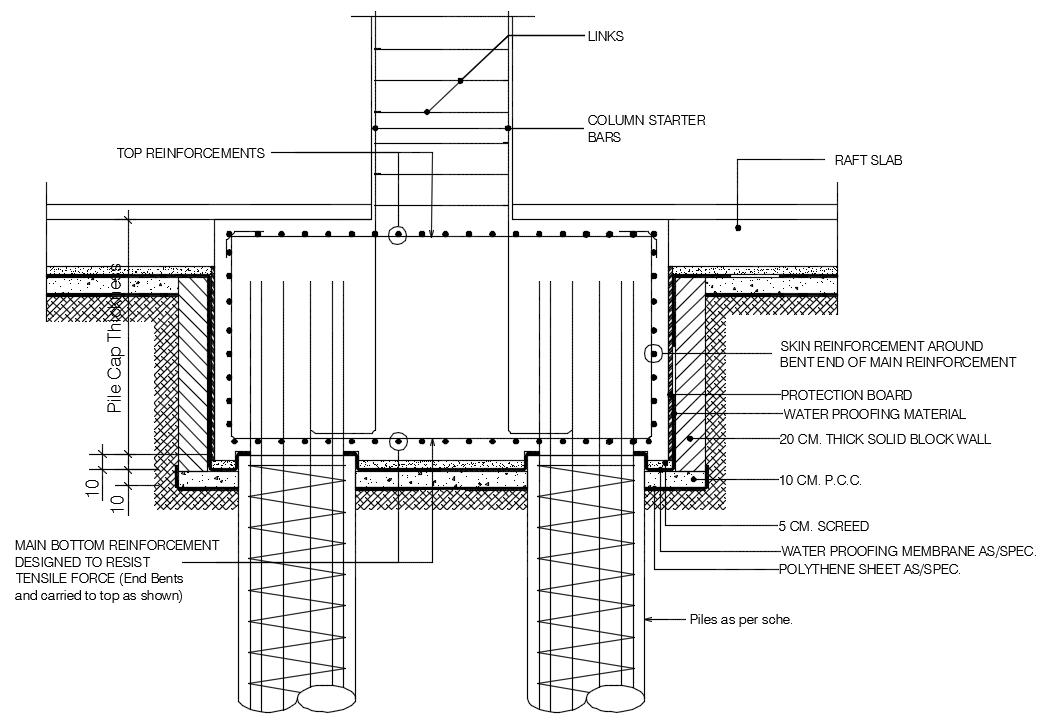

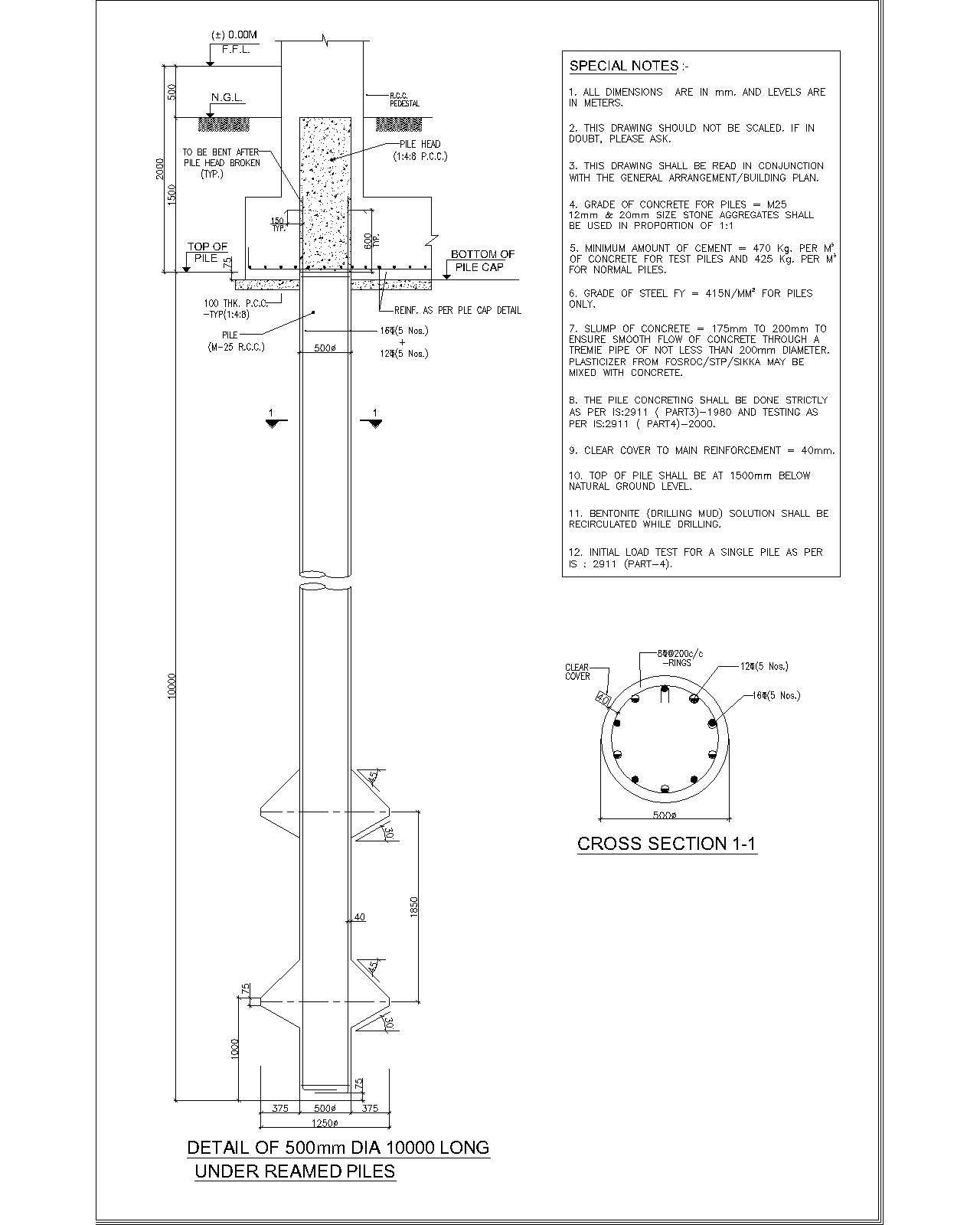

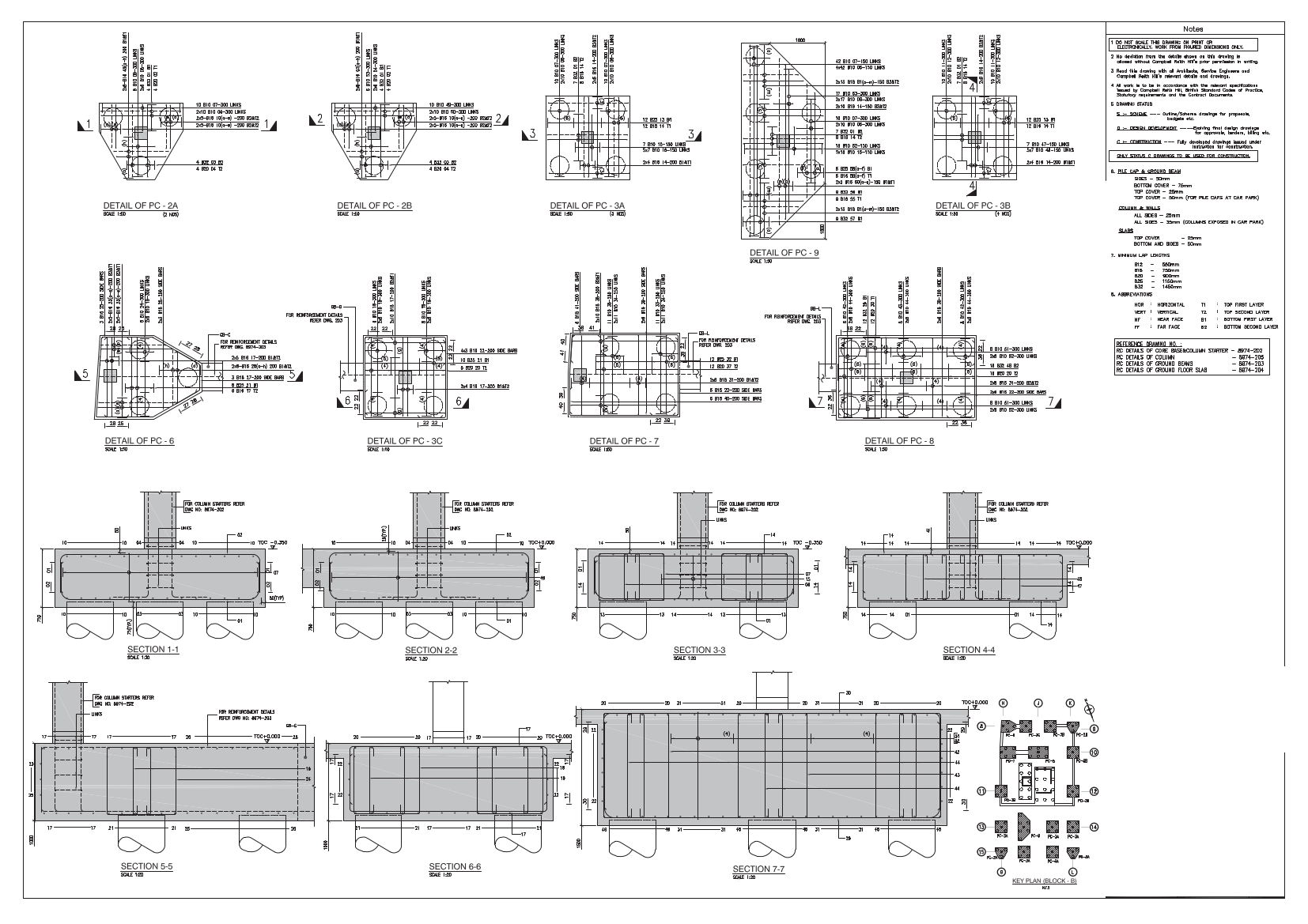

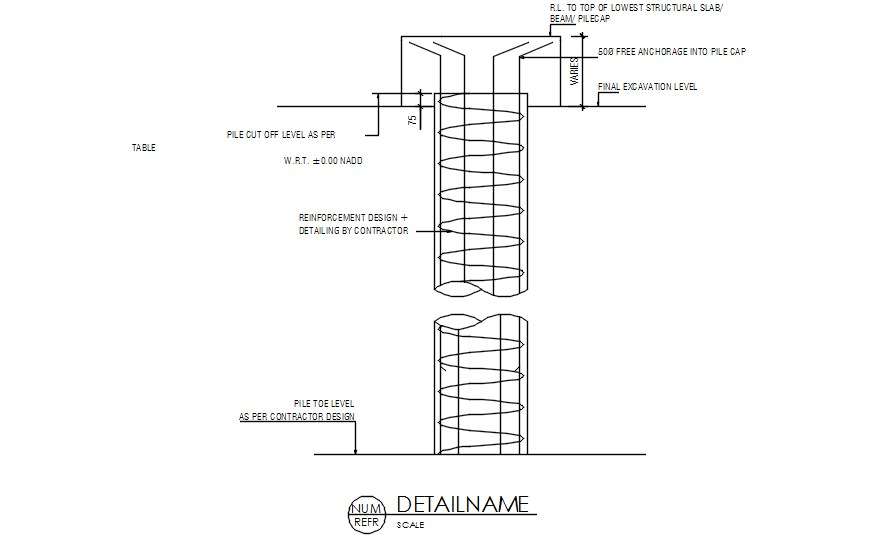

Pile Cage Drawing - Web where to start in my experience, it's worth taking the time to understand what you think is going to take place using drawings and documents, then watch it happen on site to see if you were right. I recommend printing out/viewing digitally any relevant project drawings and Suppositions in the pile cap design the pile cap is must be rigidly set to the structure. Web this section will describe each of the systems available for both pile and diaphragm wall cages, detail the available design information on each system and comment on the quality checks that need to be carried out prior use on site. Coordinates of individual piles of a group shall be worked out for longitudinal and transverse centerlines. (1) geometry of the steel necessary to resist stresses that develop because of loads applied to the drilled shaft, which is addressed in chapter 16, and (2. © blade pile group pty ltd 2015. Rise of temperature of concrete Web the design of rebar cages is critical for drilled shaft construction. Though piles are slight elastic column, that’s why some distortions will be found, and we need to measure those in the plan. Web a guide to single pile design in accordance with american concrete institute (aci 318) and australian standards (as 2159 & 3600). Pile radius = 0.5m or 500mm. I recommend printing out/viewing digitally any relevant project drawings and (1) geometry of the steel necessary to resist stresses that develop because of loads applied to the drilled shaft, which is addressed. Web the design of the reinforcing, or “rebar,” cage for a drilled shaft is a necessary step in the engineering process. Web this section will describe each of the systems available for both pile and diaphragm wall cages, detail the available design information on each system and comment on the quality checks that need to be carried out prior use. A superior ‘screw in pile’ or an alternative for bored piers, driven piles or grout piles. Eurocode 7 provides an innovative method for determining the characteristic pile resistance values directly from the results of. This latest revision also gives guidance on splicing the cage together and guidance on relatively light cages. Rebar cages will be considered from two perspectives in. Web the process of designing piles foundation generally involves good interpretation of geotechnical site data, modeling and analysis of the superstructure through an fea software, generating support reactions, foundation design checks, and optimization to come up with a safe and economical design. Web since we know the applied loads, effective length, and pile diameter, we can design the pile using. Web dmc pile foundation construction method: Web this section will describe each of the systems available for both pile and diaphragm wall cages, detail the available design information on each system and comment on the quality checks that need to be carried out prior use on site. Web the process of designing piles foundation generally involves good interpretation of geotechnical. Web the process of designing piles foundation generally involves good interpretation of geotechnical site data, modeling and analysis of the superstructure through an fea software, generating support reactions, foundation design checks, and optimization to come up with a safe and economical design. Evaluate the geotechnical capacity and structural capacity of the pile and take the less as pile capacity. Web. © blade pile group pty ltd 2015. Rebar cages will be considered from two perspectives in this manual: Evaluate the geotechnical capacity and structural capacity of the pile and take the less as pile capacity. Hence, a lapping length equal to 5dd is provided in extra. Web dmc pile foundation construction method: Eurocode 7 provides an innovative method for determining the characteristic pile resistance values directly from the results of. Web details of various types of reinforcement used in pile foundation and their introduction according to design Web the process of designing piles foundation generally involves good interpretation of geotechnical site data, modeling and analysis of the superstructure through an fea software,. This latest revision also gives guidance on splicing the cage together and guidance on relatively light cages. Coordinates of individual piles of a group shall be worked out for longitudinal and transverse centerlines. Web dmc pile foundation construction method: Not only must they provide structural support, but they must be carefully constructed to allow for concrete passing ability and construction. Rise of temperature of concrete • measures soil strength during installation. I recommend printing out/viewing digitally any relevant project drawings and It should be noted that the systems are listed in no particular order. Web summary of key points. Web #civildrawings #construction #pilein this video we will discuss abouttangent pile tangent piles wallsecant wallpile reinforcement pile cage reinforcement how. Eurocode 7 stresses the importance of static pile load tests in the design of piles. Pile centre points shall be marked at exact dmc pile locations as per the approved drawings with the help of a total station. Suppositions in the pile cap design the pile cap is must be rigidly set to the structure. 3.19 working pile — a pile forming part of the foundation system of a given structure. Web since we know the applied loads, effective length, and pile diameter, we can design the pile using a conventional method or using a software. Eurocode 7 provides an innovative method for determining the characteristic pile resistance values directly from the results of. Web pile drawing को कैसे पढ़ा और देखा जाता है Web it is normal practice with pile design to reinforce the upper section of the pile to below the level of any induced bending moment or shear, and curtail the cage where the pile is in pure compression. Web the process of designing piles foundation generally involves good interpretation of geotechnical site data, modeling and analysis of the superstructure through an fea software, generating support reactions, foundation design checks, and optimization to come up with a safe and economical design. Key factors to be considered in the pile foundations design are summarised as follows. Web this section will describe each of the systems available for both pile and diaphragm wall cages, detail the available design information on each system and comment on the quality checks that need to be carried out prior use on site. Web the design of the reinforcing, or “rebar,” cage for a drilled shaft is a necessary step in the engineering process. Web a guide to single pile design in accordance with american concrete institute (aci 318) and australian standards (as 2159 & 3600). (1) geometry of the steel necessary to resist stresses that develop because of loads applied to the drilled shaft, which is addressed in chapter 16, and (2. Web pile cap length = 4000mm.How To Make BBS Of Pile Foundation & Pile Cap LCETED lceted LCETED

Drilled Shaft Foundation Design Sketch Coloring Page

Detail Pondasi Pile Cap Dwg Download IMAGESEE

Bored pile wall. Cap beam Mat Foundation, Footing Foundation, Concrete

Pile CAD Drawing Free Download DWG Cadbull

CADS RC sample drawings & Bar Bending Schedules CADS UK

Spiral Pile foundation section details are given in this AutoCAD 2D

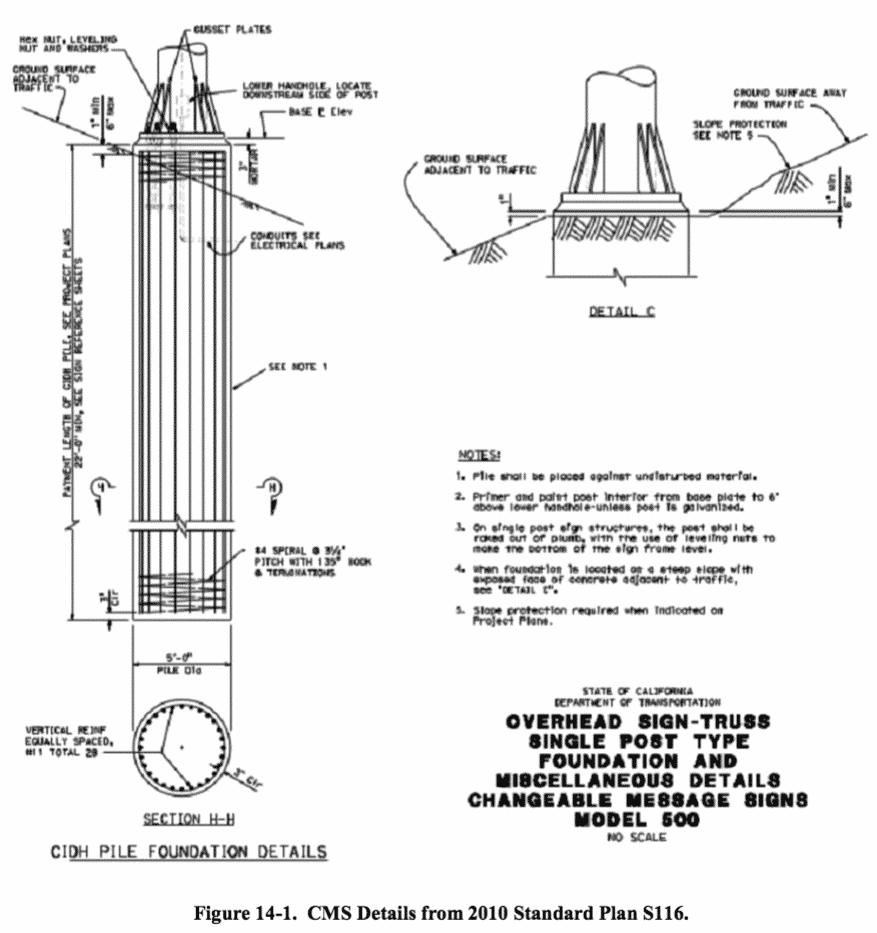

Chapter 14 Specialty Piles and Special Considerations for Pile

Pile foundation details dwg detail for autocad • designs cad Artofit

How to draw pile layout plan in AutoCAD YouTube

Web Load Which A Pile Can Carry Before Failure, That Is, When The Founding Strata Fails By Shear As Evidenced From The Load Settlement Curve Or The Pile Fails As A Structural Member.

Rebar Cages Will Be Considered From Two Perspectives In This Manual:

© Blade Pile Group Pty Ltd 2015.

Clear Cover Of The Pile= 75Mm.

Related Post: