Plating Thickness Chart

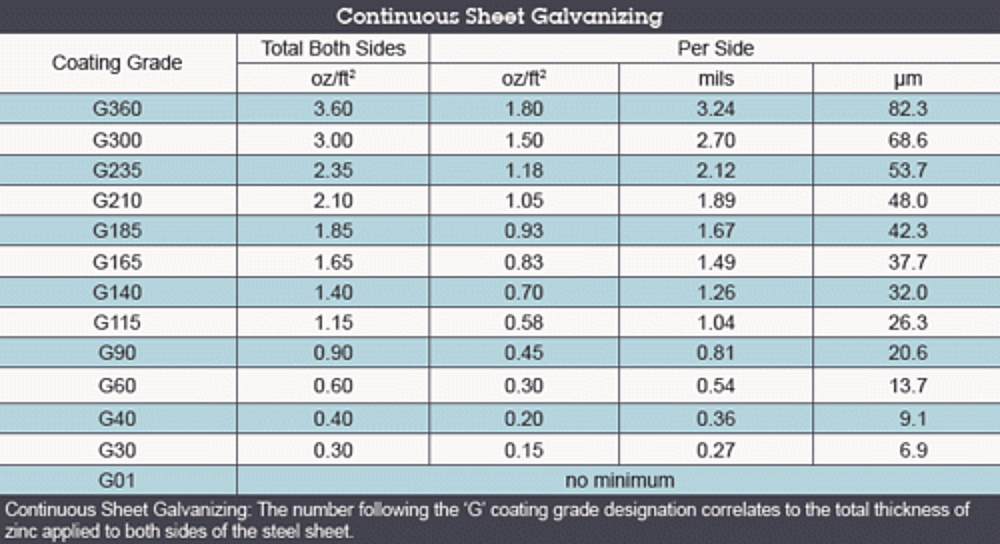

Plating Thickness Chart - Enter your thickness specification in the appropriate green box, then click the 'calc' button to activate. Web if the plating process is operated at 5 a/dm2, for example, it takes about 20 minutes to deposit a nickel coating with an average thickness of 20 ?m. Specifying plating thickness and significant surfaces for astm b633. W = weight of steel plate (lb/ft 2) t = plate thickness (in) insert 3d components with the engineering toolbox sketchup extension. 1/1000 (in) 1/1000 (mm) coating weight. This practical aid examines the following zinc coatings: Web nickel plating handbook nickel institute. Standard gauge sizes were developed based on the weight of the sheet for a given material and the equivalent thicknesses differ for each gauge size. Moreover, we know that a high level of plating solution temperature (factor b) yields minimum variability. To help architects, engineers, and other specifiers assess and select the most Web thickness may be measured at any convenient location on the product. Web each of these thicknesses, representing the same weight per unit area of zinc, would be expected to provide equivalent service life; The electrolytic plating process can cause thickness variations of the coating from point to point on a part. They are average, range, minimum, maximum and customer. Web thickness (figure 2) of each zinc coating varies. Web suggested (minimum) thickness iso 2081 designation; Gauge in mm lb/ft² kg/m²; W = weight of steel plate (lb/ft 2) t = plate thickness (in) insert 3d components with the engineering toolbox sketchup extension. These are defined as follows: Web typical thickness of electroless plating can be as thin as.0005 and up to.010. Web thickness weight per area; In the coating thickness conversion chart, different units are measured: Feet of hot rolled mild steel plates can be calculated as. 10 gauge = 3.571 mm. Web suggested (minimum) thickness iso 2081 designation; 10 gauge = 2.588 mm. Methods of defining thickness there are five (5) methods used for defining thickness at apc. They are average, range, minimum, maximum and customer negotiated. Web deposit thicknesses ranging from 0.0001 inches per side to heavy build electroless nickel plating exceeding 0.005 inches per side. These are defined as follows: Specifying plating thickness and significant surfaces for astm b633. Web if the plating process is operated at 5 a/dm2, for example, it takes about 20 minutes to deposit a nickel coating with an average thickness of 20 ?m. Web thickness may be measured at any convenient location on the product. Moreover, we know that a. Readings should be on regular areas of the coating. In contrast, thin dense chrome plating has a thickness from 0.0002 to 0.0006 inch (0.005 to 0.015 mm). Zinc plate and clear passivate fe/zn5/a: This practical aid examines the following zinc coatings: Web thickness weight per area; A sheet metal gauge chart uses the thickness and weight per area of different metals to determine standardised thicknesses or ‘gauges’. Zinc plate and clear passivate fe/zn8/a: The thickness of chrome plating varies depending on the application. What is 16 gauge thickness in mm? W = 40.8 t (1) where. Web thickness weight per area; 10 gauge = 3.51 mm. Web nickel plating handbook nickel institute. Zinc plate and clear passivate fe/zn5/a: Web the standard thickness for sheet metals will vary depending on the type of metal. The thickness of chrome plating varies depending on the application. Moreover, we know that a high level of plating solution temperature (factor b) yields minimum variability. (from 0.020 to 0.127 mm) thick on the surface of the metal. Web astm b633 minimum plating thickness requirements service condition chart. 10 gauge = 3.51 mm. The electrolytic plating process can cause thickness variations of the coating from point to point on a part. Yet those numbers do not indicate a specific dimensional value. They are average, range, minimum, maximum and customer negotiated. Methods of defining thickness there are five (5) methods used for defining thickness at apc. From quality metal finishing guide, metal finishing suppliers'. (from 0.020 to 0.127 mm) thick on the surface of the metal. Readings should be on regular areas of the coating. An average deposit thickness requirement is given as a single number i.e. Web the technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic. A sheet metal gauge chart uses the thickness and weight per area of different metals to determine standardised thicknesses or ‘gauges’. W = weight of steel plate (lb/ft 2) t = plate thickness (in) insert 3d components with the engineering toolbox sketchup extension. Web thickness may be measured at any convenient location on the product. Methods of defining thickness there are five (5) methods used for defining thickness at apc. Web if the plating process is operated at 5 a/dm2, for example, it takes about 20 minutes to deposit a nickel coating with an average thickness of 20 ?m. Gauge in mm lb/ft² kg/m²; Yet those numbers do not indicate a specific dimensional value. Web hard chrome plating leaves a layer of chrome from 0.0008 to 0.0050 in. From quality metal finishing guide, metal finishing suppliers' association. The data in the table provides a means of estimating the average coating thickness. Average deposit thickness requirements supplied as a single 10 gauge = 2.588 mm.

Zinc Plating Thickness Chart My XXX Hot Girl

PCB Copper Trace Finish Materials and Plating Methods LiteracyBase

Coating Thickness vs. Coating… American Galvanizers Association

What is proper Rhodium Plating Thickness and how to measure it?

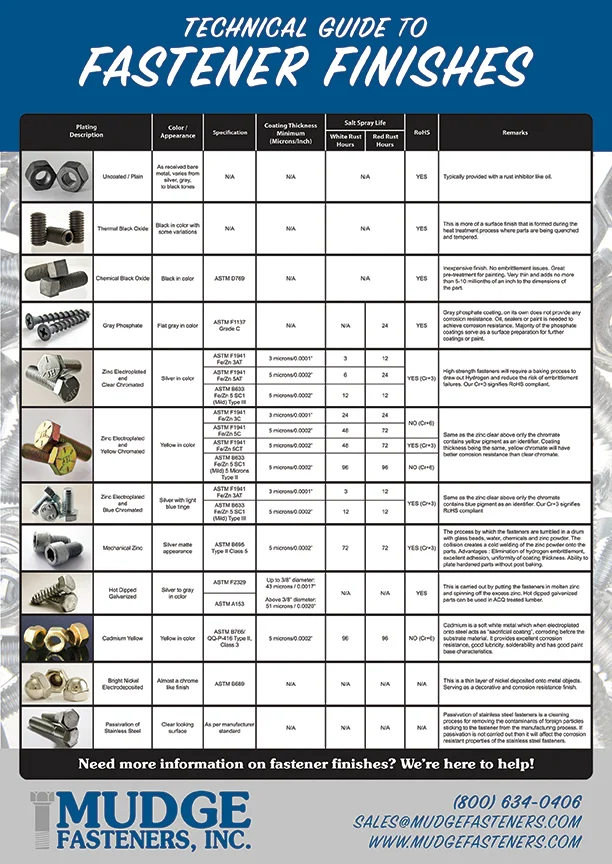

Fastener Platings & Finishes for Longevity & Appearance

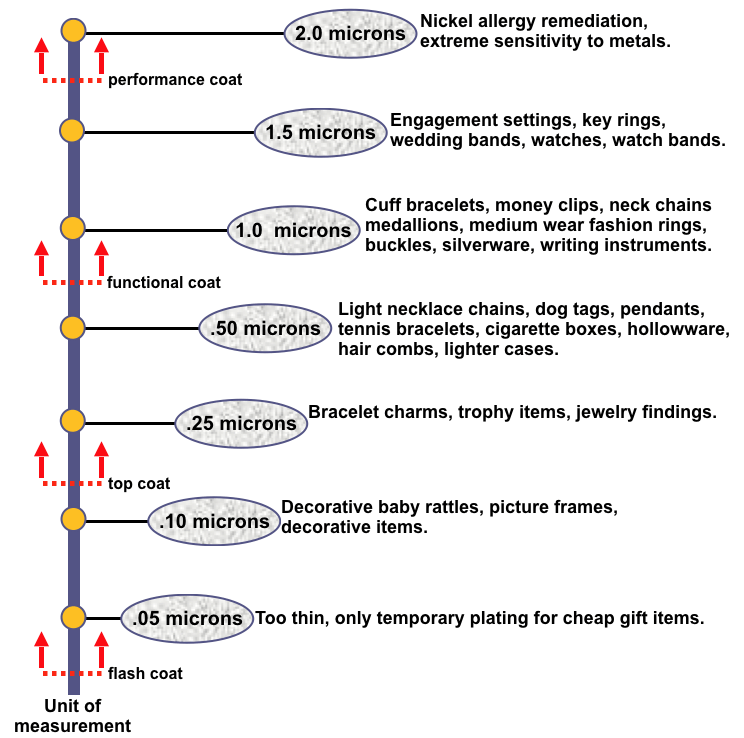

Gold Filled vs. Gold Vermeil vs. Gold Plating A 101 Guide Nendine

All Plating is Not Created Equal — Sara Golden Jewelry

Surface Finishes Chrome Plating MISUMI USA Blog

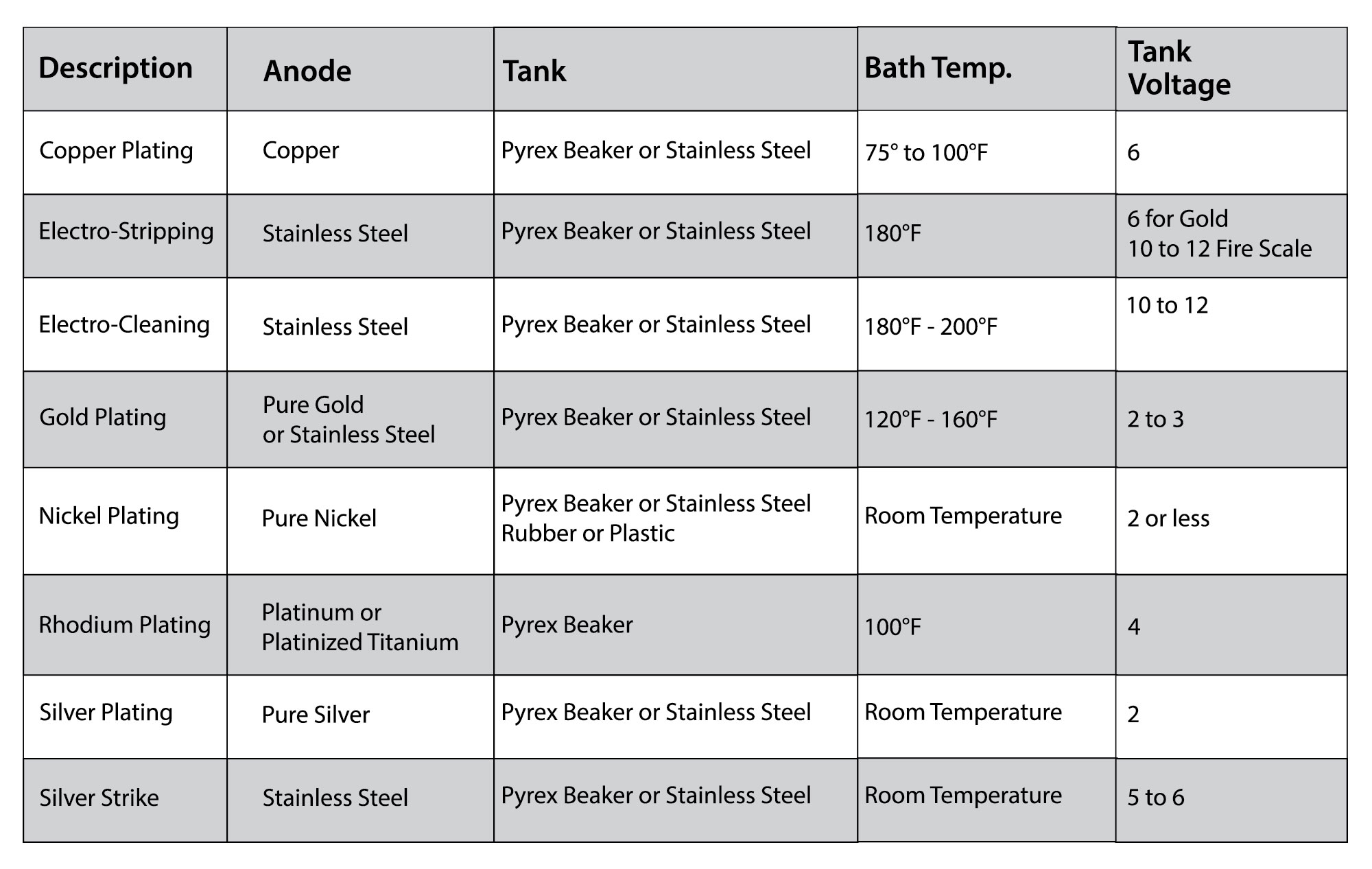

Guide to ElectroPlating Chart Esslinger Watchmaker Supplies Blog

Variation of plating thickness and thickness deviation according to

Web Typical Thickness Of Electroless Plating Can Be As Thin As.0005 And Up To.010.

Web Measurements On Large Products Should Be Made At Least 4 Inches From The Edge.

The Definition Of Each Is Provided Below:

10 Gauge = 3.51 Mm.

Related Post: