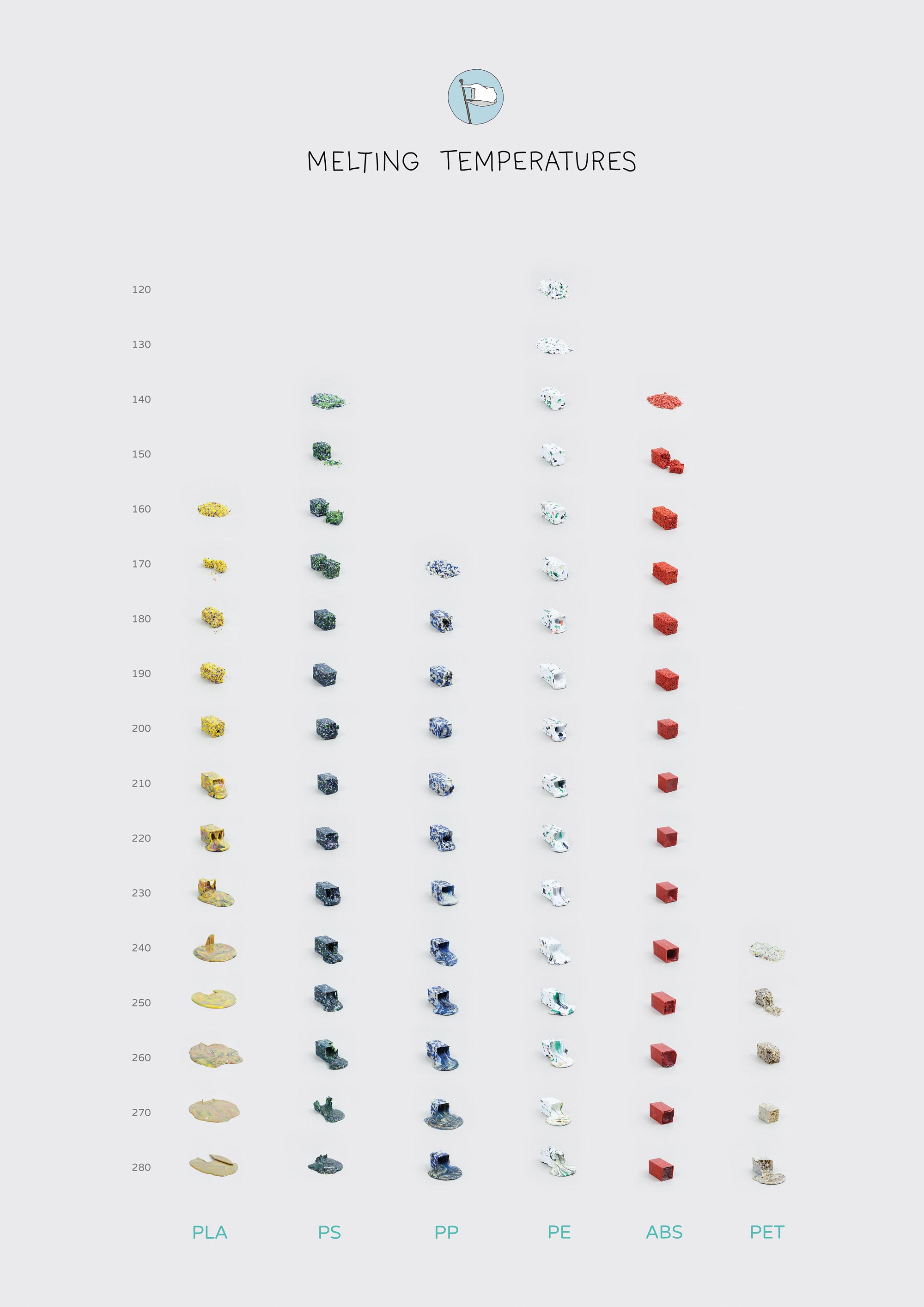

Plastic Melting Point Chart

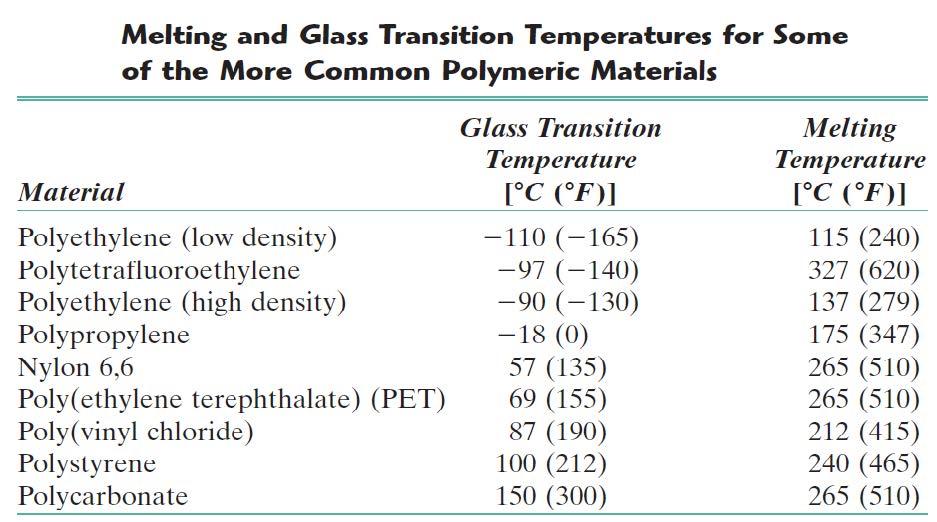

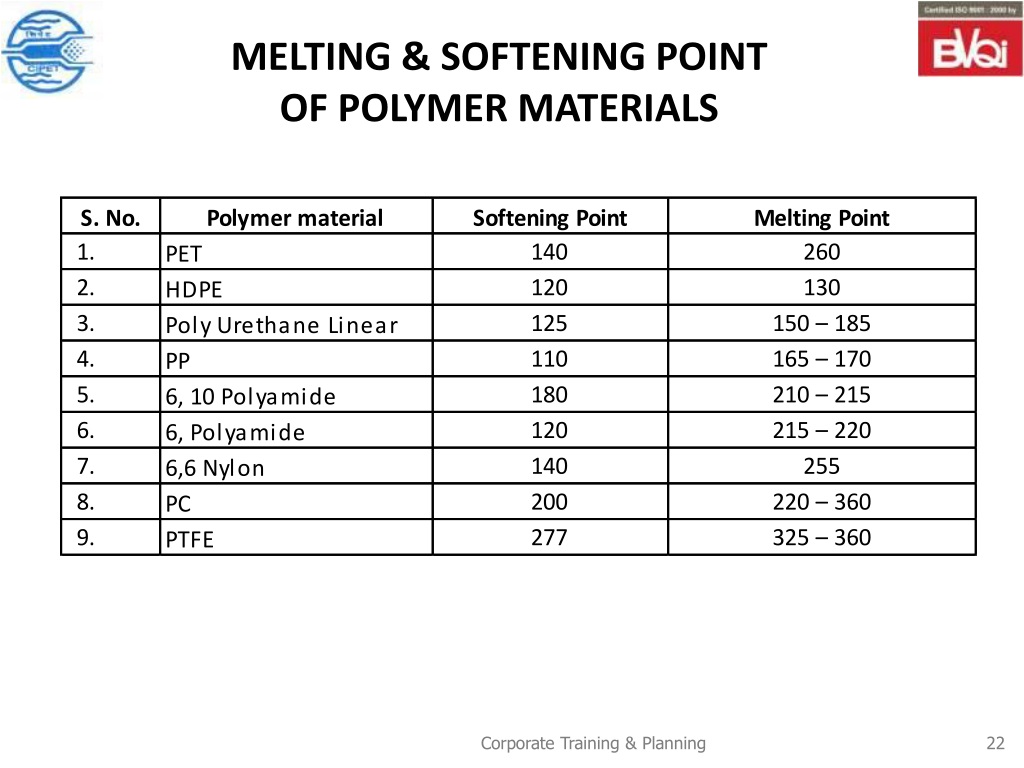

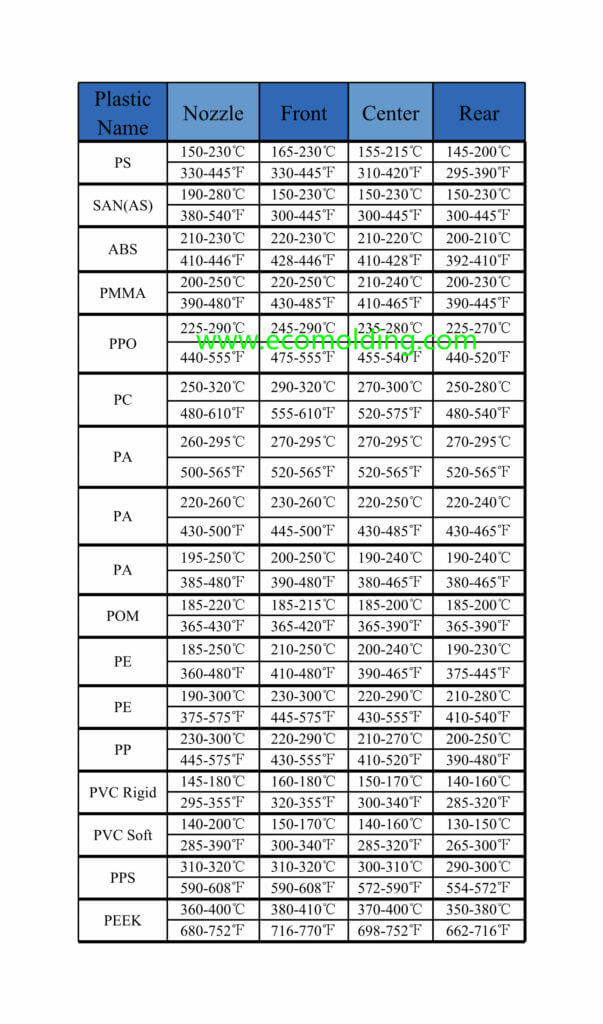

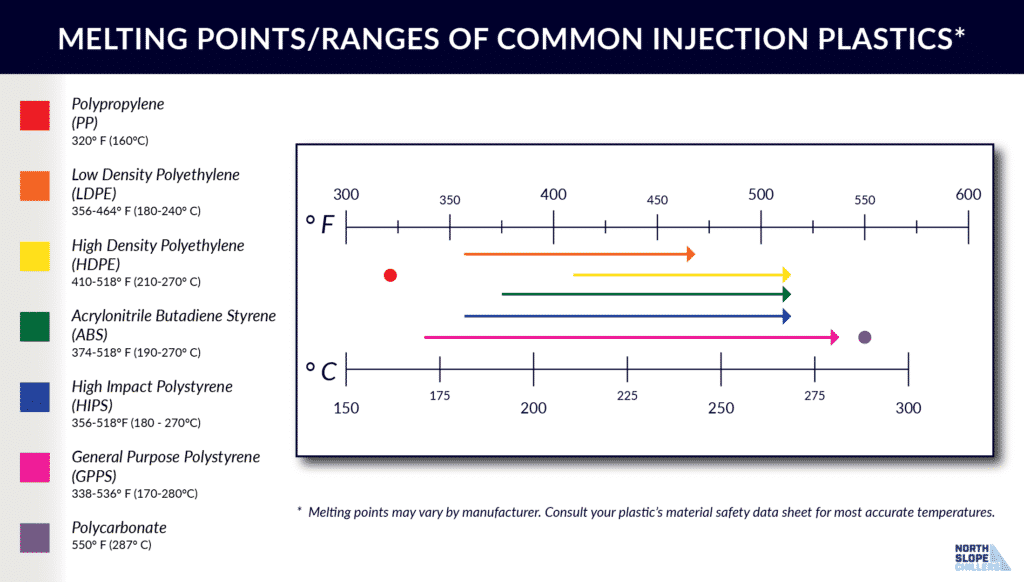

Plastic Melting Point Chart - Very good resistance to alcohols, dilute acids and alkalis; Web the following table provides a comprehensive list of melting point values for different polymers and plastics at 1 atmospheric (atm) pressure. Web the melting point of toray's toraycon™ polybutylene terephthalate (pbt) resin is 224°c—a high melting point that is on par with that of nylon or polyethylene terephthalate (pet). Web below is a comprehensive chart to the melting and molding temperatures of various plastic materials: This critical characteristic determines the conditions under which plastic can be shaped, recycled, and utilized in various applications. Additionally, factors such as molecular weight, degree of polymerization, and the presence of additives can also impact the melting point of pvc. Web the mentioned plastic melting point and plastic melting temperature chart are correct but should be used as a reference. When diving into the manufacturing world, you must know about plastic material melt and mold temperature charts. At this point, plastics soften and become pliable, making them suitable for various molding and. The melting points of various hdpe types range from 210 to 270 degrees celsius (410 to 518 degrees fahrenheit). Nevertheless, it is crucial to consider that the melting point of hdpe can differ based on the material’s grade and quality. We’ve also highlighted why it’s important to recycle plastic. Web densities and melting points of a number of plastics. Detailed temperature ranges for common plastics. Very good resistance to alcohols, dilute acids and alkalis; Detailed temperature ranges for common plastics. Here is a table explaining the plastic thermal properties. Melting point of copper alloys. Web nominal comparative properties chart of thermoplastic materials. Web the melting point of toray's toraycon™ polybutylene terephthalate (pbt) resin is 224°c—a high melting point that is on par with that of nylon or polyethylene terephthalate (pet). Web the mentioned plastic melting point and plastic melting temperature chart are correct but should be used as a reference. Range for different plastics like abs, hdpe, pp, ps, pet, pvc, pa, pmm, acetal,etc. 1 it is the sole responsibility of the end user for the testing, performance and safety of their product. Web the melting point of plastic refers. Very good resistance to alcohols, dilute acids and alkalis; Web nominal comparative properties chart of thermoplastic materials. Melting point of platinum alloys. Melting point of aluminum alloys. Understanding the melting point of plastics. The melting points of various hdpe types range from 210 to 270 degrees celsius (410 to 518 degrees fahrenheit). Web table list for plastic melting temperature and mold temp. Web densities and melting points of a number of plastics. Web the mentioned plastic melting point and plastic melting temperature chart are correct but should be used as a reference. Recommended. Web the melting point of plastic refers to the temperature at which it transitions from a solid to a liquid state. Excellent resistance to most solvents; Web nominal comparative properties chart of thermoplastic materials. At this point, plastics soften and become pliable, making them suitable for various molding and. Talking to the raw materials provider or the concerned medical molding. Web hdpe has a melting point that falls within the range of approximately 120°c to 180°c (248°f to 356°f), with an average melting point of approximately 130°c (266°f). Polypropylene, often termed pp, is a thermoplastic material with a crystalline structure formed by blending different polypropylene monomers. Web the melting point of plastic refers to the temperature at which it transitions. Nevertheless, it is crucial to consider that the melting point of hdpe can differ based on the material’s grade and quality. Very good resistance to alcohols, dilute acids and alkalis; Numerous industries use polyethylene, particularly hdpe and ldpe, for a variety of purposes. Web table list for plastic melting temperature and mold temp. Understanding the melting point of plastics. Poor resistance to hydrocarbons (aliphatic, aromatic, halogenated) Web the melting point of acrylic is typically 160 °c. Web the mentioned plastic melting point and plastic melting temperature chart are correct but should be used as a reference. Numerous industries use polyethylene, particularly hdpe and ldpe, for a variety of purposes. Web hdpe has a melting point that falls within the. Very good resistance to alcohols, dilute acids and alkalis; Melting point of aluminum alloys. Discuss the melting point of all the mainstream plastics with a defined table. Web nominal comparative properties chart of thermoplastic materials. Additionally, factors such as molecular weight, degree of polymerization, and the presence of additives can also impact the melting point of pvc. Discuss the melting point of all the mainstream plastics with a defined table. Melting point of common materials. Web nominal comparative properties chart of thermoplastic materials. Poor resistance to hydrocarbons (aliphatic, aromatic, halogenated) (320 °f) known by various names such as pmma (polymethyl methacrylate), plexiglass, and plexiglas, acrylic plastic is a transparent thermoplastic with impressive strength, rigidity, and optical clarity. Web table list for plastic melting temperature and mold temp. Here is a table explaining the plastic thermal properties. Web below is a comprehensive chart to the melting and molding temperatures of various plastic materials: Moderate resistance to oils and greases; This critical characteristic determines the conditions under which plastic can be shaped, recycled, and utilized in various applications. Nevertheless, it is crucial to consider that the melting point of hdpe can differ based on the material’s grade and quality. Because these charts are more than just numbers. Web the melting point of toray's toraycon™ polybutylene terephthalate (pbt) resin is 224°c—a high melting point that is on par with that of nylon or polyethylene terephthalate (pet). Web in this comprehensive guide, we’ve discussed the melting point of various types of plastic, mold temperature for different plastics, and tips on how to safely melt plastic. They’re the backbone for getting plastic molding right. 0.93 to 0.97 g/cm 3;

PPT IDENTIFICATION OF PLASTICS PowerPoint Presentation, free download

Material Melting Point Chart

Melting point and main sources of waste plastics. Download Scientific

Plastic Melting Temperature Chart

Portable Chillers For Injection Molding North Slope Chillers

Solved Table below shows the melting and glass transition

:max_bytes(150000):strip_icc()/Highperformance_thermoplastics_en-58d93d655f9b58468394f718.png)

High Temperature Thermoplastics

Melting Point Of Plastic Bottles Best Pictures and Decription

Melting temperatures of plastics. Download Scientific Diagram

Plastic Melting Temperature Chart

Web The Melting Point Of Plastic Refers To The Temperature At Which It Transitions From A Solid To A Liquid State.

The Melting Point Of Pvc, For Instance, Is Between 320 And 410 Degrees Fahrenheit Or 160 To 210 Degrees Celsius.

Additionally, Factors Such As Molecular Weight, Degree Of Polymerization, And The Presence Of Additives Can Also Impact The Melting Point Of Pvc.

When Diving Into The Manufacturing World, You Must Know About Plastic Material Melt And Mold Temperature Charts.

Related Post: