Pipe Support Spacing Chart

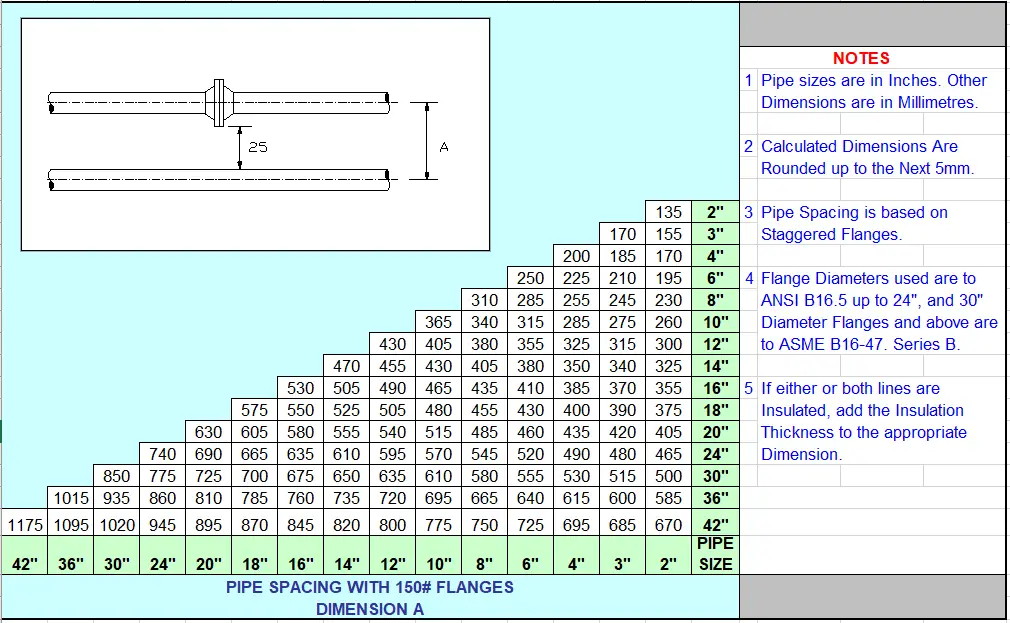

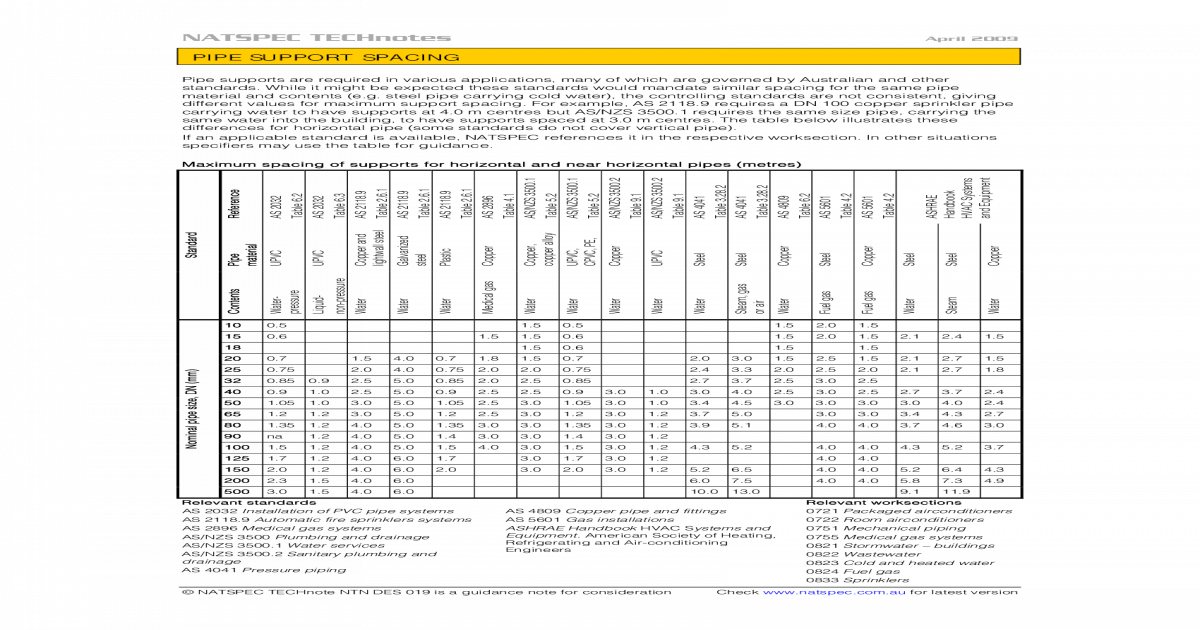

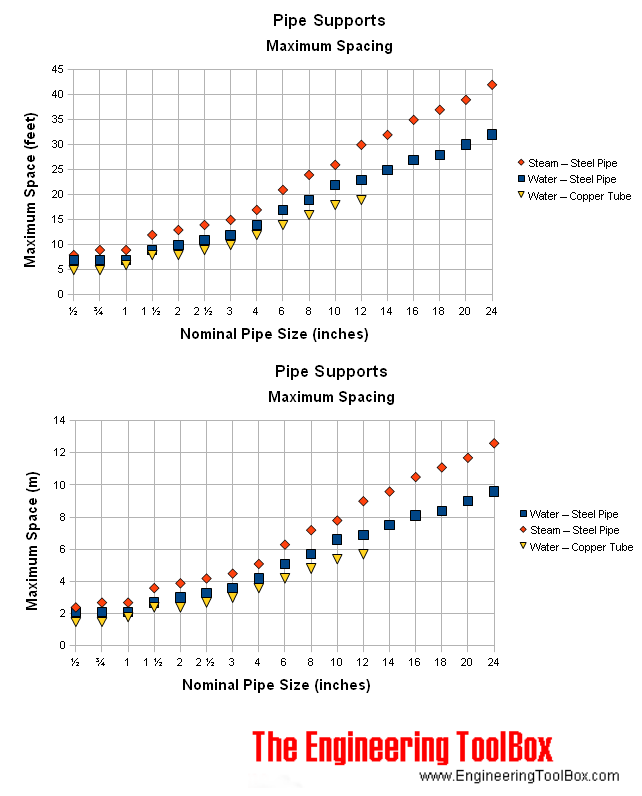

Pipe Support Spacing Chart - Tensile rating and are tested for the appropriate applications. I've seen several tables and charts, all with different values. Table 1 schedule of component detail. Pipe outside diameters as per ansi asme b36.10. Web this datasheet is to assist a piping designer in the layout of pipe supports, anchors and guides by defining an allowable pipe span. Distance between steel pipe supports. Web to prevent excessive pipe sag (normally more than 10 mm for process piping and 2.5 mm for power piping; Web support locations are dependent on pipe size, piping configuration, the location of heavy valves and fittings, and the structure that is available for the support of the piping. Recommended support spacing may be determined from equation 1. Web the pipe guiding and support spacing shown in table 1 is the suggested maximum span as specified by the asme/ansi power piping code b31.1, and is applicable for horizontal straight runs of pipe without concentrated loads such. 12.5 mm for gre/ grp piping) to eliminate exposure of elements to temperature extremes, outside their design limit. Table 1 schedule of component detail. Web 1 ft (foot) = 0.3048 m. Web a pipe spacing chart provides the minimum distance between two adjacent pipes or pipelines. Web support spacing depends upon the allowable deflection between supports, which in turn depends. Web the pipe guiding and support spacing shown in table 1 is the suggested maximum span as specified by the asme/ansi power piping code b31.1, and is applicable for horizontal straight runs of pipe without concentrated loads such. Web the given standard values are valid for steel pipes with normal thickness and up to a temperature of 400°c. Web 1. Whenever two pipes run parallel to each other, piping designers or engineers must maintain a minimum gap between the two pipes or pipelines. Web calculate spacing between pipes on a pipe rack based on dimensional standard asme b16.5 and b16.47. Dimensions of pipes and tubes. Web maximum spacing between supports at different temperatures can be found in the tables below:. 1 ft (foot) = 0.3048 m. Web in this comprehensive guide, we will discuss the intricacies of pipe support spans, covering design considerations, factors on which it depends, best practices, and pipe support spacing charts based on different codes and standards. Web support spacing depends upon the allowable deflection between supports, which in turn depends upon the pipeline, the fluid. You should consider the material used, wall thickness, density of the medium, isolation, etc. Dimensions of pipes and tubes. Web support spacing depends upon the allowable deflection between supports, which in turn depends upon the pipeline, the fluid within it, and the service temperature. Web please refer to the individual catalogue pages for specific load and temperature ratings of our. Dimensions of pipes and tubes. Always follow local code for general piping support requirements. Table 1 schedule of component detail. Pipe, tube and fittings sizes and dimensions. For really good assessment of working stresses and deflections, pipe stress calculations are needed. Special pipe supports (sps) piping support standards and codes. I've seen several tables and charts, all with different values. Web this spacing chart is a kind of general guideline that gives an idea about spacing requirements. The length related mass is larger when the steel is thicker. Web please refer to the individual catalogue pages for specific load and temperature. Web support locations are dependent on pipe size, piping configuration, the location of heavy valves and fittings, and the structure that is available for the support of the piping. Dimensions of pipes and tubes. Web maximum spacing between supports at different temperatures can be found in the tables below: The length related mass is larger when the steel is thicker.. Web support spacing depends upon the allowable deflection between supports, which in turn depends upon the pipeline, the fluid within it, and the service temperature. Inside and outside diameters, weights and more. For really good assessment of working stresses and deflections, pipe stress calculations are needed. Web calculate spacing between pipes on a pipe rack based on dimensional standard asme. Web maximum spacing between supports at different temperatures can be found in the tables below: Special pipe supports (sps) piping support standards and codes. Web support spacing depends upon the allowable deflection between supports, which in turn depends upon the pipeline, the fluid within it, and the service temperature. Pipe support types and installation guide. Web the given standard values. 12.5 mm for gre/ grp piping) to eliminate exposure of elements to temperature extremes, outside their design limit. Web the pipe guiding and support spacing shown in table 1 is the suggested maximum span as specified by the asme/ansi power piping code b31.1, and is applicable for horizontal straight runs of pipe without concentrated loads such. Pressure ratings of abs 1208, abs 1210, abs 1316 and. Web pipe support spacing table (chart) for sch 80 cpvc pipes. Tensile rating and are tested for the appropriate applications. Pipe outside diameters as per ansi asme b36.10. Web the given standard values are valid for steel pipes with normal thickness and up to a temperature of 400°c. Pipe saddles and reinforcement pads. Inside and outside diameters, weights and more. Spans are based on cpvc pipe filled with water and maximum sag of 2.5mm at center of span. Web in this comprehensive guide, we will discuss the intricacies of pipe support spans, covering design considerations, factors on which it depends, best practices, and pipe support spacing charts based on different codes and standards. Special pipe supports (sps) piping support standards and codes. Pipe, tube and fittings sizes and dimensions. Recommended support spacing may be determined from equation 1. Web allowable spans are based on a maximum bending stress of 41.37 mpa (6000 psi) or a maximum deflection of 12.7 mm (0.5in). Web to prevent excessive pipe sag (normally more than 10 mm for process piping and 2.5 mm for power piping;Pipe Spacing Chart PDF Matériaux de construction Génie du bâtiment

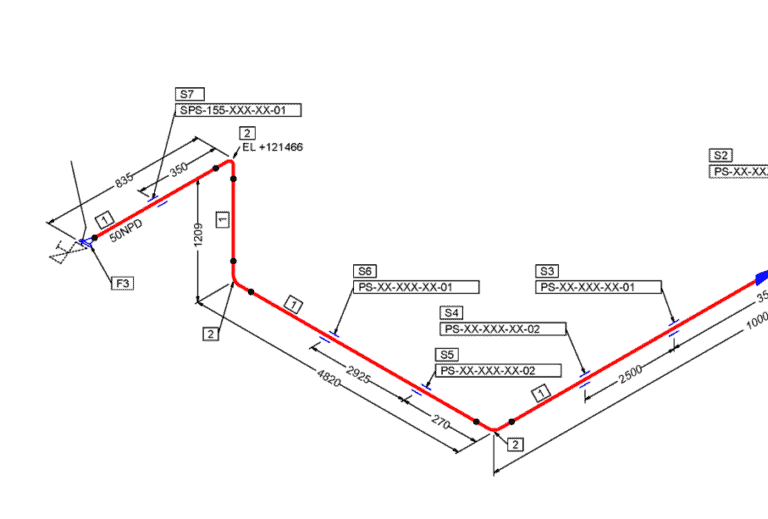

Pipe Support Span (Spacing) Guideline

PVC Pipe Support Spacing in Feet PDF

Pipe Spacing Chart Pipeline Spacing Chart What Is Piping

Pipe Support Spacing Standard

Pipe Support Spacing Chart Pdf

Ansi Pipe Support Spacing Table

Pipe Support Spacing Chart Pdf

Horizontal Pipe Hanger Supports Spacing and Rod Size

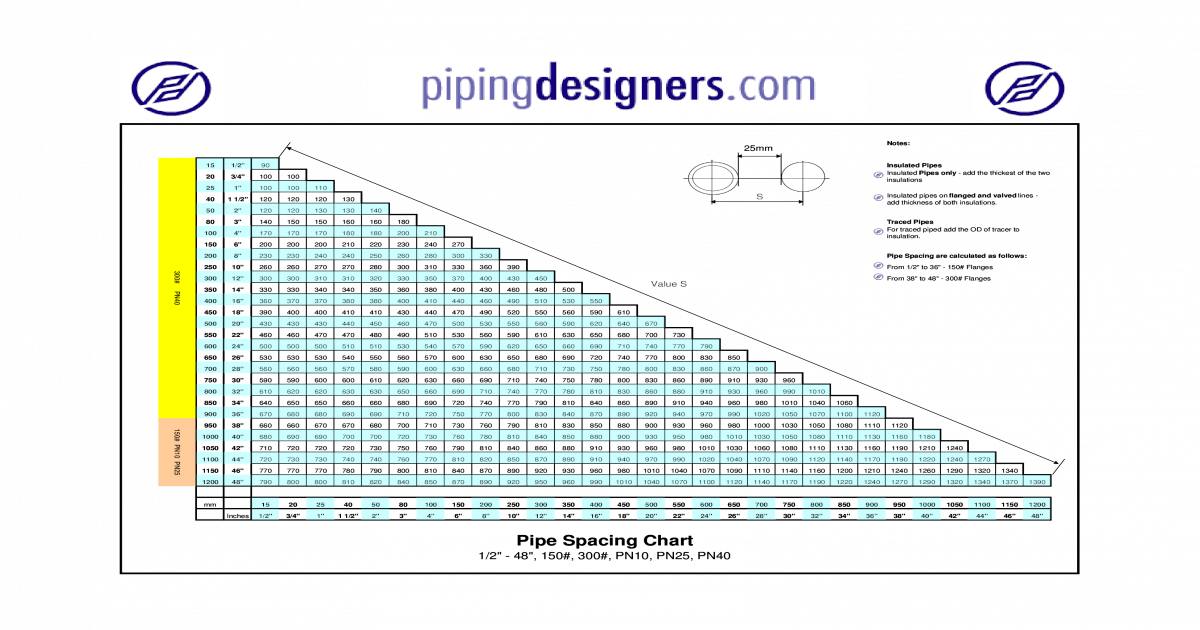

Pipe Spacing Chart Piping Designers . Spacing 15mm · Pipe Spacing

Pipe Support Types And Installation Guide.

Web Calculate Spacing Between Pipes On A Pipe Rack Based On Dimensional Standard Asme B16.5 And B16.47.

Flange Od Upto 24 Inch As Per Ansi Asme B16.5.

Whenever Two Pipes Run Parallel To Each Other, Piping Designers Or Engineers Must Maintain A Minimum Gap Between The Two Pipes Or Pipelines.

Related Post: