Printable Eyewash Station Inspection Checklist

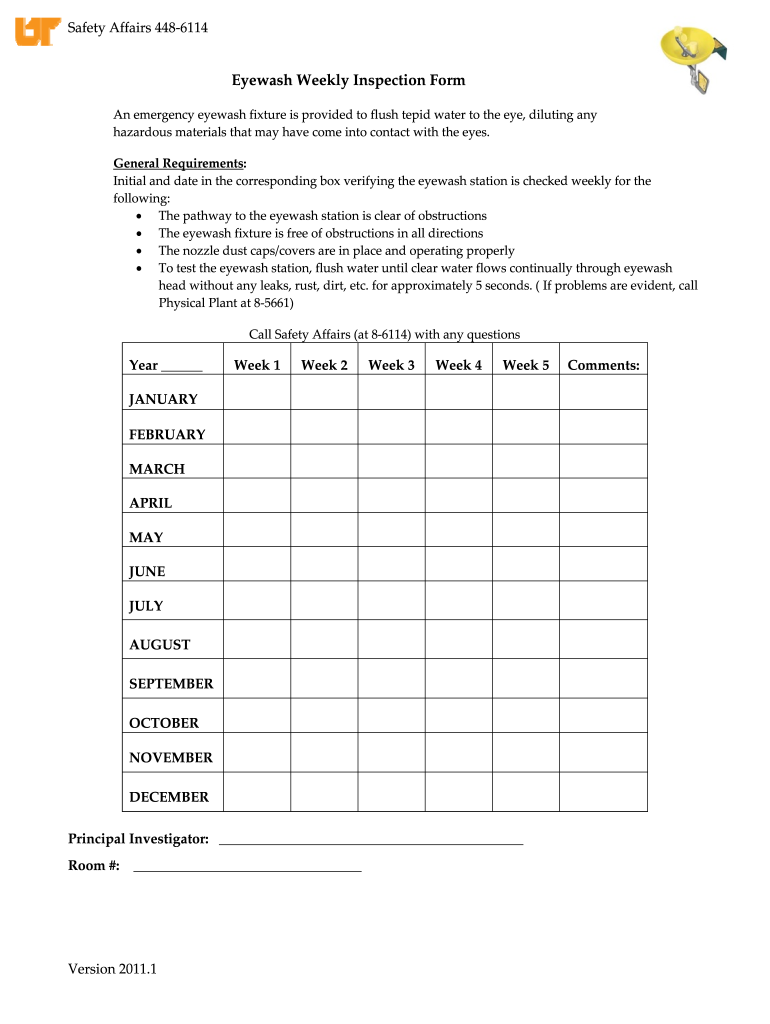

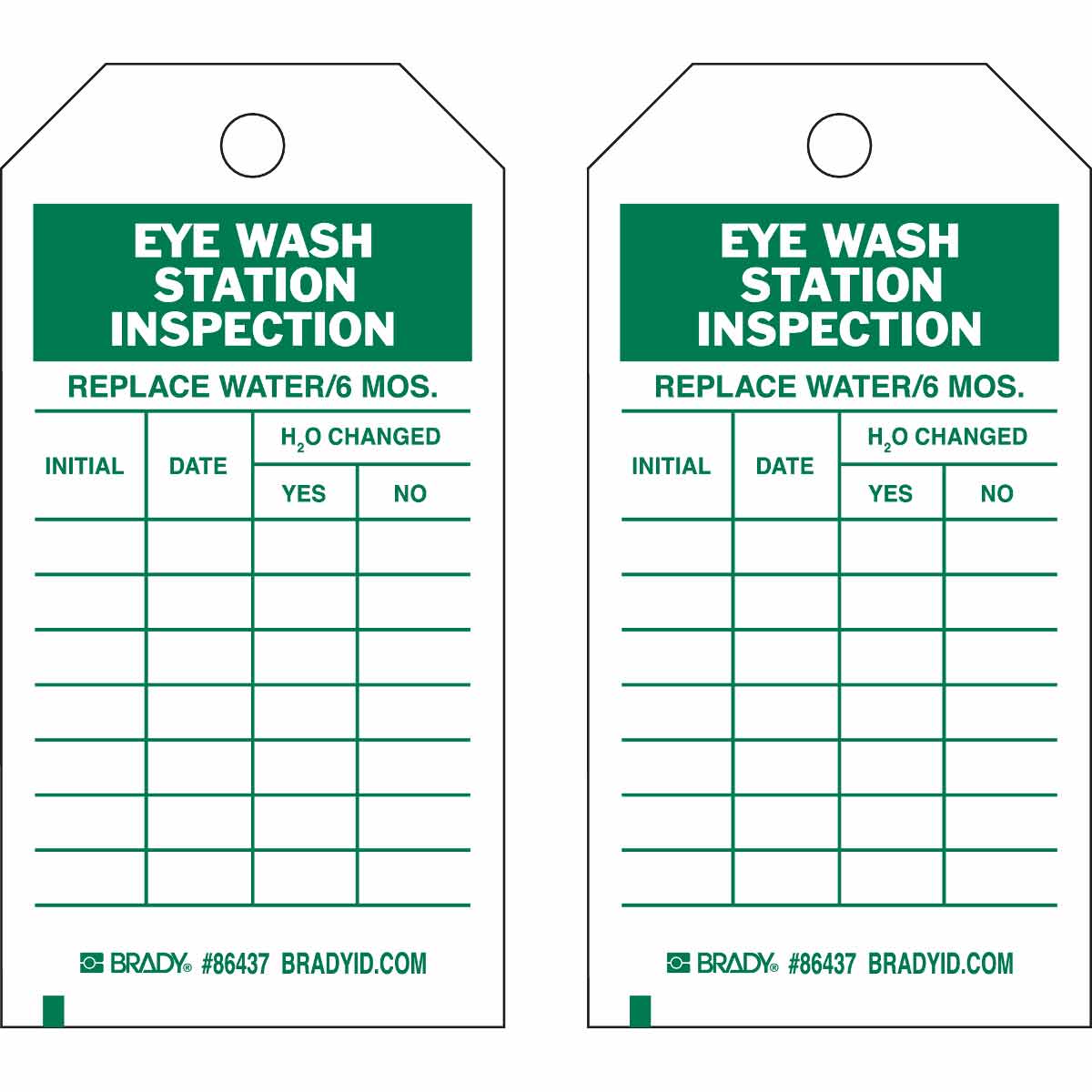

Printable Eyewash Station Inspection Checklist - As the designated safety inspector, you should be trained and/or certified in the appropriate osha and. Verify that nozzle caps are in place to prevent contamination and that the nozzles, nozzle caps, and bowl/sink are clean and sanitary. Web protecting vision, securing peace of mind: Eyewash stations shall be inspected quarterly on a fiscal year schedule: (do not attempt to flush units that. Share your form with others. Type text, add images, blackout confidential details, add comments, highlights and more. Web emergency eye wash station checklist. Web to test the eyewash station, flush water until clear water flows continually through eyewash head without any leaks, rust, dirt, etc. Pis, lab and shop managers) are responsible for initial and annual refresher training of all their workers in. Sign it in a few clicks. Every checked box represents a potential emergency averted, a vision protected, and a testament to your unwavering commitment to a safe and productive work environment. Orf is contacted and a service request # is obtained (if issues cannot be corrected at the lab level). Click on image and instantly download this 51 page guide. Ensure the safety, readiness, and good working conditions of eyewash stations by doing the following: Do not use solutionspast their expiration date. Ensure that the path to the eyewash/drench hose is not obstructed. Hold eyes open and flush for at least 15 minutes. Edit your free printable eye wash station inspection sheet online. Requests may also be called in directly. Get the printable eyewash station checklist accomplished. Sign it in a few clicks. Type text, add images, blackout confidential details, add comments, highlights and more. Hold eyes open and flush for at least 15 minutes. Share your form with others. Note any areas that may need maintenance in the observations/comments column of the weekly. Web during the annual inspection, a trained professional will check the eyewash station’s water flow, temperature, and location to ensure that it meets the standards set by the american national standards institute (ansi). Download your adjusted document, export it to the. Web eyewash station inspection checklist. The inspector will also check for any damage or wear on the equipment and ensure that the area around the eyewash station is. Draw your signature, type it, upload its image, or use your mobile device as a signature pad. Requests may also be called in directly. Web inspection sheet or eyewash tag is dated. Ensure a consistent and thorough process. The inspector will also check for any damage or wear on the equipment and ensure that the area around the eyewash station is. Call 911 and seek medical assistance. Every checked box represents a potential emergency averted, a vision protected, and a testament to your unwavering commitment to a safe and productive work environment.. Edit your free printable eye wash station inspection sheet online. Click on image and instantly download this 51 page guide in pdf format. Have you made certain that emergency equipment does not come in contact with any electrical equipment creating a risk of shock? Note any areas that may need maintenance in the observations/comments column of the weekly. Emergency eyewash. Hold eyes open and flush for at least 15 minutes. Have you made certain that emergency equipment does not come in contact with any electrical equipment creating a risk of shock? Verify that nozzle caps are in place to prevent contamination and that the nozzles, nozzle caps, and bowl/sink are clean and sanitary. Requests may also be called in directly.. Hold eyes open and flush for at least 15 minutes. Where feasible, place a catch pan or bucket under the unit if a plumbed drain is not available. An eyewash station checklist ensures that eyewash stations are properly maintained and ready for use in case of emergencies. Hold eyes open and flush for at least 15 minutes. (do not attempt. Regular inspections help identify potential issues and ensure compliance with safety regulations. Web the inspection document is maintained near the eyewash (eh&s has inspection cards available upon request). Where feasible, place a catch pan or bucket under the unit if a plumbed drain is not available. Web edit printable eyewash station checklist. Share your form with others. Ensure the safety, readiness, and good working conditions of eyewash stations by doing the following: (do not attempt to flush units that. Orf is contacted and a service request # is obtained (if issues cannot be corrected at the lab level). In an emergency, hold eyes open and flush for at least 15 minutes. Web emergency eye wash station checklist. Help your facility meet osha and ansi standards. Hold eyes open and flush for at least 15 minutes. Has the eyewash station been completely drained, rinsed, and fluid replaced with new solution on a regular basis per the. Create checklists for your safety officers to easily inspect eyewash stations and effortlessly reduce errors. Download this free emergency eyewash station checklist to guide you through inspections and maintenance activities. Web eyewash weekly checklist q eyewash is accessible within 10 seconds, or roughly 55 feet (commonly referred to as the 10 second rule) q no pallets, ladders, buckets, boxes, or other potential hazards are obstructing the path between the hazard and the eyewash station q eyewash is at the same level as the hazard q area is well lit q light bulbs and light. As the designated safety inspector, you should be trained and/or certified in the appropriate osha and. Where feasible, place a catch pan or bucket under the unit if a plumbed drain is not available. Requests may also be called in directly. Hold eyes open and flush for at least 15 minutes. Verify that nozzle caps are in place to prevent contamination and that the nozzles, nozzle caps, and bowl/sink are clean and sanitary.

Printable Eyewash Station Inspection Checklist

Printable Eyewash Station Inspection Checklist

Free Printable Eye Wash Station Inspection Sheet

Eyewash Station Inspection Template fasrize

Printable Eye Wash Station Checklist fasrlens

Printable Eyewash Station Inspection Checklist Complete with ease

Eye wash station monthly inspection checklist Fill out & sign online

Sample Example Format Templates Eye Wash Station Insp vrogue.co

Eye Wash Station Checklist Spreadsheet Sample Example And Format

Eyewash Station Weekly Checklist ITU AbsorbTech First Aid

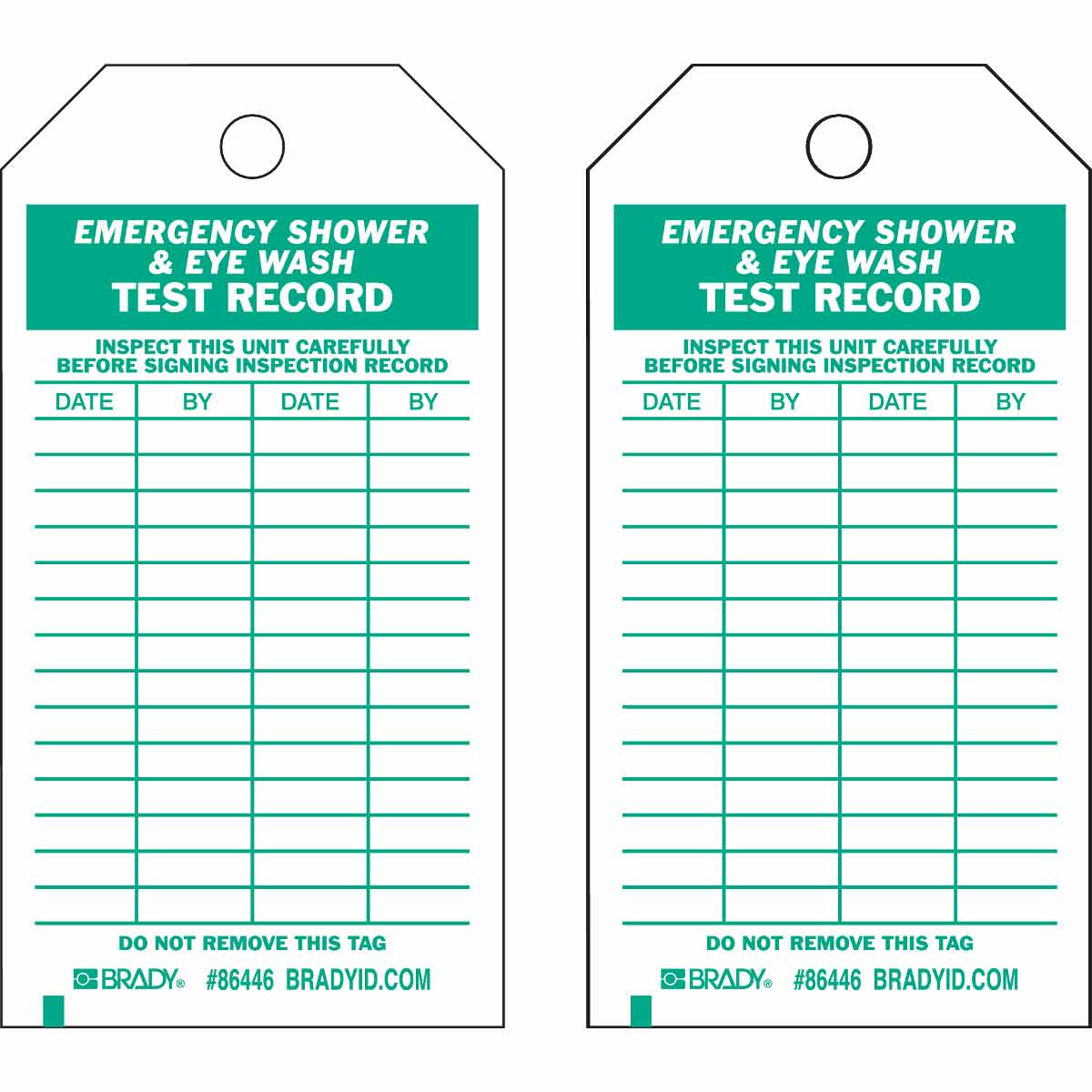

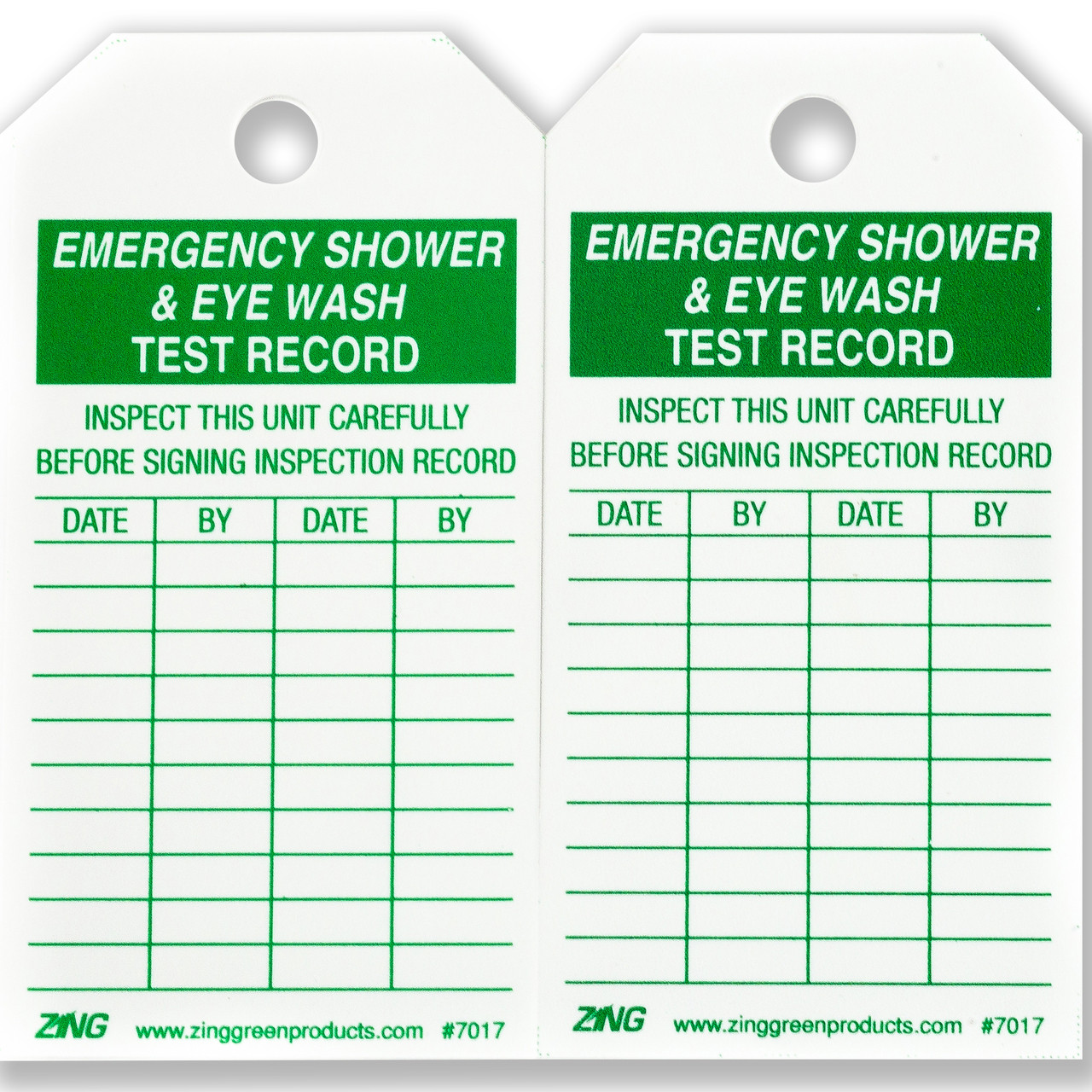

Web Hughes Safety Showers Provides A Weekly Activation Test Record For Inspecting Emergency Safety Shower Equipment.

Emergency Eyewash And Shower Equipment.

Web Edit Printable Eyewash Station Checklist.

Date Initials Comment Date Initials Comment Date Initials Comment How To Test:

Related Post: