Piping Support Spacing Chart

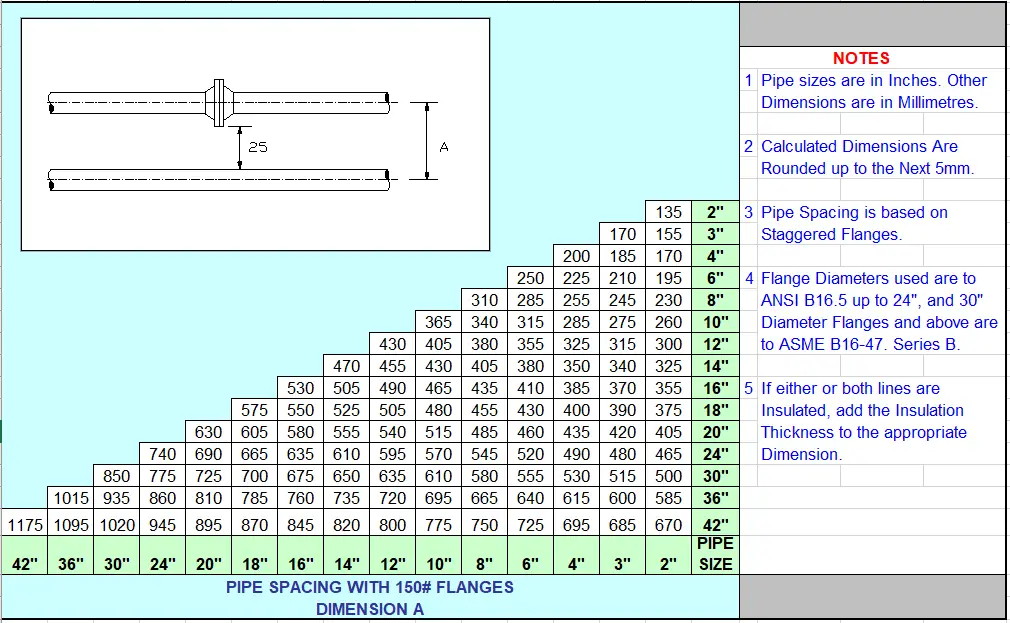

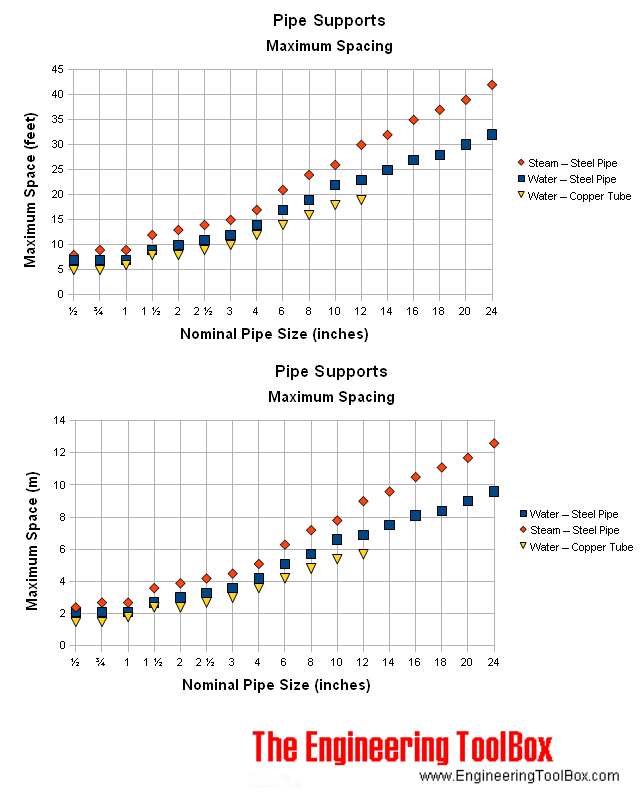

Piping Support Spacing Chart - Web a pipe support span chart is a table or diagram that provides information on the maximum allowable span for different types of piping and support configurations. Web online piping spacing calculator. + pipe walls require reinforcing at point of support. This is to guard against the lateral movements due to thermal expansion, including solar radiation. Always follow local code for general piping support requirements. At a temperature of 40 ̊c and above continuous support is recommended for visual acceptance. Web piping support plays a very crucial role in the proper functioning of piping systems. Web the pipe guiding and support spacing shown in table 1 is the suggested maximum span as specified by the asme/ansi power piping code b31.1, and is applicable for horizontal straight runs of pipe without concentrated loads such as. Web this spacing chart is a kind of general guideline that gives an idea about spacing requirements. Web piping systems in pipe racks or pipe tracks shall be guided at intervals of 2x the pipe support span for bare, vapor service. If you are working on an inspected job, you will also need to be aware of any specific code requirements for pipe support in your area. Support spans are provided for pipe temperatures of 60°f, 100°f and 140°f. The length related mass is larger when the steel is thicker. The span is the distance between two points where a pipe. Web the table above gives recommendations for maximum support spacing’s for a pipe full of water at an ambient temperature of 20 ̊c or below. Distance between steel pipe supports. Web online piping spacing calculator. Web spacing for vertical systems should usually be about two times the intervals in the table above. Spans are based on pvc pipe filled with. Web a pipe support span chart is a table or diagram that provides information on the maximum allowable span for different types of piping and support configurations. Web support spacing depends upon the allowable deflection between supports, which in turn depends upon the pipeline, the fluid within it, and the service temperature. Web the given standard values are valid for. Recommended support spacing may be determined from equation 1. The maximum pipe support spacing is dependant on the maximum allowable deflection or sag in the piping and the maximum permissible stress. Always follow local code for general piping support requirements. Web the table above gives recommendations for maximum support spacing’s for a pipe full of water at an ambient temperature. Web support spacing depends upon the allowable deflection between supports, which in turn depends upon the pipeline, the fluid within it, and the service temperature. Web piping systems in pipe racks or pipe tracks shall be guided at intervals of 2x the pipe support span for bare, vapor service. The span is the distance between two points where a pipe. Web a pipe support span chart is a table or diagram that provides information on the maximum allowable span for different types of piping and support configurations. Spans are based on pvc pipe filled with water and maximum sag of 2.5mm at center of span. Web the table above gives recommendations for maximum support spacing’s for a pipe full of. The length related mass is larger when the steel is thicker. At a temperature of 40 ̊c and above continuous support is recommended for visual acceptance. Web spacing for vertical systems should usually be about two times the intervals in the table above. Web allowable pipe span is the maximum distance between supports or hangers that a pipe can span. To maintain the integrity of the piping system, a pipe must be supported following a proper pipe support span. Distance between steel pipe supports. This is to guard against the lateral movements due to thermal expansion, including solar radiation. Web piping support plays a very crucial role in the proper functioning of piping systems. Web this spacing chart is a. Web support locations are dependent on pipe size, piping configuration, the location of heavy valves and fittings, and the structure that is available for the support of the piping. Calculate spacing between pipes on a pipe rack based on dimensional standard asme b16.5 and b16.47. Spans are based on pvc pipe filled with water and maximum sag of 2.5mm at. (2.5 mm) between supports is permissible. Pipe support carries the pipe weight with contents. Support spans are provided for pipe temperatures of 60°f, 100°f and 140°f. Allowable spans are based on a maximum bending stress of 41.37 mpa (6000 psi) or a maximum deflection of 12.7 mm (0.5in). Web a pipe spacing chart provides the minimum distance between two adjacent. At a temperature of 40 ̊c and above continuous support is recommended for visual acceptance. Web online piping spacing calculator. Web the spacing is based on a fixed beam support with a bending stress not exceeding 2,300 psi (15.86 mpa) and insulated pipe filled with water or the equivalent weight of steel pipe for steam, gas, or air service, and the pitch of the line is such that a sag of 0.1 in. Recommended support spacing may be determined from equation 1. Supports should at the very least be compliant with all codes and regulations you will face. In case of weaker thickness (often in the range of stainless steel) the. Web support locations are dependent on pipe size, piping configuration, the location of heavy valves and fittings, and the structure that is available for the support of the piping. (2.5 mm) between supports is permissible. Spans are based on pvc pipe filled with water and maximum sag of 2.5mm at center of span. Calculate spacing between pipes on a pipe rack based on dimensional standard asme b16.5 and b16.47. To maintain the integrity of the piping system, a pipe must be supported following a proper pipe support span. Web support spacing depends upon the allowable deflection between supports, which in turn depends upon the pipeline, the fluid within it, and the service temperature. Web the pipe guiding and support spacing shown in table 1 is the suggested maximum span as specified by the asme/ansi power piping code b31.1, and is applicable for horizontal straight runs of pipe without concentrated loads such as. Always follow local code for general piping support requirements. Web pipe support spacing table (chart) for sch 40 pvc pipes. * spans limited by stress (all others limited by deflection).Pipe Support Spacing Standard

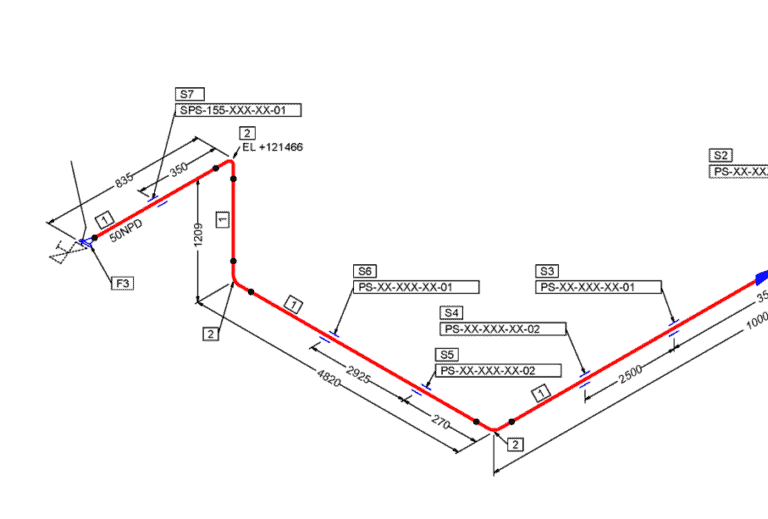

Pipe Spacing Chart Pipeline Spacing Chart What Is Piping

What are piping supports ? Piping engineer world

![Suggested Pipe Support Spacing[10] Download Scientific Diagram](https://www.researchgate.net/publication/368010030/figure/tbl1/AS:11431281117185251@1675392372773/Suggested-Pipe-Support-Spacing10.png)

Suggested Pipe Support Spacing[10] Download Scientific Diagram

(PDF) Pipe Spacing Chart Piping Designers .

The maximum steel pipe support spacing California

Pipe Support Span (Spacing) Guideline

The maximum steel pipe support spacing California

Hangers Support Spacing and Rod Size for Horizontal Pipes

PVC Pipe Support Spacing in Feet PDF

If You Are Working On An Inspected Job, You Will Also Need To Be Aware Of Any Specific Code Requirements For Pipe Support In Your Area.

Whenever Two Pipes Run Parallel To Each Other, Piping Designers Or Engineers Must Maintain A Minimum Gap Between The Two Pipes Or Pipelines.

Web This Spacing Chart Is A Kind Of General Guideline That Gives An Idea About Spacing Requirements.

Pipe Hangers Are Support Devices That Suspend Pipes From Overhead Structures, Walls, Or Other Fixed Points.

Related Post: