Powder Coating Cure Time Chart

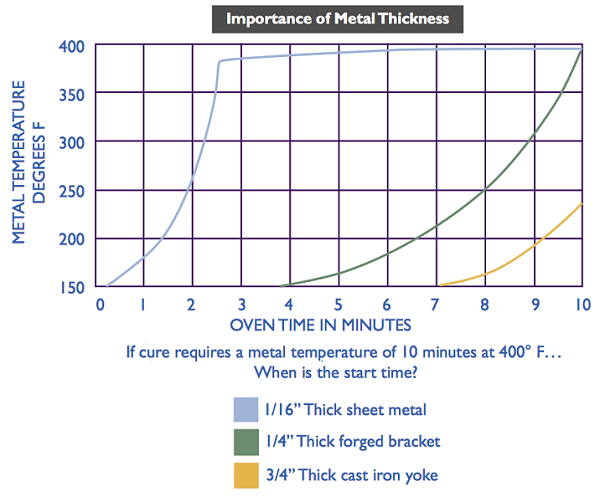

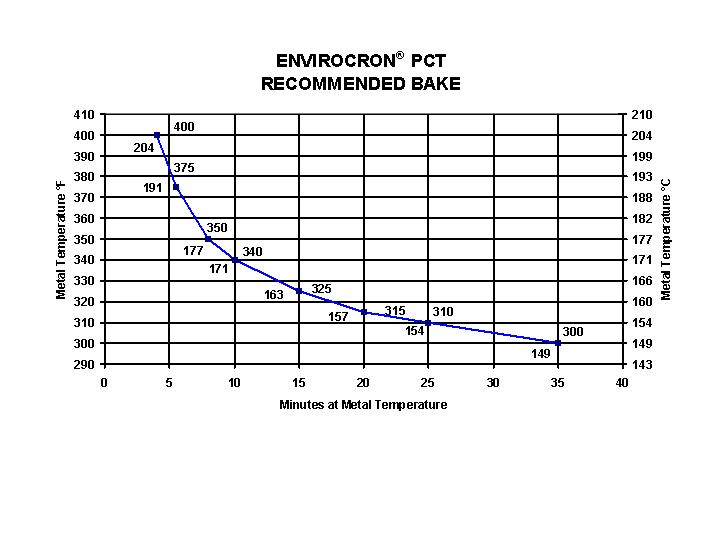

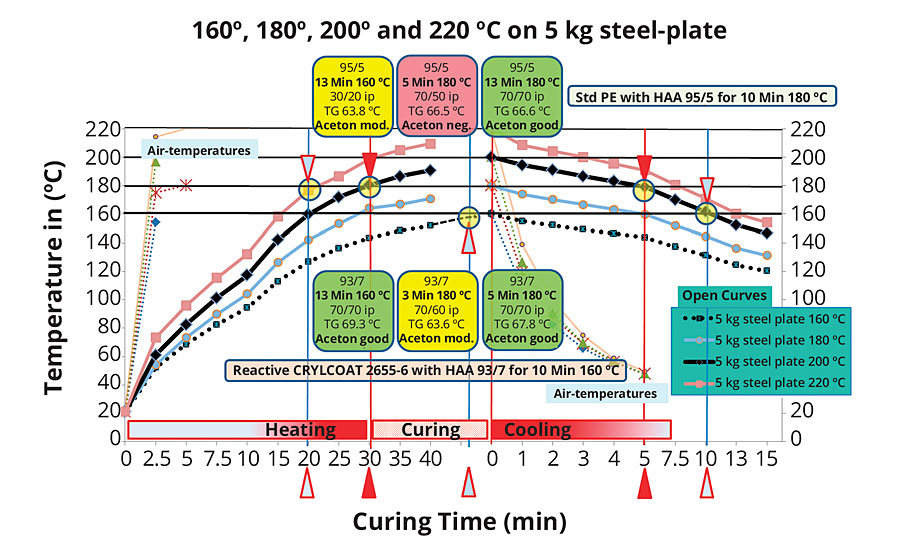

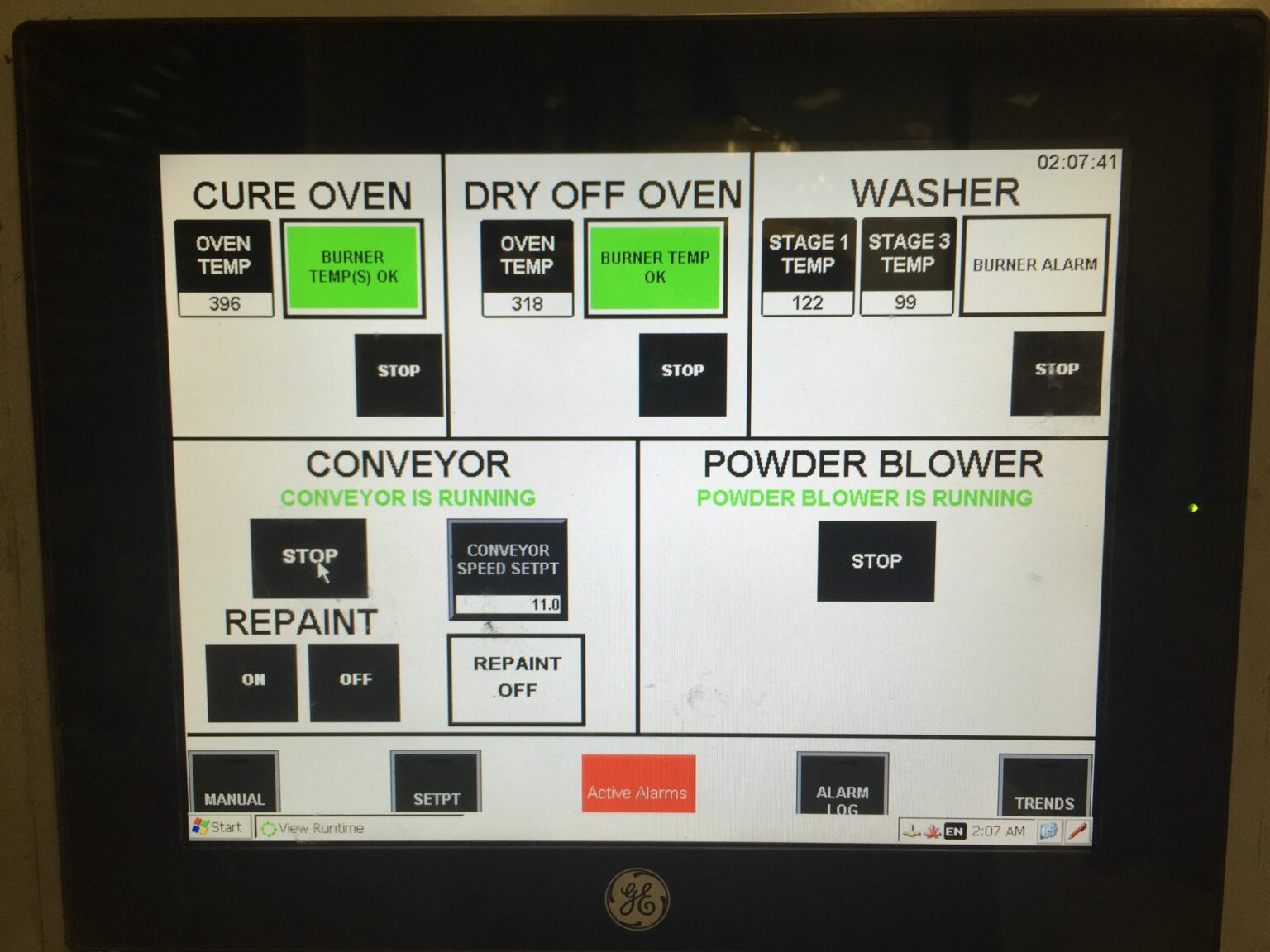

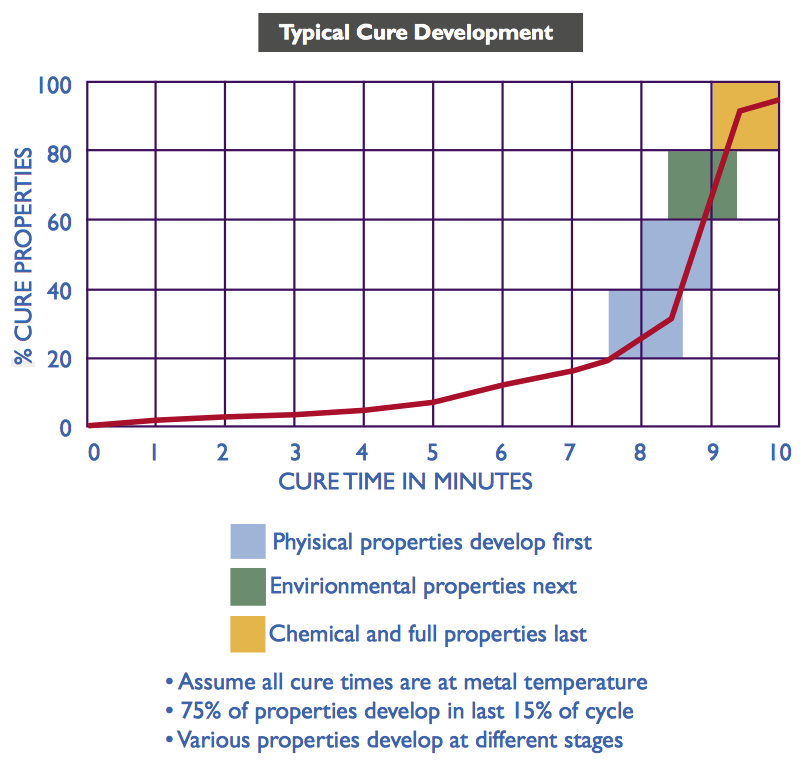

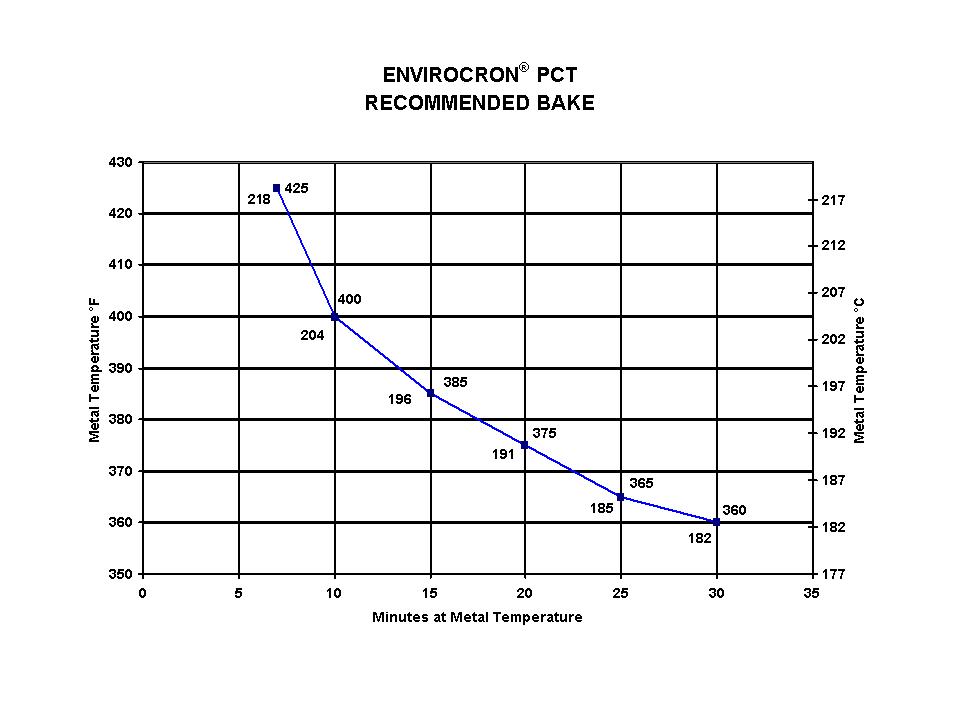

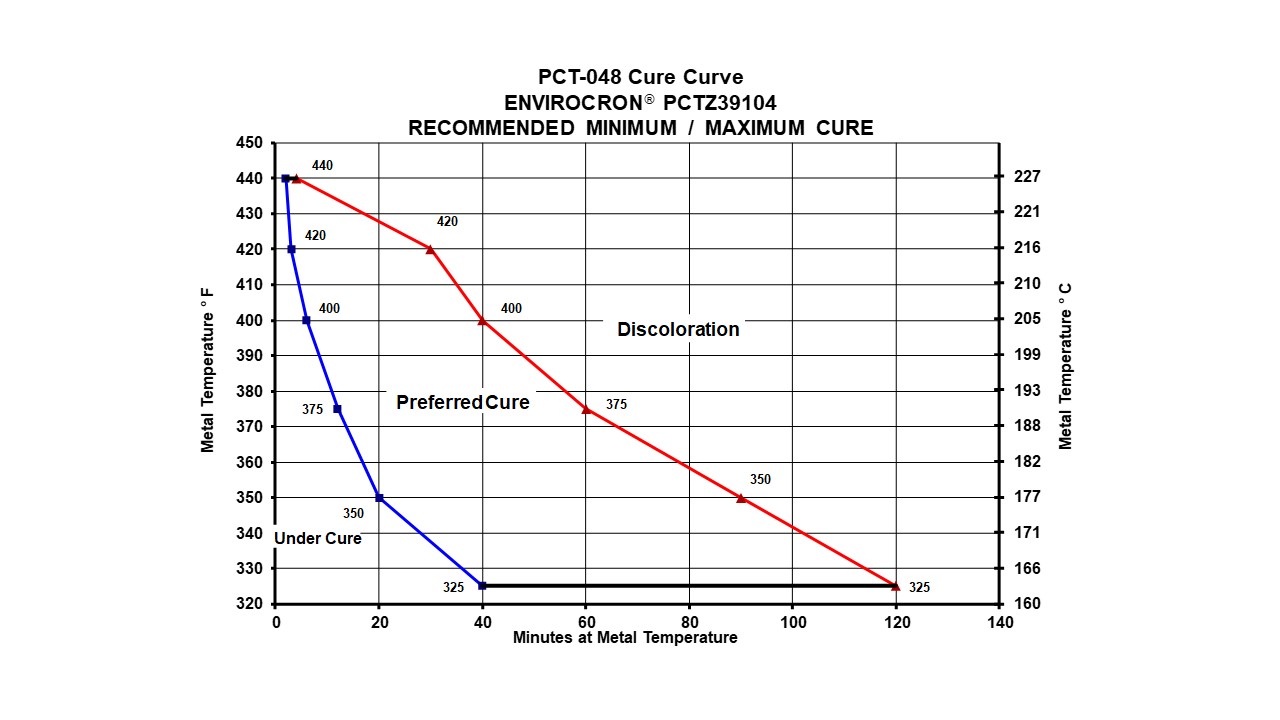

Powder Coating Cure Time Chart - Powder coating manufacturers publish specifications for curing time and temperature (typically as a “curing window” chart in product data sheets). Web a cure curve is a graphical representation of the thermal conditions required to insure that an applied thermoset powder coating is completely cured, i.e. Web what is under curing? When exposed to heat, the powder material. Web the times and temperatures stated are for minimum metal temperatures. Web ideal curing temperatures can range between 350 and 420 degrees fahrenheit with the most common forms of thermosetting powders. That will give you the cure. Powder coating is a surface treatment used to protect metals and other materials against. Web how long does curing take? What is a cure curve? Sufficient, sustained heat triggers large scale reaction within film,. Web follow the charts below for accurate curing of the hotcoattm powders. Parts are cooled to allow handling. Web a cure curve is a graphical representation of the thermal conditions required to insure that an applied thermoset powder coating is completely cured, i.e. Web these times and temperatures are available from. Web defelsko manufactures several paint and coating thickness instruments that measure the thickness of powder coatings on a variety of substrates including steel, aluminum, and. Web fast curing time. That will give you the cure. For more specific cure data, please refer to the cure graphs or talk to your ifs representative. Sufficient, sustained heat triggers large scale reaction within. What is a cure curve? Powder coating is a surface treatment used to protect metals and other materials against. Keep part a at 77of (25oc) for hand application and 140of. Powder coating manufacturers publish specifications for curing time and temperature (typically as a “curing window” chart in product data sheets). Sufficient, sustained heat triggers large scale reaction within film,. Web the cure time listed on your powder formulator’s data sheet is the time at metal temperature. Web what is a powder coating cure schedule? A cure schedule is the time and temperature combination that is required to fully cure a powder coating. For more specific cure data, please refer to the cure graphs or talk to your ifs representative.. What is a cure curve? Powder coating is a surface treatment used to protect metals and other materials against. Sufficient, sustained heat triggers large scale reaction within film,. Web ideal curing temperatures can range between 350 and 420 degrees fahrenheit with the most common forms of thermosetting powders. A cure schedule is the time and temperature combination that is required. Web what is a powder coating cure schedule? Web these times and temperatures are available from the cure schedule for the powder coating. When exposed to heat, the powder material. Web defelsko manufactures several paint and coating thickness instruments that measure the thickness of powder coatings on a variety of substrates including steel, aluminum, and. Web a cure curve is. Sufficient, sustained heat triggers large scale reaction within film,. Web whether you’re new to powder coatings or an experienced pro, you’re probably well aware that powder coating is a fantastic painting method that creates a tough, durable and. For more specific cure data, please refer to the cure graphs or talk to your ifs representative. Web follow the charts below. Web these times and temperatures are available from the cure schedule for the powder coating. Web defelsko manufactures several paint and coating thickness instruments that measure the thickness of powder coatings on a variety of substrates including steel, aluminum, and. This enhances the mechanical and chemical properties of the finish,. Powder coating manufacturers publish specifications for curing time and temperature. Web these times and temperatures are available from the cure schedule for the powder coating. Web defelsko manufactures several paint and coating thickness instruments that measure the thickness of powder coatings on a variety of substrates including steel, aluminum, and. The exact time and temperature used to cure a coated surface depend on several. Web what is under curing? Web. Powder is fully liquefied, reaching lowest viscosity, allowing film to smooth out. This means that the part will be in the oven longer than this time to achieve. Web defelsko manufactures several paint and coating thickness instruments that measure the thickness of powder coatings on a variety of substrates including steel, aluminum, and. Web what is under curing? Web how. Web the cure time listed on your powder formulator’s data sheet is the time at metal temperature. Powder is fully liquefied, reaching lowest viscosity, allowing film to smooth out. Powder coating is a surface treatment used to protect metals and other materials against. Web follow the charts below for accurate curing of the hotcoattm powders. Web ideal curing temperatures can range between 350 and 420 degrees fahrenheit with the most common forms of thermosetting powders. In some applications, shorter oven cycle times are possible by rapid heating of. Parts are cooled to allow handling. Well, one, the first thing we'll want to do is check the tech data sheet/application guide on the website. Curing usually takes less than 25 minutes. Keep part a at 77of (25oc) for hand application and 140of. Web a cure curve is a graphical representation of the thermal conditions required to insure that an applied thermoset powder coating is completely cured, i.e. Web whether you’re new to powder coatings or an experienced pro, you’re probably well aware that powder coating is a fantastic painting method that creates a tough, durable and. Web what is under curing? This enhances the mechanical and chemical properties of the finish,. Web defelsko manufactures several paint and coating thickness instruments that measure the thickness of powder coatings on a variety of substrates including steel, aluminum, and. Web the times and temperatures stated are for minimum metal temperatures.

Powder Coating Cure Time Chart

Measuring Cure Index with the PosiTest OTL Resources DeFelsko

Powder Coating Cure Time Chart

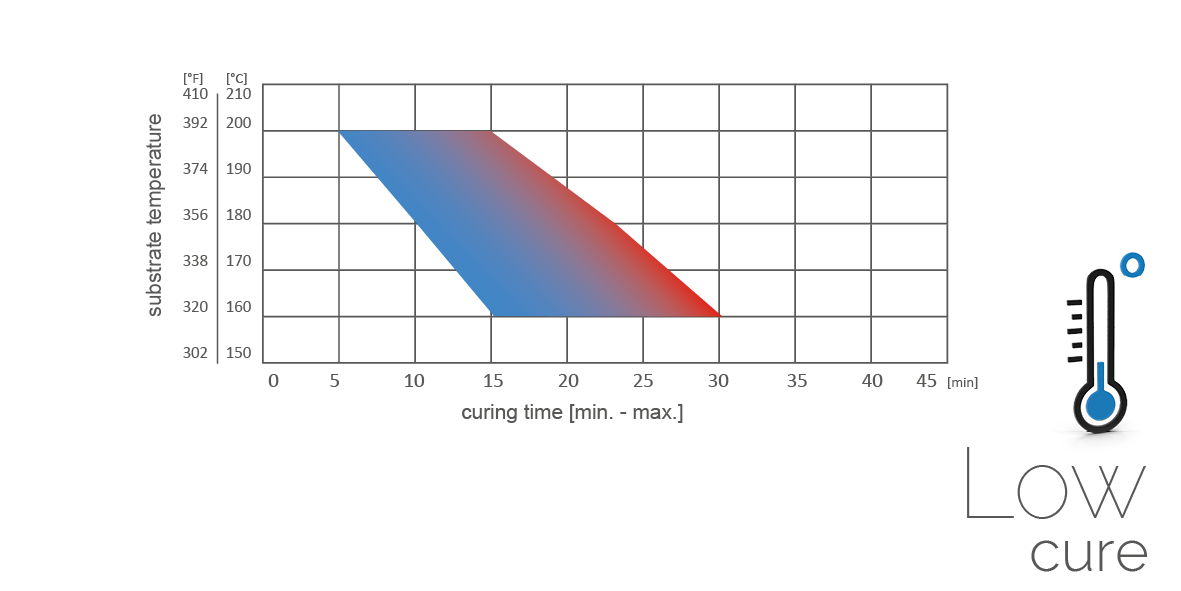

Low Cure Clear Powder Coating PPG PPG Powder Coatings

LowTemperatureCuring Powder Coatings System 20181009 PCI Magazine

Powder Coating Cure Time Chart

LowCure Powders Energy Efficient Powder Coating

Powder Coating Cure Time Chart

Bright Yellow Powder Coating PPG PPG Powder Coatings

Yellow Powder Coating PPG Powder Coating Colors PPG Powder Coatings

Web What Is A Powder Coating Cure Schedule?

That Will Give You The Cure.

The Most Common Curing Mistake People Make When Curing Is Under Curing, Usually Due To Misunderstanding How To Interpret The Cure Schedule.

Sufficient, Sustained Heat Triggers Large Scale Reaction Within Film,.

Related Post: