Pressure Tank Sizing Chart

Pressure Tank Sizing Chart - That depends on several factors, such as flow rate, pressure switch setting, and minimum run time. Web all diaphragm tank sizing begins with a basic law of physics known as boyle’s law. The tank selection is based on approximately one minute running time. Assess your household water usage and ensure the tank’s volume meets your peak demand. Web the pressure tank sizing calculator helps you determine the optimal tank size for your water system. If a pump exists, the capacity must be determined. Factors influencing the selection of pressure tank size. Air is compressed inside the tank and creates pressure. This is recommended for pumps 3/4 hp or larger. Provide water under pressure for delivery between pump cycles; P2 minimum working pressure (relative, bar); The general formula to calculate the pressure tank size is: The pump capacity should be selected according to the system demand. Desired run time of the pump. A general guideline is that 1/3 of the tank holds water and the rest is air. Factors influencing the selection of pressure tank size. Web when sizing a pressure tank, consider factors including your well pump’s size and output, your water usage and household size, the distance from the well pump to the pressure tank, and the type of well pump you own. Air is compressed inside the tank and creates pressure. Web to determine the. For commercial well system applications. What most people don’t realize is that pressure tanks don’t hold that much water. Web most manufacturers recommend a minimum run time of one minute for efficient motor cooling. Factors influencing the selection of pressure tank size. Web sizing a pressure tank. The mechanical design portion deals mainly with the thickness calculations for vessels and heads, while the process design portion deals with the sizing of process vessels and storage tanks. This is recommended for pumps 3/4 hp or larger. This is recommended for pumps up to 3/4 hp. Flow rate the flow rate. Web the right pressure tank size is important. To complete installation, you will require the following: This is recommended for pumps up to 3/4 hp. Signs that you need to replace or upgrade your pressure tank. Web if you’re drilling a new well or replacing an old well pressure tank, you might have some questions about which size well pressure tank you need. The general formula to calculate. Web diagram in fig 4 to select the optimum tank size. The diagram below is based on the following values: P1 maximum working pressure (relative, bar); Web use the pressure tank sizing formula: • full control (sba) • simple float switches for dry running protection. This is recommended for pumps 3/4 hp or larger. What most people don’t realize is that pressure tanks don’t hold that much water. Web all diaphragm tank sizing begins with a basic law of physics known as boyle’s law. How to calculate the right size for your pressure tank. Grundfos sb pumps can be equipped with: The tank selection is based on approximately one minute running time. When applied to hydronic and thermal expansion tanks it will determine the acceptance factor of the tank. How to calculate the right size for your pressure tank. Consult manufacturer guidelines for precise sizing recommendations. For commercial well system applications. The well capacity should be documented when the well has been declared ready for use and will often be referred to in. Web when sizing a pressure tank, consider factors including your well pump’s size and output, your water usage and household size, the distance from the well pump to the pressure tank, and the type of well pump you. Web when sizing a pressure tank, consider factors including your well pump’s size and output, your water usage and household size, the distance from the well pump to the pressure tank, and the type of well pump you own. Mechanical design and process design. The functions of a pressure tank are to: Pressure switch, fl ow control valve and injector. One hp and larger pumps require longer run times. Web jump to the right section: Consult manufacturer guidelines for precise sizing recommendations. The tank selection is based on approximately one minute running time. Pump to tank fi ttings. Web sizing a pressure tank. However, calculating the exact size needed requires looking at your specific water usage needs. The mechanical design portion deals mainly with the thickness calculations for vessels and heads, while the process design portion deals with the sizing of process vessels and storage tanks. When applied to water well storage tanks it will determine the drawdown factor. For commercial well system applications. Web most residential pressure tanks come in 5 sizes. When applied to hydronic and thermal expansion tanks it will determine the acceptance factor of the tank. Air is compressed inside the tank and creates pressure. A general guideline is that 1/3 of the tank holds water and the rest is air. These three variables must be calculated together to find what size pressure tank works for a system. To determine the proper size of tank, there are.

Pressure Tank Size Chart

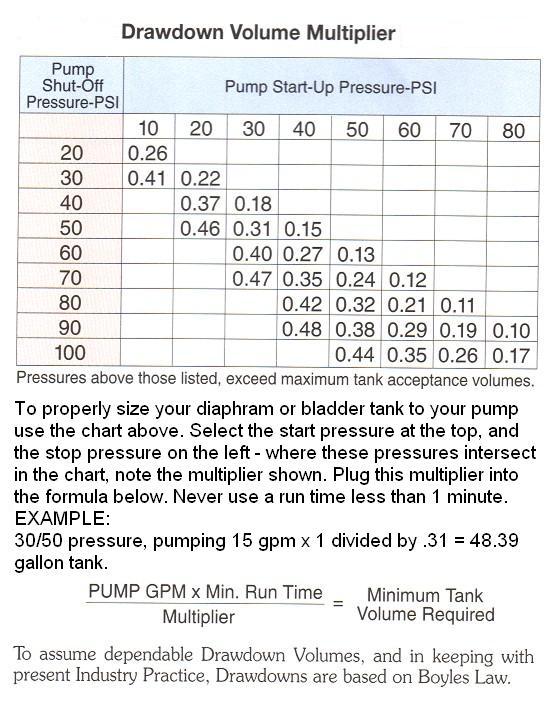

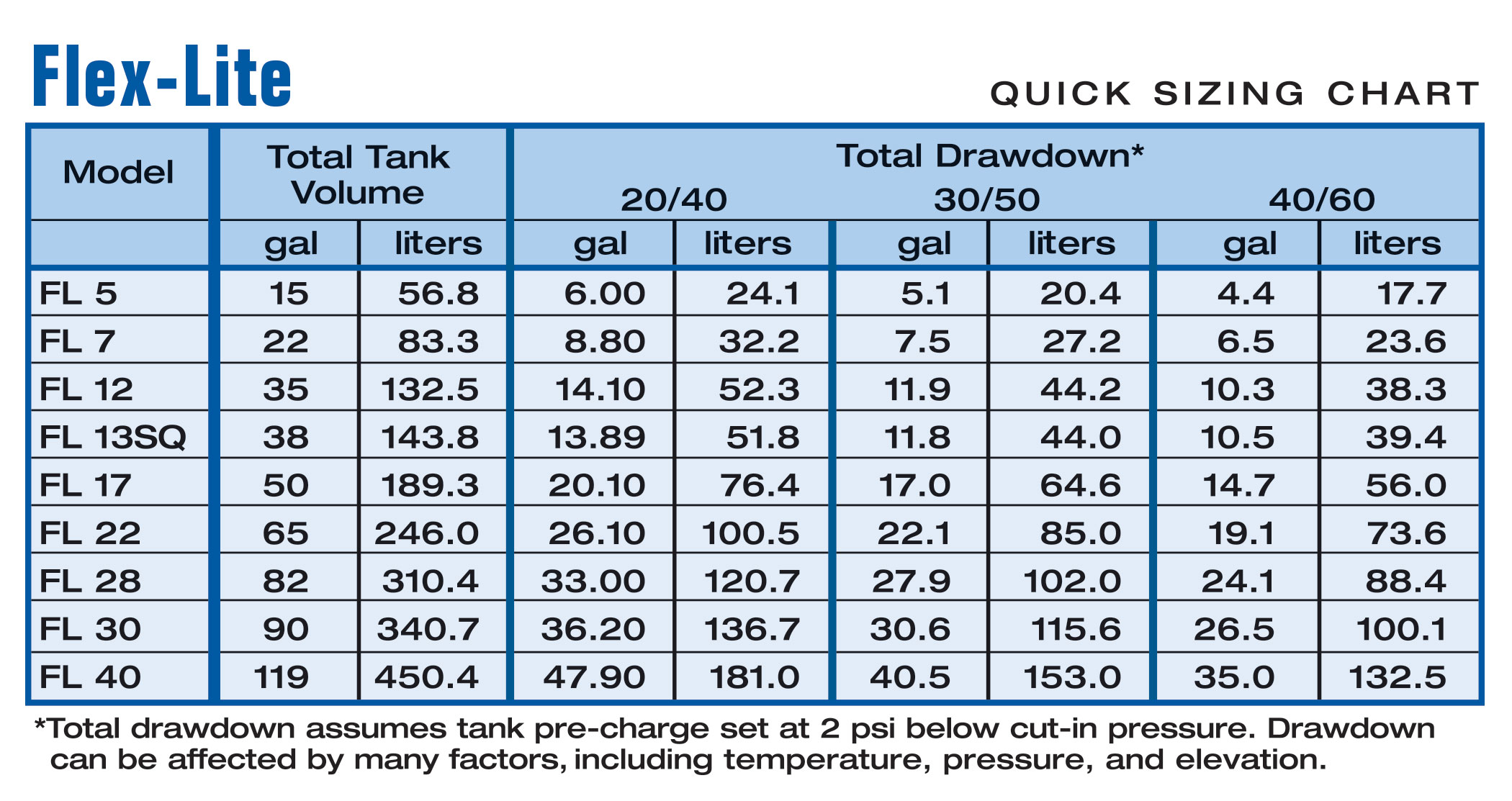

Use this tank sizing chart to determine the correct tank for your pump

How to Size a Well Pressure Tank YouTube

Pressure Tank Sizing Chart

Water Pump Water Pressure Tank Installation Diagram

Hydronic Water Expansion Tanks American Water Heaters

Pressure Tank Size Chart

Pressure Tanks Cooks Plumbing, Heating, Electrical and Air Conditioning

Pressure Tank Size Chart

Well Water Pressure Tank Sizing The Ultimate 2023 Guide / Sizing a

P1 Maximum Working Pressure (Relative, Bar);

The Formula Finds The Capacity Vt Of An Autoclave Large Enough To Give An Adequate Water Storage R For The Booster System.

The General Formula To Calculate The Pressure Tank Size Is:

Web Sizing The Water Pressure Tanks.

Related Post: